The development of the BMP-1 was linked to the development of the tanks in the Soviet Army. In the mid-50's, requirements for a prospective new medium tank were drawn up, and in doing so, it was realized that existing armoured personnel carriers would be left behind during fast-paced offensive maneuvers if the new machine was realized. Moreover, the motorized infantry would not be able to fight effectively in an environment contaminated by weapons of mass destruction. Closer cooperation between tanks and infantry was identified as a mandatory requirement under the new vision of mechanized warfare for the survival of both the tank forces and the infantry, so it was decided that an entirely new class of troop carrier was required for the future Soviet Army.

From 1959 to 1960, the GBTU (Main Armored Directorate) carried out research work on the development of the concept and the development of basic tactical and technical requirements for the new combat vehicle. During the developmental process, all existing domestic and foreign troop carriers were analyzed with the intent to identify promising solutions, and the objective was to create a Soviet IFV that was superior to the best foreign counterpart that was projected to appear in the late 1960's based on current trends.

It was to be a fully armored and sealed amphibious vehicle with high off-road mobility that could accommodate 7-10 men. The vehicle had to be fast enough to keep up with tanks and it needed to have the same travelling range as tanks at the very minimum. Full NBC protection was mandatory, and the passengers had to be able to use their personal weapons from within the vehicle without compromising the hermetic seal of the vehicle. When the passengers had to dismount, it was stipulated that they must be able to do so conveniently and with concealment and protection from incoming fire. In addition to the small arms carried by the passengers, the prospective IFV was required to have a powerful rapid-fire weapon with anti-tank capabilities to ensure its ability support infantry during offensive operations and repel the armoured vehicles of the enemy during defensive operations. However, a fire-on-the-move capability was not required.

Due to the large number of motorized rifle units in the Soviet Army and their high concentration relative to tank units, it was determined that the prospective IFV had to be inexpensive and simple to produce. The size and weight of the IFV had to be as low as possible to minimize metal consumption, it had to have a simple construction for ease of manufacture, and it had to use existing and inexpensive components from the automotive tractor industry.

Initially, an autocannon with a caliber of 20mm or 23mm was specified as the main armament of the prospective IFV, but this specification was reevaluated in the early 1960's. Instead, the feasibility of autocannons in the 30mm, 37mm and 45mm calibers and medium caliber semi-automatic guns in the 57mm, 76.2mm and 73 mm calibers with rocket-assisted projectiles was investigated. The caliber of the weapon was constrained by its recoil force which had to be within certain limits because an excessively large turret ring would take up too much space and thus reduce the number of passengers or force the size of the vehicle to be increased. As a result of a general directive by Soviet Premier Nikita Khrushchev to reorient the direction of Soviet military weapons technology development from traditional ballistic weapons towards rockets and rocket-assisted weapons, the GBTU chose the 73mm smoothbore gun concept with rocket-assisted grenades. In theory, the decision to install this weapon drastically widened the scope of the prospective IFV, as it provided the capability to destroy any enemy armoured vehicle and also eliminate entrenched enemy targets and machine gun positions in support of dismounted infantry who would be responsible for neutralizing enemy infantry with their own small arms.

After this decision was made, the Tula KBP Design Bureau (now the KBP Joint Stock Company) designed the 73mm 2A28 cannon and created a prototype one-man turret that featured an autoloader with a capacity of forty rounds and an integrated launch system for the "Malyutka" ATGM, of which four would be carried. The main gun was supplemented by a PKT coaxial machine gun. There was no requirement for a stabilizer, so the prospective IFV could only fire accurately when it was stationary. The turret ring diameter of this turret was 1,380mm, which was considered acceptable. All prospective IFV designs were required to fulfill the criteria put forth by the GBTU and all had to be compatible with the new one-man turret.

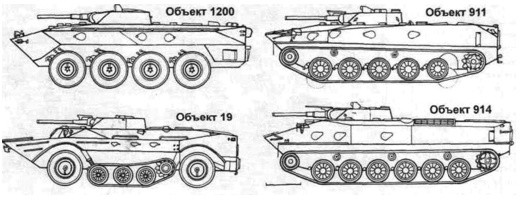

The participants of the competition were the design bureaus from Chelyabinsk (ChTZ), Kurgan (KMZ), Altai (ATZ) and Volgograd (ZiL). The Object 765 first prototype was made at ChTZ in 1962, the second in March 1963. In 1963 the vehicle passed factory tests and it was deemed suitable for conducting military tests. In July 1961, the project documentation from the ChTZ, ATZ, KMZ and ZiL design bureaus was evaluated. A total of eleven designs were submitted, of which five met the general requirements and proceeded to military tests at proving grounds in Rzhevka and Kubinka. They were the Object 19, Object 765, Object 911, Object 914, and Object 1200. Most of these prototypical designs incorporated a water jet, and many of them used an identical system to that of the PT-76. Of the five competing prototypes, the Object 765 and Object 914 were the only fully-tracked designs. The Object 1200 had a wheeled chassis in an 8x8 configuration, while the Object 19 and Object 911 both featured a combination of wheels and tracks. The Object 19 had four wheels in a 4x4 configuration that was supplemented by a pair of short retractable tracks between the wheels on each side, whereas the Object 911 had a pair of tracks that occupied the entire length of the hull and were supplemented by four retractable wheels.

During the course of testing, the Object 911 and Object 19 were eliminated rather quickly as they were found to be extremely complex but lacked any tangible advantage over a fully tracked or wheeled vehicle. The Object 1200 was a very modern design and it was an extremely capable combat vehicle, but it had insufficient off-road mobility compared to tanks due to its wheeled propulsion system. The Object 914 was a fully tracked vehicle and possessed very good tactical-technical characteristics, but its passengers were forced to egress through roof hatches due to its use of a rear engine and transmission. The Object 765 had a number of minor flaws, but it was the only design to fulfill virtually all of the requirements put forth by the GBTU. The layout of the various competing models is shown below.

In 1965, the Object 765 design was proclaimed as the winner of the competition. Aside from the primary features of the Object 765 that defined it as the world's first true IFV, there were also a number of details that marked its uniqueness among other tracked troop carriers. For instance, it was not steered with tillers like the MT-LB and the BTR-50, but instead had a T-bar steering system with excellent hydraulic assistance. This marked the progressiveness of the BMP among its foreign counterparts as well, as APCs like the British FV432, American M113, French AMX-10P and German Spz. 12-3 were all steered with tillers.

Sergey Suvorov writes in his book "Боевые машины пехоты БМП-1, БМП-2 и БМП-3. «Братская могила пехоты» или супероружие" (BMP-1, BMP-2 and BMP-3 infantry fighting vehicles. "Mass grave of infantry" or a superweapon) that when it came time for the Object 765 to enter service in the Soviet Army as the BMP, the long term viability of the vehicle came into question due to its high cost and somewhat complex construction. Broadly speaking, a high price tag was part and parcel of the creation of a radically new combat vehicle, but it was considered particularly high in comparison with existing armoured personnel carriers. Although the Object 765 was a lightweight vehicle, it was not as simple to produce as older tracked APCs like the BTR-50P, and its design did not make use of existing components in significant quantities. There was also some debate as to whether or not it offered enough advantages over the much cheaper BTR-60 to warrant its increase in unit price. According to Suvorov, it was determined that in a conventional large scale war, a cheaper wheeled APC like the BTR-60PB was much more cost efficient. A large scale nuclear war - where a vehicle like the BMP would excel - was seen as an increasingly unlikely scenario, mainly due to the fact that the USSR had managed to field submarine-launched ballistic missiles (SLBM) in the early 1960's and had therefore improved their nuclear deterrence capability to such an extent that a mutually assured destruction (MAD) situation was created between the USSR and the USA.

However, the relatively high price of the BMP was eventually accepted after some motorized infantry tactics were thoroughly reworked to make full use of the capabilities of the new vehicle. The BMP officially entered service in 1966 with mass production beginning in the same year at Kurganmashzavod (Kurgan tractor plant).

It was decided that only the motorized rifle units in close proximity to NATO forces in Europe would be equipped with the new BMP. The motorized rifle regiments integrated into tank divisions were also equipped with BMPs to maximize their shock action capability. Second line and reserve units would remain equipped with cheaper wheeled BTRs like the BTR-60PB which also entered service in 1966. In the end, the BMP turned out to be the most mass produced IFV in human history with around 40,000 samples - including a number of specialized variants - produced by the time production ended in the USSR in 1983. It was formally replaced by the BMP-2 in 1980.

In this article, we will only be examining the five primary variants of the generic BMP-1 IFV. The first iteration of the BMP design is the Object 765 Sp.1 from 1966, also known simply as "BMP", without the "-1" suffix. It is characterized by the stubby bow of its hull. The second variant is the Object 765 Sp.2 from 1969. It is distinguished from the BMP by the more elongated bow, and it is the first model to be officially designated as the BMP-1. The third variant is the Object 765 Sp.3 from 1973. This modification introduced a new mode for its autoloader for compatibility with HE-Frag rounds, with manual loading by the gunner. The fourth and final variant is the Object 765 Sp.4 from 1979, better known as the BMP-1P. It is essentially the same as the Object 765 Sp.3 except for the missile system. The BMP-1P has an external 9P135 missile launcher and had all of the control equipment for "Malyutka" missile system removed. The BMP-1P replaced the BMP-1 on KMZ production lines beginning in 1979, and in the same year, all BMP-1s coming into depots for capital overhauls began to be modernized to the BMP-1P standard.

COMMANDER'S STATION

In a BMP, the commander of the vehicle was also a motorized rifle unit commander. Depending on the specific vehicle in a standard motor rifle company, the vehicle commander may be the commander of the company, of a platoon, be the deputy to the platoon commander, or be the commander of a squad. In a standard platoon, the commander typically dismounts together with the passengers when required and acts as the squad leader, while the platoon commander remains in his vehicle.

When fighting from inside the vehicle, the commander of a BMP acts as a typical vehicle commander. He issues orders to the rest of the crew and to the passengers, who open fire from their firing ports or dismount from the vehicle only when instructed by the commander. To facilitate his duties, the commander is given a rotating cupola which includes a forward-opening hatch and three periscopes. His primary vision device was the TKN-3B, used not only for general surveillance but also fire correction, when working together with the gunner. The TKN-3B is distinguished from the TKN-3 by the lack of a target cueing system owing to the location of the commander's station. The TKN-3B uses a 2-stage cascading tube light intensifier with 0-generation photocathodes. It has no useful passive viewing capability, depending entirely on illumination from the OU-3GA2 infrared spotlight.

The hatch is of a semicircular shape and it is locked with a simple latch. Also, the hatch features a safety mechanism linked to the powered traverse system of the turret that locks the turret in place once the latch is unlocked. The system senses this via a spring-loaded solenoid button maintains contact with the latch. The button is disengaged when the latch is turned to the locked position so the turret can turn normally when the hatch is closed. Once the latch is turned to open the hatch, the button is depressed, and this sends an electric signal to the turret traverse system to suspend the traversal of the turret regardless of any inputs on the control handles and the turret is automatically locked in place.

Besides the hatch, the cupola is fitted with a small array of observation devices. The commander does not have much in the way of surveillance equipment. He is provided with a TKN-3B periscope and two TNPO-180 general purpose periscopes. This is not many, but this is compensated by the fact that the cupola can be rotated a full 360 degrees. The very light weight of the cupola makes it very easy to spin.

The ergonomic qualities of the commander's station are best described as spartan. Being located in the front of the hull next to the engine compartment, the station is longer than it is wide. The width of the "corridor" where the driver and commander is seated is only 60cm, which is quite narrow, but enough for the commander to operate the TKN-3B and swing it around (with elbows tucked in).

Because a one-man turret was specified for the BMP, the commander had to be seated in the hull. directly behind the driver. This was not particularly unusual for an armoured personnel carrier at the time as they typically did not have a two-man turret, if they had a turret at all, but even so, it was not an ideal position for a vehicle commander given that the role invariably involves a great deal of surveillance. The main drawback is that the commander cannot look towards the rear of the vehicle from the 5 o'clock to 3 o'clock sector. Moreover, thanks to a combination of its low height and the relatively small turret, it is easy to camouflage the BMP and place it in a turret defilade position behind natural concealment such as bushes, tall grass and soil mounds, but the commander's view is completely blocked if the vehicle enters a turret defilade position so the gunner must survey the environment alone from his turret station. However, the commander's location in the vehicle does not prevent him from surveying the battlefield when the vehicle is in a hull defilade position as the commander's cupola is slightly raised and has sufficient clearance to allow the periscopes to peek over an obstacle without needing the vehicle to expose its hull.

Ideally, the commander should be located in the turret alongside the gunner as this allows two crew members to search for targets independently from a turret defilade position and it permits the commander to issue orders and designate targets much more effectively. A turret also offers a taller vantage point for a superior range of vision and a turret tends to be on the center of gravity of the vehicle, thus making hull oscillations less obvious. This helps improve ride quality and ease of observation. It also enhances the commander's ability to direct the driver and the convenience of a platoon or company commander to marshal other members of the unit. The advantage of a two-man turret was recognized and subsequent developments discarded the one-man turret concept. For instance, the Object 768 prototype, designed by the in-house design bureau of the ChTZ factory as the intended successor to the BMP-1 in 1972, featured a two-man turret with a 73mm cannon of increased power. This is shown in the photo below (courtesy of the tankmuseum.ru website for the Kubinka tank museum) Additionally, the BRM-1K reconnaissance vehicle based on the BMP-1 also had its commander seated in a large two-man turret and not in the hull.

GUNNER'S STATION

The gunner's resides in the one-man turret. He is responsible for maintaining the machine gun, cannon, sighting complexes, and autoloader. It is rather cramped in the turret, but this is balanced out to some extent by the lack of a turret basket. This means that the gunner can stretch his legs whenever the turret is not moving, and as he controls the rotation of the turret, he is much more able to ensure the safety of his appendages. There is a corridor beside the turret, joining the passenger space and the front hull space where the commander and driver are situated. When not in combat, the gunner can spread his legs out into this space, with the turret locked in traverse to prevent accidents.

The turret floor is a flat sheet of aluminium with level edges except in front of the gunner's seat where the edges are bent upwards to form a shallow ridge. This ridge is there to ensure that the gunner's feet do not slip off the floor. There is also a simple sheet metal shin guard stretching from one of the struts connecting the turret floor to the turret to the ammunition and casing container to the right of the gunner. This shin guard prevents the loader from accidentally putting his knees outside the perimeter of the turret floor. All of this is shown in the photo below, taken by Hans-Hermann Bühling.

The gunner's hatch opens forward and locks in the upright position which is very typical of a Soviet vehicle. If a gunner of average height stands on his seat with the seat in the lowest setting, his head will be just over the edge of the open hatch, so the hatch itself will be able to provide his torso with frontal protection from bullets while the gunner enjoys the better view gained from having a higher vantage point.

Due to the installation of the cannon along the center axis of the turret, the gunner's station is confined to the left half of the turret and the right half of the turret is used for electronic equipment. Components of the 9S428 missile guidance system are installed on the turret wall on the right half of the turret.

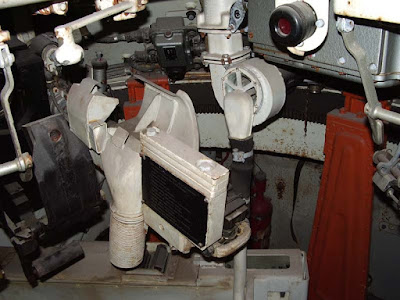

The 2A28 "Grom" cannon of the BMP lacks a fume extractor. To remove propellant fumes from the cannon and the coaxial machine gun, the turret has a special ventilator that extracts air from the fighting compartment and expels it out through a vent on the turret roof. The ventilator consists of a single centrifugal extractor fan powered by an electric motor that leads to a vent on the turret roof. There is also a duct that connects the extractor fan inlet to the container on the turret floor for spent propellant charges, thus allowing the system to extract the fumes emitted from these spent charges from propellant residue. The photo below, courtesy of Vladimir Yakubov, shows the extractor fan of the ventilator and the duct that connects the fan inlet to the container on the turret floor.

The BMP-1 technical manual mentions that the extractor fan is the same as the type used in the propellant fume extraction system for the passenger firing ports. Without this system, it would tend to be quite unpleasant to remain confined inside the small turret of the BMP with all the hatches closed during sustained fire. Even when the weapons are not being fired, this vent continues to help circulate air in the fighting compartment.

The gunner is provided with a total of five observation devices in his turret: the 1PN22M1 sight aimed directly forward, and four TNPO-170 periscopes arranged around the perimeter of his hatch. Two of the TNPO-170 periscopes are placed on the flanks of the primary sight to provide forward vision which is helpful for seeing targets and maintaining situational awareness, and the other two are placed on the sides of the hatch to allow the gunner to check his surroundings. There is a dead zone in the 2 o'clock sector because a periscope could not be placed directly behind the breech of the 2A28 "Grom" cannon, as that space was needed for loading the cannon. The photos below shows the layout of the periscopes around the gunner's hatch. Photos by Robert De Craecker.

When a mounting post was installed on the right side of the turret roof in the BMP-1P modernization for the 9P135M missile launcher, it partially obstructed the view from the TNPO-170 aimed to the right.

The front-right periscope can also be used to aim the weapons in the event that the primary sight fails. Engaging targets with the coaxial machine gun can be done by following the tracers for fire correction, and the "Malyutka" missile can be guided by eye at shorter distances. With a total of five observation devices, a BMP-1 gunner has good vision in the forward 180-degree sector of the turret but no rearward visibility whatsoever. To see behind the turret, the gunner can open his hatch or traverse the turret to the left or right by until one of the side-facing TNPO-170 periscopes is aimed to the rear. In an active combat situation or in an NBC-contaminated environment, only the latter option is feasible. The lack of rearward visibility for the gunner when he is buttoned up was addressed on the BMP-2 when a rear-view prism was added to the gunner's hatch.

The good vision from the BMP-1 turret partly compensates for the sub-optimal location of the commander's station and provides the gunner with a high level of independence in target acquisition when the commander dismounts together with the passengers.

For lighting, there is a PMV-71 dome light located on the turret roof to the left of the gunner's hatch and another one on the turret roof on the opposite side, to the right of the autoloader mechanism. The dome light contains a TN-28-10 incandescent lamp that runs on a voltage of 28 volts and consumes 10 W of power. Each PMV-71 dome light has an output of 10 candelas. For a one-man turret, the amount of illumination is quite good. The gunner has access to a master power relay to control the activation of various electrical systems in the vehicle.

Although the BMP has an overpressure ventilation system that is capable of providing sufficient ventilation for all of the occupants, the gunner has the good fortune of being able to open two hatches for additional ventilation - his personal roof hatch, and the missile loading hatch. When the missile loading hatch is open and the vehicle is moving forward, the rush of wind is deflected by the hatch directly towards the gunner much like the vent window of old cars.

The gunner's seat together with its backrest is adjustable in height. A foldable arm guard is installed on the right side of the seat to isolate the gunner from the autoloader mechanism. The top half of the arm guard is folded down to allow the gunner to access the two "Malyutka" missiles stowed in the turret when reloading the missile launcher, and the entire arm guard can be detached from the seat for unobstructed access to the turret interior. The 9V332 control box with its control joystick for the "Malyutka" missile system is folded under the seat when not in use.

With the introduction of the 902V "Tucha" smoke grenade launcher system on the BMP-1P, new control boxes had to be installed. The gunner was provided with a revised master power relay to turn on the "Tucha" electrical system, and a "Tucha" launch control box to select individual grenades to launch.

The 1ETs10M powered gun laying system provides powered turret traverse and gun elevation with satisfactory accuracy using all-electric drives. Gun stabilization was not provided and was never provided to any serially produced BMP-1 variant during its career in the Soviet Army, and later, the Russian Army. The gun can be depressed to -4 degrees and elevated to +30 degrees, but direct fire with the 73mm cannon is only possible from -4 degrees to +15 degrees due to the elevation limits of the 1PN22M1 sight.

The DGN-3 electric motor is the turret rotation drive. It runs on 24 V and has an output of 300 W. The DVN-1 electric motor is the gun elevation drive. It also runs on 24 V and has an output of 65 W. The maximum speeds of turret rotation and gun elevation are slightly higher than of a T-64 and significantly higher than of a T-62 or T-55, and the mechanical precision of the BMP gun laying system should be very similar to these two tanks. As such, the gun laying system was not only more than sufficiently precise to facilitate the use of the 2A28 cannon out to its maximum effective range of 800 meters but it could also be considered quite modern.

Vertical:

Maximum Cannon Elevation Speed: 6° per second

Minimum Cannon Elevation Speed: 0.07° per second

Horizontal:

Maximum Turret Traverse Speed: 20° per second

Minimum Turret Traverse Speed: 0.1° per second

In 1973, the BMP-1 was equipped with the 1ETs10M2 modification of the original powered gun laying system. The new model was adapted to the modification of the autoloader in accordance with the introduction of HE-Frag ammunition for the main gun. The control handles gained a switch to load HE-Frag rounds, or rather, to control the operation of the autoloader so that it selectively loads HEAT rounds if the gunner presses the "K" (HEAT) button, but only rotates the conveyor by one step if the gunner presses the "O" (HE-Frag) button.

The BMP-1 cannot fire on the move with any guarantee of accuracy unless the vehicle is travelling over a well paved road at low speed. Nevertheless, BMP gunners were trained to fire on the move at low speeds using both the 2A28 cannon and the PKT coaxial machine gun. To maximize training time without needing to cover the costs of maintenance and fuel, the training was often done on simulators. These simulators were platforms built into the ground which the BMP would park on. To simulate the experience of driving over uneven terrain, the platform oscillates at various intensities while the gunner uses the coaxial PKT machine gun to engage pop up targets representing infantry.

Video footage of a firing exercise taking place can be found on YouTube on yolkhere's channel, here (link).

The short video and the limited amount of information I have gathered doesn't say if gunners were trained to fire the 73mm cannon from the platform, but as far as I know, it was not part of the curriculum. Live fire training at the firing range was more extensive as it involved both tank and infantry-type targets and tested the coordination of the entire crew, not just the skills of the gunner. This made time on the range irreplaceable, not that further evidence was needed.

Due to the presence of the OU-3GA infrared spotlight on the commander's cupola, a deadzone with an arc of 50 degrees was created. The turret cannot be aimed at the normal angles of gun elevation over this arc, and instead, the gun must be elevated over the spotlight. Another deadzone exists over the rear arc where the gun depression angle over the troop compartment roof is reduced to a maximum of -2 degrees instead of the normal -4 degrees, but this is completely normal for practically all turreted tanks and should not have a significant effect during combat.

The PU-6 control handles are used with this system. The right handle has a thumb button for firing the "Grom" cannon and the left handle has a thumb button for firing the coaxial machine gun.

One of the design requirements stipulated for the BMP was that it had to have a sighting system equal in capabilities to the tanks it was to complement, including a night fighting capability. As a result, the 1PN22 combined day-night sight was developed. The original 1PN22 was only used in the prototype turrets installed on the five competing prototypes that took part in the 1961-1965 military competition. After the competition was won by the Object 765 in 1965, the modernized 1PN22M1 sight was created and used on all serially produced BMPs.

The 1PN22M1 is a relatively advanced sight that features a fixed magnification daytime optic and a night vision channel with a 1st Generation three-stage light amplifier. The gunner looks through the same eyepiece for both the day and night channels, and he can switch between the two channels by rotating an internal mirror. By incorporating two features into one sighting system, Soviet engineers were able to save space inside the small turret and simplify the sighting system without compromising overall effectiveness.

The head of the sight contains a mirror that is linked to the trunnion of the 2A28 cannon. The viewing window of the sight head is protected by a pane of glass, and an additional protective glass pane can be lowered when launching ATGMs to prevent the main viewing window of the sight from being scorched by the rocket exhaust. After the ATGM leaves the launch rail, the scorched glass pane is raised.

The night vision system of the 1PN22M1 sight is housed in the left side and bottom of the sight housing. The left "shoulder" of the sight contains a reflector assembly with one mirror and a prism that projects light collected from the objective lens of the sight into the U-42-M light intensifier tube at the bottom of the sight. The amplified image is then reflected to the eyepiece of the sight through four prisms.

The sight has fixed magnification of 6x and a field of view of 15° in the day channel. The magnification was adequate given the effective range of the main gun and the coaxial machine gun, but from a technical point of view, the capabilities of the sight are exceptional. The magnification power of the 1PN22M1 is directly comparable to that of tanks with larger, high power cannons like the M48, which used the M20 sight with a 6x maximum magnification, though it lacked selectable magnification settings as on the Soviet TSh2 series of sights. With a field of view of 15 degrees, however, the 1PN22M1 provided considerably expanded vision compared to tank sights like the TSh2 series (9 degrees at 7x magnification). The 1PN22M1 offers a notably higher magnification than the PGO-9 periscopic sight used on the SPG-9, which only had a 4.2x magnification with a field of view of 10.5 degrees. This means that a BMP-1 gunner should be able to identify and fire upon targets at a longer range than an SPG-9 gunner, but because the effective range is largely the same, the higher magnification of the 1PN22M1 sight did not give the BMP-1 any major advantage. Needless to say, both the commander and gunner of a BMP-1 have much less visibility when they are buttoned up compared to an SPG-9 crew.

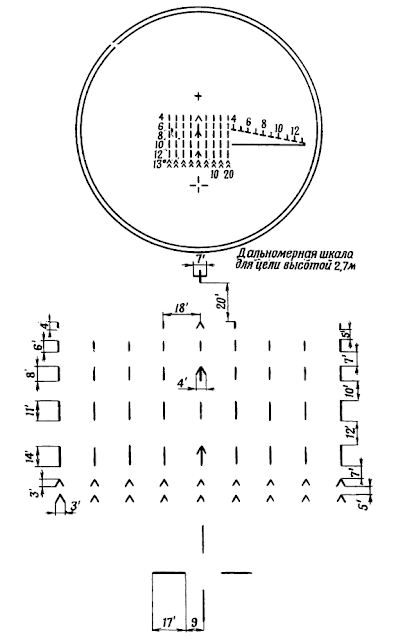

The viewfinder of the sight is abundantly marked for ballistic drop and lead. Windage was adjusted using the lead scales. The small crosshair at the top of the viewfinder is zeroed for 50 meters, so in practice, it serves as a reference point rather than an actual aiming mark. The viewfinder permits aimed fire out to a maximum range of 1,300 meters for both the PG-15V rounds as well as for the PKT coaxial machine gun. A separate scale for the PKT is not needed because it has very close ballistics to the PG-15V round out to 1,300 meters, allowing the gunner to use the range scale for both weapons interchangeably.

The point blank range of the PG-15V round fired from the 2A28 is 765 meters for a target with a height of 2 meters, meaning that up to a distance of 765 meters, the trajectory of a PG-15V round will have a total height of 2 meters. In theory, this means that if the target tank is 2 meters tall and within 765 meters of the BMP-1, the gunner can simply aim his crosshair at the roof of the target and open fire with a total guarantee of achieving a hit at some part of the tank. If the tank is 765 meters away, the shot will impact its lower glacis, and if it is 300 meters away, the shot will impact the turret. However, due to a myriad of factors such as the dispersion of shots, it is still necessary to obtain a range reading to maximize the probability of hit. For this reason, the 1PN22M1 sight features a stadiametric rangefinder in its viewfinder.

The rangefinder scale is intended for a target 2.7 meters in height, starting from 400 meters and ending at 1,300 meters. Below 400 meters, the trajectory of PG-15V rounds is flat enough that the battlesight gunnery technique is sufficiently accurate for achieving a probability of hit exceeding 90%, and fire correction can be accomplished with the burst-on-target gunnery technique if it is truly necessary. There are no range scales between the 50-meter crosshair and the 400-meter range scale. In the stadiametric scale, the target height of 2.7 meters is representative of the height of the average Western tank, including the Chieftain, M48, M60A1, Leopard 1, and even some later combat vehicles like the Marder 1.

The sight is switched to the night vision channel by redirecting the light collected from the objective lens away from the day channel optical assembly to the reflector assembly located in the left side of the sight. The light then passes through one of six light filters on a revolving disc before entering the light intensifier tube at the bottom of the sight. The gunner chooses the filter by rotating the knob at the bottom left of the sight, shown in the drawing on the left below.

The light filters are designed to provide the optimal level of contrast in various lighting conditions, including daylight. The designations of the various filters and their purposes are listed in the table below. Filters 'O' and 'KS-17' are intended for use at night under natural illumination from starlight and moonlight. Filter 'NS-10' is intended for use at twilight. Filter 'NS-11' is intended for use in overcast daylight conditions. Filters 'NS-12-1' and 'NS-12' are intended for use during sunny weather.

The night vision channel has a separate viewfinder reticle design from the daytime channel. The reticle is projected onto the viewfinder using a collimator system with an adjustable brightness. The reticle has greatly simplified lead and range correction scales compared to the day channel reticle. The sight has a fixed magnification of 6.7x and a field of view of 6 degrees in the night channel. As with the day channel, this was excellent performance compared to the tank equivalent. In this case, the standard TPN1 series of night sights, which had a smaller magnification of 5.5x but the same field of view of 6 degrees.

The gunner's hatch opens forward and locks in the upright position which is very typical of a Soviet vehicle. If a gunner of average height stands on his seat with the seat in the lowest setting, his head will be just over the edge of the open hatch, so the hatch itself will be able to provide his torso with frontal protection from bullets while the gunner enjoys the better view gained from having a higher vantage point.

Due to the installation of the cannon along the center axis of the turret, the gunner's station is confined to the left half of the turret and the right half of the turret is used for electronic equipment. Components of the 9S428 missile guidance system are installed on the turret wall on the right half of the turret.

The 2A28 "Grom" cannon of the BMP lacks a fume extractor. To remove propellant fumes from the cannon and the coaxial machine gun, the turret has a special ventilator that extracts air from the fighting compartment and expels it out through a vent on the turret roof. The ventilator consists of a single centrifugal extractor fan powered by an electric motor that leads to a vent on the turret roof. There is also a duct that connects the extractor fan inlet to the container on the turret floor for spent propellant charges, thus allowing the system to extract the fumes emitted from these spent charges from propellant residue. The photo below, courtesy of Vladimir Yakubov, shows the extractor fan of the ventilator and the duct that connects the fan inlet to the container on the turret floor.

The BMP-1 technical manual mentions that the extractor fan is the same as the type used in the propellant fume extraction system for the passenger firing ports. Without this system, it would tend to be quite unpleasant to remain confined inside the small turret of the BMP with all the hatches closed during sustained fire. Even when the weapons are not being fired, this vent continues to help circulate air in the fighting compartment.

The gunner is provided with a total of five observation devices in his turret: the 1PN22M1 sight aimed directly forward, and four TNPO-170 periscopes arranged around the perimeter of his hatch. Two of the TNPO-170 periscopes are placed on the flanks of the primary sight to provide forward vision which is helpful for seeing targets and maintaining situational awareness, and the other two are placed on the sides of the hatch to allow the gunner to check his surroundings. There is a dead zone in the 2 o'clock sector because a periscope could not be placed directly behind the breech of the 2A28 "Grom" cannon, as that space was needed for loading the cannon. The photos below shows the layout of the periscopes around the gunner's hatch. Photos by Robert De Craecker.

When a mounting post was installed on the right side of the turret roof in the BMP-1P modernization for the 9P135M missile launcher, it partially obstructed the view from the TNPO-170 aimed to the right.

The front-right periscope can also be used to aim the weapons in the event that the primary sight fails. Engaging targets with the coaxial machine gun can be done by following the tracers for fire correction, and the "Malyutka" missile can be guided by eye at shorter distances. With a total of five observation devices, a BMP-1 gunner has good vision in the forward 180-degree sector of the turret but no rearward visibility whatsoever. To see behind the turret, the gunner can open his hatch or traverse the turret to the left or right by until one of the side-facing TNPO-170 periscopes is aimed to the rear. In an active combat situation or in an NBC-contaminated environment, only the latter option is feasible. The lack of rearward visibility for the gunner when he is buttoned up was addressed on the BMP-2 when a rear-view prism was added to the gunner's hatch.

The good vision from the BMP-1 turret partly compensates for the sub-optimal location of the commander's station and provides the gunner with a high level of independence in target acquisition when the commander dismounts together with the passengers.

For lighting, there is a PMV-71 dome light located on the turret roof to the left of the gunner's hatch and another one on the turret roof on the opposite side, to the right of the autoloader mechanism. The dome light contains a TN-28-10 incandescent lamp that runs on a voltage of 28 volts and consumes 10 W of power. Each PMV-71 dome light has an output of 10 candelas. For a one-man turret, the amount of illumination is quite good. The gunner has access to a master power relay to control the activation of various electrical systems in the vehicle.

Although the BMP has an overpressure ventilation system that is capable of providing sufficient ventilation for all of the occupants, the gunner has the good fortune of being able to open two hatches for additional ventilation - his personal roof hatch, and the missile loading hatch. When the missile loading hatch is open and the vehicle is moving forward, the rush of wind is deflected by the hatch directly towards the gunner much like the vent window of old cars.

The gunner's seat together with its backrest is adjustable in height. A foldable arm guard is installed on the right side of the seat to isolate the gunner from the autoloader mechanism. The top half of the arm guard is folded down to allow the gunner to access the two "Malyutka" missiles stowed in the turret when reloading the missile launcher, and the entire arm guard can be detached from the seat for unobstructed access to the turret interior. The 9V332 control box with its control joystick for the "Malyutka" missile system is folded under the seat when not in use.

With the introduction of the 902V "Tucha" smoke grenade launcher system on the BMP-1P, new control boxes had to be installed. The gunner was provided with a revised master power relay to turn on the "Tucha" electrical system, and a "Tucha" launch control box to select individual grenades to launch.

POWERED CONTROLS

The 1ETs10M powered gun laying system provides powered turret traverse and gun elevation with satisfactory accuracy using all-electric drives. Gun stabilization was not provided and was never provided to any serially produced BMP-1 variant during its career in the Soviet Army, and later, the Russian Army. The gun can be depressed to -4 degrees and elevated to +30 degrees, but direct fire with the 73mm cannon is only possible from -4 degrees to +15 degrees due to the elevation limits of the 1PN22M1 sight.

The DGN-3 electric motor is the turret rotation drive. It runs on 24 V and has an output of 300 W. The DVN-1 electric motor is the gun elevation drive. It also runs on 24 V and has an output of 65 W. The maximum speeds of turret rotation and gun elevation are slightly higher than of a T-64 and significantly higher than of a T-62 or T-55, and the mechanical precision of the BMP gun laying system should be very similar to these two tanks. As such, the gun laying system was not only more than sufficiently precise to facilitate the use of the 2A28 cannon out to its maximum effective range of 800 meters but it could also be considered quite modern.

Vertical:

Maximum Cannon Elevation Speed: 6° per second

Minimum Cannon Elevation Speed: 0.07° per second

Horizontal:

Maximum Turret Traverse Speed: 20° per second

Minimum Turret Traverse Speed: 0.1° per second

In 1973, the BMP-1 was equipped with the 1ETs10M2 modification of the original powered gun laying system. The new model was adapted to the modification of the autoloader in accordance with the introduction of HE-Frag ammunition for the main gun. The control handles gained a switch to load HE-Frag rounds, or rather, to control the operation of the autoloader so that it selectively loads HEAT rounds if the gunner presses the "K" (HEAT) button, but only rotates the conveyor by one step if the gunner presses the "O" (HE-Frag) button.

The BMP-1 cannot fire on the move with any guarantee of accuracy unless the vehicle is travelling over a well paved road at low speed. Nevertheless, BMP gunners were trained to fire on the move at low speeds using both the 2A28 cannon and the PKT coaxial machine gun. To maximize training time without needing to cover the costs of maintenance and fuel, the training was often done on simulators. These simulators were platforms built into the ground which the BMP would park on. To simulate the experience of driving over uneven terrain, the platform oscillates at various intensities while the gunner uses the coaxial PKT machine gun to engage pop up targets representing infantry.

Video footage of a firing exercise taking place can be found on YouTube on yolkhere's channel, here (link).

The short video and the limited amount of information I have gathered doesn't say if gunners were trained to fire the 73mm cannon from the platform, but as far as I know, it was not part of the curriculum. Live fire training at the firing range was more extensive as it involved both tank and infantry-type targets and tested the coordination of the entire crew, not just the skills of the gunner. This made time on the range irreplaceable, not that further evidence was needed.

Due to the presence of the OU-3GA infrared spotlight on the commander's cupola, a deadzone with an arc of 50 degrees was created. The turret cannot be aimed at the normal angles of gun elevation over this arc, and instead, the gun must be elevated over the spotlight. Another deadzone exists over the rear arc where the gun depression angle over the troop compartment roof is reduced to a maximum of -2 degrees instead of the normal -4 degrees, but this is completely normal for practically all turreted tanks and should not have a significant effect during combat.

The PU-6 control handles are used with this system. The right handle has a thumb button for firing the "Grom" cannon and the left handle has a thumb button for firing the coaxial machine gun.

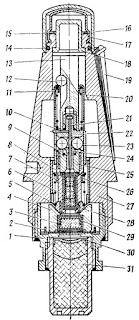

1PN22M1

One of the design requirements stipulated for the BMP was that it had to have a sighting system equal in capabilities to the tanks it was to complement, including a night fighting capability. As a result, the 1PN22 combined day-night sight was developed. The original 1PN22 was only used in the prototype turrets installed on the five competing prototypes that took part in the 1961-1965 military competition. After the competition was won by the Object 765 in 1965, the modernized 1PN22M1 sight was created and used on all serially produced BMPs.

The 1PN22M1 is a relatively advanced sight that features a fixed magnification daytime optic and a night vision channel with a 1st Generation three-stage light amplifier. The gunner looks through the same eyepiece for both the day and night channels, and he can switch between the two channels by rotating an internal mirror. By incorporating two features into one sighting system, Soviet engineers were able to save space inside the small turret and simplify the sighting system without compromising overall effectiveness.

The head of the sight contains a mirror that is linked to the trunnion of the 2A28 cannon. The viewing window of the sight head is protected by a pane of glass, and an additional protective glass pane can be lowered when launching ATGMs to prevent the main viewing window of the sight from being scorched by the rocket exhaust. After the ATGM leaves the launch rail, the scorched glass pane is raised.

The night vision system of the 1PN22M1 sight is housed in the left side and bottom of the sight housing. The left "shoulder" of the sight contains a reflector assembly with one mirror and a prism that projects light collected from the objective lens of the sight into the U-42-M light intensifier tube at the bottom of the sight. The amplified image is then reflected to the eyepiece of the sight through four prisms.

The sight has fixed magnification of 6x and a field of view of 15° in the day channel. The magnification was adequate given the effective range of the main gun and the coaxial machine gun, but from a technical point of view, the capabilities of the sight are exceptional. The magnification power of the 1PN22M1 is directly comparable to that of tanks with larger, high power cannons like the M48, which used the M20 sight with a 6x maximum magnification, though it lacked selectable magnification settings as on the Soviet TSh2 series of sights. With a field of view of 15 degrees, however, the 1PN22M1 provided considerably expanded vision compared to tank sights like the TSh2 series (9 degrees at 7x magnification). The 1PN22M1 offers a notably higher magnification than the PGO-9 periscopic sight used on the SPG-9, which only had a 4.2x magnification with a field of view of 10.5 degrees. This means that a BMP-1 gunner should be able to identify and fire upon targets at a longer range than an SPG-9 gunner, but because the effective range is largely the same, the higher magnification of the 1PN22M1 sight did not give the BMP-1 any major advantage. Needless to say, both the commander and gunner of a BMP-1 have much less visibility when they are buttoned up compared to an SPG-9 crew.

The viewfinder of the sight is abundantly marked for ballistic drop and lead. Windage was adjusted using the lead scales. The small crosshair at the top of the viewfinder is zeroed for 50 meters, so in practice, it serves as a reference point rather than an actual aiming mark. The viewfinder permits aimed fire out to a maximum range of 1,300 meters for both the PG-15V rounds as well as for the PKT coaxial machine gun. A separate scale for the PKT is not needed because it has very close ballistics to the PG-15V round out to 1,300 meters, allowing the gunner to use the range scale for both weapons interchangeably.

The point blank range of the PG-15V round fired from the 2A28 is 765 meters for a target with a height of 2 meters, meaning that up to a distance of 765 meters, the trajectory of a PG-15V round will have a total height of 2 meters. In theory, this means that if the target tank is 2 meters tall and within 765 meters of the BMP-1, the gunner can simply aim his crosshair at the roof of the target and open fire with a total guarantee of achieving a hit at some part of the tank. If the tank is 765 meters away, the shot will impact its lower glacis, and if it is 300 meters away, the shot will impact the turret. However, due to a myriad of factors such as the dispersion of shots, it is still necessary to obtain a range reading to maximize the probability of hit. For this reason, the 1PN22M1 sight features a stadiametric rangefinder in its viewfinder.

The rangefinder scale is intended for a target 2.7 meters in height, starting from 400 meters and ending at 1,300 meters. Below 400 meters, the trajectory of PG-15V rounds is flat enough that the battlesight gunnery technique is sufficiently accurate for achieving a probability of hit exceeding 90%, and fire correction can be accomplished with the burst-on-target gunnery technique if it is truly necessary. There are no range scales between the 50-meter crosshair and the 400-meter range scale. In the stadiametric scale, the target height of 2.7 meters is representative of the height of the average Western tank, including the Chieftain, M48, M60A1, Leopard 1, and even some later combat vehicles like the Marder 1.

The sight is switched to the night vision channel by redirecting the light collected from the objective lens away from the day channel optical assembly to the reflector assembly located in the left side of the sight. The light then passes through one of six light filters on a revolving disc before entering the light intensifier tube at the bottom of the sight. The gunner chooses the filter by rotating the knob at the bottom left of the sight, shown in the drawing on the left below.

The light filters are designed to provide the optimal level of contrast in various lighting conditions, including daylight. The designations of the various filters and their purposes are listed in the table below. Filters 'O' and 'KS-17' are intended for use at night under natural illumination from starlight and moonlight. Filter 'NS-10' is intended for use at twilight. Filter 'NS-11' is intended for use in overcast daylight conditions. Filters 'NS-12-1' and 'NS-12' are intended for use during sunny weather.

The night vision channel has a separate viewfinder reticle design from the daytime channel. The reticle is projected onto the viewfinder using a collimator system with an adjustable brightness. The reticle has greatly simplified lead and range correction scales compared to the day channel reticle. The sight has a fixed magnification of 6.7x and a field of view of 6 degrees in the night channel. As with the day channel, this was excellent performance compared to the tank equivalent. In this case, the standard TPN1 series of night sights, which had a smaller magnification of 5.5x but the same field of view of 6 degrees.

Night vision was provided by a passive image intensifier system running on a 40 kV power supply. The system utilizes a three-stage image intensifier cascade tube with three S-1 converter tubes. This level of technology was modern for the 1960's.

This type of image intensifier has a gain of 50,000-75,000, meaning that it is capable of amplifying light by 50,000-75,000 times. Such a high gain is necessary for Gen 1 image intensifiers to provide practical passive viewing with starlight illumination alone. In the 1PN22M1 sight, glare and flash protection is provided to preserve the intensifier tubes via the automatic reduction of the input voltage on the converter tubes, which leads to a sharp drop in the gain, as a result of which the tubes are not burned out by a sudden flash of bright light and the smearing effect of light sources is reduced.

This system enabled the gunner to identify and fire upon a tank-type target at a range of up to 400 meters with an ambient light of 0.005 lux. The maximum viewing range was limited by the inherently low resolution of the image generated by a three-stage image intensifier tube. Another tactical limitation of this type of image intensifier system is that although the image at the center was clear, the edges would be distorted, thus effectively reducing the useful field of view. A technical limitation is the low service life of the converter tubes due to the very high operating voltages.

This is the same maximum viewing range of the commander's TKN-3B periscope. At the maximum identification range of 400 meters, the gunner could simply lay the center chevron in the viewfinder on a target and open fire immediately once it is identified and expect a high probability of scoring a first-round hit. When firing at targets at ranges of up to 800 meters, the need for a range estimate arises. This can be done using the reticle markings by comparing its known angular dimensions (in arcminutes) to the dimensions of the image of the target.

As the markings show, the BMP-1 is theoretically capable of engaging targets up to a distance of 800 meters at night using the 1PN22M, but the center chevron is calibrated for 400 meters as that is the distance limit of the night vision system. It is only practical to fire at targets from further than 400 meters if the target is illuminated by natural or artificial means.

1PN22M2 was introduced in 1974. From a technical viewpoint, it is identical to the 1PN22M1 in almost every way. The only functional difference is the addition of a scale for HE-Frag rounds which extends far below the original scale for HEAT rounds due to the low velocity of OG-15V HE-Frag rounds. Around the same time, the PGOK-9 sight with compatibility with HE-Frag rounds for the SPG-9 was introduced.

As you can see in the diagram above, the sight is marked for a maximum direct fire range of only 1,600 meters for HE-Frag. This is the hard limit of the direct fire capabilities of the BMP-1 using OG-15V HE-Frag rounds, and also the maximum range of the rounds.

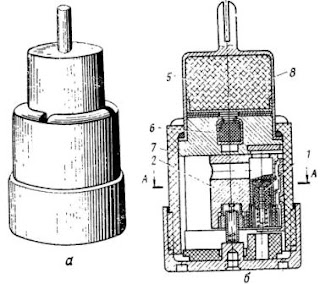

The BMP mounts the 73mm 2A28 "Grom" low-pressure smoothbore cannon. The cannon has a vertically sliding breech block with a spring-loaded folding shell casing deflector at the end of the breech assembly. The cannon has a total length of 2,180mm and a gun tube length of 2,117mm, which is longer than the gun tube of the SPG-9 despite the recoilless gun having a longer chamber for the larger propellant charge. The width of the 2A28 breech housing is very narrow - only 213mm. The cannon does not have a fume extractor.

The barrel life of "Grom" is 1,250 shots. The cannon can elevate between -4 degrees to +30 degrees, but direct fire is only possible from -4 degrees to +15 degrees due to the elevation limits of the 1PN22M1 sight. The breech block can be manually opened with a cam operated by a lever handle located underneath the casing deflector, as shown in the photo below. A recoil guard is attached to the lever.

"Grom" is incredibly lightweight, weighing only 115 kg on its own. Of course, its weight is not so impressive when compared to the SPG-9, which weighs 49.5 kg with its direct fire sight and without its tripod and aiming mechanism. This was mainly due to the need for a recoil mechanism and a breech to withstand the chamber pressure. When installed inside the BMP-1 turret, the full gun assembly includes the cast steel gun mantlet, the "Malyutka" missile launch platform on top of the recoil buffer sleeve, and a set of rollers for aligning the top of the gun breech with the missile launch platform.

As the markings show, the BMP-1 is theoretically capable of engaging targets up to a distance of 800 meters at night using the 1PN22M, but the center chevron is calibrated for 400 meters as that is the distance limit of the night vision system. It is only practical to fire at targets from further than 400 meters if the target is illuminated by natural or artificial means.

1PN22M2

1PN22M2 was introduced in 1974. From a technical viewpoint, it is identical to the 1PN22M1 in almost every way. The only functional difference is the addition of a scale for HE-Frag rounds which extends far below the original scale for HEAT rounds due to the low velocity of OG-15V HE-Frag rounds. Around the same time, the PGOK-9 sight with compatibility with HE-Frag rounds for the SPG-9 was introduced.

As you can see in the diagram above, the sight is marked for a maximum direct fire range of only 1,600 meters for HE-Frag. This is the hard limit of the direct fire capabilities of the BMP-1 using OG-15V HE-Frag rounds, and also the maximum range of the rounds.

2A28 "GROM"

The BMP mounts the 73mm 2A28 "Grom" low-pressure smoothbore cannon. The cannon has a vertically sliding breech block with a spring-loaded folding shell casing deflector at the end of the breech assembly. The cannon has a total length of 2,180mm and a gun tube length of 2,117mm, which is longer than the gun tube of the SPG-9 despite the recoilless gun having a longer chamber for the larger propellant charge. The width of the 2A28 breech housing is very narrow - only 213mm. The cannon does not have a fume extractor.

The barrel life of "Grom" is 1,250 shots. The cannon can elevate between -4 degrees to +30 degrees, but direct fire is only possible from -4 degrees to +15 degrees due to the elevation limits of the 1PN22M1 sight. The breech block can be manually opened with a cam operated by a lever handle located underneath the casing deflector, as shown in the photo below. A recoil guard is attached to the lever.

"Grom" is incredibly lightweight, weighing only 115 kg on its own. Of course, its weight is not so impressive when compared to the SPG-9, which weighs 49.5 kg with its direct fire sight and without its tripod and aiming mechanism. This was mainly due to the need for a recoil mechanism and a breech to withstand the chamber pressure. When installed inside the BMP-1 turret, the full gun assembly includes the cast steel gun mantlet, the "Malyutka" missile launch platform on top of the recoil buffer sleeve, and a set of rollers for aligning the top of the gun breech with the missile launch platform.

Rounds are fired electrically, with a mechanical striker as a backup.

The recoil mechanism consists of a hydraulic recoil buffer and coil return spring. It is wrapped around the base of the barrel and encased in an armoured sleeve, so it is concentric to the bore axis of the cannon. This is a positive influence on the dispersion characteristics of the cannon. Owing to its low operating pressure and its compact overall design, the "Grom" has a recoil stroke of only 150mm.

As the drawing below shows, the trunnion and barrel chamber of the "Grom" are at the same location, and because the BMP-1 turret has a protruding gun mount with the trunnion located in front of the turret ring, the cannon only protrudes a short distance into the turret and only the breech can be seen from inside the turret.

The recoil buffer sleeve also has built-in provisions for mounting the "Malyutka" launching rail. When a missile is mounted on the launcher, the cannon becomes somewhat unbalanced by the weight. The missile itself weighs 10.9 kg and it is located forward of the gun trunnion, making the gun rather front-heavy.

Even back in 1966, it was a somewhat unusual decision to use a low-velocity cannon in lieu of the typical heavy machine gun or autocannon as was normal for both purpose-built IFVs as well as APCs pressed into service in the IFV role. The convention that was followed by foreign militaries at the time was based on relatively sound reasoning: in a typical skirmish where tanks do not need to be involved, an armoured troop carrier should only face light resistance, and indeed, the ACAV modification of the M113 that was used by U.S forces and the ARVN during the war in Vietnam was only armed with externally-mounted M2 and M60 machine guns with gun shields for protection, and this was deemed to be enough for shock action against light infantry. In most cases, even a basic M113 was effective when the opposition was armed only with small arms and small numbers of anti-tank weapons. If additional firepower is desired for a vehicle intended for the same role, a rapid-fire autocannon would be more efficient at dispatching infantry, soft-skinned targets and lightly armoured vehicles compared to a large caliber semi-automatic cannon, but a rapid-fire autocannon has a lower efficiency against dugouts and field fortifications.

From this, it is evident that the BMP-1 was largely incapable of countering man-portable ATGMs which is a noteworthy drawback as the BMP-1 entered service during an era when such weapons were prolific. The effectiveness of the "Grom" in this role was increased when OG-15V HE rounds were introduced, but even so, another limitation came in the form of the rather short 1,600-meter maximum range of the OG-15V round.

If the BMP is being used to supplement a breakthrough attempt, it will not be the centerpiece of the attack. Soviet field manuals detail a number of formations to be used against enemy forces in certain situations, and in one of these, it is stated that when tanks are available to support the advance, one tank can be attached to each motorized infantry platoon. The three BMPs of the platoon follow the tank at a distance of 100 to 200 meters, with either dismounted or mounted infantry. The tank will take care of the toughest targets with its cannon, and the BMPs will knock out anti-tank weapons and lightly armoured vehicles in support of the tank. When a motorized infantry platoon with BMPs is operating without tank support, the modest capabilities of "Grom" would be the most potent anti-armour weapon available to the platoon besides the integrated "Malyutka" missile, so avoiding contact with enemy tanks is a priority. If enemy tanks are not encountered, the 73mm cannon will prove most useful against hardened field fortifications, buildings, and fixed weapon emplacements like machine gun and recoilless rifle nests, and so on. The penetration and blast effect of its HEAT grenades would be particularly useful on fortifications that are otherwise completely immune to machine gun fire, like a triple layer of sandbags (a common standard during the Vietnam war) or a double layer of sandbags reinforced with timber.

Given that the light weight of the BMP-1 allows it to be deployed where tanks cannot go, the firepower of a 73mm cannon becomes particularly meaningful for the troops that are deployed together with the vehicle. From this perspective, there were clear merits to the use of the 73mm "Grom" in the BMP-1. Indeed, there are are a multitude of valid reasons why a weapon like "Grom" is preferable for the BMP rather than a heavy machine gun or a rapid fire autocannon. For one, the firepower of a large caliber cannon is indispensable in many situations. The need for such weapons was met in Vietnam by configuring the M113A1 ACAV with a pintle-mounted 106mm M40A1 recoilless rifle to be operated from the passenger compartment roof hatch. The M113 ACAV with the M40A1 had tremendous firepower but the vehicle provided no protection whatsoever for the gunner and had a severely constrained rate of fire due to the small roof hatch of the passenger compartment and inconvenient location of the weapon itself; the rear of the gun tube extended behind the roof hatch, so the loader has to contort himself to fit each cartridge - almost a meter long and weighing 16.4 kg - through the breech. It was also unsafe for personnel to stand behind or even near the vehicle when the M40A1 is in use due to the colossal back blast and firing signature. The British FV432 "WOMBAT" had an even more powerful 120mm L6 "WOMBAT" recoilless rifle mounted in a layout similar to the M113 and thus shared the same fundamental shortfalls, exacerbated by the more massive size (more than 1.1 meters) and weight (27.2 kg) of the cartridges. As such, these vehicles were tactically distinct from the BMP-1 and neither of the two were proper analogues.

The British Alvis Saladin armoured car and FV101 Scorpion reconnaissance vehicle were both armed with 76mm low pressure guns in fully enclosed turrets, and the Australian Army developed a closer analogue of the BMP-1 in 1967 by mating the fully enclosed turret of the Saladin armoured car with a 76mm L5A1 low pressure gun to the hull of the M113A1, thus creating the Saladin FSV (Fire Support Vehicle). The Saladin FSV is shown in the photo belo. In continuation of this concept, the MSV was created in 1976 by mating the turret of a Scorpion with its 76mm L23 low pressure gun to the M113A1. But even so, these were still fire support vehicles and not pure IFVs. The BMP-1 was completely unique in its combination of traits in 1966 and for better or worse, remained unique throughout the remainder of the Cold War.

From the perspective of the Bundeswehr, the decision to mount the 20mm HS.820 on the SPz 12-3 and the 20mm Rh202 on the Marder was motivated by the need for sufficient firepower to deal with dismounted infantry and lightly armoured troop carriers. In the Soviet Army, this need was met by using a combination of a 14.5mm KPVT heavy machine gun and a 7.62mm SGMT or PKT general purpose machine gun. This armament scheme was established as the standard armament of Soviet armoured personnel carriers and armoured cars beginning with the BRDM-2 (1962) and the BTR-60PB (1966) which both used the same BPU-1 turret. The KPVT would be used against armoured personnel carriers - such vehicles would typically only have limited protection from 12.7mm machine guns - and infantry behind solid obstacles, and the SGMT or PKT would be used against infantry in the open. Although the KPVT was not as useful in the anti-personnel role as a 20mm or 23mm rapid-fire autocannon as its caliber is too small to deliver an effective explosive payload, it fulfilled the same niche in every other respect and was more than adequate for armoured personnel carriers. With this in mind, an escalation in firepower to encompass tanks as the primary target for an IFV like the BMP-1 is not unusual.

According to the firing table for the PG-9 grenade fired from the 2A28 cannon, the technical dispersion of the PG-9 grenade is 0.6 mils in both the horizontal and vertical axes. The technical dispersion of the OG-9 grenade fired from the 2A28 is 0.9 mils in the horizontal axis and 1.0 mil in the vertical axis.

The point blank range of the cannon with PG-9 HEAT grenades against a medium tank target with a height of 2.7 meters is 800 meters. Theoretically, this allows the gunner to neglect the range estimation process and open fire immediately at a tank within 800 meters with a reasonable expectation of scoring a first-round hit, but due to the dispersion of each shot, the reality is that range estimation is still required to achieve a reasonable probability of hit.

According to comparative data published in the book "БМП-1 (1964-2000): Боевая машина пехоты" by Sergey Malyshev, a basic BMP-1 only has a 35% chance of eliminating an ATGM team with two shots from its cannon at a range of 500 meters. This drops to a measly 10% at a range of 1,000 meters. For comparison, a 30mm autocannon (the 2A72 in this case) has a 100% chance of eliminating an ATGM team with sixteen shots at 500 meters, 50% chance at 2,500 meters, and 40% chance at a range of 4,000 meters. In this comparison, both vehicles are stationary. Against ground targets, the main downside of the 73mm HEAT rounds fired from the "Grom" is that they have an extremely limited fragmentation effect and the explosive charge is not powerful enough to ensure the elimination of soft-skinned targets in the open unless it detonates close to the target.

According to the same book, the probability of destroying an armoured personnel carrier with two shots from the 2A28 cannon is 80% at a range of 500 meters. This drops to only 25% at a range of 1,000 meters. Keep in mind that the probability of destruction is not the same as the probability of hit, as each hit is not guaranteed to destroy the target.

Zaloga claims that the "Grom" can achieve a 70% hit rate on a stationary tank-type target at 500 meters in still air, degrading to 50% at 800 meters. This is not high compared to a high velocity tank cannon, but still quite respectable, as this is already somewhat close to the performance level of the T-62 firing 3UBK-3 115mm HEAT shells, as you can see in the TRADOC bulletin diagram below. An M60A1 could achieve an 80% hit rate with its own 105mm HEAT shells at the same range thanks to its optical coincidence rangefinder.

Without knowing the target that was used to determine the probability of hit data supplied by Zaloga, it is not possible to make any firm conclusions. Nevertheless, the ineffectiveness of the "Grom" cannon at long range is hardly a secret, and its maximum effective range of 800 meters may not even be achievable in practice. During one a live firing trial, a BMP-1 was made to open fire against a stationary T-55 tank at 800 meters. Out of 50 shots, only 17 hit the tank; the others were carried off their trajectory by the wind. This translates to a 34% hit rate.

Nevertheless, it is worth pointing out that a T-55 is smaller than a typical NATO tank. The British Chieftain tank, for example, is 2.9 meters tall and 3.66 meters wide. The American M60A1 has a similar height of 2.9 meters (not counting the very large commander's cupola) and 3.63 meters wide. The German Leopard 1 was 2.6 meters tall and 3.25 meters wide while the French AMX-30 was by far the smallest at 2.52 meters in height and only 3.1 meters in width. The T-54 is only 2.4 m tall and 3.37 m wide. The probability of hit will be higher at all ranges against a larger target, and vice versa. Therefore, it can be inferred that the "Grom" has a slightly higher than 50% chance of hitting a stationary M60 or Chieftain at a distance of 800 meters under favourable weather conditions when using the standard PG-15V HEAT round. The gunner will have to rely more on the ATGM when engaging tanks at distances exceeding 800 meters, and will become totally dependent on the ATGM when fighting at distances of more than 1,300 meters.

As a fighting system, the "Grom" cannon was the most potent direct fire weapon organic to a motorized infantry squad equipped with a BMP-1. An RPG-7 with five grenades would be carried by the grenadier in the squad and it would be operated together with the assistant grenadier. The RPG-7 was a powerful weapon in its own right, but it belonged to a different class than that of the "Grom". The penetration power of the original 85mm PG-7V grenade from 1961 was also less compared to the 73mm PG-9 fired by the "Grom" - 260mm RHA compared to 300mm RHA. In 1969, the improved 70mm PG-7VM grenade entered service with a warhead derived from the PG-9 and a modified propulsion system. The deflection of the projectile from crosswinds was decreased by 1.5 times and the accuracy of fire was increased by around 20-25%. But even with these improvements, the probability of hitting targets beyond 300 meters was still a challenge.

A further examination of the functional precision of the PG-7V rocket grenade when fired from an RPG-7 against tank targets can be found in "Analysis of Rocket-Assisted Aspects of Infantry Antitank Weapons" by Dr. Thomas H. Dawson published in the November-December 1975 issue of the Army Research and Development News Magazine. The article details the technical aspects of the PG-7V rocket itself and considers its advantages and disadvantages, concluding that the drawback of increased wind deflection of the rocket design is completely overshadowed by the greatly reduced margin of error allowed in range estimations due to the increased velocity. It was found that compared to a conventional projectile with a muzzle velocity of 100 m/s, a rocket-assisted grenade like PG-7V with a boosted velocity of 300 m/s decreases the angular elevation (range estimate) error by a factor of more than 10, while the angular deflection (crosswind) error increases only by 3 times.

The hit probability data presented in the graph below shows the probability of a PG-7V grenade achieving a first round hit on a 2.3 x 2.3 meter square target with the same nominal ranging error of 15% (stadia rangefinder), technical shot dispersion of 2 mils, and the same crosswind of 3 m/s. Compared to a hypothetical conventional grenade with a muzzle velocity of 100 m/s and no rocket booster, the effective range of the PG-7V - defined as the distance at which a 50% hit probability is achieved - is twice that of the conventional grenade. The hit probability of PG-7V reaches 80% at a range of 140 meters, and it is 20% at 300 meters.

This shows that in a worst-case scenario where a crosswind is present, the effective range of the rocket-assisted grenade is 2 times better than the conventional grenade. When a crosswind is not present, the advantage of the rocket-assisted grenade is even larger.

This is corroborated by data on the number of shots needed to "defeat" an armoured target in various situations is detailed in page 58 the manual "Наставление по стрелковому делу Ручной противотанковый гранатомет РПГ-7, РПГ-7Д " (Manual on the Matters of Firing Hand-held Anti-tank Grenade Launcher RPG-7, RPG-7D) from 1972. The manual does not specify the type of armoured target or the definition of "defeat", but it can be reasonably assumed that the figures refer to the number of shots needed to hit a tank rather than the number of shots needed to kill a tank, as multiple direct hits are usually needed to knock out a postwar tank. Three types of targets are specified: a frontal aspect of a target moving at 20 km/h, a profile target moving at 20 km/h, and a target situated in a hull-down position.

At 100 meters, both the original PG-7V round and the improved PG-7VM round needed only one shot on the frontal aspect of a target moving at 20 km/h, one shot is needed on the profile of a target moving at 20 km/h, and one shot is needed for a tank in a prepared hull-down position. When the distance increases to 200 meters, the number of PG-7V rounds needed increases to two for the frontal target and four for the hull-down target, and the higher precision of the PG-7VM round begins to show itself as only three shots are needed for the hull-down target. The gap in accuracy between the PG-7V and the PG-7VM widens as the distance increases, but the limits of the RPG-7 are quite evident as the PG-7VM round achieves a 50% hit probability for the front silhouette and side silhouette of moving tanks at just 200 meters and 300 meters respectively. For comparison, the Carl Gustaf M2 (m/48) achieves the same hit probability against a moving tank at a range of 150 meters.

In a best-case scenario where the target is a static tank and there is no crosswind, the effective range where the RPG-7 achieves a 50% hit probability reaches 250 meters. The Carl Gustaf M2 (m/48) achieves the same hit probability at a range of 200 meters. The difference can be attributed to the difference in the flight velocities of the grenades fired by the two antitank systems. The RPG-7 launches a rocket-assisted grenade at a muzzle velocity of only 140 m/s but the projectile accelerates to a peak velocity of 300 m/s after it leaves the launcher, after which it starts to decelerate. The Carl Gustaf launches its HEAT grenade at a muzzle velocity of 255 m/s and the grenade experiences a continuous deceleration until it reaches the target.

At a range of 250 meters, "Grom" has a 90% chance of hitting a stationary tank-type target with its PG-9V grenade. Compared to the RPG-7 carried and operated by the anti-tank grenadier in the squad transported in a BMP-1, the maximum effective range of the "Grom" against a tank-sized target is up to three times higher. Most of the difference can be attributed to the much higher velocity of the PG-9V grenade: the muzzle velocity of the PG-9V is 400 m/s m/s and the maximum velocity is 665 m/s. In comparison, the PG-7VM round remains subsonic throughout its entire flight. The probability of hit with an RPG-7 was therefore much more sensitive to errors in range estimates and it was additionally affected by operator stance, which is a factor that is not relevant for a tripod-mounted weapon like the SPG-9 or the vehicle-mounted "Grom".

In other words, the short effective range of the "Grom" was not a problem when considering the full suite of weapons on the BMP-1 in its totality.

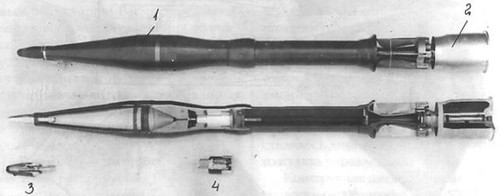

The cannon is fed with 40 rounds of ammunition by an autoloader mechanism, all of which is stored in a crescent-shaped conveyor. No additional ammunition was carried in reserve stowage racks. The electrically powered autoloader conveyor is designed to ensure a continuous supply of ammunition for the autoloader.

The conveyor is essentially a chain with external spokes where the 73mm rounds are attached. The drive sprocket, shown in the drawing on the left below and in the photo on the right below, is directly behind the gunner's seat. The electric motor for the conveyor is installed in the turret.

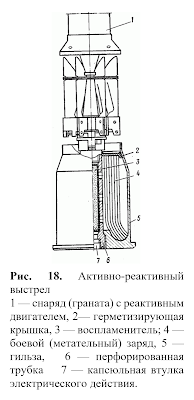

The rocket engine is located at the rear of the projectile, in front of the folding stabilizer fins. Rocket propellant is contained inside the cylindrical segment at the middle of the projectile and the exhaust gasses exit from a Venturi nozzle at the rear end of the projectile, unlike an RPG-7 rocket where multiple exhaust nozzles are arranged around the circumference of the rocket just behind the grenade warhead. A raised lip in front of the stabilizer fins acts as a bore obturator.