With contributions by Mike Ennamorato, including this introduction.

Although the T-80 is mostly remembered in the Western world for its lackluster performance during the invasion of Grozny, there was once a time when it was one of the most highly regarded assets in the vast Soviet tank fleet. In terms of technological novelty and sophistication, the T-80 was the top of the line and primarily distinguished itself from the T-64 and T-72 by having a gas turbine engine. Thus, by the end of the 1970's, the Soviet Army was the only army in the world to simultaneously operate three different main battle tanks with three different engines: an opposed piston diesel multifuel engine, a traditional V-shaped diesel multifuel engine, and a gas turbine multifuel engine.

As one should come to expect from anything on the other side of the Iron Curtain, the inception of the T-80 is rather intriguing story. While the Kharkov engineers were still ironing out issues with the 5TDF opposed-piston engine for the T-64, experiments on mounting a turboshaft engine were already in full swing. It was requested that production expand from just Kharkov (KMDB) to Kirov (LKZ) and Nizhny Tagil (UKBTM) as well. Both of the latter plants struggled to produce some of the more complex parts for the T-64 - namely the engine - due to a lack of personnel familiar with the intricacies of the fundamentally different engine, and hence, created their own variations of the basic T-64. UKBTM and LKZ split design elements and ended off designing what came to be known as the T-72 and T-80 respectively. LKZ's progeny were defined by their signature turbine engines and more robust suspension as well as a revised hull in order to accommodate the larger engine compartment and new suspension. The new hull was hybridized with the turret of the T-64A, thus forming the original model T-80. The early Object 219 sp.1 prototypes (of which few were produced) bore an even closer resemblance to the T-64A, as it was practically the same tank with the exception of the enlarged engine compartment and the different engine.

Upon entering service after extensive testing alongside its cousins the T-64A and T-72 in various climates, it was clear that this new vehicle was far more extravagant and expensive than the ones preceding it, making the T-80 much less common than its counterparts. It also came off as being a more ambitious project than T-72 (evidenced by a far longer development span). However, the final production model T-80 (Object 219 sp.2) came too late for its own good. The instant it entered low-rate production in 1976, it was already surpassed in capability by both the T-64B and T-72A: a troubling situation for a vehicle meant to replace and supplement them, made worse by its excessive price tag. As a result, the T-80B was quickly ushered into service a mere two years after the T-80, boasting the ability to fire ATGMs from the cannon while on the move with the Kobra system, and an updated armour layout that had better prospects against the latest and future anti-tank munitions. Beginning in 1980, a more powerful 1100 hp GTD-1000TF engine was installed in all new-production tanks. These upgrades along with the addition of Kontakt-1 explosive reactive armour and a further enhanced composite armour package formed the basis of the T-80BV, which arrived in 1985. The most advanced direct T-80 variant - the T-80U, arrived in 1986, and came with the revolutionary but flawed Kontakt-5 heavy reactive armour package. This new model presented improvements to just about everything; a new digital fire control system, engine, explosive reactive armour, and some other tidbits. Some late model T-80BV tanks had the T-80U turret installed but retained the familiar coat of Kontakt-1.

So without any further ado, let us dive deep into the intricacies of the T-80.

Table of Contents

- Commander's Station

- Gunner's Station

- T-80 Fire Control System

- T-80B Fire Control System

- T-80U Fire Control System

- Stabilizers

- 2E28M2 "Sireneviy"

- 2E42M1

- Autoloader

- Loose Stowage

- Cannon

- Missiles

- PKT Co-axial Machine Gun

- NSVT Anti-Aircraft Machine Gun

- Protection

- T-80

- T-80B

- T-80BV

- Kontakt-1

- Kontakt-5

- Smoke Screen

- Firefighting

- NBC Protection

- Driver's Station

- Transmission, Suspension

- Engines

- Water Obstacles

- Road Endurance

As of 23 February 2019, this article is still undergoing minor renovations. If there are any errors or inconsistencies, feel free to write them down in the comments section

The section on the armour protection of the T-80 and its variants - specifically the T-80U - can only be considered a rough guideline as of February 2019. It is still being renovated pending further research.

COMMANDER'S STATION

The commander is seated on the right hand side of the turret and enters through a relatively tight clamshell-shaped hatch. The hatch is sprung with a torsion spring to make it easier for the commander to open the heavy armoured hatch, and the hatch offers protection from bullets when locked in the open position. If the commander wants to fight outside the hatch or simply take in the his surroundings with his head out and a pair of binoculars, he is almost fully shielded from sniper fire from the front, and the hatch can be spun around along with the cupola to face any direction.

Just like with the T-64 before it, accommodations for the commander are relatively spartan but still objectively superior to the T-54 and T-62 medium tanks. The commander's seat is well padded and adjustable in height and legroom is not in short supply, but there are not many concessions for width below waist level. This is due to the layout of the MZ autoloader which stowed ammunition in a ring around the turret ring. This reduced the internal diameter of the crew compartment in the hull which was already not particularly wide. However, this is not necessarily a problem as the amount of room for the commander's upper body is more than adequate.

In summertime, the roominess of the commander's station is acceptable for the average Soviet tanker, but in winter, the commander's bulky clothing cuts down on the already modest volume of habitable space. Taller people will not find it perfectly habitable as there is plenty of headroom. For ventilation, there is a small DV-3 plastic fan mounted on a ball joint just in front of him. It is enough for European summers considering the international standards for tank ventilation of the time (there were none), but not the high heat of Northern Africa and the Middle East. Because the commander is seated inside the turret cabin, he is isolated from the hull where the NBC filtration and ventilation system is installed. As such, there is virtually no airflow inside the turret cabin besides the breeze from the DV-3 plastic fan.

Like with the T-72 and T-64, the commander of the T-80 is supplied with four general vision periscopes, but the designers managed to remedy the rearwards blind spot with the inclusion of a TPNT-1 rear view prism block embedded into the center of the hatch. It is useful for directing the driver while buttoned up. In non-combat situations, the commander could just open his hatch and peek out, of course. The TKN-3 observation device directly in front of the commander is supplemented by two TNPO-160 periscopes embedded in the fixed cupola roof pointing in the 10 o'clock and 2 o'clock sectors and another two TNPO-165 periscopes embedded into the hatch pointing in the 8 o'clock and 4 o'clock sectors, thus giving him a generous field of view around the turret. With the inclusion of the TNPT-1 rear view prism, the commander theoretically has a full 360-degree view around the turret from six observation devices. While not as comprehensive as many NATO tanks in terms of the number of observation devices, the cupola of the T-80 is rotatable, so the dead zones between the periscopes are easily eliminated by simply rotating the cupola. In broader terms, general vision periscopes are useful for directing the driver, checking the positions of the commander's platoon mates and getting a sense of the surrounding environment.

However, the commander's responsibilities are not limited to simply monitoring the situation outside. In case the autoloader malfunctions, the commander is also responsible for manually operating the autoloader carousel. The ammunition type indexer memory unit (YELLOW) performs the double function of an indicator unit with LEDs in it to show what type of ammunition is currently aligned with the elevator and ramming mechanism so that the commander knows when he has reached the desired ammo type -

- and the silver-gray object (RED) underneath it is the hydroelectric carousel rotation drive motor. If all electrical power is cut to the tank, rotating the carousel is achieved by working the hand crank attached to the side of the motor.

The commander also has a control dial to operate the autoloader in the semi-automatic loading mode where he can control the loading process step by step to use the remaining functional parts of the system in the event of an autoloader failure or troubleshoot issues with the autoloader. From this dial, the commander can hydrolock the cannon in the loading position, raise the ammunition cassette to the loading position, ram the ammunition into the cannon breech, return the ammunition cassette to the carousel, and return the cannon to the stabilized mode whereby it is ready to fire. The commander is provided with an ammunition type selection dial (BLUE) to allow him to select the type of ammunition that is to be loaded when operating the autoloader in the semi-automatic mode.

Besides all that, the commander is provided a control box (GREEN) to control the autoloader replenishing procedure. The autoloader replenishing procedure can be described as the normal loading procedure except run in reverse, and without the ramming step.

Besides having his general vision periscopes and controls, the commander also gets to play around with a multifunctional pseudo-binocular TKN-3M sight. This is his primary means of observation.

TKN-3M "Kristal"

The original T-80 from 1976 was equipped with the TKN-3M pseudo-binocular combined periscope, similar to the T-64 and T-72 before it. Pseudo-binocular meaning that although the device has two eyepieces, the two optic feeds are combined to one aperture, which the viewer sees out of. It has a fixed 5x magnification in the day channel with an angular field of view of 10°, and a fixed 3x magnification in the night channel with an angular field of view of 8°. The periscope can be manipulated up and down for elevation, and the commander's cupola must be manually spun for horizontal viewing.

By 1976, the TKN-3M was already somewhat obsolete. It featured target cuing and was very compact, but it wasn't stabilized, and featured only rudimentary rangefinding capabilities and its night vision capabilities were only borderline acceptable for 1976. Night vision came in two flavours; passive light intensification or active infrared. In the passive mode of operation, the TKN-3M intensifies ambient light to produce a more legible image. This mode is useful down to ambient lighting conditions of at least 0.005 lux, which would be equivalent to an overcast, moonless and starless night. In these conditions, the TKN-3M can be used to identify a tank-type target at a nominal maximum distance of 400 m due to the resolution limit, but as the amount of ambient light increases such as on starlit or moonlit nights, the distance at which a tank-sized target is discernible can be extended. In dark twilight hours, the TKN-3M may be able to make out the silhouette of a tank at a distance of up to 800 m or more, but the sight is hamstrung again, this time not by the absence of light, but by the low magnification. Any brighter than dawn or dusk, and the image will be oversaturated and unintelligible.

The active mode requires the use of the OU-3GA2 or OU-3GKU IR spotlight, which connects directly to the tank's 27V electrical system. With active infrared imaging, the commander can identify tank-type targets from a distance of around 400 m, or potentially more if the opposing side is also using IR spotlights. In that case, the TKN-3M can be set to the active mode but without turning on the IR spotlight. The switch for activating the spotlight is the right thumb button while the operating channel selector is on the TKN-3M itself. The problem with spotlights as a whole is that while the user can use them to spot for targets, the targets can use them to spot the user too, but from much further away. However, the OU-3 design is particularly flawed in this respect because it lacks an occluder. The lack of an occluder means that around half of the light from the spotlight is projected directly forward instead of into the parabolic reflector. As such, an enemy observer will not only see a circular patch of light. When observing a Soviet tank with its IR spotlight on, a large portion of the tank will be brightly illuminated. The additional illumination brings the minor benefit of lighting up the ground for the driver to see more clearly, so the common issue of speed control due to short visibility distance with the complementary IR periscope for the driver is slightly alleviated in battle conditions.

The maximum distance at which a tank-sized target can be identified in the active mode is stated to be 400 to 450 meters, although the spotlight can illuminate objects further away than that. The main issue is the low resolution of the image and the low magnification factor of the TKN-3M. The OU-3GA2 and OU-3GKU spotlights are not particularly powerful. Both use an incandescent lamp that consumes just 110 watts and the spotlights have an aperture diameter of only 215 mm. The only difference between the two spotlights is the shape of the hinges on which the spotlight lamp is mounted.

Without the infrared filter, the spotlight emits white light at 240 candelas. The infrared filter prevents all but approximately 0.001% of the light in the visible spectrum (360-760 nm) to pass through, and the light that passes through is at the higher end of the visible spectrum. As such, the spotlight emits a very faint red light with an intensity of around 0.24 candelas that can be perceived by the naked eye at close range when the OU-3 spotlight is activated in low light conditions. The intensity of near infrared light is much higher, of course. This light can be detected by the photosensor of a digital camera without an infrared blocking filter. The photosensor displays this infrared light - which is otherwise invisible - as pink light. This can be seen in the photos below, showing the OU-3 of a BRDM-2 (pictures from kmshik from the Gaz 69 forum).

When the OU-3 spotlight is used without the infrared filter, the TKN-3M can be used at night in the daylight mode possible and the viewing distance can be increased at the cost of exposing the exact location of the tank to everyone. This is permissible in certain circumstances, but it is not common.

Overall, the TKN-3M offers very poor night viewing capabilities compared to modern thermal imaging sights, but it was an improvement over the original TKN-3 model from 1964 due to the inclusion of image intensification technology, which was appropriately advanced for the time. However, by the late 1970's, the system was outstripped by more advanced Western passive image intensifying optics.

The OU-3GA2 spotlight is mounted coaxially to the TKN-3M periscope via a connecting rod, visible in the photo below to the left hand side of the spotlight. Due to the vertical offset in the mounting position of the spotlight, some parallax error is to be expected.

Rangefinding is accomplished through the use of a stadiametric scale sighted for a target with a height of 2.7 m, which is the average size of the average NATO tank. The TKN-3 is not stabilized, making it difficult to reliably identify enemy tanks or other vehicles at extended distances while the tank is travelling over rough terrain, let alone determine the range. The left thumb button initiated turret traverse for target cuing. The range of elevation of the periscope is +10° to -5°. Because the OU-3GA2 spotlight is directly mechanically linked to the periscope, the elevation angles remain the same when using the TKN-3M in the night vision mode.

Target designation is done by placing the crosshair reticle in the periscope's viewfinder over the intended target and pressing the cue button. The system relies on the use of a single direction sensor installed on the cupola ring, so the system can only account for the cupola's orientation and not the elevation of the TKN-3M, so the cannon will not elevate to meet the target. This was not a serious issue because the gunner should be able to see the target quite easily from his sight once the turret has slewed on target.

|

| TKN-3 viewfinder |

PNK-4S Universal Sighting Complex

For the Soviet optronics industry at the time, the PNK-4S was only a small technical innovation, but the device placed the T-80 on the same level as the best NATO tank at the time, namely the Leopard 2 with its revolutionary PERI-R17 independent panoramic sight. Like the PERI, the PNK-4S complex combines the functionality of an auxiliary gunnery complex with that of a comprehensive surveillance unit, giving the commander full authority with regards to the fire control system including the ability to directly override the gunner, which can be useful in some situations, such as to immediately engage a standout threat at the very instant it is spotted. All this is done with a simple thumbstick on the control module located to the right of the TKN-4S pseudo-binocular surveillance device around which the PNK-4S system revolves.

The decision to use a thumbstick was probably because a full joystick could not be easily manipulated with precision while the operator's body and arm was rocking around if the tank were going over rough terrain, while the thumb would be completely stationary if the hand was securely gripping the handgrip. The index finger rests on the trigger button at the back of the handgrip.

The PNK-4 system is a part of the 1A45 fire control system, as it connects directly to the tank's ballistic computer and fully duplicates the control scheme of the gunner. It can also be used independently from the fire control system in case of an emergency as explained further in the TKN-4S section. When used in the gunnery mode, the PNK-4 module is locked facing forwards. Horizontal cupola rotation control then becomes horizontal turret control, and vertical sight movement then becomes gun elevation. Independent vertical stabilization is still present, so that the sight does not elevate when the gun does to load.

The control module has all the necessary controls for the use of the main gun, including ammunition selection vis-à-vis the autoloader. Late T-80U variants with a remotely controlled anti-aircraft on the cupola would also make use of this control module for aiming and firing. With all this and the TKN-4S sighting complex, the T-80U could boast of having one of the most sophisticated hunter-killer systems in the world at the time.

The foremost improvement of the TKN-4S over the TKN-3M is the addition of an independent stabilizer with its own gyroscopic sensor and compensator motor, visible on the left side of the main periscope housing as the large bulging module. The stabilizer is designated as the 1ETs29-4s. The stabilization accuracy on the vertical plane is at least 0.30 mils, while the stabilization accuracy on the horizontal plane is much lower at 0.88 mils, because of the much greater burden of the cupola compared to the mirror in the sight aperture. This means that the maximum deviation from the original point of aim is 0.30 m vertically and 0.88 m horizontally at a distance of 1000 m. The sight can maintain this level of performance while the cupola is rotating at speeds of up to 35 degrees per second. The vertical range of elevation is quite reasonable, spanning from -10° to +20°, granting the commander an uninterrupted line of sight on any given target while the tank is on the move over terrain of any degree of impassibility (within reason).

The PNK-4 system is a part of the 1A45 fire control system, as it connects directly to the tank's ballistic computer and fully duplicates the control scheme of the gunner. It can also be used independently from the fire control system in case of an emergency as explained further in the TKN-4S section. When used in the gunnery mode, the PNK-4 module is locked facing forwards. Horizontal cupola rotation control then becomes horizontal turret control, and vertical sight movement then becomes gun elevation. Independent vertical stabilization is still present, so that the sight does not elevate when the gun does to load.

The control module has all the necessary controls for the use of the main gun, including ammunition selection vis-à-vis the autoloader. Late T-80U variants with a remotely controlled anti-aircraft on the cupola would also make use of this control module for aiming and firing. With all this and the TKN-4S sighting complex, the T-80U could boast of having one of the most sophisticated hunter-killer systems in the world at the time.

TKN-4S

The foremost improvement of the TKN-4S over the TKN-3M is the addition of an independent stabilizer with its own gyroscopic sensor and compensator motor, visible on the left side of the main periscope housing as the large bulging module. The stabilizer is designated as the 1ETs29-4s. The stabilization accuracy on the vertical plane is at least 0.30 mils, while the stabilization accuracy on the horizontal plane is much lower at 0.88 mils, because of the much greater burden of the cupola compared to the mirror in the sight aperture. This means that the maximum deviation from the original point of aim is 0.30 m vertically and 0.88 m horizontally at a distance of 1000 m. The sight can maintain this level of performance while the cupola is rotating at speeds of up to 35 degrees per second. The vertical range of elevation is quite reasonable, spanning from -10° to +20°, granting the commander an uninterrupted line of sight on any given target while the tank is on the move over terrain of any degree of impassibility (within reason).

Another major improvement over the TKN-3M came in the form of a higher maximum magnification factor of 7.6x in the day channel in the high magnification setting, along with the option to switch to a low magnification setting of 1.0x. The night channel has a fixed 5.2x magnification. The principal advantage of the increased magnification in daytime is that it enables the commander to see and designate targets at ranges suitable only for missiles and beyond what was determined to be the maximum effectiveness threshold for ballistic munitions. The field of view under x1 magnification is 47° for the day channel and 7° under maximum magnification, or 7°40' under maximum magnification in the night channel, owing to the relatively low effective viewing distance at night. The night vision module uses newer third generation light intensification technology; better than what the old TKN-3MK had, but still not competitive against first-gen thermal imagers. Like the TKN-3, the TKN-4S can operate under active IR imaging or passive light intensification. In the latter case, the TKN-4S facilitates the identification of a tank-type target at a distance of at least 700 meters under ambient lighting conditions no brighter than 0.003 lux. This is a major improvement over the TKN-3MK, which only allowed the user to identify a tank type target at 400 meters under 0.005 lux of ambient light. The viewing distance for the TKN-4S can be improved by the presence of moonlight, which can increase the viewing distance by several hundred meters.

Another major improvement over the TKN-3M came in the form of a higher maximum magnification factor of 7.6x in the day channel in the high magnification setting, along with the option to switch to a low magnification setting of 1.0x. The night channel has a fixed 5.2x magnification. The principal advantage of the increased magnification in daytime is that it enables the commander to see and designate targets at ranges suitable only for missiles and beyond what was determined to be the maximum effectiveness threshold for ballistic munitions. The field of view under x1 magnification is 47° for the day channel and 7° under maximum magnification, or 7°40' under maximum magnification in the night channel, owing to the relatively low effective viewing distance at night. The night vision module uses newer third generation light intensification technology; better than what the old TKN-3MK had, but still not competitive against first-gen thermal imagers. Like the TKN-3, the TKN-4S can operate under active IR imaging or passive light intensification. In the latter case, the TKN-4S facilitates the identification of a tank-type target at a distance of at least 700 meters under ambient lighting conditions no brighter than 0.003 lux. This is a major improvement over the TKN-3MK, which only allowed the user to identify a tank type target at 400 meters under 0.005 lux of ambient light. The viewing distance for the TKN-4S can be improved by the presence of moonlight, which can increase the viewing distance by several hundred meters.Because the TKN-4S is designed to use the same OU-3GA2 spotlight as the TKN-3, the active mode option does not present any improvements, only just enabling the commander to identify a tank-type target at a distance of 800 m. This is a significant improvement, but still vastly inferior in general effectiveness compare to 1st Gen thermal imaging systems.

The difference between the active and passive modes of operation is that in the active mode, the maximum practical viewing distance changes minimally across a wide range of ambient lighting conditions and weather conditions. Passive light intensification is more sensitive in this respect. If not for mortar and artillery-delivered IR illumination flares which could be aimed and shot over enemy positions, active infrared imaging would be completely obsolete. In such a scenario, however, the IR spotlight is rendered totally redundant.

In hindsight, it is quite clear that pursuing light intensification technology instead of investing in prospective thermal imaging technology was a huge mistake, one that ended up setting back the Soviet Union by nearly a decade in this particular field. Up until quite recently, modern day Russia had still been playing catch-up with Western tanks by assimilating French sighting technology through technological cooperation. However, that doesn't change the fact that the TKN-4S still had a fairly modern nightvision feature, when the day-only PERI-R17 didn't. All in all, the TKN-4S was arguably one of the most advanced and most versatile device of its type available to any modern tank in the world, until that title was usurped after the fall of the USSR when the new CITV was introduced on the M1A2 Abrams in 1992 along with the new PERI-R17A2 in 1998. Both had thermal imaging technology, and were generally better in every possible way.

Unlike the TKN-3, which had only a simple lead measuring scale and a stadia rangefinder scale, the TKN-4S has markings for all ammunition types and all the necessary range and lead scales, plus the stadiametric rangefinder. Because the PNK-4 system lacks a ballistic computer and laser rangefinder, the targeting procedure is devolved into manual mode. The commander must manually find the range to the target using the stadia scale, of which there are two. The one on top is for a target 2.5 meters in height, for a modern tank-type target like the Leopard 2 and Abrams, which are shorter than their predecessors. The one below it is for a target 2.0 meters in height, for APC-type targets like the M113.

Besides all that, the TKN-4S has a handy 1x periscope installed just under the rubber forehead pad for wider forward vision, supplementing the two TNPO-160 periscopes flanking the device. It's not much, but it does grant the commander an almost totally uninterrupted field of vision around the frontal 180-degree arc of the cupola.

Strangely enough, the PKN-4 complex does not include a laser rangefinder, despite the availability of quite compact models already in the late 70's. To determine the distance to a tank-type target, the commander must still rely on a stadiametric ranging scale similar to the type found on the TKN-3, although the precision of the operation may have increased marginally thanks to the higher magnification factor. Still, this isn't that big of a problem, because the gunner can quickly and painlessly conduct ranging himself anyway, and the gunner should be putting more time in observing the target than the commander anyway, who is supposed to be spending his time looking for other things to shoot at.

GUNNER'S STATION

The original T-80 turret was essentially identical in form and in function to the one from the T-64A, the T-80 itself being a derivative of it. Just like the turret of the T-64A, the gunner in the T-80 was provided with nothing but a single front-facing periscope for general vision. Later on, both the T-80B and T-80U turrets gave the gunner's station two TNPO-165 general vision periscopes facing forward and one TNPO-160 periscope aimed to the left, giving the gunner a good view of his surroundings in addition to helping to improve the lighting condition of his station, which is pretty neat as well.

Keep in mind that in most NATO tanks, the gunner is not provided with any general vision devices at all, but inversely, the station in the T-80 is slightly more cramped and amenities are few are far in between. Wider tankers will find it very difficult fitting into the station due to the narrow hatch, but lankier people will find the tank more accommodating, especially since there is plenty of room to stretch his legs. If the gunner is short and slim, all the better.

Besides the controls for gunnery related things, the gunner also has access to a multitude of toggle switches for a variety of things around his station. Among them are switches for the ventilation system (just below his hatch), switches for the dome light, switches for the intercom system, and others.

The new and more spacious turret of the T-80U also enabled the crew to carry a small number of additional cartridges. It certainly was not the most reassuring design feature, but more importantly, the ammunition somewhat reduced the available space, so removing them was quite normal.

Fire Control

Being the best tank in the Soviet Union meant a few things. One of them was having the best optics and compact computer technology money could buy. One of the few interesting and unique traits of Soviet-style sighting complexes was the control handles. Instead of a thumbstick like on the Chieftain or a pair "steering wheel" style hand grips where turret slewing was done by turning the handles like, well, a steering wheel (z-axis), spinning the turret was done by rotating the grips on the y-axis. The hand grips have two buttons each. The left trigger button is for firing the coaxial machine gun and the left thumb button is resetting the laser rangefinder. The right trigger button is for firing the main cannon, and the right thumb button is for firing off the laser rangefinder.

T-80 obr. 1976

TPD-2-49

The earliest T-80s were essentially modified T-64As, and as such, they had a great many things in common. Among these commonalities was the use of the TPD-2-49 optical coincidence rangefinder.

By 1976 standards, the TPD-2-49 was already incredibly outdated. It was first used on the original T-64 introduced in 1966, but since then, the TPD-K1 laser rangefinding sight had been invented and was already in use on the T-64B and T-72A, both introduced in 1976.

The optic aperture is split into two halves, top and bottom. The two input lenses see different parts of the same target, and the gunner must use the adjustment dial near his hand grips to line up both halves and obtain a seamless picture.

This process was cumbersome and somewhat inaccurate - the error margin was 3 to 5%, which meant that the range could be off by up to a shocking ±200m at 4000m, or a much less serious ±30m at 1000m range. However, it's worth considering that the average tank engagement distance expected in Europe was estimated to be 1500m, relieving the TPD-2-49 somewhat. Plus, the use of hypersonic APFSDS ammunition meant that the error margin could usually be ignored since the ballistic trajectory was so flat that amount of drop was completely negligible at out to 1500m or more. The problem was much more pronounced with HEAT and HE-Frag ammunition, which were heavier, had a worse ballistic coefficient and traveled at much lower velocities. With the advent of long range ATGM systems mounted on jeeps, scout cars, IFVs and even light tanks, accurate long-distance fire with HEAT and HE-Frag shells was imperative.

One downside of optical coincidence rangefinders is that they tend to have reduced accuracy on camouflaged targets. Tanks or other targets concealed with camouflage netting and bushes can be difficult to accurately range because the outlines of the tank may not be very clear to the gunner, and determining the silhouette through other visual cues is time consuming, not to mention that it requires at least a fairly experienced gunner. Other methods of breaking up the silhouette of the tank can be effective. As such, the T-64A turret and fire control system could be considered practically obsolete by the time it was integrated as part of the T-80, so only a few hundred of the original 1976 production variant were ever manufactured and some were subsequently brought back up to current technological standards with the retrofitting of the TPD-K1 sight during the early 1980's.

TPN-1-49-23

The TPN-1-49-23 was the gunner's night vision sight for the original T-80, but it was relatively short-lived and it was replaced soon after by the more advanced TPN-3-49. The TPN-1-49-23 can either use ambient light intensification or use infrared light conversion and intensification by relying on the L-4A "Luna-2" IR spotlight for illumination. The Luna-2 spotlight is mounted coaxially to the main gun. Unlike the commander's OU-3GA2 or OU-3GKU spotlight, the L-4A spotlight uses a xenon arc lamp with an IR filter instead of an incandescent lamp. It draws power from the tank's 27V electrical system and consumes 600 W of power. Removing the IR filter transforms the IR spotlight into a regular white light spotlight, but this can only be done in a non-combat situation.

Take a look at this video here to see the L-4A spotlight in action.

The L-4A spotlight has an aperture diameter of 305 mm, smaller than the spotlights for the M60A1 and the Chieftain. The Chieftain's spotlight, for instance, has an aperture diameter of a staggering 570 mm, and consumes 2 kW of power. This is admittedly quite beneficial for searching for targets, because although the beam itself is only about 570 mm in diameter, dust, water vapor and smoke in the air help dissipate the light and increases ambient light levels, and illuminating a reflective object such as the ground will generate a bigger lit up spot. But despite the huge size and power of the spotlight, the nightsight on the Chieftain has an identification distance of just 1000 m. Despite using a much, much less powerful spotlight, the performance of the TPN-1-43-29 is quite close, with the ability to identify tank-type targets at around 800 m. The passive setting allows the same target to be spotted at ranges of up to 800 m if the ambient light is no less than 0.005 lux, which is the typical brightness of a moonless, starlit night with clear skies. Clarity and spotting distance improves with increasing brightness. The identification distance is expanded to around 1,000m on moonlit nights, and it is possible to spot tanks at distances of more than 1,300 m during dark twilight hours, although low magnification and mediocre resolution complicates viewing beyond that range. This level of performance is on par with the best Western equivalents of the mid to late 60's, but for 1976, the TPN-1-49-23 was simply no longer competitive. It did, however, have light intensification technology, which tanks like the M60 did not have until 1977.

If used as a backup sight, it can be used to identify tank-type targets at up to 3,000m in daylight or more, if the geography and weather permits it. It has a field of view of 6 degrees at 5.5x maximum magnification. Variable zoom allows reduction of magnification to 1x to give the gunner much better general visibility for spotting targets.

The sight has dependent stabilization in the vertical plane with 20 degrees of elevation and 5 degrees of depression. Dependent stabilization means that the sight is technically stabilized, but it piggybacks on the vertical stabilizer for the cannon. Since the cannon has to elevate by +3 degrees for the loading cycle, the gunner will usually lose sight of his target immediately after firing, so he will be unable to observe the "splash" so that he knows how much elevation correction he needs to apply. The commander can see, of course, but that's not a very convenient way of doing things.

Though the cover can be removed and the sight used during daytime, the light intensification channel must never be activated, because excessive light input will overload the sight unit and possibly damage it. In accordance with this, the aperture has shutters linked to the trigger unit. Upon firing, the shutters automatically close to shield the unit from the intense flash of cannon fire at night. These shutter may also be manually opened and closed via a handle.

TPN-3-49

Complementing the primary sighting complex from the original T-80 all the way to the T-80U is the obligatory nightvision sighting system, which also functions as the backup sight in the event of the destruction of the main sighting unit.

There are three selectable reticle settings for the viewfinder, one for each ammunition type; APFSDS, HEAT, and HEF. Each reticle different ranging scales for the gunner to input range data onto. Gunnery is reduced to its most basic level when using the TPN-3-49. Determining the range to the target is done by comparing the size of its profile with the size of the chevron, which is a rudimentary and rather imprecise method of rangefinding that is still implemented in the most modern sighting systems as a fallback option for when everything else fails. Unfortunately, this is the only way for the gunner to conduct rangefinding. However, it was determined that since the viewing distance was so short, it didn't really matter anyway.

The sight is not connected with the 1V517 ballistic computer. Laying the gun onto the target is done by lining up an adjustable horizontal line to an appropriate graduation on the range scale, which also moves the chevron up and down. So for instance, if a tank-type target is located 900 m away, the gunner places the horizontal line between the "8" mark and the long mark, which drops the chevron slightly. By using the handgrips to lay the dropped chevron up and back on target, the cannon is given proper supraelevation and a ballistic solution is formed.

The maximum identification distance of a tank-type target is 1,300 meters in the active channel, and 850 meters in the passive channel under lighting conditions no brighter than 0.003 lux. This figure will increase as ambient light gets brighter, but an important point to take is that the amount of ambient light needed to achieve the 850 m identification distance - 0.003 lux - is lower than the 0.005 lux standard by which the performance of the TKN-3 is measured by. This essentially means that on the same night, the gunner will be able to see about a half kilometer further than the commander. Although the TPN-3-49 appears to be less capable than the gunner's IR sight on the British Chieftain with its 1000-meter nominal identification range, it's worth noting that that system uses a 2 kW spotlight that has a diameter of around 570 mm.

In accordance with its function as a night sight, TPN-3-49 features an automatic internal shutter that blocks off the light intensifier device via an electric signal from the trigger on the gunner's handgrips. This is to protect it from burning out from the flash of the cannon firing, as the device is extremely sensitive and a bright flash of light so close to the sight will generate a sudden spike in voltage large enough to fry the vacuum tubes. Of course, the image produced may also be bright enough to cause eye damage to the gunner. The light amplification channel must never be activated during daytime, because daylight is already bright enough to permanently damage the sight.

The armoured housing for the sight head of the TPN-3-49 can be distinguished by its small and squarish front profile, and the small bolt at each corner of the armoured cover. It is taller than the housing for the TPN-1-49-23.

T-80B (1978)

1A33 Fire Control System

1G42 Sight

The T-80B was equipped with the more advanced 1A33 fire control system featuring the 1G42 primary sight with the associated fire control sensors and computers together with the Kobra missile system. The 1G42 sight has an accelerometer and an independent gyroscopic sensor enforcing an independent 2-axis stabilization system. Supplementing all that is the 1V517 digital ballistic computer, the 1B11 crosswind sensor and the 1B14 ambient temperature sensor. Atmospheric data from the sensors is fed to the ballistic computer together with range data to form a firing solution. The system also includes a Delta-D sensor which records the distance traveled by the tank after the lasing of a target. This allows the tank to accurately engage a target without re-lasing it even if the tank has approached or receded from the target.

Unlike the rather outdated 1A40-1 fire control system used in the T-72B, the 1G43 features fully automatic lead calculation and automatic gun superelevation. What this means is that the aiming chevron at the center of the sight picture remains static as the FCS adjusts the elevation to account for ballistic drop and adjusts the orientation of the turret to account for lead. The sight is not displaced sideways as the gun is adjusted for lead, thanks to the 2-axis stabilizer in the 1G42 - the horizontal stabilizer rotates the sight aperture to compensate for the shifted orientation of the turret, thus allowing the gunner to maintain an unchanged view of the target.

The diagram below shows the markings and indicators in the sight picture. The digital readouts at the bottom of the sight picture show the type of ammunition currently loaded and the distance to the target. Beside the digital readouts are two LED light bulbs. The one on the left lights up to indicate that the cannon is ready to fire, and the one on the right lights up when the commander designates a target.

Besides the digital component of the targeting system, there is a range scale at the top meant for manual gunlaying in an emergency. It works just like in earlier gunsights like the TSh2B-32 for the T-54; the gunner turns a dial and the range scales move up and down while the horizontal line running across it stays fixed. The only difference between the old TSh2B-32 and the 1G42 is the range scale for APFSDS ammunition - marked "Б" in the diagram above - is not vertical, but split into a diagonal line instead. This is because the ballistic drop of 125mm APFSDS is too small to be represented on a vertical range scale - the scale would appear as a solid black bar with indiscernible markings and range values.

The horizontal sliding line lying on the vertical range line (labeled as "Шкала Боковых Поправок") moves up and down together with the range scale as the dial is turned. When the dial is turned for a farther distance, the sliding line slides down, and vice versa. The intersection point between the horizontal and vertical line forms the crosshair when firing in manual mode.

The crosswind sensor is shown in the photos below. It uses a rather old-fashioned windmill-type anemometer to measure windspeed and not a digital hot wire anemometer in later designs with a meteorological mast. Since the 1B11 anemometer can only be affected by crosswinds, the device cannot measure headwinds and tailwinds. It device is heated to prevent failure by icing and to enable windspeed measurements in low temperature environments.

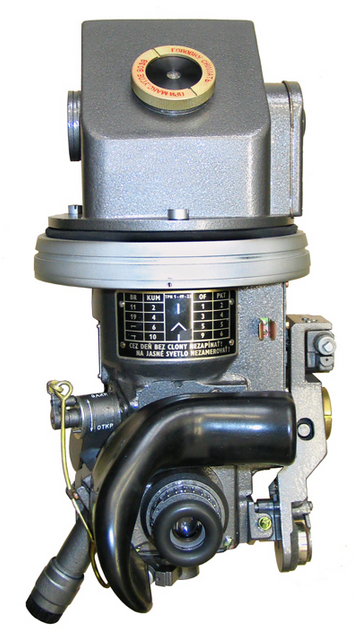

GTN-12

The Kobra gun-launched guided missile is guided to its target via a radio command link, and the radio signal is transmitted by the GTN-12 antenna unit located directly in front of the commander's cupola. The transmitter is linked to the sighting system using the 9S416-1 control system, which translates the shifting of the point of aim in the 1G42 sight to generate a command signal for the missile, thus forming a SACLOS guidance regime.

The infrared bulb at the tail of the 9K112 missile is detected and tracked by the 1G42 sight. Due to the use of radio guidance, it is possible to jam the 9K112 missile during its flight. However, it does not appear that such equipment was developed or fielded by the expected enemy so this appears to be a very minor drawback.

T-80U

1A45 Fire Control System

1G46 Sight

The 1G46 sight is rather large and bulky, weighing in at 115 kg. The sight has independent two-plane stabilization with a range of elevation of -15 to +20 degrees, and a range of traverse of 8 degrees to either side. According to Ukroboronexport, the minimum laying speed in both axes is 0.05 degrees per second, which equates to the ability to lay the chevron with a maximum error of 0.88 meters at a distance of 1,000 meters in both the vertical and horizontal planes. The sight has two magnification settings to choose from: 2.7x or 12x.

The layout of the sight is almost exactly the same as the 1G42. The only differences are in the shape of the stadia rangefinder, the size of the horizontal sliding line for manual aim, and the shape of the digital readouts and the indicator lights at the bottom of the sight picture. A photo of the reticle can be seen below (credit to Stefan Kotsch).

The 1G46 sighting complex also comes with a liquid cooled laser beam encoding and transmitting unit attached to the right hand side, unlike the T-72B, which used its 1K13-49 auxiliary sight for this purpose. This probably explains the heavier weight of 1G46 compared to other Soviet sighting complexes. The missile control unit is pictured below.

T01-P02-01 "Agava-2"

The revelation that new Western developments in thermal imaging technology was producing compact thermal imaging sights that were rapidly outstripping the capabilities of light intensifying night vision sights resulted in new research on creating analogous devices to up the ante. Thermal imaging was not an unknown scientific field for the Soviet military industry during the 1980's as prototype imaging systems for tanks had already been developed by the early 80's and installed on a small number of T-80 tanks on a trials basis. Working prototypes were already available for testing purposes by the early 80's, but problems with establishing mass production held up the development of thermal sights in the Soviet Union for a long time. In this sense, Soviet tank technology was behind the West by almost a decade, in both technological achievement as well as industrial know-how.

Only the command variant models of the T-80U, the T-80UK, had the Agava-2 installed due to their prohibitively high cost. The widespread introduction of this technology was not only a manufacturing challenge, but it would have bloated the already incredibly high price of the T-80 tank series. Due to the lack of widespread service compared to the basic T-80U, it was not common to find T-80UK tanks during the 1990's, but still, the Agava-2 had a few interesting quirks that are worth investigating.

Instead of an optical eyepiece or a "fishbowl" lens like the type found on the Abrams, the viewfinder on the Agava-2 was a 384x288p CRT monitor screen similar what the PZB-200 used. The sight itself is only capable of limited optical zoom, from 1.8x to 4.5x. To attain a greater degree of magnification, electronic interpolation (digital enhancement) is used to generate 18x zoom.

|

| (Not actual resolution of viewfinder screen) |

Under the highest magnification setting, the sight facilitates the identification of a tank-type target at a distance of around 2500 m under clear weather conditions. While the sight itself may be more than serviceable enough at combat distances, the low resolution and small size of the monitor makes it difficult to distinguish targets from one another at longer distances.

The commander is also provided with a 4.33" CRT monitor which feeds from the Agava-2, giving the commander a duplicate image of what the gunner is seeing.

The armoured housing that protects the sight aperture can be distinguished from the one for the TPN-3-49 by a hinge on the left of the armoured window cover. The window can be opened from within the tank via a simple pullstring, as you can see below. This particular T-80 is an experimental T-80B equipped with the Agava-2. The armoured housing is identical between all models.

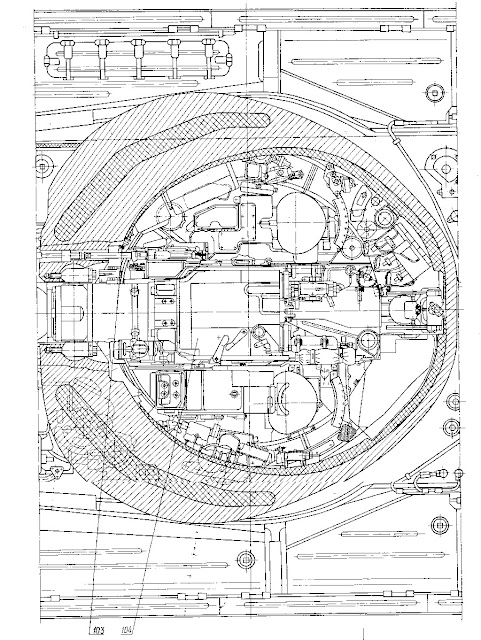

STABILIZERS

By 1976, it would have been unimaginable to not include full two-axis weapons stabilization as a prerequisite for the T-80. Being a developmental offshoot of the T-64A, the original T-80 came with the same two-axis stabilizer system. The layout of the stabilizer components remained the same as the T-64A, which was also true when the 2E42 was introduced, as shown in the drawing below.

2E28M, 2E28M2

The 2E28M two axis stabilizer is used in the original model T-80 being the newest stabilizer at the time of its development, while the 2E28M2 was used for modernized T-80 models with the TPD-K1. The stabilization system is precise enough to guarantee hits on tank-sized targets at distances of up to 1.6 kilometers while the tank is travelling cross country, as indicated by Soviet tank gunnery exercise norms.

The hydroelectric generator for the hydraulic gun elevation mechanism is pictured below.

The maximum turret rotation speed is 18° per second. It would take it a minimum of 20 seconds to do a complete 360° revolution. An inherent shortcoming of hydraulic stabilizers is their risk factor in case of turret penetration. Hydraulic fluid is highly flammable, and it would most likely cause and spread an internal fire very quickly. This is an especially serious concern to the T-80, since the layout of its autoloader does not shelter the ammunition from burning fluids. 2E38M2 uses MGE-10A, a type of mineral hydraulic oil with very low temperature sensitivity, having an operating range of between -65°C to 75°C. The entire system operates at 7.25 psi. This is quite dangerous, as with all hydraulic systems, because hydraulic oil may spurt out from burst tubes at high speeds, spraying large portions of the interior with the flammable liquid.

The entire stabilization complex is centered around the use of a gyrostabilizer meant for measuring angular velocities in order to enforce corrections. The weight of the sum of all the components is 320 kg.

Vertical Stabilizer:

Maximum elevating speed: 3.5° per second

Minimum elevating speed: 0.05° per second

Horizontal Stabilizer:

Maximum turret slew speed: 18° per second

Minimum turret slew speed: 0.07° per second

The hydraulic fluid reservoir for both the 2E28 is mounted to the roof of the turret, just adjacent to the commander's head. It has a clear window with replenishing indicators. Maintaining the stabilizer and its associated subsystems is the gunner's responsibility.

2E42M1

The components shown in the photo above are the amplidyne generator for the turret traverse motor, the hydraulic arm for the vertical stabilizer with its attached hydraulic pump, and the turret traverse motor itself, from left to right.

The photo below shows all of the components for the turret rotation mechanism. From left to right: Amplidyne generator, relay control box (to control rate of rotation), and the electric motor for turret traverse.

The 2E42M1 combines a hydroelectric turret rotation and stabilization drive with a hydroelectric cannon elevation and stabilization drive.

The hydroelectric pump for powering the cannon elevation system is located under the cannon's breech, and the hydroelectric pump for turret traverse is installed in front of the gunner, behind his sight unit.

| Amplidyne generator for 2E42M1 visible in the upper left corner of the photo |

Besides being more precise than the 2E28M-2, the horizontal stabilizer motor is also more powerful, giving the turret on the T-80U a quicker rate of rotation.

Vertical Stabilizer:

Maximum elevating speed: 3.5° per second

Minimum elevating speed: 0.05° per second

Horizontal Stabilizer:

Maximum turret slew speed: 24° per second

Minimum turret slew speed: 0.054° per second

The sum total of the components belonging to the stabilization system weighs 320 kg.

AUTOLOADER

Being a direct offshoot off of the T-64 family, the T-80 inherited its autoloader directly from its parent design. The official designation of the autoloader is the MZ ("Механизмом Заряжания") which directly translates to "Loading Mechanism", identical to the T-64A, but an updated version with new radio-guided gun-launched missile compatibility rapidly supplanted the original variant when the T-80B entered service shortly after the original T-80. Another updated version with an improved electronic system was used in the T-80U. In all of its variations, the MZ autoloader is of a hydroelectric type, utilizing hydraulic actuators to drive almost all of its moving parts. Between it and the AZ autoloader used on the T-72 series of tanks, it is quicker to load and has a considerably larger capacity, but it also has its own peculiarities and drawbacks. As usual, the gun needs to be lifted to a fixed angle to line it up properly for the loading mechanism to ram fresh rounds into the chamber, and this is done by the hydraulic vertical stabilizer piston of the cannon. To hold it in place, the gun is hydrolocked.

The autoloader carousel rotation mechanism is hydraulic, as is the lifting arm that brings the ammunition cassettes up to the ramming position behind the gun breech. The hydraulic lifting arm for the ammunition cassettes is located on the false floor of the turret crew cabin, as you can see in the photo below. A total of 2.2 liters of MGE-10A hydraulic fluid is used in the autoloader.

The ammunition cassette lifting arm can be seen in action in this video of the autoloader of the T-64.

Both the gunner and commander are provided with controls to the autoloader. The gunner's autoloader controls can be seen below. Photo credit to "coast70" from the QIP.ru photo sharing platform. The dial on the left allows him to select his desired ammunition type, and the big black button on top initiates the loading sequence. The white display panel on the right indicates the status of the autoloader.

The two-part cartridges are stowed in an 'L' position in the autoloader carousel, thus forming a basket around the turret ring. The basket carousel is mounted directly to the turret ring and moves with the turret, but it rotates independently of the turret when cycling for new ammunition. The turret ring of all T-80 turrets are designed with two ball bearing race rings: one between the turret and the hull and one between the turret and the autoloader carousel. This can be seen in the drawings below.

The autoloader carousel rotates at a rate of 26 degrees per second, and some additional fractions of a second are needed for the system to brake when the desired ammunition type is reached. When loading ammunition into the autoloader, the ammunition type is indexed by setting the appropriate type in the autoloader loading control box located next to the commander. Turning the carousel by one step takes up 12-15% of the total loading time, and turning it by three steps takes up 17-22%

The propellant charges are held vertically and the projectiles are held horizontally. This arrangement exposes the vulnerable propellant charges vertically, and without any armour protection to speak of (the aluminium cassettes are too thin), this layout increases the probability of ammo deflagration in the event that the armour of the tank is perforated from the front, sides and rear. The propellant charges are the most volatile half of the two-part ammunition, and storing them in such close proximity to the turret ring area of the tank where the majority of shots land would not bode well for the tank if the armour was perforated. Indeed, the thought of being surrounded by a ring of volatile propellant is hardly comforting for the crew in the turret. However, the layout of the autoloader carousel also allows the maximum possible quantity of ammunition to be stored within the geometric constraints of the turret ring diameter. The layout of the autoloader also gives the crew slightly more vertical space compared to the AZ autoloader of the T-72.

The cartridge cassette is composed of two lightweight aluminium trays connected by a hinge.

The second half of the cassette is raised by the hydraulic elevator mechanism acting upon an angled lug in front of its hinge point. The same elevator supplies most of the force propelling the cassette upwards, and it also helps support the weight of the cassette when it is unfurled. The first half of the cassette has an eccentric mounting point for the system of levers of the alignment mechanism to act upon.

As you can see in the GIF above, the two halves of the cassette split apart and release the cartridge from its bonds just a moment before the ramming cycle begins.

One drawback of the MZ autoloader is that it takes up some horizontal space because the ring of ammunition is installed within the diameter of the turret ring so the crew stations are narrower than the turret ring diameter would suggest. According to factory drawings of the T-64 (Object 432), the diameter of the crew cabin in the turret is 1590mm, although it may be worth noting that the Object 432 is armed with a 115mm D-68 gun and not a 125mm D-81 gun, and that the autoloader carousel holds 30 rounds of the slightly more compact 115mm cartridges instead of 28 rounds of 125mm cartridges. However, the difference is very small. The internal diameter of the turret crew cabin is less than the width of the hull and much less than the tank's turret ring which is 2,162mm in diameter. The photo below shows how the autoloader carousel occupies a significant amount of space and reduces the internal diameter of the crew compartment. The backrest visible in the lower half of the photo is the gunner's seat, and the gun is to the right.

One of the distinguishing features of the MZ autoloader is its ammunition capacity - it holds a remarkable 28 rounds of ammo, more than the 22 rounds carried on the T-72, more than the 22 rounds in the ready racks in the bustle of an M1 Abrams (105mm), much more than the 17 or 16 rounds in the M1A1 Abrams (120mm), and nearly double that of the 15 rounds on the Leopard 2. The average loading speed of the MZ autoloader is easily on par with an average human loaders, and even outpaces the AZ autoloader of the T-72 by around one second under ideal circumstances. According to a T-80 technical manual, the combat rate of fire is 7-8 rounds per minute. This is corroborated by the T-64A and T-64B/B1 manuals, which give a combat rate of fire of 8 rounds per minute from the same autoloader and the same fire control system. However, the autoloader itself is capable of loading a round and returning the gun to aim on a target of the gunner's choosing in only 6 seconds if the gunner chooses not to change ammunition types, so the maximum technical rate of fire is actually 10 rounds per minute. A translated cyclogram of the steps in the loading cycle is presented below:

This cyclogram comes from the document "Автоматические Системы Заряжания Вооружения Бронетанковой Техники" (Automatic Gun Loading Systems of Tanks) published by the Russian Ministry of Defence, 2011.

The average time between shots is 7.1 seconds to 19.5 seconds, but the 19.5 second loading time is only true if the gunner is switching from one ammunition type to another and the desired ammo type happens to be the last one in the carousel. Since the autoloader carousel can only rotate in one direction, this forces the carousel to rotate over 26 other rounds (347 degree rotation) at a rotational speed of 26 degrees per second to reach the last one in the carousel. By dividing 347 degrees by 26 degrees per second, we find that the rotation of the autoloader carousel takes up 13.5 seconds, plus a few fractions of a second to account for the initial acceleration period and the braking time. The loading of the cartridge itself takes just under 6 seconds to complete and the total time taken adds up to 19.5 seconds. However, 19.5 seconds is not realistic with a standard combat load of ammunition during real combat, as the autoloader will choose the first round of ammunition of the type specified by the gunner. If, for instance, the tank carried a 3:3:3 ratio of APFSDS, HEAT and HE-Frag (which it does not), the autoloader carousel would have 9 shots of each type loaded plus one extra round. Assuming that the gunner began with APFSDS and decided to switch to HEAT, the carousel would need to rotate over 8 other APFSDS shells to reach the first HEAT shell. If he began with APFSDS and decided to switch to HE-Frag, the carousel would need to rotate over 17 other shells to reach the first HE-Frag shell. This is not quick, but the time needed to rotate over 17 rounds is still much less than 26 rounds. If the gunner switches from HE-Frag back to APFSDS, the carousel will need to rotate over 8 rounds to reach the first APFSDS round. Unless the ammunition is loaded in an unusual order and autoloader is operating under the most unusual circumstances, it would be impossible for a loading cycle to take as long as 19.5 seconds to complete.

Tankers often came up with their own solutions on how to solve these problems, and one of the solutions was to load ammunition in a repeating pattern, as detailed by Major Mikhail Chobitok in this excerpt from "T-64: Main Battle Tank" by M. Saenko:

"Затолкать артвыстрелы в конвеер МЗ можно в любой последовательности. Но в бою, время на заряжание пушки – дороже золота.

Поэтому, если при загрузке равномерно чередовать боеприпасы по типам, то и поиск (а соответственно и заряжание) их будет быстрее.

Конвеер МЗ при заряжании вращается только в одну сторону. Если загрузить сначала все бронебойные, потом все кумулятивные, потом все осколочные, то, выбрав на заряжание любой тип, будешь ждать, пока конвейер прокрутит все и доберется до нужного. А для эффективной стрельбы вероятность нахождения боеприпаса в конвейере должна быть одинаковой! Вот и думай танкист, как тебе быть… Пришлось повозиться."

Translated:

"Loading the rounds into the MZ autoloader conveyor can be in any order. But in battle, the time to load the gun - more expensive than gold.

Therefore, if the ammunition is evenly arranged in alternate ammo types, then the search for the ammunition (and therefore loading) will be faster.

The conveyor when loading the MZ autoloader rotates in one direction only. If you load at first all armor-piercing, then all HEAT, then all HE-Frag, then, having chosen on loading any type, you will wait until the conveyor scrolls everything and gets to the correct one. But to effectively fire the probability of finding ammunition in the conveyor should be the same! Think as if you were a tanker... you have to tinker."

In other words, the ammunition was arranged thusly:

APFSDS - HEAT - HE-Frag - APFSDS - HEAT - HE-Frag - APFSDS - HEAT - HE-Frag

This makes it quicker for the gunner to switch from one ammunition type to the other, but when the ammunition is arranged in such a way, the carousel must rotate over two shells to get to the same ammo type for every loading cycle. So if the gunner needed to fire at the same target with the same type of ammunition twice in a row (such as if he were engaging a tank with APFSDS, for example), the loading cycle would take 7.5 seconds. This matches the claimed 7.5 second reload speed implied by the combat rate of fire according to the manual. This is not a coincidence. The average minimum time between shots of 7.1 seconds is achieved under the assumption that the autoloader always loads the next round in the carousel (6 seconds) and another 1.1 seconds is taken to aim the gun. This may be how the 8 RPM rate of fire figure is obtained. However, Chobitok does not explain how he or his compatriots accounted for the fact that the combat load of T-64 tanks did not contain an equal ratio of the three ammunition types, which was further complicated by the advent of gun-launched "Kobra" missiles in 1976.

Of course, this was not necessarily how all T-64 crews did it. It is reasonable to expect that this became a technique that was later passed down by word of mouth to fresh arrivals at specific tank companies, but it may not be institutional knowledge that was taught nationally to all recruits in tank schools.

Either way, it should be quite obvious by now that the rate of fire may not be the same in all situations, even if all tank crews adhered strictly to the same method of loading ammunition into the carousel. One must not forget that it is often the skill of the crew that determines how much time passes between each shot. Both the gunner and commander do their part to seek out potential threats through their respective vision devices, but the commander must also identify the target upon discovery and he must convey this information to the gunner. The gunner must then verify that he is seeing the same object as the commander, and then proceed determine the range to the target. On the original T-80 with the TPD-2-49 optical coincidence sight, rangefinding can take four seconds or more, depending on the skill of the gunner, but the average time needed to find a target using the tank's vision devices is rather more hazy. As such, the actual time needed to take the first shot is invariably longer than 7.1 seconds, and only subsequent shots on the same target - so the time needed to find and range the target is eliminated - can occur at the theoretical maximum speed of 6 seconds.

The autoloader is insensitive to scorching heat, freezing cold, nor does it care how fast the turret is spinning, thanks to its impeccable sense of balance. It does not matter if the tank is rocking around like a bucking bronco at 50 km/h over the most gutted dirt paths. The autoloader will still load a shell in the specified time, every time. The common argument that the autoloader can be "knocked out" by hard impact or a hit on the tank's armour is fallacious - a hit on the tank's armour that does not fully penetrate yet is powerful enough to disable the autoloader would also be powerful enough to concuss the people inside the turret and effectively disable the gunner and commander as well as the loader. From an economics standpoint, an autoloader makes sense too. Manufacturing an autoloader on an assembly line costs a certain amount, but training a loader would take at least around 3 months and cost more, and a shoddily trained candidate will not be able to perform "up to spec". Of course, it can be pointed out that depending on unskilled labourers to assemble the autoloaders would also produce the same effect, but really, but shoddy craftsmanship would most likely manifest as reduced reliability, not as reduced loading speed.

REPLENISHMENT

When reloading the cassettes, these halves must be locked together with a special key before the cassette can be indexed and lowered back into the autoloader. This is shown in the photo below.

Ramming is conducted by a rigid chain actuator located at the back of the turret, directly behind the breech of the gun. The rammer passes through the open back end of the cassette, shoving the propellant and the projectile assembly into the gun chamber in one swift motion and immediately retracting so that the spent shell stub of the previous round can be placed into the cassette before it is folded up back into the autoloader carousel.

According to the manual, the process of restocking the entire combat load of ammunition including non-autoloader stowage can take between 25 and 30 minutes to complete, while replenishing the ammunition reserves of the autoloader carousel takes between 13 to 15 minutes. Reloading the autoloader is a simple process. All that happens is that the normal loading cycle is reversed, so instead of shells being rammed into the breech of the cannon, the cassettes are raised into position, where they are loaded with a fresh round, then lowered back into the autoloader.

One of the peculiarities of the autoloader is that the entire row of cartridges stowed around the perimeter of the turret ring completely isolates the driver from the rest of the crew. This makes it practically impossible for the commander to communicate with him without using the intercom system or for the driver to evacuate the tank through the turret. The latter requirement is quite a serious one because the driver cannot exit through his own hatch if the tank cannon is directly above it. However, the designers were kind enough to create provisions for creating a passage between the driver's station and the turret.

However, even this small provision is extremely flawed. The driver can only enter the turret via a small cutout in the turret cabin, but in order to get through the ring of ammunition, he must first remove two cassettes from the ring. This is done using a special lever, which the driver must secure to a protruding lug at the base of the ammunition cassette and then lift it off its mounting point on the carousel ring. This is quite easy if the cassette is empty but extremely difficult if it is not, considering that the tank's two-part ammunition weighed as much as 33.0 kg in the case of standard HE-Frag cartridges and the driver must perform his task from within the confines of the tank, not to mention that the cassettes themselves add some weight as well. The driver would need to deposit the two dismounted cassettes onto the turret cabin floor, preferably with assistance from the two crewmen in the turret.

LOOSE STOWAGE

Whereupon the entire load of ammunition in the autoloader has been expended, the crew has the option of replenishing it with extra cartridges from racks placed here and there all around the interior of the fighting compartment of the tank. The original T-80 and the T-80B had a rather small reserve capacity of just 7 cartridges, stowed in the hull in a conformal fuel tank-cum-ammo rack located on the port side of the hull, just behind the driver's seat.

The new T-80U and its turret had space to store 10 extra cartridges. Stowing extra ammunition in the turret was a substantial security risk with the chance of catastrophic ammo detonation jumping up by two times, since now the turret and not just the hull was potential cause for a popped turret. So as mentioned before in the "Gunner's Station" segment, the crew could, and would have opted not to make use of the racks in the turret.

CANNON

There only ever were a few things in common between the members of the Soviet "tank triad", and the cannon was one of them. Like its brothers, the T-80 mounted the 2A46 125mm smoothbore cannon, but along with the T-64, the T-80 was consistently ahead of the T-72 in implementing the latest and most advanced 125mm gun variants.

The initial T-80 was equipped with the 2A46-1 cannon (D-81TM) which was an improved variant of the original 2A26 (D-81T). The T-80B was equipped with the 2A46-2 cannon which featured the necessary electronic equipment to fire guided missiles.

AMMUNITION

This section will only contain details on the missiles compatible with T-80, as the basic types of ammunition available to the T-80 are identical to what was available to the T-72. Therefore, if you wish to read about APFSDS, HEAT and HE-Frag ammunition, please head over to the T-72 article.

MISSILES

The relevance of gun-launched guided missiles designed for tank cannons of a limited bore diameter is arguable, to put it mildly, but what is most certainly true is that they were prohibitively expensive and their value against new NATO composite armour arrays was questionable at best until the new tandem charge Refleks-M missile arrived. Besides, the tank would have had very few chances to exploit the incredible range offered by its arsenal of missiles due to the infrequency of encountering large expanses in Central and Western Europe. The huge flatland fields of the Ukraine were optimal, but the Red Army was certainly not planning on being on the defensive.

However, missiles are not used just for shooting at ground targets. Airborne targets are fair game as well. In fact, besides the Germans, Soviet tank crews are the only tankers that are trained to engage low-flying aircraft as part of their curriculum. The only difference was that West Germans were taught to attempt to use APDS shells to do the job. With speedier 125mm APFSDS ammunition, the T-80 was capable of this too, as mentioned before, but the likelihood of scoring a hit isn't very high.

The missiles used for the T-80 are split into two halves; rocket motor and fuse for the front half, and warhead plus guidance receiver for the back. The two halves are snapped together by the straightening motion of the loading cassette as it is moved into the ramming position.

9M112 "Kobra"

|

| From Stefan Kotsch's website |

The 9M112 missile had only a single charge warhead placed at the front half of the missile. The shaped charge liner was possibly made of aluminium. An improved version with a copper warhead was also in use, designated 9M112M. The basic 9M112 version was introduced in 1976, while the improved 9M112M was introduced in 1979. The main improvement of the 9M112M over the basic 9M112 was the use of the new 9N129 warhead with a 20% higher penetration. 9M112M entered service in 1978 and began mass production in 1979. The 9N129 warhead uses OKFOL for a more powerful blast effect and for a more energetic cumulative jet.

The placement of the shaped charge warhead at the front of the missile severely limits the standoff distance. This has a negative effect on its penetration power, and renders the missile no more powerful than the typical 125mm HEAT shell.

Penetration:

9M112: 250mm at 60°

9M112M: 300mm at 60°

The missile is soft-launched out of the gun barrel by the 9D129 propellant charge.

The 9M112 missile is guided by radio command and directed by the GTN-12 radio antenna. The "Kobra" system is fully integrated into the 1A33 fire control system and works together with the 1G42 sight, which the gunner uses to designate the aiming point. The integral laser rangefinder in the 1G42 sight is also used to determine the distance to the target in order to determine the appropriate mode of guidance. At engagement distances of 4 km, the missile does not fly at a level altitude. Kobra climbs to 3 to 5 meters above the bore axis of the tank and cruises at this elevated altitude until it reaches within 600 to 800 meters of the target, whereupon it descends back to cannon level and continues until it hits the target. The system uses range data from the 1G42 sight in order to plan a flight path and guide the missile toward the target when it enters the final phase of its flight. This enables it to avoid striking bushes, low hills and other natural obstacles throughout its long journey to the target. Together with the low firing signature of the missile, this feature may also decrease the reaction time of the target, as the elevated cruising altitude of the missile puts it above the direct line of sight of a potential target and the missile is also more difficult to see when framed against the backdrop of the sky.

In the direct fire more, the missile travels at a level altitude and reaches the target in this manner. This direct fire mode is generally intended for use against helicopters, but it is also intended as an emergency mode for shooting high priority targets that appear suddenly at close range if the tank already has a missile loaded.

3UBK20

9M119 "Refleks"

The 9M119 "Refleks" laser beam-riding missile is similar to the 9M119 "Svir" used in the T-72B, but with an increased range of 5,000 meters instead of 4,000 meters. Guidance is accomplished by the integrated 9S517 laser beam unit on the 1G43 sighting complex.

The missile is soft-launched by a 9Kh949 reduced load piston-plugged ejection charge, giving the missile some momentum before the rocket motor kicks into action. The piston plug is designed to properly seat the missile in the chamber, but its primary purpose is to protect the laser beam receiver at the base of the missile from propellant gasses. The total weight of the 9Kh949 charge is 7.1 kg.

The missile itself has an efficient layout with the rocket motor placed in the middle, the warhead at the very rear, and the control surfaces and mechanism at the front along with the fuse at the tip. The large distance between the tip of the missile and the warhead means that the warhead is given a large standoff distance without the need for a special standoff probe. The layout enables the 125mm missile to have a comparable flight range as the 127mm ITOW missile, and superior armour penetration performance, but in a much more compact package. With 700mm of penetration, "Refleks" is a much more serious weapon with a much better chance of defeating the new generation (at the time) of NATO tanks like the Leopard 2 and M1 Abrams, albeit from the side. The chances of defeating such tanks from the front with this missile are rather slim.