This iteration of the BMP family is technically excellent in the application of available technologies and features, especially when compared to its predecessor, the BMP-1, but some view the BMP-2 is nothing more than a "rehash" of the old and obsolete BMP-1 design. While that is technically true, the sentiment behind such an accusation points to an incorrect mindset. The BMP-2 is a product improved BMP-1, but it is not quite the same thing as its predecessor. Far from it. It is so heavily modified that the only similarities are in the general layout and the powertrain. Even the hull was structurally different due to the use of a new steel. The most obvious difference between the BMP-2 and its predecessor is, of course, the new turret, now armed with a deadly 30mm autocannon. The modifications resulted in an almost entirely different vehicle with greatly expanded capabilities. However, the BMP-2 never got past the lack of a modern thermal imaging system like the M2 Bradley's ISU (Integrated Sighting Unit), and it only got worse as time went on, as the BMP-2 stagnated technologically while its contemporaries continually evolved.

From 1980 to 1989, the factory now known as Kurganmashzavod produced a total of 14,000 BMP-2 models of all types. At the peak of production in 1989, between 1,800 to 1,900 units exited factory gates every year - triple the maximum annual rate of production of the M2 Bradley. These production numbers ensured that many Soviet motorized infantry units were equipped with fully armoured and highly mobile troops transports with more firepower than before. From 1988 to 1991, the production of the BMP-2 ran in parallel with the BMP-3, and in the 1990's, most of the production capacity of the KMZ plant had been redirected towards producing the BMP-3 to fulfill export contracts. Small orders of BMP-2s and BMP-3s were delivered to the Russian Army, but the volume of deliveries was small due to the economic situation of the Russian Federation at the time. In 2005-2006, the Russian Army received its last batch of approximately 40 new-built BMP-2s. Since then, no new BMP-2s have been supplied to the Russian Army, but KMZ still engages in the production of spares and routinely carries out overhaul and modernization work for existing vehicles.

TABLE OF CONTENTS

- Commander's Station

- TKN-3B

- TKN-AI

- 1PZ-3

- Communications

- Gunner's Station

- Sighting Complexes

- Stabilizers

- 2A42 Cannon

- Ammunition

- Secondary Weapon

- Supplementary Weapons

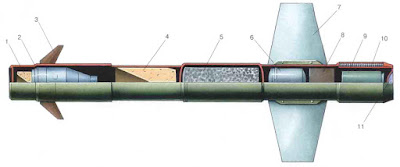

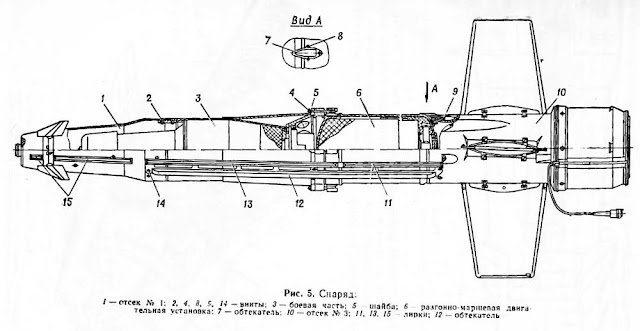

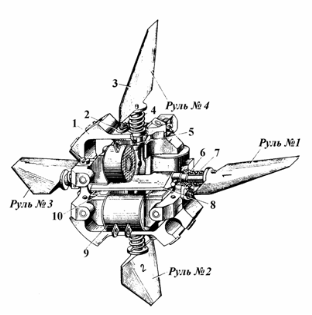

- Missiles

- Protection

- Applique Armour

- Fuel Tank Doors

- Smokescreen

- NBC Protection

- Fire Fighting

- Passengers

- Driver Station

- Mobility

- Fuel Endurance

- Water Obstacles

- Distribution

COMMANDER'S STATION

The commander of a BMP-2 is the squad leader of the Soviet motor rifle squad, the same as in a BMP-1. While he has been moved from the hull to the turret, the squad leader fulfills the same role as the commander of a BMP-1. He dismounts along with the passengers when required, leaving the gunner to do double duty in his absence.

The commander has his own hatch, which has an unusual clam shell shape to grant enough space to accommodate the extremely sparse array of periscopes.

The commander of the BMP-2 is only given a miserly two (!) general vision periscopes to supplement his ubiquitous TKN-3B. Not only is that less than what the gunner gets, it's also much less than what the commander's NATO counterparts get. The commander of the Marder 1, for instance, is furnished with a generous array of five periscopes covering 160 degrees frontally. However, it must be mentioned that the cupola rotates, so unlike the gunner seated beside him and the commander of a Marder 1, the commander of a BMP-2 can spin the cupola around to see all 360 degrees around him. It is not as convenient as being able to glance in whichever direction at leisure, but the overall effect is similar, and at least the commander of a BMP-2 has a greater field of view than a 160 degree frontal arc. It would, of course, be much better to have two more periscopes like on the cupolas of T-54 and T-62 tanks. To top it all off, there is a TNPT-1 rear view periscope mounted in the hatch to give the commander immediate rearward awareness. It is useful for directing the driver when buttoned up. In non-combat situations the commander may opt to peek out of his hatch instead.

As usual, all of the periscopes are heated with the RTS-27 heating system to prevent fogging. RTS stands for "Регулятор Tемпературы Стекла" (Regulyator Temperatur' Stekla), which literally means "Glass Temperature Regulator".

Unfortunately, it seems that this system is a common source of complaints, according to forum posts on the Russian internet. The RTS periscope heating system is installed in nearly all Soviet vehicles, including the T-72, T-64, BTR-80, and many, many more. However, none of them have had any complaints about periscopes fogging up, except for the BMP-2 and its predecessor. Based on anecdotal evidence collected from several BMP-2 crew members, both current and former, it seems that the RTS heating system doesn't always work on the BMP-2 for some reason. It has been the source of much grief during the winter, as the periscopes usually fog up so badly that it becomes impossible to see through them. It is possible that this is simply due to the poor condition of training vehicles, but this is only speculation. It seems strange that such a simple system went wrong here when it could function fine in everything else.

TKN-3B

One considerable advantage to the BMP-2 in overall fighting efficiency over its contemporaries is that the commander has the TKN-3B combined active/passive pseudo-binocular periscope at his disposal. Pseudo-binocular meaning that although the device has two eyepieces, the two optic feeds are combined to one aperture, which the viewer sees out of. The TKN-3B has a fixed 5x magnification in the day channel with an angular field of view of 10°, and a fixed 3x magnification in the night channel with an angular field of view of 8°. The periscope can be manipulated up and down for elevation, but the commander's cupola must be manually spun for horizontal viewing.

For tanks like the T-72, the TKN-3B might be a somewhat mediocre tool compared to the PERI-R17 panoramic sight with television feed for the Leopard 2, but for an IFV like the BMP-2, it was rather remarkable. It wasn't stabilised, and featured only rudimentary rangefinding capabilities, and its nightvision capabilities were not competitive by 1980 (the TKN-3 first entered service in 1963), but it at least had nightvision capabilities, and it had a decently high magnification. Night vision came in two flavours; passive light intensification or active infrared. In the passive mode of operation, the TKN-3B uses its light intensification module to amplify ambient light to produce a legible image. This mode is useful down to ambient lighting conditions of at least 0.005 lux, which would be equivalent to an overcast, moonless and starless night. In these conditions, the TKN-3B can be used to identify a tank-type target at a nominal maximum distance of only 400 m due to the resolution limit, but as the amount of ambient light increases such as on starlit or moonlit nights, the distance at which a tank-sized target is discernible can be extended. In dark twilight hours, the TKN-3M may be able to make out the silhouette of a tank at a distance of up to 800 m or more, but the sight is hamstrung again, this time not by the absence of light, but by the low magnification. Any brighter than dawn or dusk, and the image will be oversaturated and unintelligible.

The active mode requires the use of the OU-3GA2, an IR spotlight operating on 110W, connected directly to the BMP-2's 27V electrical system. With active infrared imaging, the commander can reliably spot large objects from a distance of more than a kilometer depending on meteorological conditions, but identifying targets as tanks or trucks or APCs can only be done at around 800 m, but potentially more if the opposing side is also using IR spotlights, in which case, the TKN-3 can be set to the active mode but without turning on the IR spotlight. This is possible because the switch for activating the spotlight is the right thumb button while the operating channel selector is on the TKN-3 itself, meaning that they can be turned on separately.

The problem with IR spotlights as a whole is that although the user can use them to spot for targets, the targets can use them to spot the user too, but from much further away. Because of the diffraction of light waves, anybody observing the user won't just see a dot of light. If you observe a tank with its IR spotlight on, most of the tank would be brightly illuminated from miles away. The diffracted light does have the benefit of lighting up the ground better for the driver to see, though, so the common issue of speed control due to short visibility distance with the complementary IR periscope for the driver is slightly alleviated in battle conditions. If you look at the photo above, you can clearly see what I mean by this. The spotlight (running on a small pocket battery in this case) illuminates the apartment building, but also the most of the ground. If you had an infrared filter on your gunsight or rifle scope, like the PSO-1 for the SVD rifle, you could very easily see the source of light and call out its position.

Shortcomings in the night vision capabilities of the TKN-3B may be solved by the use of illumination rounds fired over enemy positions. This doesn't solve all of its problems, of course, because the low resolution may complicate the quick and proper identification of enemy vehicle types at long distances, and overhead lighting doesn't penetrate dense forest canopies. More recently, IR illumination rounds similar to the British L58A1 have been developed and put into service, which may benefit the TKN-3B greatly. Needless to say, this new type of ammunition is a godsend for the ageing BMP-2s of today..

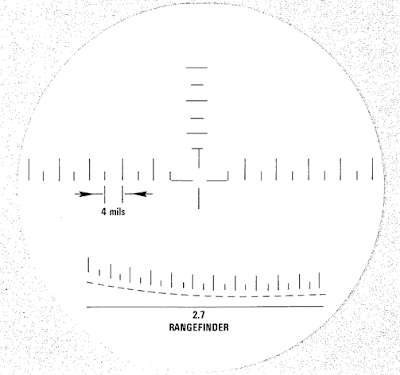

Rangefinding is accomplished through the use of a stadiametric scale sighted for a target with a height of 2.7 m, which was the average size of the average NATO tank or IFV. The TKN-3B is unstabilized, making it exceedingly difficult to properly identify enemy tanks or other vehicles at extended distances while the BMP-2 is travelling over rough terrain, let alone determine the range. The left thumb button initiated turret traverse for target cuing. The range of elevation is +10° to -5°. The OU-3GA2 spotlight is also directly mechanically linked to the periscope to enable it to elevate with the TKN-3B.

|

| TKN-3 viewfinder |

The TKN-3B gave the BMP-2 a true hunter-killer capability, something totally foreign to NATO IFVs of the era. By simply placing the crosshairs on the target and pressing left thumb button, whereupon the turret will spin to meet the target. The cupola lacks a contra-rotating motor, but it is light enough and the ball bearings of the cupola are smooth enough that it does not have enough inertia to not spin away with the turret, making it easy for the commander to keep the cupola aimed at the target while the turret spins around to meet it. This was not so easy in the T-62, which gave the commander a steel rung for the commander to hold on to. The fact that this hunter-killer feature exists is of huge importance, as the commander is elevated from a simple observer to an active participant. He could participate even further if required, using his 1PZ-3 multipurpose sight.

TKN-AI

The TKN-AI is a descendant of the TKN-3 family. It has improved nightvision capabilities, but offers little else. Like the all members of the TKN-3 family, TKN-AI is unstabilized and controlled manually. The magnification in the daytime channel is 4.75x and the magnification in the night channel is 5x.

TKN-AI features a pulsed laser spotlight, but evidence shows that it can be replaced with a PL-1-01 laser beamer, presumably to increase the range of vision. The laser spotlight superficially resembles an OU-3 spotlight from a distance, but as you can see in the photo above, the aperture for the IR laser is much, much smaller than the external diameter of the spotlight itself. Both the spotlight and the PL-1-01 beamer can switch from active illumination to pulsed illumination, whereby the IR laser beam is modulated and pulsed to an operating frequency is 5.2 kHz with an illumination pulse duration of 130 ns. This is meant to reduce laser backscatter when viewing through haze or fog. The identification distance for a tank-type target is 1000 meters in the active mode, but it might be possible to increase the detection range by installing the PL-1-01 instead of the spotlight.. The device is also capable of rangefinding using timed laser pulses controlled by the TKN-AI. The claimed accuracy of ranging is 20 m within a range of distances between 200 m and 3000 m.

Besides active infrared imaging, the TKN-AI features a passive mode with a 2+ generation image intensifier module. It is possible to identify a tank-type target at 600 meters in the passive mode, which is slightly better than the 500 m range of the TKN-3B.

Modernized BMP-2s using the TKN-AI are known to have participated in exercises, like the one in the photo below. It can be seen with the characteristic PL-1-01 pulsed laser beamer where the old OU-3 IR spotlight should be.

However, this upgraded device still retains some drawbacks of older IR nightvision devices. Being a rather powerful IR laser projector, an illuminated PL-1-01 can be spotted from great distance with a simple helmet-mounted nightvision monocular or goggles by the target of observation, though the IR beam is also likely to blind the observer at the same time.

The IR beam itself may also be visible if there is smoke or fog around the battlefield as it will diffuse the light of the laser beam and make it visible to anyone equipped with nightvision equipment. If that occurs, then it would be extremely simple for any observer to trace the beam back to its originator, thus revealing the location of the BMP-2, leaving it open to artillery or air attack. The object of the commander's attention will also be alerted as long as he has nightvision equipment, since he would be able to see himself or the area around him illuminated by the laser.

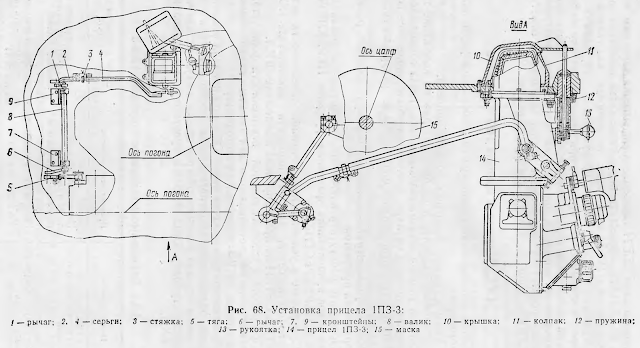

Besides manning the periscopes and managing the vehicle, the commander is also in charge of fending off air attacks. To do this, he is provided with a 1PZ-3 anti-aircraft sight mounted on the turret ceiling in front of his cupola. It can also be used as a backup sight for ground targets if the need arises. When not in use, the aperture window is covered by an armoured hood.

The 1PZ-3 sight is monocular with a very large range of elevation. It features internal electric heating and has two special light filters. The sight can be used without a filter when firing upon ground targets, but if necessary, a "Special" filter or a "Neutral" filter can be applied by turning a lever. The "Special" filter is simply a laser protection filter that protects the operator from being blinded by direct laser illumination, and the "Neutral" filter is a neutral density filter that reduces the amount of light that is transmitted to the operator's eyepiece, thus darkening the image. This makes it easier for the operator to detect and track aircraft in the sky during bright daylight hours, but it can also be used when engaging ground targets if necessary.

The sight lacks independent stabilization, but because of its direct mechanical connection to the stabilized 2A42 cannon in the turret, the sight is stabilized in the vertical plane. However, due to the coarse nature of this type of stabilization, the stabilization precision is not high and the viewfinder image may vibrate when the vehicle is moving on rough ground. The sight can elevate and depress as far as the cannon can, which would be from -5 degrees to +75 degrees in elevation.

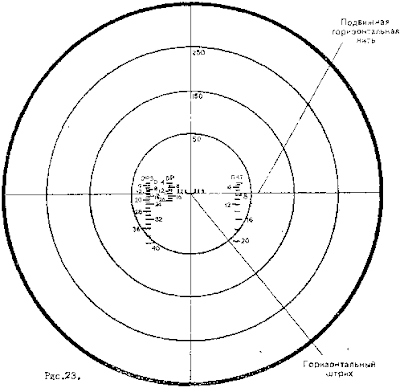

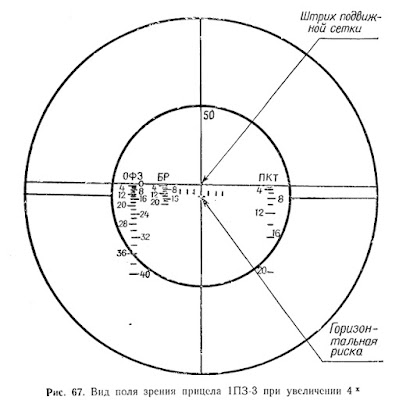

The sight has two magnification settings; 1.2x and 4x. The field of view through the sight is 49 degrees in the 1.2x setting and 14 degrees in the 4x setting. The lower magnification was only suitable for engaging aircraft. Shooting at air targets flying at subsonic speeds is theoretically possible at ranges up to 2,500 m and at altitudes up to 2,000 m. In practice, the effective range is much less.

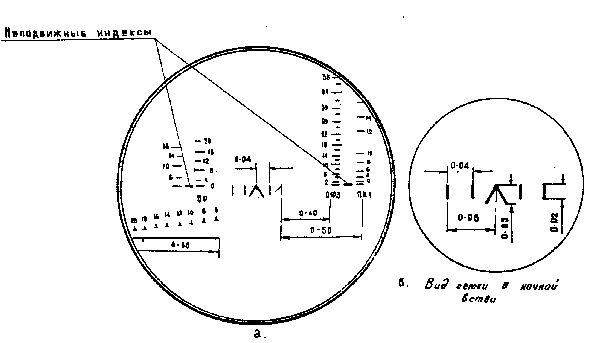

The two images below show the sight under the 1.2x and 4.0x magnification settings.

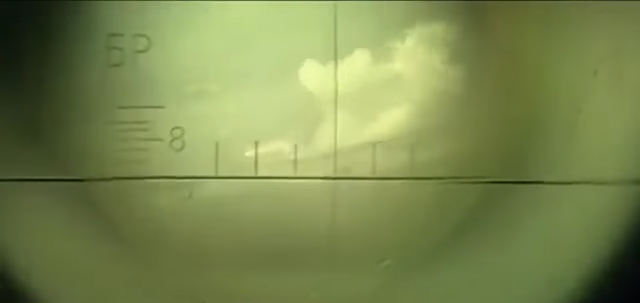

As far as anti-aircraft sights go, the 1PZ-3 had no outstanding characteristics and contained only the essential markings for leading moving aircraft. The sight also has the secondary purpose of serving as the commander's only optic for ground targets and being the BMP-2's backup gun sight as well, and to that end, its viewfinder provides graduated range scales and simple deflection markings, as shown in the images above. To aim, the operator turns a knob to raise and lower a horizontal line until it matches the desired mark on the fixed range scales. The horizontal line forms a crosshair with the fixed vertical line running down the center of the viewfinder. The operator elevates the autocannon or coaxial machine gun of the BMP-2 until the crosshair is superimposed on the target, and then he can open fire.

The commander may override turret and weapons control at the press of a button and take over using the control handles that he is furnished with.

Here is a screenshot of the reticle of a 1PZ-3, taken from a video of a BMP-2 firing its cannon:

These tools, taken as a whole, mean much more than the sum of their parts. The independent surveillance equipment, target designation, duplicated gunnery controls and independent sighting systems give the commander a level of dominance over his own machine that many of his NATO counterparts did not have. While the commander of an M2 Bradley did have a gunsight extension to see what the gunner sees and a set of gunnery controls to use them with, he did not have a sight of his own, as there was no backup sight, and he did not have his own cupola and he did not have a magnified optic with a stadia rangefinder. The BMP-2 had all of these, and the BMP-2 had a fully matured hunter-killer capability to go with it.

From the introduction of the BMP-2 in 1980 until 1984, the commander was in charge of the R-123M radio, installed at the very rear of the turret shelf (the turret is wider than the turret ring, so there is a wide shelf at the base). Voice transmissions are done using the throat microphone integrated into his tanker's helmet. The throat microphone is reportedly of good quality and much more useful than an open microphone. The commander can listen to both extra-vehicular transmissions or communications from his own crew from the headphones of his tanker helmet.

The R-123 radio had a frequency range of between 20 MHZ to 51.5 MHZ. It could be tuned to any frequency within those limits via a knob, or the commander could switch between four preset frequencies for communications within a platoon. The switching process takes 3 seconds to complete. The radio has a transmitting and receiving range of between 16km to 50km, depending on the antenna used and the type of terrain. The R-123M had a novel glass prism window at the top of the apparatus that displayed the operating frequency. An internal bulb illuminated a dial, imposing it onto the prism where it is displayed. The R-123M had an advanced modular design that enabled it to be repaired quickly by simply swapping out individual modules.

The dismounted squad leader will have an R-392 or R-126 radio to communicate with the commander of the BMP-2 at shorter distances. The squad should be operating 800 meters away from its BMP at the most, though this obviously is dependent on the tactical situation as well.

In 1984, the now-outdated R-123 radio was replaced by the R-173 radio, which had a frequency range of between 30 MHZ to 75.999MHZ. It has 10 preset frequencies. It had an electronic keypad for entering the desired frequency, and an LED display. Its main improvement over older radios is the ability to send encrypted analogue and digital signals.

Sometime in the late 2000's, most BMP-2s had a new and advanced R-168-2UE-2 frequency-hopping encypted radio installed to replace the obsolete R-173, which was found to be susceptible to eavesdropping and jamming during the first Chechen campaign/invasion.

The R-168 family of radios is now standard throughout the Russian ground forces, from infantry platoons to tank companies. It can produce frequency hops 100 times a second, and the data is encrypted as well. It can also send and receive digital data.

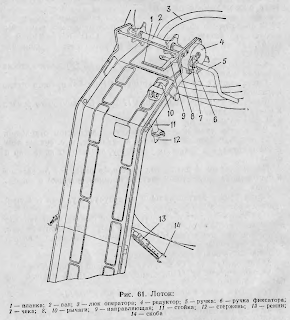

The commander can exit the vehicle by two means - the hatch above him, or by spinning the turret to face the rear, and then going out through the passenger compartment. In the latter case, he must swing open the turret basket perimeter shield (shown below) to exit the turret. The last two photos are provided courtesy of Mr. Tim Gow from the excellent megablitzandmore blog for modelers.

Besides the necessary tools and spare parts, there isn't much space inside the vehicle for stowing long term supplies. The turret doesn't have external bins or baskets either, but it does have numerous loops around its rear perimeter, as you can see below.

The loops are meant for securing foliage and camouflage netting on the turret, but the crew can strap their personal effects onto them too.

The gunner's station is relatively sparse. All of the weapon controls are placed directly in front of the gunner, and most of the accessories, including the intercom control box, dome light and the turret traverse lock are arranged around the turret wall. The gunner has three fixed general vision periscopes, two on each side of his primary sight and another aimed to the left. The gunner is also provided with a TNPT-1 rear view periscope in his hatch. This periscope lets him see directly behind the turret. All in all, the gunner has the same number of general vision periscopes as a BMP-1 gunner but

This gives him relatively good visibility and he can take over the vehicle from the commander if the commander dismounts with the passengers. The gunner's has no periscope aimed to the right of the turret, and it was not really possible to provide a view to the right at all because the ATGM launcher already occupied that part of the turret roof. Compared to its direct foreign counterparts, the BMP-2 accommodated its gunner quite well in this respect. The gunner in an M2 Bradley, for instance, has two general vision periscopes flanking the ISU (Integrated Sight Unit) covering the 11 o'clock and 1 o'clock sectors like in the BMP-2, but half of the view from both periscopes is blocked by the large housing for the sight and the view from the left periscope is completely blocked when the TOW launch pod is raised. A Marder 1 gunner had three periscopes, but they only covered the left side of the turret and were evidently only meant to compensate for the commander's inability to see to the left as the view was completely blocked by the external autocannon installation and the gunner's sight.

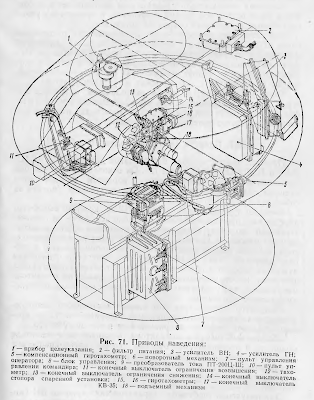

The BPK-1-42 combined day-night sight was the primary sight for a BMP-2 gunner. It has a fixed magnification of 5.6x in the day channel, and a fixed 5x magnification in the night channel. Rangefinding is accomplished with a stadiametric scale in the lower right corner of the sight view finder. The BPK-1-42 sight has dependent stabilization in the horizontal and vertical planes. The elevation limits of the mirror head of the sight ranges from -8 degrees to +30 degrees. The stabilization system of the weapons provides dependent stabilization to the sight via a simple connection rod.

There are two eyepieces on the sight. The one on the left is the optic for the nightvision channel. Observation and target engagement at night is achieved in either the passive or active modes. The passive mode uses an image intensifier tube to amplify ambient light to a visible level. It is possible to identify tank-type target at distances of up to 600 or 700 meters on a cloudless, starry night with ambient light levels of at least 0.005 lux.

The active mode requires the use of the co-axially mounted OU-5G infrared spotlight for illumination. Although the OU-5G spotlight is only approximately the same size as the OU-3 spotlight used for the commander's TKN-3B periscope and is only rated for a somewhat power of 180 W, its illumination capability is greatly superior as it uses a xenon lamp instead of an incandescent lamp. It has a white light output of 15 million Candelas - half that of the L-4A spotlight used on tanks, which also used a xenon arc lamp but ran on 600 W.

The ribs on the BMP-2 (and BMP-1) measured 25mm in height, 12mm in thickness, and were spaced 200mm apart, but due to the steep angle of the slope of the BMP's engine access panel, the difference in spacing is nullified. One important detail is that the ribs are not exactly vertical, but perpendicular to the engine access panel, so they are sloped inwards at 12 degrees. These measurements and the photos below were provided by Chris Conners, proprietor of the excellent American Fighting Vehicle Database website (afvdb.50megs).

The shape and orientation of the ribs on the engine access panel can be seen in the image below.

The geometry of the access panel itself is surprisingly complex. It is thinnest immediately behind each rib, and gradually thickens as it approaches the next one. The thinnest part of the panel is 10mm and the thickest part is 15.5mm. The effectiveness of the panel against gunfire is unclear, but there can be no doubt that it is at least proofed against 7.62mm bullets of all varieties as well as 12.7mm armour-piercing bullets as well.

This phase diagram taken from "Armour: Materials, Theory, and Design" illustrates the importance of steep sloping to the engine access panel. In this case, a 6.35 mm aluminium alloy plate was used as a target and 6.35 mm-diameter steel-cored bullets as projectiles. A 6.35 mm projectile like this is representative of the steel armour-piercing core of the average 7.62mm rifle bullet. The AP core of a 7.62x54mm Russian B-32 bullet, for instance, has a diameter of 6.1 mm with a weight of 5.39 grams. It has a nominal muzzle velocity of 830 m/s. The AP core of a .30 caliber M2 AP bullet has a diameter of 6.2 mm and weighs 5.17 grams. It has a muzzle velocity of 855 m/s. The AP core of a 7.62x51mm M61 bullet has a diameter of 6.3 mm and weighs 3.8 grams. It has a muzzle velocity of 838 m/s.

Even with such a thin aluminium alloy plate, the armour piercing core simply ricochets without achieving perforation. Depending on the impact velocity, the end result may vary. At 700 m/s, the bullet will ricochet intact, but above that, it will fracture on impact and the fragments ricochet off the plate. As the aluminium plate used in the experiment is highly likely to be 5083 aluminium alloy, inferior to ABT-101 alloy.

The lower glacis is probably the stronger half of the front hull. It is a 15mm plate sloped at 56 degrees - thinner than same plate on the BMP-1 which was 19mm thick sloped at 57 degrees. The reduced thickness was compensated by the increased hardness and strength of the new BT-70Sh steel which raised the effective thickness of the 15mm plate on the BMP-2 to the same level as the BMP-1. In practical terms, this compares favourably to the 32mm plate sloped at 24 degrees that forms lower glacis of the Marder 1, A1 and A2 when attacked with small arms and some autocannons, including the ordnance from the Marder 1. For instance, German DM43 APCR ammunition of the 20x139mm caliber fired from the Marder 1's Rh202 autocannon is able to penetrate 32mm of RHA armour at 0 degrees at 1,000 meters, but its performance drops sharply down to just 8mm of penetration on armour sloped at 60 degrees at the same distance. For the better half of its life during the Cold War, this part of the BMP-2 was therefore frontally immune to 12.7mm machine gun bullets and to 20mm shells and anything in between from close range. The vastly more effective DM63 APDS was introduced sometime in the mid-80's, and that would have been able to defeat the frontal armour of the BMP-2 out to 1,000 meters and more.

Like the BMP-1, the side armour of the BMP-2 is good for a vehicle of its weight if the Marder 1 is used as a reference point. The armour on the sponsons and the firing ports is 13mm thick and vertically sloped at 15 degrees. The armour on the lower side of the hull is 15mm thick and flat. The flotation aids mounted on the sponsons as side skirts are filled with foam and are equivalent to 10mm of steel. The flotation aids protect the tracks and provide additional spaced armour for the hull, but they only cover a third of the area of the hull profile. The sides provide reliable protection from 7.62mm machinegun fire, and resist .50 caliber AP ammunition only from above 200 meters. The field manual FM 7-8 "Rifle Platoon And Squad" from 1980 notes that a .50 caliber machine gun will penetrate the side of a BMP from 200 meters or less.

Besides the physical thickness of armour, the passenger compartment of the vehicle has an extra 7 to 8 degrees of horizontal slope. Combined with the minor vertical sloping on the sponsons, this additional horizontal slope increases the protection for both the passengers and the internal fuel tanks from attacks in the frontal arc of the BMP.

This design quirk lends evidence to the intention of the designers to afford extra protection to the most sensitive assets of the vehicle. It would be extremely incorrect to say that the BMP-2 (and by extension its predecessor) was a "deathtrap" for being designed without consideration for combat survivability. The extra 8 degrees of horizontal slope will do absolutely nothing if the vehicle is struck by an RPG, or if it runs over a large IED, but it will be significant when the BMP is advancing towards a hail of heavy machine gun fire.

The thin strip of sloped armour (above) at the very top of the hull sponsons is no better nor worse than the rest of the side armour. The photo below, courtesy of Mr. Conners once again, gives us an idea of how thick it really is. Knowing that the sponsons are 16mm thick, we can compare that (the straight bit) to the bent flap of steel, which is bent directly from the sloped strip of the overtrack hull. Using pixel scaling, the thickness comes out at 7.13mm. Not very thick, but with its slope of 60 degrees, it is more than enough to deflect 7.62x51mm AP bullets from any distance.

The thickest sections of armour are found at the center of the turret surrounding the gun mantlet. The physical armour thickness reaches its peak at the base of the turret underneath the gun mantlet as the drawing below shows.

The thickness of this part of the turret is unknown, but based on the thickness of the turret roof depicted in the drawing, it is much thicker than the turret cheeks. The turret cheeks form the front half of the circular turret and it has a thickness of 20mm. It is sloped 43 degrees at the front of the turret, declining to 36 degrees at the sides. Ignoring the horizontal slope component from the circular shape of the turret, the cheek armour has a line-of-sight (LOS) thickness of 27.3mm with only its vertical slope of 43 degrees. This is a close equivalent to the turret of the BMP-1, but the BMP-2 turret is slightly tougher as it is built from BT-70Sh steel with a higher hardness and higher yield strength than the 2P high hardness steel of the BMP-1.

Like the hull, the turret armour offers complete immunity from .50 caliber and 14.5mm armour-piercing bullets in its frontal arc and can resist 23mm BZT shells (API-T) from 500 meters.

The rear half of the turret is weaker, having a thickness of just 10mm and sloped at 28 to 20 degrees, with the smallest slope angle at the rearmost point of the turret. From the side, the turret has enough armour to resist 7.62mm armour-piercing bullets at point blank range.

Once opened, the turret hatches serve as armoured shields. As they are about as thick as the turret roof armour is, which is about 13.6mm, they are fully proof against anything less than a 12.7mm bullet. The shield gives the commander full body and arm protection once he is outside, making him a very tricky target for any potential snipers. If the commander would prefer not to have his head above the hatch so conspicuously, he can rotate the cupola a bit to the side to poke his field binoculars out so that everything except his eyes can be sheltered behind the shield-hatch.

The conflict in Ukraine has proven that artillery is still an incredibly important asset, even in an unconventional war. Apparently, the majority of armoured vehicle losses were due to artillery fire. Among the many victims was the BMP-2 below. As you can see, the roof armour was no match for a 122mm high explosive shell.

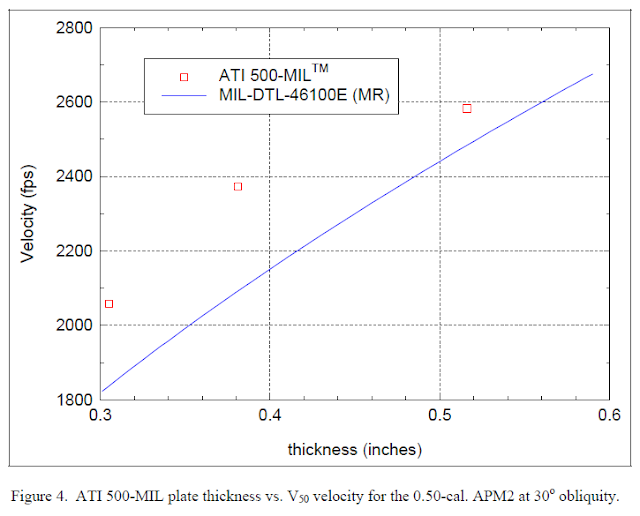

If you haven't read the bullet penetration test document presented here (link). I have condensed the relevant information to a usable format:

Muzzle Velocity of M2 AP: 876 m/s

V50 of 7.7mm ATI 500-MIL plate at 30°: 627 m/s

V50 of 9.7mm ATI 500-MIL plate at 30°: 723 m/s

V50 of 3.1mm ATI 500-MIL plate at 30°: 787 m/s

This means that at 960 m, .50 cal AP will go through 7.7mm of 534 BHN steel angled at 30 degrees to the vertical. At 600 m, it will go through 9.7mm of the same steel angled at 30 degrees. At 400 meters, the bullet is defeated by 3.1mm of AT 500-MIL plate, indicating the possibility of a catastrophic failure of the steel core by shattering.

Here is the graph generated as part of the test conclusion and discussion.

Keeping in mind that the muzzle velocity of a .50 caliber AP bullet is 2910 ft/s, we can see that the only velocity at which the penetration of the bullet will exceed 13mm (0.51 inches) is just under 2,600 ft/s. Referring to our ballistic chart here (link), we can see that the velocity of 2,450 ft/s corresponds with the distance of around 400 meters. Therefore, the upper side hull armour of the BMP-2 can resist a .50 caliber AP bullet from 400 meters given that the hull is angled slightly by a few degrees. The lower side hull armour is 15mm thick but completely flat, so it is actually slightly weaker. Conversely, the middle of the hull where the flotation aid is present would be immune to .50 cal AP even from point blank range due to the high combined thickness of armour and the spacing of the flotation aid from the hull sponson.

The turret is vertically sloped at 28.5 to 35 degrees and has additional horizontal slope due to its rounded shape, so it is able to resist .50 caliber AP bullet from closer distances. However, the rear of the turret is only 10mm thick and is flatter, so it is only capable of resisting .30 caliber bullets.

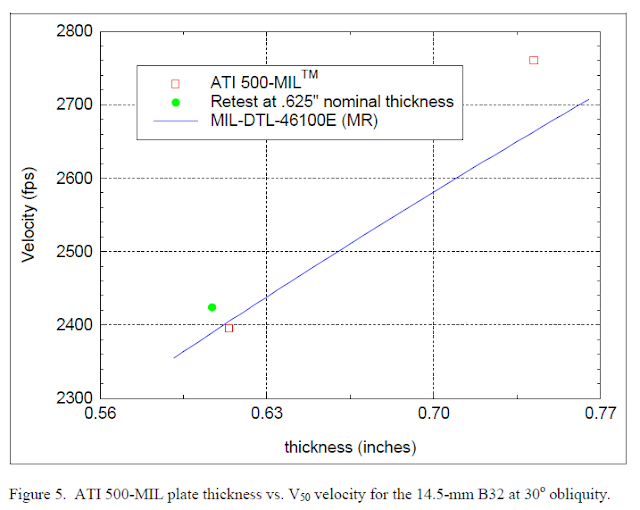

Muzzle Velocity of 14.5 B-32: 988 m/s

V50 of 15.6mm of ATI 500-MIL plate at 30 deg: 730 m/s

V50 of 15.4mm of ATI 500-MIL plate at 30 deg: 739 m/s

V50 of 18.8mm of ATI 500-MIL plate at 30 deg: 841 m/s

This means that at 980 m, a 14.5mm B-32 bullet will go through 15.6mm of ATI 500-MIL plate angled at 30 degrees to the vertical. This is almost exactly double the performance of the .50 M2 round for a very small increase in caliber and small increase in overall dimensions. At 915 meters, the 14.5mm B-32 bullet will go through 15.4mm of the same steel at the same slope. At 525 m, the 14.5mm B-32 bullet will go through 18.8mm of the same steel at the same slope.

Here is the graph of thickness against V50:

As you can see, the side hull will be defeated from any distance within 600 meters.

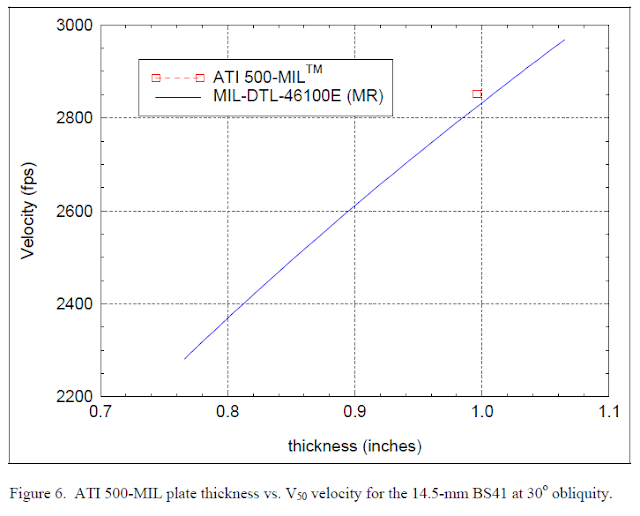

Muzzle Velocity of 14.5mm BS-41 bullet: 1005 m/s

V50 of 24.5mm of ATI 500-MIL plate at 30 deg: 869 m/s

The inherent suitability of a WC (Wolfram-Carbide, or Tungsten Carbide) core for anti-armour purposes is very apparent here. At 435 meters, the BS-41 bullet can perforate 24.5mm of ATI 500-MIL plate steel angled at 30 degrees.

Reading the graph tells us what we already know. The sides of the BMP-2 cannot defend from this type of bullet from a reasonable distance, but the frontal armour of the hull and turret will have no problems even at close range.

Contrary to popular belief, the infamous fuel-filled rear doors were far from being a hazard to the crew. To the contrary, there is evidence that much more thought was put into the design of these doors than commonly believed. The walls of the fuel tank are pressed from rolled sheets of medium hardness steel. According to Victor Malginov, the outer plate of the door is 13mm thick and the inner plate is around 5mm thick. The thickness of the outer plate is the same as the thickness of the rear hull armour, and the doors are slightly sloped at the same angle as the reset of the rear hull armour: 13.5 degrees. This is enough to stop ball ammunition from small arms at point blank range, grenade fragmentation from any distance, and splinters from small mortars. When taken together with the fuel and the inner ~5mm plate, it is clear that the ballistic protection offered by these doors is not worse than the side armour of the vehicle and may even be slightly better.

There is a prevailing myth that the fuel tanks could be set afire if the fuel tanks were hit by incendiary ammunition. The biggest issue with this is that incendiary ammunition simply was not common. Incendiary 7.62x51mm ammunition is rare, and so is incendiary 5.56mm ammunition, and in the latter case, it would not be able to defeat the outer 13mm plate of the fuel tank door in the first place. Even .50 caliber AP-I ammunition is rare compared to ball rounds and the standard APM2 armour piercing round. The standard .30 caliber APM2 armour piercing round also lacks an incendiary filler.

In the event of a penetration from an API bullet, the incendiary element will only ignite fuel just behind the exterior wall, because fuel needs to be oxidized in order to burn, and the only source of oxygen for the fuel that is exposed to the incendiary blast is the fuel just around the entry hole of the bullet, since fuel will leak out from that hole into open air. However, in such a case, the entire tank is completely safe from ignition. Burning fuel will simply leak out of the tank in harmless rivulets. If the interior wall of the fuel tank is perforated as well, the fuel will not be ignited due to a lack of heat, since the incendiary blast is on the other side of the fuel tank. This is because the incendiary element is located in front of the armour piercing core, and the external wall of the door-tank is more than enough to initiate ignition, and the incendiary blast will be partially outside the fuel tank, and partially inside, but due to the spaced effect and the presence of fuel, the blast will not be able to reach the interior side of the fuel tank.

So we know that if fuel is to be ignited, it will only be ignited outside the fuel tank. But what of the steel penetrator core that's still flying straight through the fuel tank? Fluids, including diesel fuel, are more than capable of slowing down or even outright defeating ballistic projectiles given sufficient volumes of it. How much is needed to stop specific bullets is not known, but with two thick armoured walls on either side, it's not hard to imagine that the rear doors could probably resist 7.62x51mm AP rounds without much effort. Large caliber artillery splinters would find themselves quickly stopped due to their irregular shape, but not before punching large holes into the outer walls. The parts of the rear doors cut out for firing ports do not hold fuel, but are compensated with an additional layer of armour welded on top of the door as shown below:

These add-on plates reportedly have a thickness of 6-8mm. As such, the total thickness of steel at this zone would be between 24-26mm, and the protection value is increased by the curvature of the pressed steel door.

Given these facts, it's easy to see how the designers approached the task of increasing protection without increasing weight, as that was critical to the vehicle's amphibious qualities. The outer plate is thick enough to prevent punctures from most threats and the rear doors as a complete unit can resist most shell splinters from large caliber artillery and most small arms fire. The only credible threat within the context of the role of the BMP-2 would be heavy machine guns firing armour piercing ammunition, but in reality, the chances of a BMP-2 exposing its rear end to a heavy machine gun emplacement or a vehicle armed with one is exceedingly low that it may as well be a non-issue.

But for all that, the crew's initiative still plays the most important role. It is important to remember that both rear doors only hold a combined total of 122 liters of fuel out of a net total of 460 liters. In other words, the crew could easily make do without having them filled when in combat. It was never an issue in the first place, since Soviet vehicles have always carried more fuel than most, and even without the contents of the rear doors, the BMP-2 would still carry nearly the same amount as the M113. The rear doors may be filled with water, or soil, or sand to totally nullify the chance of fire and further boost its resilience. The website "Box O' Truth" did their own tests on the effectiveness of sand as a bullet stopping obstacle in their article "The Sands of Truth", which can be found here (link). As it turns out, 7.62x51mm ball ammo won't go through 5 1/2 inches of sand (139.7mm) of sand, nor will 5.56mm SS109 rounds. But what are the dimensions of the rear doors?

Well, they measure about 275mm wide at the widest at the top, tapering down to 172mm wide at the thinnest at the bottom. This site (link) states that a single .50 cal M2 AP round fired from the barrel of an M2 machine gun is capable of penetrating:

Taking 275 to 172 milimeters of sand together with the ~5mm and 13mm steel walls of the rear doors, it appears that the doors have a reasonable chance of shrugging off .50 cal AP bullets at short range. If not, then the occupants are at least fully shielded from 7.62x51mm AP bullets, though they probably wouldn't need the sand for that. Even if the fuel doors were empty, they would still be as good as what some other IFVs have for armour. Take the CV90 as an example:

In conclusion, there is more than enough evidence indicating that the armour on the BMP-2 was far from "paper thin". While it is true that its contemporary the M2 Bradley had greatly superior side armour with its double spaced armour configuration over its one inch thick 5083 aluminium hull, some context is needed before direct comparisons can be drawn. The M2 Bradley had to contend with powerful Soviet 14.5mm machine guns which could be found on the majority of BTR-60 and BTR-70 armoured personnel carriers as well as BRDM armoured cars, whereas the BMP-2 only had to face off against .50 caliber machine guns. Hunnicutt says that the Bradley's side armour is resistant to 14.5mm AP rounds from 200 meters, and it has been shown that the BMP-2's side armour is theoretically resistant to .50 cal AP rounds from around 400 meters. In practical terms, the fact that the side armour of the BMP-2 is nominally weaker is a minor detail. When seen in the appropriate context, the BMP-2 was not worse than its contemporaries in armour protection.

Immediately as the Afghan campaign began in earnest during the turn of the decade, chinks in the BMP-2's armour began to show. Although the vanilla BMP-2 was more than good enough when faced with Kalashnikov fire, it was almost immediately apparent that heavy machine gun fire from Mujahideen ambushes (usually from a DShK) could easily perforate the 16 - 18mm side armour at very close distances. To counter this development, the BMP-2D, also known as the "Afghan BMP" variant was created. It introduced an array of armoured spaced plates mounted over the upper sides of the hull and a steel side skirt draping down from the overtrack sponsons to protect the bottom half of the hull. The top strip on the upper side was also reinforced with an extra sheet of 6mm steel welded on top of it. Contrary to some claims, the front hull armour was not reinforced, only the belly.

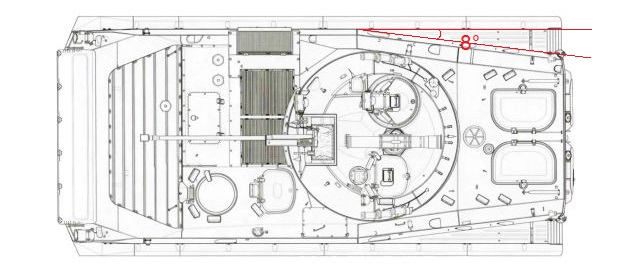

The decision to only add protection to the sides and rear of the vehicle and not the front was informed by actual data gathered during the conflict. Ignoring the fact that the front of the vehicle was immune to 12.7mm machine gun fire, real combat damage reports showed that the front was almost never targeted by enemy forces throughout the duration of the war. According to the study "Исследование Боевых Повреждндений Образцов Отечественной БТТ" (Study of Combat Damages To Samples of Domestic BTT), the distribution of hits sustained by BMPs from armour-piercing bullets was 33% to the sides of the hull, 50% to the rear of the hull and 17% to the roof of the hull. The turret did not receive any damage or received a statistically negligible proportion of damage. Thus, additional spaced armour plating was allocated to the side and rear projections of the BMP-2D.

The steel side skirts are 6mm thick, and so are the steel panels on the hull sponsons that were mounted about two inches away from the base armour. The protective mechanism was twofold - it forced the incendiary element of an API bullet to deflagrate early and expend itself in the spaced gap, and it also chips off part of the penetrator core and creates fractures so that when it impacts the high hardness steel armour plate of the hull, the bullet shatters completely. If the bullet impacts at a higher obliquity, the armour piercing core can be shattered completely, thus completely neutralizing it as a threat.

Those two factors, in addition to the thickness of the panels themselves, entirely neutered the threat of 12.7mm and 14.5mm shots across the side of the hull even from close range. Extensive research on the effects of spaced armour with hard but thin sheets on high caliber armour piercing bullets has shown that even sheets as thin as 4.4mm are capable of shattering 12.7mm B-32 steel cored API bullets at shallow angles beginning from 20°, and that the same can be done with 5mm sheets on 14.5mm B-32 steel cored API bullets, or even tungsten carbide-cored BS-41 bullets. Indeed, that was precisely what the famous "bazooka plate" spaced armour on Pz. IV tanks was actually meant for, and not for defence from bazookas. The original double-spaced side hull armour configuration on the M2 Bradley was implemented for the same reason: protection from 14.5mm machine guns at distances as close as 200 meters, although the Bradley's side armour required two layers of spaced steel plates because bullets do not shatter easily on the soft and thin aluminium hull.

In addition to ballistic protection, the new side hull armour contributed to the vehicle's increased survivability from roadside IEDs, which were often composed of a cluster of partially buried artillery shells rigged to explode all at once. The extra steel side skirts would be extremely useful for defeating such shrapnel as artillery shell splinters lack an efficient ballistic shape and would break apart much more readily on non-homogeneous armour than the core of an armour-piercing bullet.

The floor of the hull is 8mm thick in all incarnations of the BMP-1 and BMP-2. It is stamped with reinforcing ribs for added stiffness, both for structural reasons as well as to reduce deflection from the influence of an explosive blast. A small 1.5 kg track-breaking mine exploding under the track would easily rend the track and blow off a roadwheel, but it would not pierce the belly. Heavier anti-tank mines were a much more serious challenge to overcome.

The BMP-2 features a collective NBC protection suite, collective meaning that the interior of the vehicle is fully sealed from the outside environment, so that the crew and passengers do not need to don hazard suits. Beginning in 1984, the BMP-2 received a lining and cladding of anti-radiation pads. The BMP-2 obr. 1986 had the cladding fitted since the beginning of its production.

The turret cladding is called "Nadboi". It is about an inch thick, and most likely made of laminated borated polyethylene fiber sheets. If you look closely at frayed edges (photo below), you can see that it is distinctly fiber-like.

The walls of the turret are entirely covered with it, and so is the roof. "Podboi" is designed to absorb neutrons from a nuclear explosion.

The interior walls of all of the occupied compartments of the vehicle is lined with an anti-radiation lining. It is effective at capturing neutrons, but more importantly, it has the secondary purpose of providing some much needed insulation. This is especially important if the vehicle is coated in burning napalm, seeing as the steel for the roof is only a little more than half an inch thick.

Swedish tests on purchased ex-East German T-72s found that its lining of borated polyethylene was extremely effective at capturing spall, so it should be no different for the BMP-2, although the lining in the BMP-2 is much thinner. The external cladding should also give some small bonuses towards the overall effectiveness of the turret armour. The anti-radiation lining is notably absent from the the rear fuel doors, but this is not a problem. Water is surprisingly effective at absorbing radiation. Presumably diesel fuel is, too.

The protruding bow of the hull is crammed chock full of equipment, including a GO-27 gamma radiation detector. You can see it mounted to the starboard side hull in the photo below, to the left of the steering column.

The GO-27 sensor and automatic sealing system is responsible for detecting nuclear and chemical particles and for initiating the lockdown protocol. Every gap and port exposing the interior of the tank to the outside environment will be sealed, and the ventilation system will be put into supercharge mode.

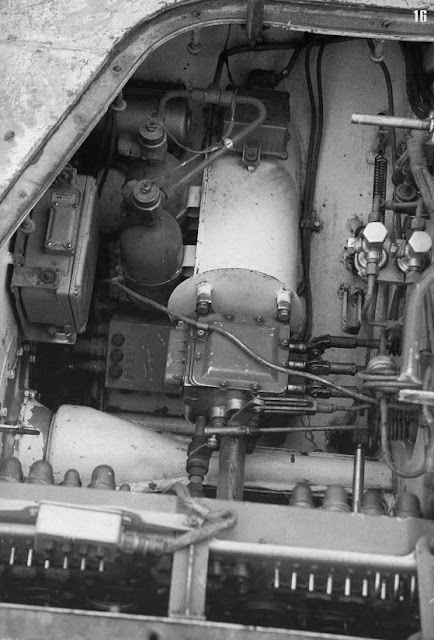

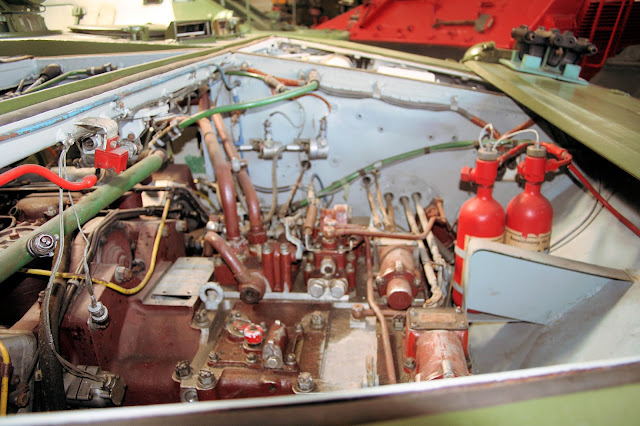

The automatic fire extinguishing system is only installed in the engine compartment. It operates on four TD-1 thermal sensors placed strategically around the engine to ensure a higher chance of prompt detection. On paper, at least. There are two five-liter fire extinguishers containing halocarbon agent 114B connected to the automatic fire extinguishing system. The fire extinguishers and a single TD-1 thermal sensor can be seen in the photo below (TD-1 is on the left side of the frame, above the green tube)

In addition to that, there is a single handheld OU-5 five liter carbon dioxide fire extinguisher placed in the passenger compartment. Not very effective, to be honest. If the vehicle was hit and the interior was on fire, the first thing to do would be to bail out and run, because any fire would probably escalate into a blaze, because of the centerline fuel tank. Although the BMP-2 is just as well armoured as any other IFV, it is distinctly worse off if the armour were penetrated.

The BMP-2 is the communal steed for the nine men (including the crew) that comprise a typical Soviet motor rifle squad. On paper, the BMP-2 is designed to fit a maximum of ten people, but when employed as per doctrine, there will be one seat left empty. For dismounts, six men would be seated in the passenger compartment behind the turret, and the seventh - the squad leader - sits in the turret as the commander of the vehicle. The seat behind the driver is left empty unless a ten-man squad is deployed. The BMP occupied by the Platoon Leader is the so-called "Platoon Headquarters". This vehicle carries only two passengers, the Platoon Leader and the Assistant Platoon Leader.

The eighth man in a ten-man squad may be a MANPADS gunner attached to the vehicle from company assets, or some other specialist. One rifleman in one of the squads of the platoon may be a designated marksman, and issued an SVD instead of an AK-74. If a ten-man squad is deployed, it is possible to run the BMP-2 with a full three-man crew and have seven dismounts.

The composition of a typical dismount squad is as follows:

The maximum number of troops carried per vehicle is less than the eight passengers carried by the BMP-1 (shown below) by one, but this is not too bad as both the BMP-1 and BMP-2 carry a squad of the same size. The missing seat will result in a BMP-2 platoon carrying fewer specialist personnel like medics. However, this can be remedied by removing one of the riflemen and replacing him with a specialist. Overall, the fighting efficiency of a BMP-2-based Soviet motor rifle platoon increased substantially over one based on the BMP-1, mostly thanks to the higher power of the 2A42 cannon.

The firepower of a Soviet motor rifle platoon is quite similar to a U.S Army mechanized infantry platoon in most regards. The M2 Bradley could seat nine men; six of them being dismounts. As the commander of a Bradley Fighting Vehicle (BFV) does not dismount, a BFV platoon would be numerically inferior to a BMP platoon, but the IFV would be more potent due to having a full crew. However, this can be countered by deploying a ten-man BMP squad. If ten-man squads are deployed in the BMP platoon, the disparity would be even larger, and the BMP platoon would gain additional capabilities due to having a full crew.

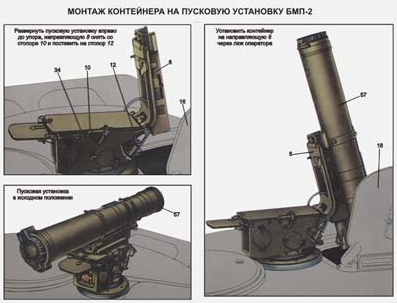

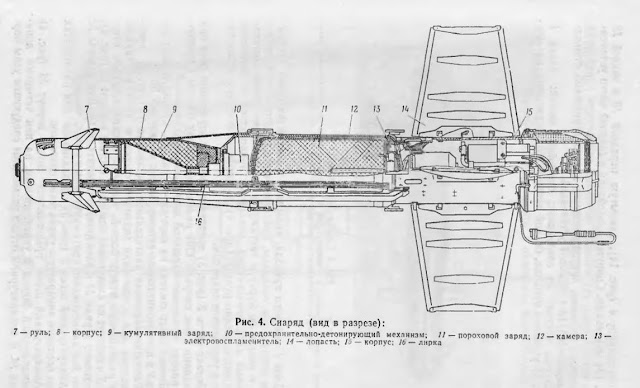

A BFV squad should be slightly superior in issuing lead, since they have a belt-fed squad automatic weapon (M249) rather than a magazine-fed one (RPK), but this is offset by the extra rifleman in a BMP squad. With regards to anti-armour and anti-air firepower, a BMP platoon is significantly superior. As you may recall, there is a 9P135M missile launcher mounted at the back of the turret basket of the BMP-2. This 9P135M launcher can be used alongside the missile launcher on the BMP-2 and the RPG-7 carried by the grenadier to seriously increase the anti-armour and anti-bunker capabilities of the squad. In addition to that, the BMP-2 has a means of defence against air attack, as there is an extra seat that may be occupied by a dedicated MANPADS operator. Otherwise, the seat can be used to store extra supplies. The introduction of the M2A1 Bradley equalized the difference in manpower, as it carried seven dismounts as opposed to six, but the BMP squad's advantages in anti-armour and anti-air firepower remain. It was not until much later that the BFV platoon gained a decisive advantage with the introduction of the Javelin and the wide proliferation of the M240B.

The height of the hull is 1,210mm, the width of the hull (not including the sponsons) is 2,250mm and the bench on which three people are supposed to sit on is only around 1,400mm long. After subtracting the thickness of the roof and belly armour, the internal height of the hull at the passenger compartment is 1,197mm. The height of the hull would be considered good in a tank but only because the seats are typically mounted close to the floor and the occupants are provided with a certain amount of legroom. In the case of the BMP-2 (and BMP-1), the low height of the hull forced the seats to be mounted close to the floor but the hull is too narrow to permit the passengers to stretch their legs.

With bulky body armour, personal firearms, hundreds of rounds of ammo or even winter clothing, a ride in the BMP-2 can be very oppressive indeed. For a short trip of half an hour or so, a seasoned soldier should have very little to complain about as it is certainly much better than walking, and on long marches in unattractive weather, it may even be luxurious, but the total lack of stretching room and the shoulder-to-shoulder arrangement becomes incredibly uncomfortable as time drags on. However, according to military historian Kenneth Estes, the BMP-1 actually met all U.S Army ergonomics requirements after evaluations were conducted on captured examples. It could be surmised that the designers sought to provide an acceptable level of comfort without compromising the mass and silhouette of the vehicle and succeeded.

The benches are well padded with thick cushions. The benches are mounted to the floor with a clearance of only about 20 cm, so passengers have to draw their knees up almost to chest level when seated, which is rather disconcerting, truth be told.

The real estate underneath the port side half-bench is perfectly sized for two "spam cans" of 5.45x39mm or 7.62x39mm ammo, or a crate of hand grenades, or a crate of 40mm grenades. The other half of the bench is a fuel tank with a cushion on it, so nothing can be stowed under it. The starboard side half-bench has the fuel pump underneath it, so no luck there.

The back of the seats nearest to the door are shelves. Stored inside is a fuse box, and some relay boxes. The bottom shelf is usually empty. "Spam cans" of ammunition can be stowed here. The photo below shows such a shelf in a BMP-1.

The squad leader is seated behind the driver, where the commander in a BMP-1 would be seated. The squad leader's seat is accessible through the rectangular hatch above it. The squad leader has the "privilege" of being provided with two periscopes. One aimed forward, and one aimed to the forward-left. The (low quality photo) view from the forward periscope is pictured below.

There is nothing else of interest in his station. It's worth noting, however, that being forced to use the hatch the exit the vehicle and not doors like the rest of the passengers makes the squad leader's station a poor place to be, as you'd not only take longer to dismount, you'd be exposed to all and sundry while you are on the hull roof, and you'd have to jump down from quite a height. It's also a lot harder to get out if you are wearing body armour or winter clothing. All this has made the squad leader's seat a rather unpopular one, so unsurprisingly, some BMP-2 operators have opted to cut the squad down to six men and omit the seventh passenger. Instead, his spot is used by the crew to stow their personal effects, plus extra ammunition and first aid kits and anything else that might be needed.

The passengers get one fixed TNPO-170A periscope each, aimed to the side and slightly forwards. The visibility from these periscopes is adequate for providing the passengers with a sense of their surroundings and can help them find targets to fire at from their firing ports.

Both of the rear doors have a single TNPO-170A periscope in them as well. (photo below is of Czech OT-90, but is identical)

The ventilation system of the BMP-2 is composed of four small air inlets located on the edges of the hull roof. Filtration of chemical and biological particles is accomplished by fabric-type filters inside. These ventilators are also responsible for generating an overpressure inside the vehicle when entering NBC-contaminated areas.

This ventilation system also has a heating system and directed air outlets for every passenger (Green) in front of the fume evacuation inlets (Red). The pipes for these systems can be seen here:

As you can see, the air outlets are placed just next to a periscopes. This is approximately eye level, so each passenger gets a weak stream of cool air blown in his face. Heat for the heating system is not generated electrically, but by the circulation of water around the engine. It would get hotter when the vehicle is in motion, and less so when idling.

There is a narrow corridor between the driver's station and the passenger compartment. A similar corridor exists in the BMP-1, but that one is larger due to the smaller turret. Although it is incredibly narrow, it is still possible to pass through this corridor in the BMP-2. The corridor is useful when doing work in the vehicle, as it allows tools and parts to be transferred from the cramped driver's station to the passenger compartment, but otherwise, it is not to be used in normal operations. During combat, it should only be used in case of an emergency where exiting via the driver's hatch or the squad leader's hatch is not possible.

A similar corridor is present in the M2 Bradley.

A simple perimeter shield separates the turret from the passenger compartment, lest any accidents happen to the person sitting closest to the turret.

For the passengers in the passenger compartment, there are two entry and exit paths to choose from: the roof hatches, or the rear doors. The former option admits only one person at a time, and jumping down from almost six feet up isn't the most appealing idea when the vehicle is in motion, and even if the vehicle was static, the roof hatches are mostly used only under unusual circumsmtances, like if the vehicle is sinking in water. They are far more suitable for other things like getting fresh air, shooting at airplanes, and so on. The roof hatches are spring-loaded with torsion bar springs and locked in place with a simple lever. When a passenger turns the locking lever, the hatch springs open and it can be locked in the open position by pushing it further until it is held under spring tension. The less interesting option for dismounting the BMP-2 is, of course, the rear doors.

The infantry was perceived to be most effective if they disembarked at a range where they could use their weapons most effectively. Soviet strategists estimated the ideal disembarking distance to be between 200 and 400 meters. Stopping the vehicle to allow the infantry dismount at such a close distance to the enemy was simply not an option. The only way to stay alive in the absence of adequate cover was to keep moving, and keep shooting, so the infantry must disembark while the vehicle is doing this at a reduced speed. The current accepted convention of a ramp with a single door would not suffice, as the door would be suitable on the move, but would be (and it usually is, even in modern vehicles) too small too allow for the rapid exit of all of the passengers at a reasonable pace, and the wide ramp cannot be deployed on the move. The most optimal configuration for the expected role of the BMP as it was envisioned was a pair of wide doors.

1PZ-3

Besides manning the periscopes and managing the vehicle, the commander is also in charge of fending off air attacks. To do this, he is provided with a 1PZ-3 anti-aircraft sight mounted on the turret ceiling in front of his cupola. It can also be used as a backup sight for ground targets if the need arises. When not in use, the aperture window is covered by an armoured hood.

The 1PZ-3 sight is monocular with a very large range of elevation. It features internal electric heating and has two special light filters. The sight can be used without a filter when firing upon ground targets, but if necessary, a "Special" filter or a "Neutral" filter can be applied by turning a lever. The "Special" filter is simply a laser protection filter that protects the operator from being blinded by direct laser illumination, and the "Neutral" filter is a neutral density filter that reduces the amount of light that is transmitted to the operator's eyepiece, thus darkening the image. This makes it easier for the operator to detect and track aircraft in the sky during bright daylight hours, but it can also be used when engaging ground targets if necessary.

The sight lacks independent stabilization, but because of its direct mechanical connection to the stabilized 2A42 cannon in the turret, the sight is stabilized in the vertical plane. However, due to the coarse nature of this type of stabilization, the stabilization precision is not high and the viewfinder image may vibrate when the vehicle is moving on rough ground. The sight can elevate and depress as far as the cannon can, which would be from -5 degrees to +75 degrees in elevation.

The sight has two magnification settings; 1.2x and 4x. The field of view through the sight is 49 degrees in the 1.2x setting and 14 degrees in the 4x setting. The lower magnification was only suitable for engaging aircraft. Shooting at air targets flying at subsonic speeds is theoretically possible at ranges up to 2,500 m and at altitudes up to 2,000 m. In practice, the effective range is much less.

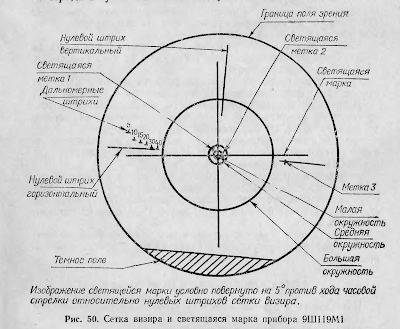

The two images below show the sight under the 1.2x and 4.0x magnification settings.

As far as anti-aircraft sights go, the 1PZ-3 had no outstanding characteristics and contained only the essential markings for leading moving aircraft. The sight also has the secondary purpose of serving as the commander's only optic for ground targets and being the BMP-2's backup gun sight as well, and to that end, its viewfinder provides graduated range scales and simple deflection markings, as shown in the images above. To aim, the operator turns a knob to raise and lower a horizontal line until it matches the desired mark on the fixed range scales. The horizontal line forms a crosshair with the fixed vertical line running down the center of the viewfinder. The operator elevates the autocannon or coaxial machine gun of the BMP-2 until the crosshair is superimposed on the target, and then he can open fire.

The commander may override turret and weapons control at the press of a button and take over using the control handles that he is furnished with.

Here is a screenshot of the reticle of a 1PZ-3, taken from a video of a BMP-2 firing its cannon:

These tools, taken as a whole, mean much more than the sum of their parts. The independent surveillance equipment, target designation, duplicated gunnery controls and independent sighting systems give the commander a level of dominance over his own machine that many of his NATO counterparts did not have. While the commander of an M2 Bradley did have a gunsight extension to see what the gunner sees and a set of gunnery controls to use them with, he did not have a sight of his own, as there was no backup sight, and he did not have his own cupola and he did not have a magnified optic with a stadia rangefinder. The BMP-2 had all of these, and the BMP-2 had a fully matured hunter-killer capability to go with it.

COMMUNICATIONS

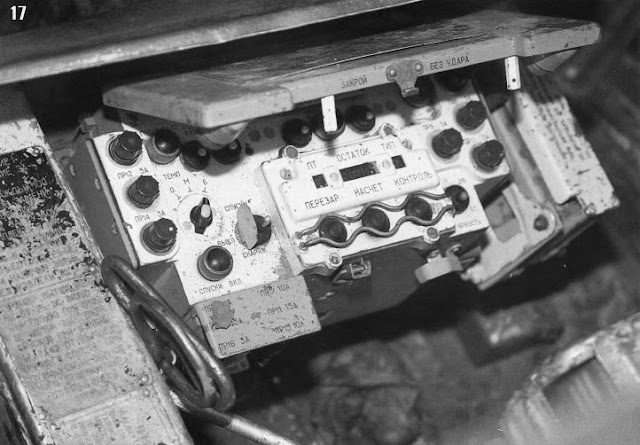

From the introduction of the BMP-2 in 1980 until 1984, the commander was in charge of the R-123M radio, installed at the very rear of the turret shelf (the turret is wider than the turret ring, so there is a wide shelf at the base). Voice transmissions are done using the throat microphone integrated into his tanker's helmet. The throat microphone is reportedly of good quality and much more useful than an open microphone. The commander can listen to both extra-vehicular transmissions or communications from his own crew from the headphones of his tanker helmet.

R-123M

The R-123 radio had a frequency range of between 20 MHZ to 51.5 MHZ. It could be tuned to any frequency within those limits via a knob, or the commander could switch between four preset frequencies for communications within a platoon. The switching process takes 3 seconds to complete. The radio has a transmitting and receiving range of between 16km to 50km, depending on the antenna used and the type of terrain. The R-123M had a novel glass prism window at the top of the apparatus that displayed the operating frequency. An internal bulb illuminated a dial, imposing it onto the prism where it is displayed. The R-123M had an advanced modular design that enabled it to be repaired quickly by simply swapping out individual modules.

The dismounted squad leader will have an R-392 or R-126 radio to communicate with the commander of the BMP-2 at shorter distances. The squad should be operating 800 meters away from its BMP at the most, though this obviously is dependent on the tactical situation as well.

R-173

In 1984, the now-outdated R-123 radio was replaced by the R-173 radio, which had a frequency range of between 30 MHZ to 75.999MHZ. It has 10 preset frequencies. It had an electronic keypad for entering the desired frequency, and an LED display. Its main improvement over older radios is the ability to send encrypted analogue and digital signals.

R-168-2UE-2

Sometime in the late 2000's, most BMP-2s had a new and advanced R-168-2UE-2 frequency-hopping encypted radio installed to replace the obsolete R-173, which was found to be susceptible to eavesdropping and jamming during the first Chechen campaign/invasion.

The R-168 family of radios is now standard throughout the Russian ground forces, from infantry platoons to tank companies. It can produce frequency hops 100 times a second, and the data is encrypted as well. It can also send and receive digital data.

The commander can exit the vehicle by two means - the hatch above him, or by spinning the turret to face the rear, and then going out through the passenger compartment. In the latter case, he must swing open the turret basket perimeter shield (shown below) to exit the turret. The last two photos are provided courtesy of Mr. Tim Gow from the excellent megablitzandmore blog for modelers.

Besides the necessary tools and spare parts, there isn't much space inside the vehicle for stowing long term supplies. The turret doesn't have external bins or baskets either, but it does have numerous loops around its rear perimeter, as you can see below.

The loops are meant for securing foliage and camouflage netting on the turret, but the crew can strap their personal effects onto them too.

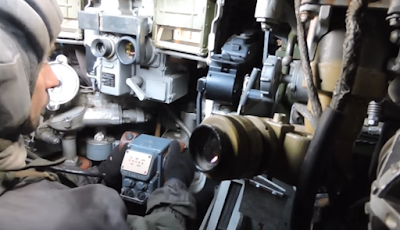

GUNNER'S STATION

The gunner's station is relatively sparse. All of the weapon controls are placed directly in front of the gunner, and most of the accessories, including the intercom control box, dome light and the turret traverse lock are arranged around the turret wall. The gunner has three fixed general vision periscopes, two on each side of his primary sight and another aimed to the left. The gunner is also provided with a TNPT-1 rear view periscope in his hatch. This periscope lets him see directly behind the turret. All in all, the gunner has the same number of general vision periscopes as a BMP-1 gunner but

This gives him relatively good visibility and he can take over the vehicle from the commander if the commander dismounts with the passengers. The gunner's has no periscope aimed to the right of the turret, and it was not really possible to provide a view to the right at all because the ATGM launcher already occupied that part of the turret roof. Compared to its direct foreign counterparts, the BMP-2 accommodated its gunner quite well in this respect. The gunner in an M2 Bradley, for instance, has two general vision periscopes flanking the ISU (Integrated Sight Unit) covering the 11 o'clock and 1 o'clock sectors like in the BMP-2, but half of the view from both periscopes is blocked by the large housing for the sight and the view from the left periscope is completely blocked when the TOW launch pod is raised. A Marder 1 gunner had three periscopes, but they only covered the left side of the turret and were evidently only meant to compensate for the commander's inability to see to the left as the view was completely blocked by the external autocannon installation and the gunner's sight.

SIGHTING COMPLEXES

BPK-1-42

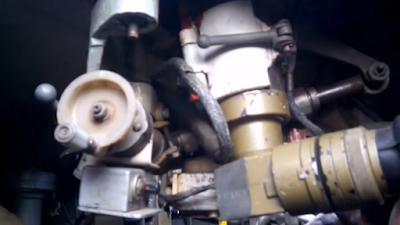

The BPK-1-42 combined day-night sight was the primary sight for a BMP-2 gunner. It has a fixed magnification of 5.6x in the day channel, and a fixed 5x magnification in the night channel. Rangefinding is accomplished with a stadiametric scale in the lower right corner of the sight view finder. The BPK-1-42 sight has dependent stabilization in the horizontal and vertical planes. The elevation limits of the mirror head of the sight ranges from -8 degrees to +30 degrees. The stabilization system of the weapons provides dependent stabilization to the sight via a simple connection rod.

The active mode requires the use of the co-axially mounted OU-5G infrared spotlight for illumination. Although the OU-5G spotlight is only approximately the same size as the OU-3 spotlight used for the commander's TKN-3B periscope and is only rated for a somewhat power of 180 W, its illumination capability is greatly superior as it uses a xenon lamp instead of an incandescent lamp. It has a white light output of 15 million Candelas - half that of the L-4A spotlight used on tanks, which also used a xenon arc lamp but ran on 600 W.

Using the IR spotlight, the nominal maximum detection range for a tank-type target is 650-900 meters. The main issue is that by the time the BMP-2 entered service in the early 1980's, active infrared illumination was entirely anachronistic as NATO ground forces had already shifted completely to passive systems including image intensifier technology and thermal imaging technology. On the BPK-1-42, the passive mode has the obvious advantage of not emitting any radiation which might be picked up by the surveillance equipment of enemy forces.

The nightvision optic is equipped with an electric shutter linked to the trigger on the gunner's handgrip, which is in turn linked to the BU-25-2S control console (we will examine this later under the 2A42 section). Every time the cannon fires, the shutter activates and protects the aperture from the blinding flash. This is because the light intensification tube operates on extremely high voltages to amplify ambient light to visible levels. If a bright flash was captured, the intensification tubes would burn out from the huge power surge, or even explode. This would happen behind the thick aluminium casing of the sight casing, but he gunner is not entirely safe. Although the image intensification tube would be destroyed, it would still put the amplified image of the flash on the eyepiece for a split second, potentially blinding him.

The right eyepiece is for daytime use. First, the gunner finds the range to the target using the stadiametric rangefinder. Then, he inputs the range into the sight using a dial located on the right side of the sight housing. The chevron aiming point and the range scales will then drop until the fixed range indicator markings align with the desired range on the range scales. Then, the gunner uses the handgrips and elevates the cannon until the dropped chevron is placed squarely on the target, thus obtaining a ballistic solution. This video is recommended if the written description is insufficiently clear (link). The viewfinder markings may be illuminated by an internal light bulb to facilitate aiming at twilight hours.

Both the active and passive night channels use the same viewfinder, but due to the constricted field of view through the night channel, the range adjustment scales and stadia rangefinder scales were blocked out, leaving only the reticle in the center of the viewfinder. This was permissible because the viewing range of the sight was only 800 meters, so fire correction can be done by using the burst-on-target gunnery method. However, the gunner could still shoot further than 800 meters if the conditions allow it. When using the BPK-1-42 sight at night, the range is set to a battlesight of 800 meters. In this setting, the tip of the center chevron and the upper tip of the windage marks are calibrated for a distance of 800 meters and the bottom end is calibrated for 1,200 meters. Rangefinding can be done knowing the angular values of the chevron and lead lines. By comparing the height and width of the target to these markings, the gunner could then estimate the distance using a formula. However, the probability of achieving a hit with a short burst from the autocannon using only the battlesight technique is quite high due to the short distances involved.

The viewfinder of the sight is shown below. Note the small field of view in the night channel (represented by the small circle around the reticle) compared to the day channel.

The sighting range against ground targets with BT (AP-T) shells is 2,000 meters. With OFZ (HE-I) and OT (F-T) shells, the range is 4,000 m. Obviously, the lack of any serious rangefinding equipment is an serious detriment to the ability of the gunner to quickly and efficiently dispatch armoured threats. Still, it is some consolation that this shortcoming is not something exclusive to the BMP-2, and that all of its chief rivals, namely the Marder 1 and Bradley, are similarly neglected in this department. The Bradley, for example, did not receive a laser rangefinder until the M2A2 ODS modification in 1991, by which time the BMP-2s of the Soviet Army could hardly be considered a threat for obvious reasons.

Nevertheless, the BMP-2 was somewhat disadvantaged in that its 30mm AP-T shells had a much lower muzzle velocity compared to the 20mm and 25mm APDS rounds that the Marder 1 and M2 Bradley used. It would be easier for a Bradley gunner to obtain a first round hit using his stadia rangefinder or by using the gunnery techniques such as battlesight and bracketing thanks to this advantage. The advantage held by the BMP-2 gunner is the high rate of fire of the 2A42. He can use the battlesight technique to fire off a burst without delay after seeing a target, and then rely on the dispersion of the shells to obtain at least one hit. The disadvantage, of course, is the high expenditure of ammunition for a relatively small effect on the target.

The sight aperture is protected by a pane of ballistic glass, but there is also a retractable steel cover that could be opened and closed from the inside of the turret. The steel cover only covers the nightvision channel aperture. This helps to prevent accidental exposure of the nightvision system to bright light in daytime. The decision to not have any protection for the daytime sight aperture is very strange.

In March 1986, the BMP-2 was modernized into the BMP-2 obr. 1986. One of the upgrades was the replacement of the BPK-1-42 with the BPK-2-42. The most noticeable difference is the revision aiming reticl. The daytime sight channel was slightly improved with a fixed 6x magnification to extend the engagement envelope, and the nighttime channel was also slightly improved with a 5.5x magnification. The sight provides an angular field of view of 10° in the daytime channel and the 6°40′ in the night channel. The increased field of view was partly due to the expansion of the windage markings.

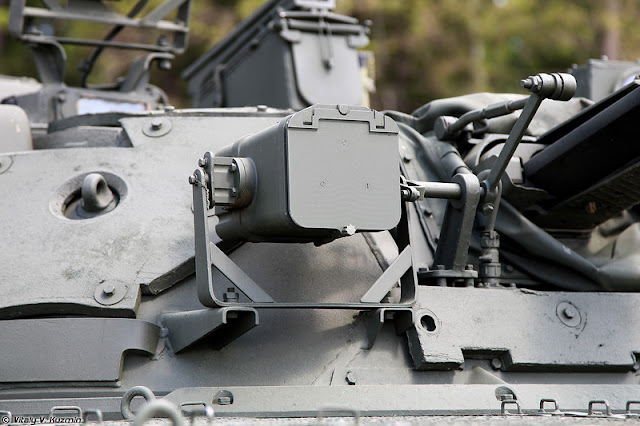

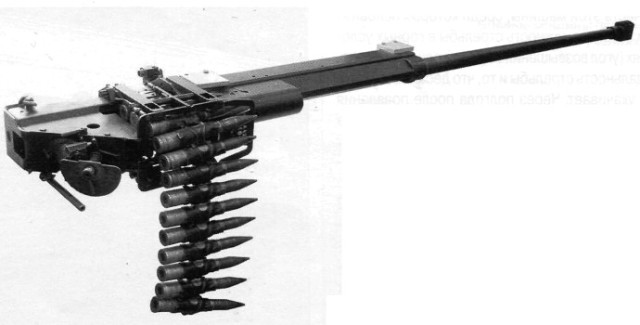

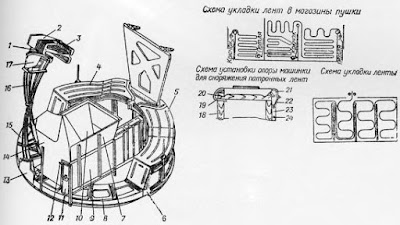

All of the BMP-2s used in the Suvorov Attack challenge during the International Army Games 2016 and 2017 were equipped with the PL-1-01 laser beamer instead of IR spotlights. The PL-1-01 is a pulsed laser beamer that can be used for illumination, replacing the previous infrared spotlight. The BPK-2-42 sight is not compatible with the PL-1-01, so it must follow that the original sights have been swapped out for the newer TKN-4GA-01, or TKN-4GA-02, or SOZh. The photo below (Credit to Vitaly Kuzmin) shows the PL-1-01 on the right hand side of the cannon.