BTR-80

The BTR-80 is an amphibious armoured personnel carrier, and is the successor to the BTR-70 and BTR-60 designs. Its inception was closely connected to the events unfolding in Afghanistan at the time, but the design of the vehicle had minimal innovation. The BTR-80 follows the traditional BTR layout; three sections of the vehicle, divided into the driver and commander's section at the front, passengers' and gunner's section in the middle, and the compartmentalized powerplant section at the rear. All the vehicle's occupants share a common space within the vehicle, and exit via side doors - a huge improvement over the side hatches of the BTR-70.

COMMANDER'S STATION

The commander in a BTR-80 would be the squad leader of a motorized infantry squad consisting of 8 men, including himself. While in the BTR-80, his job is to scan for possible threats and determine the next course of action.

The commander has a TKN-3M day/night binocular periscope with an accompanying OU-5-1 IR spotlight at his disposal, along with three TNPO-115 periscopes. Two of the periscopes flank the TKN-3M aperture and one is aimed to the right of the commander. The commander does not have a cupola, but the TKN-3 is is mounted in a ball joint housing to enable viewing in elevation and azimuth. The OU-5-1 IR spotlight is directly attached to the TKN-3M and will move with it. The photo below (from ambbrescia.com website) shows a TKN-3M with a heavy layer of cosmoline in its ball mount in a preserved BTR-80.

The TKN-3M has a fixed 5x magnification in the day channel, and a field of view of 10 degrees. The maximum target identification range is around 3000 m at daytime. The night channel has a 3x maximum magnification and a field of view of 8 degrees. The active mode requires the use of the OU-5-1 IR spotlight which supplies infrared light needed to illuminate the target.

Due to the simple lack of an electronic fire control system for the weapons in the BPU-1 turret, the BTR-80 does not provide the possibility of target designation with the TKN-3.

The commander has access to the R-123 radio. As of today, it is woefully obsolete. Enemy troops could easily listen in to any and all communications sent through these radio sets, which proved to be a fatal weakness during the Chechen campaign. The R-123 radio had a frequency range of between 20 MHZ to 51.5 MHZ. It could be tuned to any frequency within those limits via a knob, or the commander could instantly switch between four preset frequencies for communications within a platoon. It had a range of between 16km to 50km. The R-123 had a novel glass prism window at the top of the apparatus that displayed the operating frequency. An internal bulb illuminated a dial, imposing it onto the prism where it is displayed. The R-123 had a relatively advanced modular design that enabled it to be repaired quickly by simply swapping out individual modules.

.jpg) |

| TKN-3 periscope aperture with OU-5-1 IR spotlight attached to the same rotating block |

Due to the simple lack of an electronic fire control system for the weapons in the BPU-1 turret, the BTR-80 does not provide the possibility of target designation with the TKN-3.

.jpg) |

| TKN-3 in ball joint housing |

The commander has access to the R-123 radio. As of today, it is woefully obsolete. Enemy troops could easily listen in to any and all communications sent through these radio sets, which proved to be a fatal weakness during the Chechen campaign. The R-123 radio had a frequency range of between 20 MHZ to 51.5 MHZ. It could be tuned to any frequency within those limits via a knob, or the commander could instantly switch between four preset frequencies for communications within a platoon. It had a range of between 16km to 50km. The R-123 had a novel glass prism window at the top of the apparatus that displayed the operating frequency. An internal bulb illuminated a dial, imposing it onto the prism where it is displayed. The R-123 had a relatively advanced modular design that enabled it to be repaired quickly by simply swapping out individual modules.

|

| Commander's workstation. Note the conveniently placed firing port. |

GUNNER'S STATION

The gunner is seated inside the small one-man turret. The turret reaches the same level of armour protection as the hull and weighs 540 kg when fully loaded with all of its standard equipment. The turret race ring diameter is 1,075mm. The size of the turret is such that only a small part of the gunner's head is physically inside it, and the KPVT machine gun occupies the entire length of the turret, as shown in the drawing above. Due to the location of the eyepiece of the gunner's sight, his eyes are level with the turret ring and only the top part of his head intrudes into the space inside the turret. As such, the small size of the turret itself does not imply that the gunner's station is particularly cramped, especially considering that there is no turret basket around the gunner's seat.

For general visibility, the gunner is furnished with only two periscopes in addition to his periscopic sight to view the outside world. There is a single TNP-205 general vision periscope placed next to the 1PZ-2 sight, and one TNPT-1 rear-view prism directly above him on the turret ceiling. This pitiful combination means that the gunner has very little independence in detecting targets at short to medium distances, and even less in detecting targets located above the vehicle. This was somewhat offset by the abundance of observation devices in the passenger's compartment and the good visibility from the commander's station, but the height of the turret makes it a better vantage point than the hull for surveillance purposes. Even so, this arrangement was already enough to make the fully-enclosed turret a much better alternative to a pintle-mounted machine gun with a gunshield.

The photo on the left below (credit to Vitaly Kuzmin) shows the gunner's station of a modernized BTR-80, as indicated by the TKN-4GA-01 sight. The photo on the right shows an original BTR-80 turret with the old 1PZ-2 sight. Note the TNPT-1 rear-view prism on the turret ceiling and the dome light placed conveniently above the ammunition boxes of the KPVT and PKTM, making it easy for the gunner to load and service the machine guns in darkness.

The gunner is seated on a simple suspended seat with an oblong cushion. The backrest can be adjusted in height, the seat can be adjusted forwards and backwards, and the entire seat frame can be raised or lowered from its mounting point at the turret ring as shown in the drawing on the left below. The seat is not very comfortable for long periods as it has no padding, and there is no footrest nor any form of shielding to protect the gunner's legs as he spins around when the turret is rotated. Being seated on a seat that is suspended above the floor of the hull, the gunner has a better chance of surviving a landmine blast underneath the vehicle, which is also aided by his central location in the BTR. The travel lock for the turret is located near the gunner's left shoulder, and BTR-80s that are equipped with the 902V smoke grenade system have a control box located next to the turret travel lock. The mechanism for opening and closing the protective shield for the 1PZ-2 gunsight is located near the roof of the turret, directly above and to the left of the 1PZ-2 sight housing.

It is worth noting that the KPVT and PKT machine guns installed in the turret are well balanced at their center of gravity, but when the ammunition boxes are loaded onto the cradle, the entire assembly becomes somewhat rear-heavy. To counteract this, a balancing spring was installed, connecting the top of the gun cradle to the ceiling of the turret. With this, the gunner is able to smoothly elevate the weapons with only a light effort.

Gun elevation and turret traverse are done manually with the use of two manually-operated handwheels. The turret traverse handwheel also has the solenoid triggers for the KPVT and PKTM machine guns. The electrical system for the firing of the weapons are located underneath the weapon mounts.

A motivated gunner can slew the turret at a very quick speed, but the lack of powered traverse and stabilization is a drawback nonetheless. As an armoured personnel carrier that is still in service in the present, the lack of powered traverse was a noted grievance of BTR-80 gunners according to a TV Zvezda interview. Still, one could argue that the protection of a full turret like the turret makes it inherently superior to having an exposed pintle-mounted machine gun on the roof of the vehicle, as in the case of the M113 and earlier versions of the BTR-60.

SIGHTING COMPLEX

The gunner is provided with a periscopic monocular 1PZ-2 day/night dual purpose sight. This sight has variable magnification settings of either 1.2x or 4x magnification. In the 1.2x magnification setting, the field of view is 49 degrees, and 14 degrees in the 4x magnification setting. The sight has no independent stabilization system. The aperture mirror of the sight has a maximum elevation limit of +81 degrees and a maximum depression limit of -10 degrees, but the weapons themselves can only elevate to +60 degrees and depress to -4 degrees due to the design of the turret and gun mount. The periscopic mirror in the sight aperture is vertically aligned with the weapons complex with mechanical linkages, and as such, the range of elevation of the sight is the same as the weapons.

This is more than enough to allow the gunner to fire at aircraft and input range corrections for ground targets located at high elevations, but the sight has no ability to track moving aircraft other than the simple concentric lead rings in the viewfinder of the sight. The same viewfinder is used against all target types, but the reticle markings for ground targets are too small to be used in the 1.2x magnification setting and the reticle markings for anti-aircraft work are not visible in the 4x magnification setting. In practice, the 1.2x magnification setting is mainly used for firing at aircraft or for non-precision fire at ground targets, and the 4x magnification setting is used exclusively for firing at ground targets.

The 1PZ-2 is used for aiming both the KPVT and PKTM coaxial machine gun. Both machine guns are sighted to a maximum range of 2,000 meters, but the maximum ranges for precise direct fire with these two weapons is mainly determined by the tracer burn-out distances of their tracer rounds. Fire correction is difficult without the help of tracers because the impact of the bullets is imperceptible at long ranges. As a rule, the maximum effective range of a 7.62mm machine gun on troops in open terrain does not exceed a kilometer and it is not effective against aircraft. Officially, the maximum effective range of the KPVT on lightly armoured vehicles is stated to be 1,000 meters and the maximum effective range on unarmoured targets or infantry is 2,000 meters. Against slow low-flying aircraft, the maximum effective range of the KPVT is 1,500 meters.

The sight has a simple reticle with fairly basic accommodations for range estimation and fire correction. A vertical line runs down the entire height of the viewfinder and a movable horizontal line runs across the entire length of the viewfinder. To adjust the sights for different ranges, the horizontal line in the viewfinder is lowered until it matches the corresponding number marked in the range scales. The intersection point between the vertical line and the horizontal line is the aiming point.

The drawings below show the reticle when it is adjusted to engage two types of targets. The first drawing (5.23) shows the reticle when it is calibrated for the KPVT to a distance of 1,400 meters and aimed at the center mass of an APC-type target. The second drawing (5.24) shows the reticle when it is calibrated for the PKT to a distance of 900 meters and aimed at the center mass of a car.

Lead and windage is adjusted using the horizontal deflection scale in the center of the reticle. A short horizontal bar above the horizontal deflection scale is calibrated to mark a distance of 500 meters for the KPVT. It aligns with the fixed horizontal line of the anti-aircraft rings. The horizontal deflection scale is also used for range estimations, but for more precise measurements, the gunner will have to rely on the commander as he has access to a stadiametric rangefinder in his TKN-3 periscope.

As usual, an internal bulb in the sight can be turned on to illuminate the reticle when fighting in low light conditions. To adjust the contrast of the image seen through the sight, the gunner can switch between two filters in the sight by turning a knob. For firing at ground targets, a neutral filter is used. For firing at air targets or for firing in the direction of the sun, a tinted filter is used.

The photo below shows the view through through the 1PZ-2 under 1.4x magnification. The tinted filter is in place.

The photo below shows the view through through the 1PZ-2 under 4x magnification. The neutral filter is in place, so the actual color of the target can be clearly seen.

The sight has a basic nightvision module. It is of the active infrared type, and it works in tandem the OU-3GA2M IR spotlight. The power of the 110 W spotlight is enough to allow the gunner to see and identify tank-sized targets up to 400 meters away, but seeing smaller vehicles such as armoured personnel carriers would be more difficult. The same reticle from the daytime channel is used in the night vision channel but with illumination provided by a green light bulb inside the sight. The illuminated reticle may also be used in the daytime channel when fighting during twilight hours.

Overall, the night vision capabilities of the sight are extremely lackluster. It is not a serious contender in the world of night vision devices, and turning on the infrared spotlight would probably reveal the vehicle's position faster to enemy observers.

The 1PZ-2 is a utilitarian tool that fulfills all of the basic criteria for its purpose, but no more. In technological terms, it belongs firmly in the 1950's. Nevertheless, the 1PZ-2 is already more advanced than the PP-61AM periscopic sight that was standard for the BTR family of troop carriers since the BTR-60PB.

Recently modernized BTR-80 units have had the new TKN-4GA-01 sighting complex installed. This is the same sight used in the BTR-82A, but unlike the BTR-82A, the gun on the BTR-80 remains unstabilized so the weapons still cannot be fired accurately on the move on rough terrain.

The turret was slightly modified to accommodate the larger and more modern sight and the mechanical linkages connecting the sight to the elevation mechanism of the weapons. Control of the turret and weapon elevation was still manually effected using hand cranks, but the elevation mechanism was modified to integrate with the new TKN-4GA-01 sight.

The patent of the modernized BPU-1 turret with PL-1-01 laser beamer and TKN-4GA sight can be viewed via this (link). The patent was filed jointly by the Arzamas plant and GAZ in 2006.

In the observation mode, the magnification of the daytime channel is fixed at 1x with an angular field of view of 49 degrees. In this mode, the magnification of the main optic is the same as the anti-aircraft optic, so the sight essentially becomes a stabilized binocular periscope and the gunner can spot targets with greater ease while the vehicle is moving. Once the gunner identifies a target and is ready to engage, he can switch to the higher magnification mode and use the monocular day sight to engage. In the daytime gunnery mode, the sight is monocular and only the right eyepiece is used. In the day setting, the sight offers a fixed 8.2x magnification and an angular field of view of 7 degrees. In the night setting, the sight has 8x magnification and an angular field of view of 7 degrees.

The simple anti-aircraft optic included in the TKN-4GA-01 is not improved over the 1PZ-2 but the greater magnification in the daytime channel compared to the 1PZ-2 enables the gunner to see and engage targets at longer ranges with more confidence than before, making the BTR-80 more effective overall. Another important upgrade lies in the inclusion of the PL-1-01 laser beamer, which not only has a greatly superior range compared to the earlier OU-3 IR spotlight but also features pulse modulation allowing its IR laser to penetrate more deeply into mist and fog, making it much more effective than the hopelessly outdated incandescent IR lamp used in the OU-3 during poor weather conditions. The PL-1-01 can also be used as a laser rangefinder in conjunction with sights of the TKN-4GA series, having an error margin of ±20 meters at a measuring distance of 200 meters to 3,000 meters. Combined with the 8.2x magnification in the daytime channel and the additional observation features implemented in the sight, this increased the effective firing range of the KPVT against lightly armoured targets, reduced the reaction time of the gunner to new threats, decreased the ammunition consumption rate per engagement, and vastly improved the combat effectiveness of the BTR-80 at night.

The photo below shows the view through through the 1PZ-2 under 4x magnification. The neutral filter is in place, so the actual color of the target can be clearly seen.

The sight has a basic nightvision module. It is of the active infrared type, and it works in tandem the OU-3GA2M IR spotlight. The power of the 110 W spotlight is enough to allow the gunner to see and identify tank-sized targets up to 400 meters away, but seeing smaller vehicles such as armoured personnel carriers would be more difficult. The same reticle from the daytime channel is used in the night vision channel but with illumination provided by a green light bulb inside the sight. The illuminated reticle may also be used in the daytime channel when fighting during twilight hours.

Overall, the night vision capabilities of the sight are extremely lackluster. It is not a serious contender in the world of night vision devices, and turning on the infrared spotlight would probably reveal the vehicle's position faster to enemy observers.

The 1PZ-2 is a utilitarian tool that fulfills all of the basic criteria for its purpose, but no more. In technological terms, it belongs firmly in the 1950's. Nevertheless, the 1PZ-2 is already more advanced than the PP-61AM periscopic sight that was standard for the BTR family of troop carriers since the BTR-60PB.

TKN-4GA-01

Recently modernized BTR-80 units have had the new TKN-4GA-01 sighting complex installed. This is the same sight used in the BTR-82A, but unlike the BTR-82A, the gun on the BTR-80 remains unstabilized so the weapons still cannot be fired accurately on the move on rough terrain.

The turret was slightly modified to accommodate the larger and more modern sight and the mechanical linkages connecting the sight to the elevation mechanism of the weapons. Control of the turret and weapon elevation was still manually effected using hand cranks, but the elevation mechanism was modified to integrate with the new TKN-4GA-01 sight.

The patent of the modernized BPU-1 turret with PL-1-01 laser beamer and TKN-4GA sight can be viewed via this (link). The patent was filed jointly by the Arzamas plant and GAZ in 2006.

In the observation mode, the magnification of the daytime channel is fixed at 1x with an angular field of view of 49 degrees. In this mode, the magnification of the main optic is the same as the anti-aircraft optic, so the sight essentially becomes a stabilized binocular periscope and the gunner can spot targets with greater ease while the vehicle is moving. Once the gunner identifies a target and is ready to engage, he can switch to the higher magnification mode and use the monocular day sight to engage. In the daytime gunnery mode, the sight is monocular and only the right eyepiece is used. In the day setting, the sight offers a fixed 8.2x magnification and an angular field of view of 7 degrees. In the night setting, the sight has 8x magnification and an angular field of view of 7 degrees.

The simple anti-aircraft optic included in the TKN-4GA-01 is not improved over the 1PZ-2 but the greater magnification in the daytime channel compared to the 1PZ-2 enables the gunner to see and engage targets at longer ranges with more confidence than before, making the BTR-80 more effective overall. Another important upgrade lies in the inclusion of the PL-1-01 laser beamer, which not only has a greatly superior range compared to the earlier OU-3 IR spotlight but also features pulse modulation allowing its IR laser to penetrate more deeply into mist and fog, making it much more effective than the hopelessly outdated incandescent IR lamp used in the OU-3 during poor weather conditions. The PL-1-01 can also be used as a laser rangefinder in conjunction with sights of the TKN-4GA series, having an error margin of ±20 meters at a measuring distance of 200 meters to 3,000 meters. Combined with the 8.2x magnification in the daytime channel and the additional observation features implemented in the sight, this increased the effective firing range of the KPVT against lightly armoured targets, reduced the reaction time of the gunner to new threats, decreased the ammunition consumption rate per engagement, and vastly improved the combat effectiveness of the BTR-80 at night.

KPVT

The KPVT is an open-bolt single-feed heavy machine gun, fed with 50-round belts held in individual boxes. It is a modification of the original KPV infantry heavy machine gun, adapted into a coaxial machine gun for tanks. It fires the 14.5x114mm cartridge at a cyclic rate of 600 rounds per minute out of a 1.346 m barrel. The barrel is shrouded in an air-cooling jacket and supported with a metal frame on its mount in the BTR-80 turret. At the muzzle of the barrel is a conical flash hider and booster assembly. The booster is connected to the air-cooling jacket, and allows the propellant gasses escaping from the barrel to push the barrel against the end of the jacket, causing it to recoil backwards a short distance. The short-recoil action reduces the recoil impulse and more importantly, reduces the shot dispersion by dampening the vibrations of the machine gun. The machine gun cradle itself also contains a pair of recoil buffers to further enhance the accuracy of the weapon.

Ten ammunition boxes with a belt of 50 cartridges each are provided for a total of 500 rounds of ammunition. The boxes much be manually loaded by the gunner. First, the empty ammunition box is removed by pressing on the locking lever on the side of the box holder. The box will drop to the floor, and the gunner can retrieve a fresh box from the hull and load it into the box holder by pushing it in from below. If the turret is aimed forward, the closest ammunition rack to the gunner is to his immediate left and right. More boxes are stowed at the two rear corners of the hull and to the right of the commander's station.

Once a fresh box has been loaded, the next task is to put the ammunition belt into the feed system of the machine gun. To do this, the weapons complex must be elevated to the maximum limit as the KPVT occupies the entire length of the turret and it would not be possible for the gunner to reach the feed system. Raising the weapons complex also allows the top cover of the KPVT to be opened and for the gunner to find the feed lips and slot the belt of cartridges into the machine gun. After this, the charging cable is pulled to cock the gun and ready it to fire. The two pictures below show this process. The photo on the left shows a gunner straightening out a belt of rounds and the screenshot on the right shows a gunner preparing the cock the machine gun (screenshot from this video).

Additional boxes of ammunition may be stowed inside the vehicle if the crew chooses to. They could simply be placed on the floor, on the seats, or anywhere that does not interfere with the general function of the vehicle.

Ten ammunition boxes with a belt of 50 cartridges each are provided for a total of 500 rounds of ammunition. The boxes much be manually loaded by the gunner. First, the empty ammunition box is removed by pressing on the locking lever on the side of the box holder. The box will drop to the floor, and the gunner can retrieve a fresh box from the hull and load it into the box holder by pushing it in from below. If the turret is aimed forward, the closest ammunition rack to the gunner is to his immediate left and right. More boxes are stowed at the two rear corners of the hull and to the right of the commander's station.

Once a fresh box has been loaded, the next task is to put the ammunition belt into the feed system of the machine gun. To do this, the weapons complex must be elevated to the maximum limit as the KPVT occupies the entire length of the turret and it would not be possible for the gunner to reach the feed system. Raising the weapons complex also allows the top cover of the KPVT to be opened and for the gunner to find the feed lips and slot the belt of cartridges into the machine gun. After this, the charging cable is pulled to cock the gun and ready it to fire. The two pictures below show this process. The photo on the left shows a gunner straightening out a belt of rounds and the screenshot on the right shows a gunner preparing the cock the machine gun (screenshot from this video).

The feeding system is a two-stage type like the PK series of machine guns, despite the rimless design of the 14.5x114mm cartridge. In the first stage, a cartridge is pulled out of the belt, and in the second stage it is placed into a slot cut in the breech face. The spent case from the previous round is pushed down and out of this slot by the new cartridge, previously extracted from its belt. The spent case is then pushed out of the slot and into an ejection chute by a special ejector lever.

The forward-ejection mechanism for spent cases is one of the main features of the KPVT that differentiates it from the standard KPV infantry machine gun, which was considered mandatory for machine guns adapted for tank usage (typically as a coaxial machine gun). The gun mantlet of the BPU-1 turret has a special duct for ejected cases underneath the barrel clamp of the machine gun for this purpose. The ejection mechanism of the KPVT propels the spent cases forcefully enough to enable the system to function normally even when the machine gun is fully elevated, as the short video clip below shows (taken from an show about the BTR-80 from the Russian NTV channel).

The drawing on the left below depicts the gun mantlet of the BPU-1 turret, showing the opening for the spent case ejection port underneath the opening for the KPVT barrel. The base of the turret has a cutout below the ejection port opening to ensure that the spent cases can clear the port even when the machine gun is fully depressed. The photo on the right below (courtesy of Sergey Sinitsyn) shows the ejection duct underneath the barrel clamp for the KPVT and the spring-loaded lid on the duct, which is necessary to help ensure that the turret remains sealed from NBC contaminants when cases are not being ejected.

Additional boxes of ammunition may be stowed inside the vehicle if the crew chooses to. They could simply be placed on the floor, on the seats, or anywhere that does not interfere with the general function of the vehicle.

Although the cyclic rate of fire is 550-600 rounds per minute, the practical rate of fire is officially listed as 70-80 rounds per minute in the manual for the KPVT. The practical rate is achieved by limiting fire to short bursts of 2-5 rounds. When necessary, long bursts of up to 20 rounds against ground targets may be used, and when engaging aerial targets, the machine gun is fired in long bursts exclusively. Continuous full automatic fire is permitted up to 150 rounds for each barrel, after which it is necessary to let the barrel cool or replace it.

A spare barrel for the KPVT is carried in the vehicle. The KPVT has a heavy barrel and it is sufficiently cooled by air alone as long as it is fired in bursts, so it does not require barrel changes during combat. As usual, the machine gun is fired in bursts to ensure an efficient rate of ammunition consumption, and the subsequent reduction in the practical rate of fire also ensures that the barrel does not overheat. Furthermore, the presence of a coaxial 7.62mm machine gun to supplement the KPVT allows the gunner to conserve 14.5mm rounds when engaging soft-skinned targets and enemy infantry in the open. However, if the barrel is worn out or damaged during combat, having a spare barrel on board allows the vehicle to continue fighting after a quick barrel swap.

The available bullet types are the B-32, BS-41, BZT, BZT-M, MDZ, and MDZ-M which are armour-piercing incendiary (API), armour-piercing incendiary tracer (API-T) and instantaneous incendiary-high-explosive (HEI) respectively.

B-32 is an AP round made from tool steel, while the BS-41 is an AP round made from tungsten carbide. BS-41 is superior to the B-32, but the latter is still the most numerous type due to its economy. The BZT and BZT-M rounds are the tracer counterparts to the B-32 and BS-41 respectively. Both of these rounds have similar, and very modest penetration capabilities, and only serve to duplicate the flight trajectories of their counterparts. The also BZT-M differs from the BZT by having a slightly more powerful propellant to match its speed to that of the BS-41. The MDZ and MDZ-M rounds fulfill a niche requirement as anti-helicopter ammunition. This type of bullet has a limited advantage in the anti-personnel role in that it produces a small amount of splinters upon detonation, and it can set field fortifications alight.

A spare barrel for the KPVT is carried in the vehicle. The KPVT has a heavy barrel and it is sufficiently cooled by air alone as long as it is fired in bursts, so it does not require barrel changes during combat. As usual, the machine gun is fired in bursts to ensure an efficient rate of ammunition consumption, and the subsequent reduction in the practical rate of fire also ensures that the barrel does not overheat. Furthermore, the presence of a coaxial 7.62mm machine gun to supplement the KPVT allows the gunner to conserve 14.5mm rounds when engaging soft-skinned targets and enemy infantry in the open. However, if the barrel is worn out or damaged during combat, having a spare barrel on board allows the vehicle to continue fighting after a quick barrel swap.

The available bullet types are the B-32, BS-41, BZT, BZT-M, MDZ, and MDZ-M which are armour-piercing incendiary (API), armour-piercing incendiary tracer (API-T) and instantaneous incendiary-high-explosive (HEI) respectively.

B-32 is an AP round made from tool steel, while the BS-41 is an AP round made from tungsten carbide. BS-41 is superior to the B-32, but the latter is still the most numerous type due to its economy. The BZT and BZT-M rounds are the tracer counterparts to the B-32 and BS-41 respectively. Both of these rounds have similar, and very modest penetration capabilities, and only serve to duplicate the flight trajectories of their counterparts. The also BZT-M differs from the BZT by having a slightly more powerful propellant to match its speed to that of the BS-41. The MDZ and MDZ-M rounds fulfill a niche requirement as anti-helicopter ammunition. This type of bullet has a limited advantage in the anti-personnel role in that it produces a small amount of splinters upon detonation, and it can set field fortifications alight.

B-32 (AP-I)

The B-32 bullet is composed of a hardened steel core with 1.8 grams of volatile incendiary mixture packed at the tip. The steel core is to defeat light armour, and the incendiary mixture is useful for injuring the occupants or setting internal equipment alight. The normal operating pressure of the cartridge is 326.6 MPa, and it reaches a maximum pressure of 343.2 MPa.

One interesting aspect about the B-32 bullet is that it shares the exact same external and internal design as the 12.7mm B-32 and 7.62mm B-32, differing only in scale. The B-32 bullet design was originally made for the 7.62x54mm cartridge, but was later adopted in larger calibers due to its very good ballistic shaping.

The B-32 bullet contained 1.3 grams of aluminium-magnesium-barium nitrate incendiary compound in the tip and the BZT bullet contained 1.56 grams of the same incendiary compound, which is substantially more than the 0.84 grams of magnesium-barium incendiary compound in .50 caliber spotting rounds. The tracer of the BZT bullet burns out at 2,000 meters. These characteristics made the KPVT an excellent ranging machine gun as the flash of the impact would be more visible at long distances and in poor weather conditions.

Muzzle velocity: 1,021 m/s

Muzzle velocity: 1,021 m/s

Core: Heat-treated tool steel

The velocity limits of B-32 for various thicknesses of steel are listed as follows:

Muzzle Velocity of 14.5 B32: 988 m/s

V50 of 15.6mm of ATI 500-MIL plate at 30 deg: 730 m/s

V50 of 15.4mm of ATI 500-MIL plate at 30 deg: 739 m/s

V50 of 18.8mm of ATI 500-MIL plate at 30 deg: 841 m/s

This means that 980 m, a 14.5mm B-32 bullet will go through 15.6mm of ATI 500-MIL plate angled at 30 degrees to the vertical. This is almost exactly double the performance of the .50 M2 round for a very small increase in caliber and small increase in overall dimensions. At 915 meters, the 14.5mm B-32 bullet will go through 15.4mm of the same steel at the same slope. Odd, but not a big deal. A 0.2mm error margin is easily explained away by quality issues. At 525 m, the 14.5mm B-32 bullet will go through 18.8mm of the same steel at the same slope.

Here is the graph of thickness against V50:

The B-32 bullet has limited effect against an M2 Bradley IFV, as the core will be defeated by the two spaced steel plates that protect the aluminium armour underneath. The spaced side armour of the M2 Bradley reportedly provides all-round protection from 14.5mm armour-piercing rounds from a range of 300 meters.

Muzzle Velocity of 14.5 B32: 988 m/s

V50 of 15.6mm of ATI 500-MIL plate at 30 deg: 730 m/s

V50 of 15.4mm of ATI 500-MIL plate at 30 deg: 739 m/s

V50 of 18.8mm of ATI 500-MIL plate at 30 deg: 841 m/s

This means that 980 m, a 14.5mm B-32 bullet will go through 15.6mm of ATI 500-MIL plate angled at 30 degrees to the vertical. This is almost exactly double the performance of the .50 M2 round for a very small increase in caliber and small increase in overall dimensions. At 915 meters, the 14.5mm B-32 bullet will go through 15.4mm of the same steel at the same slope. Odd, but not a big deal. A 0.2mm error margin is easily explained away by quality issues. At 525 m, the 14.5mm B-32 bullet will go through 18.8mm of the same steel at the same slope.

Here is the graph of thickness against V50:

The B-32 bullet has limited effect against an M2 Bradley IFV, as the core will be defeated by the two spaced steel plates that protect the aluminium armour underneath. The spaced side armour of the M2 Bradley reportedly provides all-round protection from 14.5mm armour-piercing rounds from a range of 300 meters.

BS-41 (AP-I)

A souped-up armour-piercing cartridge first introduced for anti-tank purposes in 1941. It is very useful against lightly armoured vehicles like armoured cars and bullet-proofed utility and transport vehicles like M113s, Humvees and LAVs. Armoured attack helicopters are fair game as well. The extra penetration ability granted by the tungsten carbide core enables the the BS-41 to be useful against modern utility trucks and cars, but with the emergence of new and more advanced ceramic armour technology, the BS-41 cartridge will find its usefulness diminishing rapidly.

The bullet also has an incendiary compound packed at the tip of the bullet, just like the B-32. The bullet contained 1.3 grams of aluminium-magnesium-barium nitrate incendiary compound in the tip.

Muzzle velocity: 1005m/s

The bullet also has an incendiary compound packed at the tip of the bullet, just like the B-32. The bullet contained 1.3 grams of aluminium-magnesium-barium nitrate incendiary compound in the tip.

|

| Penetration of BS-41 into mild steel |

Core: Tungsten carbide

Bullet Mass: 64.2 g

Bullet Length: 51.2mm

Core Diameter: 11.72mm

Core Length: 38.72mm

Core Mass: 38.72 g

Incendiary Compound Mass: 0.97 g

Bullet Mass: 64.2 g

Bullet Length: 51.2mm

Core Diameter: 11.72mm

Core Length: 38.72mm

Core Mass: 38.72 g

Incendiary Compound Mass: 0.97 g

Penetration:

40mm RHA @ 100m35mm RHA @ 350m

32mm RHA @ 500m

20mm RHA @ 1000m

80.5mm Mild Steel @ Muzzle

125mm 5083 Aluminium Armour @ 100m

Testing was conducted on the BS-41 against ATI 500-MIL plate, a high strength type of steel with a hardness of 500 BHN. This is much harder than normal RHA, which tends to have a hardness of around 300 BHN. The average hardness of mild steel is 145 BHN.

Muzzle Velocity of 14.5mm BS41 bullet: 1,005 m/s

V50 of 24.5mm of ATI 500-MIL plate at 30 deg: 869 m/s

At 435 meters, the BS41 bullet can perforate 24.5mm of ATI 500-MIL plate steel angled at 30 degrees. According to widespread claims on various websites and old Army documents, the 14.5mm BS-41 bullet is apparently also capable of perforating 40mm of steel armour (the properties of which are not specified, but assumed to be around RHA steel) at 100 meters at 0 degrees, and 32mm of the same steel at 0 degrees at 500 meters.

BZT, BZT-M (APT-I)

The BZT and BZT-M have armour-piercing cores and incendiary tips like their armour-piercing-only counterparts, but these have an additional tracer element at the rear. The BZT has a steel core, and the BZT-M has a tungsten carbide core, both of equal dimensions. The tracer can burn until at least 2000m. These bullets are linked in a belt of AP ammunition in a 1:4 ratio.

Muzzle velocity: 995m/s (BZT) - 1005m/s (BZT-M)

Core: Heat-strengthened steel

Penetration: 20mm RHA @ 100m (BZT)

Tracer ignition distance: 50m - 120m from muzzle

As you can see in the pictures above, the BZT class of bullets have a shortened armour piercing core, with the addition of a volatile incendiary mixture packed in front of it at the tip of the bullet.

As you can see in the pictures above, the BZT class of bullets have a shortened armour piercing core, with the addition of a volatile incendiary mixture packed in front of it at the tip of the bullet.

MDZ, MDZ-M

The MDZ is a high explosive incendiary (HE-I) bullet designed primarily for anti-aircraft work, but it is also suitable for soft skinned vehicles vehicles such as trucks, jeeps, and cars. The bullet has a bimetallic jacket containing an explosive filler. A detonator cap is installed at the nose of the bullet. It is extremely lightweight and occupies much less space compared to a mechanical fuze.

The filler of the MDZ bullet consists of ~5 grams of phlegmatized PETN. The phlegmatizer content is unknown, but the explosiveness of PETN (as determined by a Trauzl test) is 523 ml, while the A-IX-2 explosive-incendiary compound has an explosiveness of 530 ml, the same as pure hexogen. The explosiveness of the phlegmatized PETN charge is likely to be between A-IX-1 and A-IX-2. In terms of explosive payload, the MDZ bullet is similar to the 20x99mm OZ (HE-I) shell for the the ShVAK aircraft cannon, which contained 5.6 grams of A-IX-2.

The MDZ bullet is specified to blast a hole with a diameter of 20-30cm into a 1mm duralumin sheet at a distance of 1,500 meters. This is superior to a 20mm OZ round for the ShVAK, which is only capable of creating a 150x160mm breach in a 0.9-1.5mm duralumin sheet simulating the skin of aircraft.

Overall, the useful payload of the MDZ bullet is similar to the 20mm ShVAK OZ shell, despite the considerable difference in total projectile weight of 31 grams. The forged steel body of the OZ shell may be heavier and more effective at fragmenting compared to the jacket of the MDZ bullet, but at least in terms of weight, the difference is not as large as the total projectile weight suggests due to the fact that the OZ shell has a large mechanical fuze whereas the MDZ bullet does not.

The MDZ-M bullet entered service in 2002. It was very similar to the original MDZ bullet from 1955, but with a slightly reduced explosive power and increased incendiary effect. As a result of the changes made to the filler, the weight of the bullet decreased slightly to 58.5 grams. The front is occupied by the explosive-incendiary charge, and the rear is occupied by the incendiary charge.

The relatively thick steel wall of the bullet allows it to punch through the thin aluminium skin of transport helicopters like the Mi-8 and the Huey and explode inside with great fragmentation and incendiary effects. For example, the aluminium skin on the fuselage of an Mi-8 utility helicopter is made from D16AT aviation aluminium alloy with a thickness of only 0.8-1.0mm, and the fuselage skin for many Western military and commercial helicopters is usually made from 7075 aviation aluminium alloy with an average thickness in the vicinity of 0.025 inches (0.635mm). This includes gunships like the AH-1 Cobra. The effect of an MDZM bullet on a sheet of aluminium is shown in the promotional display shown below.

The explosive-incendiary charge is composed of a 50/50 mixture of barium nitrate and PETN. The incendiary charge is No.7 Incendiary Compound, which is composed of a 50/50 ratio of barium nitrate and a mixture of aluminium and magnesium powder. In total, the explosive-incendiary charge weighs 2.9 grams and the incendiary charge weighs 1.55 grams. This payload is comparable to the total 4.6-gram payload of the 20mm OFZ (HEF-I) round for the ShVAK aircraft cannon, but due to the more energetic filler, it may have a stronger explosive and incendiary effect.

The MDZ-M bullet is advertised to be capable of blasting holes with a diameter of 20-40 cm in aluminium sheets with a thickness of 1-1.5mm.

MDZ (MDZ-M)

Muzzle velocity: 1,000-1,008 m/s (1,000-1,015 m/s)

Bullet weight: 58.5 g (58.0 g)

The 14.5mm cartridge is no longer a reliable means of dealing with light AFVs in the present day due to the universal up-armouring of this class of vehicle, thereby leaving the 14.5mm caliber with only of limited use against certain targets. Surprisingly though, even with the KPVT machine gun, the BTR-80 is still much better armed than modern competitors, which are usually armed with only .50 caliber machine guns. The KPVT grants the BTR-80 superior anti-masonry capabilities and superb anti-personnel performance thanks to its ability to penetrate straight through sandbag, wood and cement fortifications in addition to a substantial demoralizing factor. In a direct comparison to some NATO armoured scout cars and APCs armed with 20mm autocannons - usually the excellent Rh202 - like the Spähpanzer Luchs, the BTR-80 comes off much worse in every way, without a doubt. Thus, we can classify the KPVT as something in between a .50 caliber machine gun and a 20mm autocannon.

As mentioned before, the KPVT is not stabilized. The gunner is only able to fire accurate if the vehicle is stopped or moving at a very relaxed speed over even ground. This has the effect of limiting the usefulness of the BTR-80 as a fire support vehicle.

SECONDARY

Unlike a typical armoured personnel carrier, the BTR-80 has a coaxial machine gun. The machine gun is fed with 250-round boxes. Eight boxes are carried inside the BTR for a total ammunition load of 2,000 rounds. All boxes are within reach of the gunner who is responsible for reloading the machine gun. The machine gun has a cyclic rate of fire of 700 to 800 rounds per minute. The co-axial machine gun can be fired either by depressing the trigger button on the gunner's handgrips, or by pressing the emergency manual trigger button located on the trigger unit installed at the back the receiver of the machine gun.

FIRING PORTS

There are eight firing ports on the BTR-80. Of this, there are three firing ports on the port side and four on the starboard side, all of which are canted forward to allow troops to fire to the front of the vehicle. The commander is also provided with his own firing port. Six of the firing ports are designed for a Kalashnikov rifle (AK-47, AKM or AK-74) and the other two are designed to mount a PKM machine gun. Depending on the specific firing port, the horizontal range of motion varies from 30 degrees to 50 degrees. The drawing above, taken from a BTR-80 technical manual, shows the range of motion of each firing port.

The firing ports for PKM machine guns feature a special frame designed to help support the weight of the weapon, which can also be secured by a travel lock when not in combat.

The firing port itself and the armoured plug provides the same protection as the hull armour, and the triple-layered armoured glass window in each firing port offers protection from grenade and shell fragments. When not needed, each firing port can be sealed with an armoured lid which is operated from inside the vehicle.

There are two square roof hatches over the troop compartment, which allow dismounts to aim their personal weapons, RPGs, or MANPADs from the vehicle whilst affording some cover for the dismount. This feature is most useful for MANPADs. Unlike RPGs or automatic weapons, the accuracy of a MANPADS is not significantly affected by motion.

Each of the roof hatches also feature firing ports, although these are only simple round port holes that allow any type of weapon to be fired at targets above the vehicle. The main use of these ports would be to allow troops to fire at targets in tall buildings or cliffs flanking the vehicle while under the relative safety of bullet-resistant armour. Firing at aircraft would be not only be totally futile, but also rather counterproductive since there are MANPADS launchers available.

The commander's firing port is aimed directly forward and can traverse in a 50° horizontal arc and 50° in a vertical arc. The addition of this firing port required the commander's windshield to be shifted closer to the driver's windshield.

The firing port attendees were provided with sheet steel cartridge casing deflectors that would snap onto the receiver of their Kalashnikovs, since AK-type rifles ejected spent casings with quite a bit of force, so the user would otherwise pelt hot brass at his neighbour's face when he opened fire. The casing deflectors prevent this by redirecting spent casings downwards. Aside from that, the firing port stations were also fitted with a fume extractor system. Air hoses were attached to the sheet steel cartridge casing deflectors and were positioned just in front of the rifle's ejection port to suck in the powder gasses that escape from the ejection port as the rifle fired. Without this system, the BTR would be flooded with powder fumes, especially if all eight passengers have been firing continuously for extended periods of time without permission to open any of the hatches. This system is similar to the one installed in the BMP-1 and BMP-2.

In addition to the weapons organic to the BTR-80, the vehicle can also carry grenades, grenade launchers, assault flamethrowers, additional small arms ammunition, and MANPADS launchers, machine guns - both light and heavy - and even AGS grenade launchers or other equipment. The BTR-80 can transport almost anything that its occupants need for short missions.

PROTECTION

In accordance with its intended role, the BTR-80 was designed as a lightly-armoured vehicle. According to the specifications for the basic tactical-technical characteristics of the BTR-80, its requirements for protection did not change from its predecessors - its frontal armour had to resist 12.7mm armour-piercing bullets and it had to offer complete protection from 7.62mm armour-piercing bullets from all angles of fire. The basic requirements were already fulfilled by the BTR-60PB and BTR-70, but the BTR-80 achieved a higher level of security by having slightly thickened plating on the front and sides of the hull. The previous BTR models required more standoff distance in order to provide the required protection. Together with the revised powertrain, the added armour increased the weight of the BTR-80 by 18% compared to the BTR-70. The increased armour protection further decreased the chances of a successful armour perforation from small arms down to point blank range, although it should be noted that bullets tend to require some standoff distance to fully stabilize and that a yawing bullet has drastically less penetration power than a stabilized one.

The turret and hull are monocoque structures constructedt from welded 2P high hardness, high strength armour steel plates of two thicknesses: 7mm and 9mm. The 2P grade is a manganese-molybdenum steel with a carbon content of 0.23-0.29%. 2P grade plates with thicknesses of 8mm to 14mm have a tensile strength of 1450 MPa and a hardness of 388 – 495 BHN, while plates with thicknesses of 4mm to 7mm have a hardness of 444 – 514 BHN. For a lack of more specific information, the 2P plates used to construct the BTR-80 are assumed to have a hardness of 500 BHN.

For comparison, MIL-A-12560 specifies that RHA steel for a plate with a thickness of 6.35mm to 12.7mm should have a hardness of 341 BHN to 388 BHN. The direct foreign equivalent of 2P grade steel in specification is MIL-DTL-46100 high hardness armour steel for combat vehicles, so for any evaluation of the armour of the BTR-80 to be valid, the armour penetration of threat munitions should be in terms of the MIL-DTL-46100 standard and not in terms of RHA.

The use of high hardness steel (HHS) armour has been the norm for Soviet armoured personnel carriers since 2P steel was developed in the 1950's, but the higher efficiency of 2P grade steel compared to armour steels of lower hardnesses is only true for certain types of projectiles. Bullets from small arms are more readily defeated with high hardness plates set at an oblique angle, but fragmentation and splinters from grenades, shells and bombs are more efficient at piercing high hardness armour plate as their blunt shapes change the mechanism of penetration from ductile hole formation or fracturing to adiabatic shear plugging. This is shown in the graph below.

As the graph illustrates, the ballistic limit for .30 caliber M2 armour piercing bullets steadily increases until it plateaus when the hardness of 450 BHN is reached, but for .50 caliber fragment simulating projectiles, the highest ballistic limit (within the scope of the study) is achieved at a moderate hardness of 300 BHN. The efficiency of the 10mm plate drops drastically with increasing hardness and it reaches its lowest point at a hardness of 450 BHN. As the hardness decreases, the efficiency of armour against fragments and splinters increases, making aluminium armour plate a better choice than high hardness steel.

The upper frontal plate measures 9mm thick at an angle of 64 degrees and the lower frontal plate is 9mm thick at 45 degrees. The bow deck between the upper glacis and the lower glacis is 7mm thick and it is sloped at 84 degrees with the trim vane laid on top of it. The interstitial plate joining the two plates measures 7mm thick at an angle of 87 degrees. The angled corners are the same thickness as the upper and lower front plates beside them. The sides of the hull are 9mm thick on both the upper and lower sides. Besides a relatively high thickness and an optimal hardness for protection from small caliber fire, the side armour of the hull has the additional benefit of between 20 to 30 degrees of vertical slope on both the upper and lower halves. Like the rest of the side hull armour, the side doors have a thickness of 9mm. The rear of the hull, and the roof and the floor all measure in at 7mm thick. This is enough against 7.62x39mm BZ rounds and various 7.62mm ball rounds, but 7.62mm M61 AP rounds would be enough to defeat this armour.

The table below from the 1992 publicly disclosed paper "LAV Armor Plate Study" shows the ballistic limit of three thicknesses of high hardness steel armour plates in the MIL-DTL-46100 standard against 12.7mm B-32 armour-piercing bullets at an obliquity of 45 degrees. The third row lists an extra-hardened plate (XH) that does not represent the armour standard and it should be ignored. From the table, it can be seen that the velocity limit of 12.7mm B-32 on a 9.71mm plate at 45 degrees is 2,528 ft/s. This is equivalent to a distance of 150 meters.

According to a variety of sources, the mass efficiency of high hardness armour is 1.3 times the mass efficiency of RHA steel against armour piercing bullets. The .30 caliber M2 armour-piercing bullet can perforate 0.45 inches of RHA steel set at 30 degrees at muzzle velocity according to the Navy Criterion. With the 1.3 mass efficiency coefficient of 2P steel, the 9mm of side armour on the BTR-80 hull is more than enough to offer comprehensive protection from this bullet. The less potent M61 armour-piercing bullet is even less likely to puncture the armour plate.

However, the thickness of the side armour of the hull is not nearly enough to provide any meaningful amount of protection from 12.7mm-caliber threats except ball rounds, and only if the bullet impacts the armour at a considerable angle. NII Stali states that without additional armour, the upper side of the BTR-80 hull can be defeated by the 12.7mm B-32 armour-piercing bullet from a distance of 1,500 meters.

The video below shows a BTR-80A sustaining hits to the side from an SVD rifle at point blank range. The bullets used are 7.62mm B-32 bullets which are equivalent to .30-06 M2 AP rounds. The BTR-80A does not have increased protection compared to a basic BTR-80 as the BTR-80A model is not designed for newly built vehicles but is instead a modernization package for existing vehicles.

The roof of the BTR-80 is resistant to some small arms fire, but only from a limited range of angles. When fired upon at an angle, the roof would be able to resist .30 caliber M2 AP rounds, but if the vehicle is somehow attacked directly from above, its modest thickness indicates that it would only be resistant to 7.62mm ball rounds and 7.62x39mm BZ (AP-I) rounds. Regardless, battle damage research indicates that hits from machine guns to the hull roof in Afghanistan were rare compared to hits to the sides and rear of the hull, and the roof is not necessarily a vulnerable zone in the vehicle's armour. Even in a worse case scenario where a BTR-80 is ambushed from above while travelling along a mountain pass or down a street flanked by tall buildings, it is very difficult to fire upon the roof at a perpendicular angle. Instead, firing on the BTR-80 from a high elevation would reduce the obliquity of the upper side hull armour plate (while simultaneously increasing the obliquity of the lower side hull plate), making it relatively more vulnerable. If, for example, the vehicle was fired from a height corresponding to the maximum elevation angle of the KPVT in the BPU-1 turret (60 degrees), the bullets would impact the roof at an angle of at least 30 degrees and this is already enough to resist a 7.62mm armour-piercing bullet.

The turret walls are 9mm thick angled at 45 degrees at the front and sides, thinning down to 7mm at the rear but maintaining the same vertical slope angle throughout. As such, the front armour of the turret shares a similar level of protection as the front of the hull but the sides and rear of the turret have a somewhat higher level of protection than the sides and rear of the hull, primarily due to the increased slope obliquity. Furthermore, the circular shape of the turret adds an additional horizontal slope component that enhances its protection from small arms fire. The semi-cylindrical gun mantlet shares the same thickness as the front of the turret and mainly depends on its curved surface for its protective value. Like the hull, the roof of the turret is 7mm thick.

Overall, the level of protection offered by the BTR-80 was sufficient for the role of this class of troop transport for a conventional war. This is a very basic level of protection, so generally speaking, the BTR-80 only viable as a "battle taxi". It offers sufficient protection to go up against the organic firepower of a typical American mechanized rifle platoon, not counting any anti-tank weapons carried by the platoon, like the LAW, for example. If attacked by anti-tank grenades, the armour of the BTR-80 is not only incapable of resisting a complete perforation, but the welds that join the plates may burst with a direct hit as demonstrated by the BTR-80 in the photo below. This particular example was lost to an RPG attack in Ukraine.

However, the blast of an RPG grenade is usually not enough to breach the armour plates themselves even if it can be pierced easily by the shaped charge jet.

Needless to say, it is dangerous for a BTR-80 to directly confront enemy vehicles armed with autocannons as its armour is simply inadequate against such threats while returning fire with the KPVT may not be enough to eliminate the threat. In general, proper reconnaissance and planning should ensure that motorized infantry riding in BTRs do not face resistance armed with more than small arms. Against such forces, the BTR-80 is well-armed and well-protected enough for the task.

If the BTR-80 is acting as a battle taxi against a lightly-armed enemy force, there is no sense for the passengers to not be inside the armoured hull as the vehicle performs adequate as a shield from bullets and splinters. However, in situations where heavy weapons and mines are expected, soldiers often prefer to ride on top of the vehicle rather than in them, as this helps improve the chance of surviving a mine blast but also allows them to quickly dismount and spread out because such incidents are often followed up with an enemy ambush from hidden positions. Being outside the vehicle has many more disadvantages on its own, obviously, the primary one being that this practice makes the soldiers vulnerable to claymore mines, jumping mines, and to the most basic IEDs. If the BTR-80 is driven over an anti-tank mine with a tilt-rod fuze or a large IED, the chances of survival for the driver and commander would tend to be lower than the soldiers riding on top of the vehicle.

One important factor in the survivability of the BTR-80 to enemy fire is its relatively small size and low silhouette. The total height of the vehicle up to the infrared spotlight on the turret is 2.41 meters, but the height from ground level to the hull roof is only 1.91 meters. The average Soviet military-age male was considered to have a height of 1.7 meters, but a 95th percentile male is 1.83 meters. As such, the hull itself is only barely taller than a male soldier of above-average height and the small turret is a very small target to begin with. The low profile gives the BTR-80 good concealment potential in densely vegetated environments and it is a more difficult target to hit, especially when its speed is utilized properly. Being quite low to the ground, terrain features like rocks, mounds, shrubs and even tall grass can hide the BTR-80, and the tiny turret can be easily camouflaged.

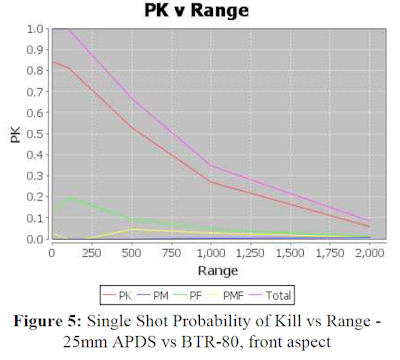

The graph below from the study "Simple Physical Models in Support of Vulnerability and Lethality Data for Wargaming and Simulation Environments" shows the importance of a small silhouette. It shows the simulated probability of kill with a stationary vehicle firing a single 25mm APDS shot against a fully exposed stationary BTR-80, taking into account the known empirical data for the penetration of 25mm APDS and the armour protection of the BTR-80.

From the graph, it can be seen that the probability of a first round kill reaches 85% at point blank range and the probability of some combination of all mission kill types including a mobility kill, firepower kill, or a mobility plus firepower kill is at 100% until the distance exceeds 100 meters. This bodes ill for the BTR-80, but the chance of surviving the first hit increases drastically with the increase in distance such that at 1,000 meters, the probability of a first round kill has dropped to just 28%. At a distance of 2,000 meters, this drops even further to only 6%. Going by the general military criteria of "combat effectiveness", firing single shots ceases to be a combat effective gunnery technique at distances beyond 500 meters as the probability of a kill is below 51%. Firing in bursts is necessary to ensure a kill, and firing in bursts is absolutely necessary if the BTR-80 is maneuvering. At a distance of two kilometers, a moving BTR-80 has a very good chance of avoiding destruction even in the face of persistent enemy fire. The mobility of the BTR-80 makes a large difference and it is the main asset of the vehicle when it is so heavily outgunned, so it is also quite fortunate that the probability of achieving only a mobility kill on a BTR-80 with 25mm APDS is extremely low at all ranges - the blue line in the graph barely touches 1%.

SMOKE GRENADES

The BTR-80 is provided with the 902V "Tucha" smoke grenade launching system which includes six 3D6 smoke grenade launchers arranged at the rear of the turret, aimed forward. The grenades are aimed by the gunner using his 1PZ-2 sights.

NBC PROTECTION

The BTR-80 has a overpressure NBC protection suite similar to its predecessors. The higher pressure within the hull prevents particulate contaminants from entering the vehicle, and the occupants are supplied with purified air from an air filtration system. The air outlets for purified air are the only form of ventilation that the passengers are given when the vehicle is fully sealed.

FIREFIGHTING

The BTR-80 features an automatic fire extinguishing system, which works in the engine compartment. There are four TD-1 thermal sensors arranged in the engine compartment at strategic positions to sense a fire. Two Freon 114B2 fire extinguisher bottles are provided, allowing for two discharges. Once a fire is detected, the system floods the entire engine compartment with the extinguishing agent, and seals all ventilation points to starve the fire of fresh air, and to limit the escape of the extinguishing agent to the atmosphere. The system functions automatically by default, but it can be manually activated if the crew notices the fire before it is registered by the sensors.

Additionally, the occupants are provided with OU-2 hand-held 1-liter fire extinguishers filled with the Freon 114B2 halocarbon extinguishing agent. Since 1985, an OP-10A powder fire extinguisher was included, mainly for extinguishing external fires.

ADDITIONAL ARMOUR

BTR-80s have been seen with slat armour sets in various conflict zones as a response to the presence of RPG threats. These slat armour kits are only provided in small numbers to the Southern Military District and most often seen in the North Caucasus. BTR-80s mounted with slat armour screens are very commonly seen during anti-terrorist operations in Chechnya. The Ukrainian army has mounted slat armour on most of their BTR-type vehicles in light of the recent conflict in the Donbas region. Their availability on short notice is quite noteworthy as it indicates the ease of which they can be deployed. Slat armour is a cheap and convenient solution that provides a reasonable level of protection from common anti-tank threats that is compatible with the thin base armour of the vehicle.

The BTR-80 below is equipped with a slat armour kit developed by NII Stali. The slat armour screens cover the entire length and height of the hull sides and most of the front, with gaps left in the bottom edge of the lower glacis and the top edge of the upper glacis (presumably to not interfere with the view from the periscopes). The side doors in the hull are not protected by slat armour. In the example below, the lower half of the slat armour screens on the sides of the hull have been folded up. This feature is designed to permit free access to the wheels. The armour kit includes a layer of spaced armour plating underneath the slat armour screens made from ST-44 high-hardness steel to act as a dampener for shaped charge warheads as well as to provide additional protection from small arms fire. Note that the windscreens are also shielded by spaced armour panels, and that the panels on the lower glacis of the hull are divided into multiple longitudinal strips. These particulars can be used to differentiate it from other appliqué armour kits developed for the BTR-80.

The addition of the spaced armour plating underneath the slat armour panels helps to mitigate the damage caused by the blast of shaped charge grenades that successfully detonate despite the presence of the slat armour, and NII Stali advertises that the armour kit provides the upper side of the hull with protection from 12.7mm B-32 armour-piercing bullets from a distance of 325 meters. The claimed success rate of defeating anti-tank grenade threats such as the PG-9S grenade (fired from the SPG-9 recoilless gun) is 50% and the overall probability of the armour being breached by a PG-9S grenade is claimed to be 20%.

According to NII Stali, the entire armour kit weighs 1,000 kg. When installed on a BTR-80, the resulting gain in weight can be considered quite modest as the coverage offered by the additional armour is very generous. On the hull, the armour kit covers 90% of the front, 80% of the side and 90% of the rear. On the turret, the armour kit covers 60% of the front, 80% of the side and 100% of the rear. The slat armour screens work at any angle of attack.

The photo below shows a Russian BTR-80 with NII Stali slat armour kit in the Donbas region of Ukraine. The slat armour screens on the sides of the hull have been unfolded but the screens at the front of the hull have been removed for some reason.

PASSENGER ERGONOMICS

The vehicle can transport 8 troops, although it is quite cramped at full capacity. Fortunately, due to the open space accommodation, soldiers can arrange their equipment and themselves wherever they want and in whatever position they find most comfortable. During marches, there are three crew members - the gunner, the commander and the driver. However, the commander is the squad leader of the motorized infantry squad and he dismounts with the 7 other squad members of the BTR-80, so the vehicle is left without a commander and nobody is left to use the radio other than the driver. The BTR-80 will continue to provide local fire support with only the driver and gunner manning the vehicle.

A reasonable amount of attention is given to passenger comfort, although it is still surprisingly cramped inside. The vehicle is deceptively small.

When speaking of internal space, one of the many important factors to consider is the internal height of the vehicle. As mentioned before, the total height of the vehicle including the turret is 2.41 meters, but the height from ground level to the hull roof is only 1.91 meters. With a ground clearance of 475mm, the internal height of the BTR-80 hull is only 1.435 meters - less when the height of the false floor is accounted for. The total height of a seated 95th percentile USSR male is 1.345 meters, so a male soldier of above-average height should be able to sit inside the passenger compartment of the BTR-80 with his combat gear (including helmet), but the dimensions of the vehicle are best suited for a man of average height.

Departing from other designs, troops must dismount from side doors instead of a typical rear door or ramp. This has its own advantages and shortcomings. Frankly speaking, exiting from these narrow doors in full gear is more inconvenient than it should be, but the choice of two doors means that if one side of the vehicle comes under fire, troops can disembark from the other side. This means that in an ambush scenario, the occupants have a good chance to escape unless surrounded from both sides. The doors are split into two portions - the upper half which swings sideways and outwards, and the bottom half, which drops down and forms a step, which is useful if the vehicle is on the move.

The upper half of the door is hinged on the side so it is easy to open and close with the built-in handle, but to close the lower half, there is a pullstring with a handle and a simple pulley to help fight against gravity when lifting the door. The string is spring-loaded so it will coil itself up once the door is closed.

Additionally, the passengers may also exit the vehicle via top hatches. These are the main points of exit when the BTR is afloat on a body of water. As shown in the diagram below, the rim of the hatch opening on the hull roof is upturned, forming a lip, and the hatch closes over the lip. The rim of the hatch is downturned, and a rubber lining under the rim of the hatch is pressed against the lip to form a seal. Due to the presence of the hatch and the lip of the hatch opening, there is a measure of leak protection against water or flammable fluids even if the rubber lining has worn out, or burnt away in the case of a flame attack. To flow into the vehicle, fluid would first have to flow under the small gap between the rim of the hatch and the hull roof, which is the first barrier against thickened fuels such as napalm or improvised mixtures used in molotov cocktails. The fluid would then need to overcome the rubber seal and then flow up and over the lip, which is the second barrier.

The accommodations for the passengers include two benches facing away from each other and periscopes for the passengers to monitor the situation outside the vehicle. The benches are designed this way due to the presence of the transmission, which is a byproduct of the rear engine layout of the BTR-80. Six people can be seated on the benches, three on each side. All six passengers are provided with their own firing ports and their own periscopes. There are stowage clips and bins for various essential provisions located between the benches and the engine compartment partition.

There are two more individual seats at the front of the vehicle, behind the driver's and commander's seats. The seats are placed facing inward towards each other. The passengers seated here are in an ideal position to help the gunner load the machine guns in the small one-man turret.

There two periscopes for the two passengers seated at the front of the hull, one facing the 11 o'clock direction and one facing the 1 o'clock direction. The passengers at the back of the hull have seven periscopes of which four are TNPO-115 periscopes aimed to the side, two are TNP-165A periscopes aimed towards the 11 o'clock and 1 o'clock directions, and one is a TNPO-115 facing the rear. All of the periscopes are heated to prevent fogging except for the TNP-165A model. The drawing below shows the layout of periscopes with black lines showing the wires for the heating system.

DRIVER'S STATION

When driving in a non-combat situation, the driver relies on one of the two windscreens at the front of the vehicle for most of his driving work. In this condition, the armour panels for the windscreens are locked in a horizontal position to act as a visor, which helps to reduce glare from the sun and shelters the windscreens from snow and rain, thus helping to improve driving visibility. When combat becomes imminent, the driver must switch to an array of three TNPO-115 periscopes mounted to the ceiling, supplemented by another TNPO-115 periscope on the side of the hull. Sometime during the production run of the BTR-80, a fourth TNPO-115 periscope was added to the hull ceiling to further improve the driver's visibility towards the left, which makes sense given that the USSR and most of the world drove on the right side of the road. Like all other Soviet wheeled armoured vehicles since the early 1960's, the windshields of the BTR-80 omitted the vision blocks that were standard for early BTR-60 models and the BRDM-1 armoured car in the interest of improving ballistic protection. Still, five periscopes is enough to allow the driver to maneuver the BTR-80 safely , but visibility is still somewhat hampered compared to a heads-out driving status or when driving with the windshield.

At night, driving visibility is seriously affected as the driver must rely on a single forward-facing TVNE-4B night vision periscope. One of the TNPO-115 periscopes is swapped out for the TNVE-4B. The night vision periscope has a viewing distance of 120 meters. Due to the limited field of view and viewing distance, it is not safe for the BTR-80 to be driven at normal daytime speeds, so the average speed of the vehicle has to be severely restricted. When driving at night in a non-combat condition, the driver may drive with the help of a pair of night vision goggles.

MOBILITY

Despite its ungainly appearance, the BTR-80 is a very assertive cross-country vehicle. The weight of the vehicle is 13.6 tons plus 3% for a full combat load, adding up to a total of 14 tons in a combat configuration. This is somewhat heavier than the BTR-70 which weighed 11.5 tons, but the increased weight of the BTR-80 is compensated by the major improvement in performance gained from switching from a pair of petrol engines to a single diesel engine.

Early versions were originally powered by a single KamAZ-7403 diesel engine. The KamAZ-7403 produces 260 hp at an engine speed of 2,400 RPM and has a specific fuel consumption rate of 0.5 liters per kilometer. All BTR-80s manufactured only in 1993 have a YaMZ-238M2 diesel engine instead of the KamAZ-7403. This engine produces 240 hp at the same engine speed. Very few vehicles have the YaMZ-238M2 engine as its use was only a temporary measure due to the burning down of the Kamaz engine plant in 1993.

When installed in the BTR-80, the engine is slightly tilted forward. This was mainly done to leave enough room for the water jet duct installed on the floor of the engine compartment.

The BTR-80 has a power-to-weight ratio of 19.1 hp/ton. The vehicle can cross a two meter-wide trench and scale a vertical obstacle with a height of 0.5 meters. The chassis has a generous 475mm of ground clearance, allowing the BTR-80 to drive right over tree stumps, rocks, and the like. The maximum speed on paved roads is 100 km/h, although drivers are never allowed to exceed 90 km/h during peacetime and the official top speed on paved roads is 80 km/h. The average cross-country speed is between 20 km/h to 40 km/h.

The air intakes for the engine are located on the hull roof, just in front of the engine access panel and behind the starboard and portside passenger roof hatchs. The inlet is covered by a dome to prevent accidental water intake from rain and from waves when the vehicle is swimming in a body of water. This design also inherently protects from flame attack. The drawing on the left below shows the air cleaner and air heater and how it connects to the air inlet. The photo on the right below shows the air supply tube leading from the air cleaner to the engine.

The cooling system of the BTR-80 has an open-type ventilation scheme, where the radiator is placed inside the engine compartment and the intake fan draws air through the radiator via the engine compartment itself. As such, any open port that leads to the engine compartment can serve as a radiator intake vent. The main intake is on the engine deck, directly atop the engine.

The radiator intakes have a distinct design, similar to the engine air intake. The intake is divided into three panels, each with two elongated slots. The slots have high walls, and are covered with caps. During normal operation, air entering the engine compartment flows in an S-shaped path: air flows under the rim of the cap, makes a turn and flows over the wall of the slot, and then makes another turn and flows down, into the engine compartment. When the engine compartment needs to be sealed, the cap on each slot can be closed so that the rim rests on the surface of the panel and the inner surface of the cap presses against the rubberized rim of the wall of the slot, forming a tight seal, as shown in section A-A in the diagram on the left below.

Upon entering the engine compartment, the air flows around the engine and towards the rear of the compartment, reaching the radiator. Air passes through it, entering the centrifugal fan, and is ejected from the compartment via an outlet vent on the rear portside corner of the engine compartment. The radiator and radiator fan are shown in the image below.

Exhaust fumes are collected from the exhaust manifolds on either side of the engine and routed to a pair of mufflers mounted externally on the rear corners of the hull. Each of the two mufflers are encased in a sheet steel shroud and covered from the front with a thin armoured shield. These also function as exhaust cooling shrouds, using the differential pressure of the hot, high-velocity exhaust gasses flowing to the rear to draw cool atmospheric air into the shroud from the front. The induced flow of atmospheric air by exhaust gasses is also used to as the mechanism for extracting dust collected in the filters of the engine air cleaners.

The BTR-80 carries fuel in two 150-liter fuel tanks at the very back of the hull, located on the flanks of the engine cooling system. The fuel tanks feature internal anti-slosh partitions. The fuel filler ports are next to the brake lights. With a full load of 300 liters of diesel, the maximum driving distance of the BTR-80 is 600 km on a paved road and between 223 km to 480 km on cross-country trips. The fuel tanks are installed on either side of the radiator.

The transmission is of a hydromechanical planetary type with five forward gears and one reverse gear. All eight wheels are powered, but only the two front pairs of wheels are steering wheels with lateral deflection control. The vehicle has a minimum external turning radius of about 13.2 meters. Besides supplying power to the wheels, the transmission also includes a power takeoff system for the self-recovery winch installed in the bow of the vehicle and another power takeoff system for the water jet propeller. Due to the need for a watertight hull for amphibious operations, the entire powertrain - excluding the axles - is installed on top of the floor of the monocoque armoured hull, and a false floor is placed on top so that the occupants of the vehicle do not walk on the exposed chassis. In effect, the BTR-80 has a double floor, albeit a thin one.