MT-LB

The MT-LB was developed by KhTZ (Kharkov Tractor Plant) as a successor to the AT-P and AT-L prime movers. It is worth noting that the KhTZ factory is distinct from the more famous KhPZ (Kharkov Locomotive Plant), responsible for the T-34, T-54, T-64, and so on. The MT-LB was intended for a tactical tractor-transporter role, acting as a prime mover for both anti-tank guns and artillery pieces. At the time it entered service, the most modern anti-tank gun available in the USSR was the 100mm T-12. Thanks to its lightweight design, this gun could be dependably towed by even the AT-P (Артиллерийский Тягач - Полубронированный, or Artillery Tractor - Semi-armoured), but even so, the size and payload capacity of the AT-P was too limited to effectively serve as the prime mover for the T-12, and the semi-armoured prime mover concept was becoming questionable due to the proliferation of tactical nuclear weapons.

In contrast to the AT-P, the AT-L (Артиллерийский Тягач - Лёгкий, or Artillery Tractor - Light) was ostensibly providing untroubled service as a prime mover for heavy mortars and 122mm howitzers, but after some years of use in the army, hull cracking was observed due to vibrations from the suspension. On top of this, it was found in 1959 that its capacity for modernization was limited, as the level of mobility could not be feasibly improved by fitting a larger, more powerful engine because it led to the hull becoming excessively nose-heavy.

With the AT-P and AT-L not performing to the desired level and lacking future prospects, the army found a need for a replacement for both vehicles. This was despite the fact that both vehicles had only recently entered service; the AT-P in 1954, and the AT-L in 1952. Given the need to fulfill the roles of two different prime movers, the successor vehicle in development at KhTZ was aptly named the MT-L (Многоцелевой Тягач - Легкий, or Multi-purpose Tractor - Light).

When the MT-L was still in development, the perceived need for a basic level of protection for a combat prime mover led to the Army's insistence on a fully enclosed armoured hull complete with NBC protection for the new vehicle, resulting in the creation of the MT-LB. With the addition of armour, the weight of the vehicle rose, although it was kept under control by the lowering of the vehicle silhouette. Compared with the 8.5-ton curb weight of the MT-L, the 9.7-ton curb weight of the MT-LB indicates that the weight gain was relatively limited despite the retention of almost all preexisting features; only the winch of the MT-L was removed in the MT-LB.

Testing was carried out in the regions customarily used by the Soviet military, including the Arctic and Turkmenistan for cold and hot climate trials. On 25 December 1964, the development cycle of the MT-LB concluded and it was accepted into service in the Soviet Army alongside the MT-L. KhTZ began the process of retooling its AT-L production line to switch to MT-LB production, which was handled with difficulty, as the assembly line for AT-Ls had been maintaining an average production rate of 5 vehicles a day to meet demand. Under such circumstances, the idea of producing both the MT-L and MT-LB simultaneously only complicated matters. As there was a considerable difference in the hulls of the two vehicles, it was decided that the capacity of the KhTZ plant was to be concentrated into a single production line dedicated solely to the MT-LB, and the technical documentation for the MT-L was transferred to the Semipalatinsk Machine-Building Plant, where the technology was used to improve the plant's products. With this decision, the MT-L was effectively discontinued, and the success of the MT-LB was secured. According to the article "Универсальный Солдат Многоцелевой Транспортер-Тягач МТ-ЛБ" in the No.5 2014 issue of the "Наука и Техника" magazine, serial production of MT-LB at KhTZ officially began in 1966, but the first batch of vehicles was delivered only in 1967.

To gain a better technical understanding of the MT-LB and the advancement it represented, it is necessary to first look at its predecessor, the AT-P. The creation of the AT-P was initiated on the basis of providing a modern successor to the successful T-20 "Komsomolets" and Universal Carrier prime movers, the latter of which was fairly ubiquitous in the Red Army thanks to Lend-Lease deliveries from Britain. The Universal Carrier and T-20 "Komsomolets" were both very basic vehicles, being more or less a container for an engine and its drivetrain. The accommodations for crew and passengers were spartan, simple clutch-brake steering was used, and the design followed civilian automotive conventions more than military conventions. This can be seen in their hulls, being built on a chassis with the armour plates riveted to a load-bearing frame upon which the drivetrain was installed, rather than having a monocoque construction. The AT-P was, in turn, a more modern iteration of the T-20, sharing its basic design and most of its design characteristics while introducing some modern ones, such as dispensing with the chassis concept in favour of a monocoque load-bearing hull and replacing the suspension bogies with individually sprung roadwheels. As the successor to the AT-P, the MT-LB completely diverged from this design heritage.

The MT-LB was not a rudimentary prime mover like the AT-P and T-20. It was fitted with all of the requisite features for operation in cold environments, NBC-contaminated combat zones, for crossing water obstacles, for self defence, and had full armour protection with internal space for a full unit of fire for an anti-tank gun. This was the most major advance over the AT-P, which was considered semi-armoured because its cargo compartment was open-topped and the few crates of ammunition it could carry had to be tied down externally on the sponsons regardless of whether a full passenger load was carried or not, as shown below. Additional features of the MT-LB included a self-replenishing pneumatic system for windshield washing, for operating the on-board pneumatic brakes, and for the pneumatic brakes of a towed trailer (if present).

Prior to developing the MT-L and MT-LB, the KhTZ plant was responsible for the AT-L light artillery prime mover and GT-T amphibious prime mover, both of which were unarmoured tractor-transporters. Several major elements of the GT-T formed the basis for the design of the MT-L, which in turn made their way to the MT-LB. The most prominent design elements in common between the two vehicle families was the suspension, and the watertight monocoque load-bearing steel hull. The familial connection between the GT-T and the MT-LB was further deepened when the updated GT-TB model was later introduced, featuring an adapted version of the YaMZ-238 engine originally used in the MT-LB.

However, the form of mid-engine, front-transmission layout used in the GT-T was not used in the MT-L. The GT-T had its engine sharing the crew cabin, with the crew seats placed astride the engine, which was imperfect in many respects but allowed for a completely free cargo bed. The same layout was used in the AT-P. Instead, the MT-L used the drivetrain layout of the ATS-59, even including a similar rear winch. Additionally, the gearbox and steering mechanism unit was derived from the type used in the AT-L, which entered service in 1947. Overall, there were very few novel ideas implemented in the MT-L, but its design was innovative in that it combined many successful features taken from existing prime movers. In fact, the mid-engined layout - which is rarely encountered in the present day and could be considered the most distinguishing feature of the MT-LB - was wholly typical of Soviet tracked tractor-transporters.

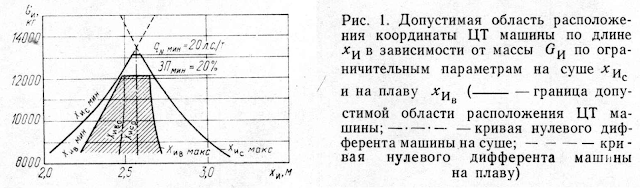

Unlike most armored combat vehicles, tracked tractor-transporters are used, as a rule, with variable loads, so the layout must be designed to provide a satisfactory weight distribution across the suspension without a load, and optimal weight distribution with a load, so that the traction and ride quality is maximized at all times. For this reason, the placement of the engine in the middle of the hull, slightly forward of the geometric center of the track base, was particularly advantageous. This also has the minor benefit of limiting the maximum ground pressure for a given load.

As older prime movers were gradually decommissioned as they reached the end of their service lives, the demand for the MT-LB in the Soviet Army during the early 1970's reached a point that the production capacity of KhTZ was not enough to accommodate the volume of orders, not just domestically, but also in the armies of Warsaw Pact countries. To fill this demand, the BETA factory in Bulgaria and the Stalowa Wola Steelworks plant in Poland were commissioned with licences to produce the MT-LB, and MT-LBs commenced licensed mass production in 1972 in Bulgaria, then in Poland in 1976.

Having the combination of a large load capacity, a relatively large cargo compartment, excellent weight balance, high power reserve, a basic level of armour protection and a high degree of operational commonality with domestic light and medium trucks, the MT-LB was frequently taken as the basis for lightweight specialized military vehicles. This differentiated it from similar vehicles made as personnel carriers, which tended to be designed with smaller gross weight ratings, adequate for passengers and a small complement of equipment, but no more. With the MT-LB, many modifications could be added without violating the buoyancy reserve and without needing automotive upgrades to maintain the same level of performance.

As an example of this, the BRDM-2 was rated for a combat weight of 7 tons, and it only meets its rated performance metrics as-is. The Strela-1 modification, built on the basis of the BRDM-2 hull, required weight-saving measures such as the removal of the belly wheels and their drive system in order to maintain the same combat weight of 7 tons. With the MT-LB, a much heavier system could be fitted, with the resulting Strela-10 vehicle weighing 12.3 tons without violating the specifications of the basic MT-LB. In fact, the weight of 12.3 tons reached the 20% limit of the reserve buoyancy required to maintain a safe swimming capability, but not the limit of other parameters.

Following the MT-LB, the MT-LBu variant was created to function as a basis for support vehicles, ranging from artillery fire control posts, to mobile headquarters for air defence units, and even radar stations. To accommodate this equipment, a new enlarged hull (taller by 485mm, longer by 800mm) with 7 roadwheel pairs and a revised layout (reverting to the MT-L layout) was used.

The MT-LBu will not be covered in this article for the time being, partly because it is largely the same as the basic MT-LB while also being substantially different, and partly because some features of the MT-LBu are somewhat indeterminate, as changes are made on an individual basis depending on the requirements of the modification. Generally speaking, an MT-LBu is usually unarmed, but a machine gun for self-defence may be fitted on specialized models that faced some danger of attack from enemy reconnaissance probes or exploitation forces. For instance, the 1V13, 1V14 and 1V16 artillery battery fire control vehicles were armed with a pintle-mounted DShKM, theoretically allowing them to serve as a base of fire for troops while the howitzers or guns of the battery fire upon the armoured vehicles of the enemy force with direct fire.

Although it is often lauded for its versatility in contemporary literature, the original MT-LB was largely confined to its role as an artillery prime mover during its service in the Soviet Army. In the 1980's, it started to see some use in northern Russia as cargo carriers to remote areas thanks to its high cross-country mobility, and after the dissolution of the Soviet Union, this practice saw a boon as private civilian ownership of MT-LBs became possible. In its original capacity as a military vehicle, the MT-LB was, for the most part, not a pure armoured personnel carrier or a pure tractor, but an artillery prime mover, however vague that distinction may be. Only the MT-LBu can be said to have taken on a wide variety of roles during its time in the Soviet Army, which is due to the fact that it was specifically designed to do so.

Rather than the MT-LB, it was the MT-LBu that became the de facto tracked platform for light specialized systems in supporting roles. The next increment in weight class was the GM-123, an older but capable medium tracked vehicle repurposed from the abandoned SU-100P hull that found a range of uses in specialized roles. Other notable lightly-armoured medium platforms were the GM-575 and its modifications (578, 568) in 1967, and the GM-569 series and its modifications (567, 577, 579) in 1978, both made specifically for army tactical air defence systems.

Unlike the MT-LBu, the MT-LB itself was only occasionally used as a basis for specialized vehicles; the notable were the Strela-10 and "Shturm-S". It may be surmised that this was partly due to the limited scope for unification within the niche of light tactical combat vehicles, and partly because the BMP had just entered service, and its hull was more suitable for specialized vehicles operating in, or ahead of the frontline.

The main variants of the MT-LB in the Soviet Union were the:

- MT-LBV

- MT-LB with self-entrenchment equipment (allegedly exclusively imported from Poland)

- MT-LBVM

- Modifications 32, 35 and 49

The MT-LBV, entering service in 1972, introduced new roadwheel swing arms, fenders and mudguards to accommodate a wider set of tracks.

The MT-LBVM model, entering service in 1982, replaced the machine gun turret with a 12.7mm NSVT heavy machine gun weapon station.

Modifications 32, 35 and 49 are simplified versions of the MT-LB, primarily made for cargo ferrying purposes. These three models are shown in ascending order below. On Modification 35, there is a large circular hole on the hull roof with an unknown purpose.

According to the analysts of the Central Scientific Research Institute of armament and military equipment of Ukraine, there are between 40 to 50 thousand MT-LB vehicles of various models in service with 42 armed forces throughout the world. An article on the Russian Ministry of Defence website makes a similar claim that more than 44,000 MT-LB and MT-LBu vehicles were produced, including for the armies of more than two dozen foreign countries.

In its role as an artillery prime mover, the MT-LB had no analogues in the world at the time it entered service. That said, the reason it had no analogues was because towed artillery was being phased out in favour of self-propelled artillery at the time, and efforts were focused in this direction among all of the major military powers of the world. In terms of its design, it was technically deficient in many of the design details relevant to combat vehicles, sharing more in common with utility vehicles such as contemporary domestic military trucks and artillery prime movers.

The MT-LBVM modification, which entered service in 1982, was created based on feedback from Afghanistan. The modifications consisted of a new remote weapon station with an 12.7mm NSVT machine gun instead of the original 7.62mm turret. Its combat weight rose only negligibly, to 10.5 tons. This feedback was related to the use of MT-LBs as tracked personnel carriers in direct combat, like BTRs, and the MT-LBVM was likewise intended for this role. In this configuration, MT-LBs have served as tracked replacements for wheeled BTRs in motor rifle units stationed in the Far East and Northern Russia, where impassable terrain severely restricted the choice of transportation. In this regard, the MT-LBVM did not have any analogues in the world at the time, as the closest equivalent was the Bv 206S which only entered service in the early 2000's.

INDEX

- Ergonomics

- Firing Ports

- Ventilation

- Heater

- Commander's Station

- Armament

- TKB-01-1 Turret

- TKB Turret

- Protection

- Driver's Station

- Cargo

- Mobility

- Engine

- Engine Accessories

- Cooling

- Fuel System

- Transmission

- Steering System

- Suspension

- Water Obstacles

Special thanks to Cate from the CRIB blog and Lottie from the Australian Armour & Artillery Museum Cairns for photos, measurements and other assistance.

ERGONOMICS

The crew consists of 2 people - driver and commander. When used as an armoured personnel carrier, there are a total of 11 seating spaces available in the cargo compartment. This passenger capacity gave ample surplus space for a motorized infantry squad, which was composed of only 7 men during the periods relevant to the MT-LB (post-1964).

The seating layout in the cargo compartment consists of two benches, seating four people each, supplemented by a fold-out seat just behind the engine compartment corridor. There are an additional two fold-out seats in the corridor itself. The walls and ceiling have no linings for insulation, radiation shielding or otherwise; the only lining present is the rubber anti-slip floor mats.

The passengers in the cargo compartment sit facing inward, with the possibility of fully outstretching their legs in the span of space between the benches. The person occupying the supplementary fold-out seat sits opposite the duct of the heater. The benches are rectangular floor fuel tanks with a contoured upper surface, complete with thick foam cushions. The photo below shows the cargo compartment benches of an MT-LB without the cushions and backrests.

The backrests of the benches are folding sheet steel panels with a cushion. When carrying cargo instead of passengers, the backrests are folded down onto the benches to provide a level surface to place cargo.

With the engine offset to the port side of the hull, the void on the starboard side formed a narrow corridor between the crew compartment and the cargo compartment. The other two seats are hinged to the engine compartment partition, and unfold into this corridor between the crew cabin and the cargo compartment. Two passengers sit may facing forward in this corridor. The void in the engine compartment partition for the space for these seats is the space under the right cylinder bank and exhaust manifold of the YaMZ-238 engine.

The corridor has a width of 450mm and a full length of 1,300mm. When folded out, the seats take up almost the entire width in the corridor.

To reduce the impact of engine heating on the temperature at this corridor, which would otherwise be very high because it is next to the right exhaust manifold, the engine compartment partition is insulated with a spaced reflector sheet in addition to an asbestos lining, whereas the other partitions have only an asbestos lining.

The image below shows the three types of seats available in the cargo compartment. From left to right, these are the corridor seats, the supplementary seat, and the benches. The fold-out seats are largely the same in basic design, and are the same in terms of ergonomics. The seats are around an inch lower than the benches, giving slightly more headroom.

When transporting a gun crew while carrying an allocation of ammunition, two passengers would be seated here in order to clear up space on the left half of the cargo compartment for ammunition crates. For instance, when transporting the 6-man crew of a T-12 anti-tank gun, all 6 men can be seated on the right half of the hull and all can leave through the right rear door in single file, leaving the left half for ammunition. An example of this packing layout is depicted in the drawing below.

When used to transport cargo, there are no passengers and no practical utility in allowing the crew to move between the crew and the cargo compartments, so this passage could be used as additional cargo space. When under heavy fire from the front, it also provides the crew with the invaluable option of evacuating the vehicle through the rear doors.

Because most of the cargo compartment roof is allocated as cargo space, the passengers are limited to only two roof hatches, occupying under a third of the available roof space. The roof hatches have a square shape and are quite large, which is beneficial in emergency situations such as when exiting the vehicle with a life jacket, but they are not long enough to allow more than one person to pass through or stand in the opening. For mounted combat, the maximum number of passengers firing from the hatches is two. As the hatches open forward, they could also help in providing small arms protection for passengers opting to fight from the hatches.

A strong example of the vehicle's design focus as a prime mover can be seen in its hull layout, particularly the location of the engine. Although this layout is not volumetrically inefficient, nor is it impractical for accommodating passengers, it is highly inefficient in terms of providing the maximum length of free space for a given total hull length. Although the corridor next to the engine compartment allows men to be seated or additional cargo to be stowed, the contiguous length of the cargo compartment is only 40% of the total structural length of the hull. This is in contrast to the BTR-60, 70 and 80 where the crew and passengers all occupy a single contiguous compartment that spans around 65-70% of the hull structural length. The same is true for truck-type personnel carriers with a conventional front-engine layout like the BTR-152.

It is also not optimal in terms of integrating a turreted weapons module, particularly ones occupying a substantial swept radius of space below the turret ring. This is immediately apparent in the hull of the 2S1 "Gvozdika", which was adapted from the MT-LB. By retaining the same powertrain without revising the hull layout, it was not possible to mount a 3-man turret and have rear ammunition racks without extending the hull and suspension by one roadwheel. In contrast, during the development of the 2S1, one of the competing proposals based on an extended Object 765 (BMP) hull was not only able to integrate the turret, but had rear rack space for an additional 20 cartridges.

The structural height of the MT-LB hull without its machine gun turret is 1,211mm. That is, the height from the hull belly to the roof plates is 1,211mm, excluding the thickness of the plates themselves, and excluding any additional height from hatches or external fittings. Considering the armour plate thickness of 7mm on both the belly and roof, the internal height is 1,197mm.

For reference, according to data in the U.S Army the IFV Task Force Study, which was carried out in 1978, the M113A1 has an internal hull height of 1,206.5mm at the cargo compartment, which is a large difference from the structural hull height of 1,422mm due to the thick aluminium roof (1.5") and belly (1.1") plates, tall torsion bar housings (5.4"), and false floor paneling (0.5") on top of the torsion bar housings to provide a flat floor surface in the cargo compartment.

The nominal dimensions of the cargo compartment, according to an MT-LB manual, are 2,605 x 1,948 x 1,150 mm. These dimensions are measured from the engine compartment firewall to the rear doors for length, between the fuel tanks in the sponsons for width, and between the reinforcing beams on the floor and the surface of the ceiling for height. In practice, the benches, which are not removable to free up cargo space, reduces the actual height available for cargo along half of the given cargo compartment width. The nominal cargo space is calculated to be 5.8 cubic meters, but the actual space is somewhat less when the seats are taken into account. This is practically the same as the cargo space in an M113.

The benches are placed 500mm behind the engine compartment firewall, leaving empty space in front of the left bench for loose stowage and a space in front of the right bench for the supplementary fold-out seat. The remaining 315mm of space between the benches and the rear doors is taken up by the track tensioning mechanisms for each idler wheel.

The length of the benches is 1,790mm. This is exactly the length required to fit four men with a 50th percentile shoulder width in shoulder-to-shoulder seating. The maximum height of the benches from the floor is 300mm, which can be seen in the cross-sectional drawing below, where the top surface of the bench is shown to be only a little higher than the axis of the towing hitch, itself 260mm from the floor*. The minimum headroom, when measured from bench surface to ceiling, is 860mm. When measured from the surface of the dip in the bench, the headroom is 950mm. All measurements regarding passenger seating were kindly provided by Lottie of the Australian Armour & Artillery Museum Cairns.

*MT-LBVM manual lists a nominal height of 667mm to towing hitch, and nominal ground clearance of 400mm

The seated headroom, when taking into account the contour of the dip in the bench and the compression of the foam cushion when sat on, can be expected to be around 890mm. This means that when the passengers are sitting in an erect posture, the height of the cargo compartment is nominally sufficient to accommodate a contemporary 50th percentile Soviet male, who would have a standing height of 170cm, or a 30th percentile American adult male, according to data from a 1966 U.S Army anthropometric study conducted with Army personnel. According to the 1966 data, a 30th percentile male would have an erect seated height of 888.1mm. According to the 1974 ergonomics monograph "Обитаемость Объектов Бронетанковой Техники", which references anthropometric data of Soviet military personnel in the tank forces, the statistical average seated height is 891mm, with a standard deviation of 30mm. Using two standard deviations to describe the maximum seated height, it was determined to be 952mm, although actual measurements showed that the actual tallest seated height among real servicemen was 940mm.

In practice, passengers belonging to those percentile groups will likely not be able to sit in an erect posture due to the discomfort of a lack of head clearance in off-road driving and especially if the passengers are wearing helmets, which will add over an inch to their height. This can be seen in the photos below. Note that the passenger on the right (with the red armband) is not seated on a bench in this MT-LBVM for some reason, but on the ammunition racks for 12.7mm ammo boxes. Because of this, the reinforcing frame on the ceiling interferes with his headroom.

Based on the seat height, it can be surmised that although it is possible for the passengers to fully outstretch their legs in the span of space between the benches, the seats were designed with a conventional upright seating posture in mind, and as such, were built with a relatively high popliteal height to accommodate the legs. Because of this design decision, the cargo compartment may feel shorter than the driver's positions in domestic tanks where the politeal height of the seat is much shorter, despite the MT-LB hull actually being structurally taller than domestic tank hulls. For comparison, the M113A1 has a 990mm of headroom, despite the interior hull height being almost identical. This was achieved by sacrificing popliteal height with lower benches, only 216mm above the floor.

In principle, the MT-LB accommodates the same demographic of soldiers as the BMP, which should not be surprising since combat vehicles were designed according to the same ergonomic guidelines. In the case of the BMP, it has a structural hull height of 1,175mm and a seated headroom space of 890mm, according to West German technical drawings, or 892mm (35.125") with a seat height of 267mm (10.5") according to the IFV Task Force Study. Although the hull is slightly shorter, the same headroom is provided by having lower seats with thinner cushions, at the expense of legroom.

On the MT-LBV, the possibility of using a standard vehicle as a casualty evacuation vehicle was provided by the implementation of special mounting brackets to secure standard stretchers, which have a length of 2,200mm with a handle diameter of 42mm. The cargo compartment can fit four stretchers, one on the floor between the benches, and three in a second tier above the benches. This is equal to an medevac-configured M113, although the stretcher placement is different.

It is worth noting that the MT-LBV is not a battlefield ambulance when used this way, as an ambulance provides space and facilities for paramedics to deliver emergency treatment inside the vehicle.

Passengers ingress and egress the MT-LB through two rear doors. Each door is 910mm wide and 820mm tall. The width of the doors is reasonable, as they make use of all the available hull width, but the height of the rear doors was partly restricted by the large reinforcing strut for the towing hitch, making it necessary to climb through the doors owing to their ground level rather than simply stepping into the cargo compartment. The main upside to having double doors of this design is that at least one door is available when a mortar base plate is carried, and it allows everyone in the cargo compartment to dismount as quickly as possible while a gun or a trailer is hooked to the towing hitch, since both doors can be freely opened over the carriage legs of a towed item.

There is only a single B-2 vision block and a single TNPO-170 periscope fitted to the cargo compartment. The B-2 vision block is on the right, next to the right firing port. Its position is considerably lower than the eye level of seated passengers, so it is too low to be comfortably used for general observation when seated, but it is placed conveniently enough for someone manning the firing port. Similarly, the TNPO-170 in the right rear door is only comfortable to use by someone manning the firing port. The periscope is embedded in the door within a pocket, so that there is no gap in the door armour. Structurally, there is no real reason for the periscope mount to have been designed for an upright periscope and not inverted, which could have placed it at eye level. It could be speculated that passenger vision was simply not a serious consideration given the nature of the MT-LB, unlike in the BMP where the passengers were infantry, needing situational awareness to avoid becoming disoriented when disembarking into combat.

There are very few interior lighting devices distributed in the cargo compartment. Although the driver and commander are adequately furnished with one PK-201A dome light each, supplemented with additional lamps to illuminate instrument panels, the cargo compartment is only provided with a single PK-201A dome light. Together with the small number of vision devices for passengers, this means that the cargo compartment will be quite dark when all hatches are closed.

FIRING PORTS

There are a total of four firing ports available in the cargo compartment of the MT-LB, providing a modicum of under-armour fighting capability in contaminated environments. There is a firing port on each side of the cargo compartment, and a B-2 vision block next to the right firing port. The empty space in the sponson where the vision block and firing port are located grants plenty of room to swing a rifle around when firing out, but this space is otherwise not used for anything, and can be used to stow personal effects, machine gun ammunition, or anything else needed by the crew or passengers.

There are another two firing ports embedded in the rear doors. They are also closed with a cover when not in use.

Due to the lack of fume extraction or additional ventilation at each firing port like in a BMP, it would have been impractical to sustain the use of the four firing ports beyond a few magazines from each rifle.

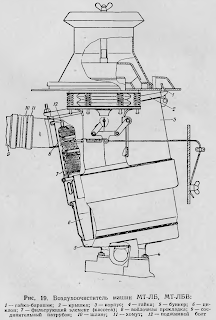

VENTILATION

The primary means of ventilation in an MT-LB is a supercharger. It provides a normal blower mode to provide air circulation for general ventilation, and a supercharger mode to purify the air of radioactive dust and create an overpressure inside the vehicle in the event that the air is contaminated by nuclear fallout. The ventilator is turned on with a switch on the driver's instrument panel, with an additional switch to turn on the supercharger mode. To use the ventilator, the intake hood is first opened with a handle, which also tugs on a pullcord to open the dust vent. The intake hood is located just behind the commander's TKB-01-1 turret.

To read more on the supercharger ventilator used in Soviet armoured fighting vehicles of the period, visit this Tankograd article.

The supercharger mode would not only be used to filter out radioactive particles, but also to purify dusty air in general use, whenever the MT-LB travels through a dry and dusty area. In humid environments, the dehumidified air also helps improve comfort inside the vehicle by displacing humid air, although it does not function as effectively as an air conditioner that dehumidifies interior air by recirculating it. The blower end of the ventilator is aimed toward the cargo compartment, which is presumably good for the passengers, but less so for the two crew members seated up front.

At some point in the mid 1970's, this dust-filtering ventilator was replaced with an FVU, or filter-ventilator unit. The main difference is that a HEPA filter is incorporated as a second filter stage to purify the air after dust separation. This class of vehicular collective HEPA filter (FPT-50, 100, 200) did not enter mass production in the USSR until the end of the 1960's, so throughout the 1960's and early 1970's, collective protection from chemical and biological agent was absent except for a few vehicles such as the T-72. For the MT-LB, the FVU was not present in a 1974 manual, but appeared in a 1976 manual.

The new FVU consists of the supercharger and filter cartridge connected in series. The same air intake and the same controls were retained, but the entire assembly was now contained in a box. For normal ventilation needs, including overpressure ventilation, the FPT-200M filter cartridge is bypassed to avoid unnecessary filter expenditure. The ventilator is turned on with a switch on the driver's instrument panel, and by turning a handle on the lower side of the box, marked (21) in the drawing below, the connecting duct between the supercharger and the filter cartridge is sealed shut and the flow of air from the fan is diverted to a vent hole on the underside of the box.

The FVU not only introduced a HEPA filter, but also had a new high-efficiency dust separator with a VNSTs-200 supercharger. As its name indicates, the VNSTs-200 supercharger produces an airflow rate of 200 cubic meters per hour (117 CFM), and the same is true for the FPT-200M. Like the previous model of supercharger, the VNSTs-200 is used to purify dust from the air and create an overpressure inside the occupied spaces of the vehicle. The supercharger is a centrifugal compressor fan that delivers a flow of air into an annular array of cyclone filters at high velocity, where dust particles are centrifugally separated from the air owing to their high inertia relative to air, and purified air exits the front end of each cyclone via a central tube. The dust exits the cyclones from the rear end where it is then piped to an exhaust hole in the hull wall, where it is vented out along with only 10-15% of the total outgoing air.

After dust separation, air is ducted to the FPT-200M HEPA filter cartridge. Air enters the cylindrical cartridge from one end, passes through the annular filter and exits through a side vent in the cartridge, exiting the FVU box from a slot on its underside. The HEPA filter should not be used with humid air, so the moisture separation action of the supercharger is important for its proper function. Unlike in the case of the earlier ventilator, where the blower would help circulate air in the cargo compartment, the downward-facing vents of the FVU box make it less ineffective as a ventilator.

Early MT-LBs fitted with only the dust-filtering ventilator can be identified by the square hood of the dust vent slit, as shown in the image on the left below. Later MT-LBs with an FVU lack this slit, instead having a small hooded dust vent hole just behind the commander's vision block, as seen in the image on the right below, courtesy of Vitaly Kuzmin.

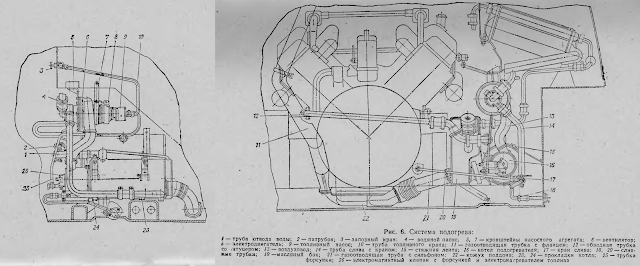

HEATER

The personnel heater is distinct from the engine preheater, which is located in the engine compartment. Heating of the cargo compartment is provided by an OV-65G heater-ventilator, a device that was later installed in various heavy duty trucks for cabin heating. As the FVU of the MT-LB would only blow cold air into the cargo compartment in winter, the OV-65G was designed to take over the role of a ventilator. It is used exclusively for space heating, and is not used for engine preheating. Hot air is delivered from the outlet through a set of ducts, as shown in the image below.

This, however, is an early variant of the heater ducts for the cargo compartment, which is rarely encountered on existing vehicles in the present day. A new duct design was introduced at some point after the late 1960's, and this design is found on the vast majority of MT-LB samples.

According to the specifications, the OV-65G is a 132 W fuel-burning heater (or 108 W on 12 V electrical system) with an airflow volume of 250 cubic meters per hour (147 CFM), or 220 cubic meters per hour (129.5 CFM) on 12 V. It has a maximum heating capacity of 6,000 kcal/h, with an air heating temperature differential of +95°C. It consumes 1 liter of fuel per hour. The cylindrical heater-ventilator has an air intake with a centrifugal forced induction fan on one end to draw air from the cargo compartment, and the other end is the outflow vent for the heated air. Fuel is piped into the burner from a fuel line and external air is supplied through a tube on the underside of the heater-ventilator, connected to an intake on the roof of the hull by a rubber hose. Exhaust gasses exit from an outlet on the top of the heater-ventilator, out the roof. The heater-ventilator has its own, separate 5-liter fuel tank inside the engine compartment, with a fuel pump located inside the heater-ventilator driven by the same motor as the blower fan.

The heater-ventilator supplies a flow of hot air down an air duct leading to the floor of the cargo compartment, where hot air is distributed to the feet of the bench seats via a central duct. The compartment is then heated by forced convection; as hot air rises, an updraft is created that circulates warm air throughout the compartment, both heating and ventilating it. Additionally, air is also delivered to the driver's compartment by a pipe that runs across the engine compartment via the left sponson, next to the radiator intake and exhaust ducts. In the driver's compartment, the pipe passes along the front left corner of the sponson and curves behind the instrument panel to blow hot air at the driver's feet. The ductwork of the heating system is shown in the diagram below.

The hot air duct is the silver duct prominently visible in the photo on the left below, and the air outlets along the central floor duct on the floor are also faintly visible. The photo on the right prominently shows the outlets on the central floor duct. Before it reaches the central floor duct, the silver-coloured duct has a small vent on its underside to blow at the feet of the passenger seated at the supplementary fold-out seat next to the right bench. In the early variant of the heating duct, there is a separate branch of the duct with an outlet for this purpose.

The duct to the driver's compartment is shown in the image below.

The ducting system, along with the torsion bar covers, serve a dual purpose as a structural reinforcement frame for the thin hull belly. The use of these structural elements for multiple functions can be considered to be quite a good design solution to offset the parasitic weight of reinforcing members, which would otherwise not be needed if thicker armour was used to form the monocoque hull. Strangely enough, however, there is no partition to cover the heater-ventilator, so whoever is seated on the bench directly in front of it will probably feel quite hot.

The downside to this ducting arrangement is that even though the passengers seated in the cargo compartment and the driver have good heating, the commander does not enjoy any direct heating. Even the passengers sitting in the engine compartment corridor have the heat of the engine.

In warm weather, when the heater is not needed, the duct is unbolted and stowed on the engine compartment firewall to free up space for cargo, people and equipment. It is also possible to use the heater-ventilator as a ventilation blower with no heating. The blower fan in the OV-65B and the fuel pump are both powered by the same electric motor, but the fan is driven at one end and the pump at the other via a clutch. When the heater-ventilator is turned on, it is the motor that is turned on, which starts the fan but not the fuel pump, which is turned on separately by engaging its clutch, and only after the glow plug is switched on. If used simply as a blower fan, the OV-65G provides additional air circulation in the cargo compartment and driver's compartment together with the supercharger ventilator, likely flowing as drawn in the image below.

COMMANDER'S STATION

The commander of an MT-LB is provided with two seating positions. His station is directly underneath the TKB-01-1 turret. Here, he has direct access to the radio, his control panel and his only magnified observation device, which is the sight for his machine gun. His second position is on a seat straddling the driveshaft cover that divides his station from the driver's station, where a hatch is located overhead. This jockey seat is spring loaded so that it stays folded up and flat against the backrest when not in use. Due to the height of the driveshaft cover, it is not possible to sit here when the hatch is closed. Seated here, he has a free view of his surroundings above the hatch to navigate by eye, which more often than not means that he spends most of his time in this position. To ingress and egress from the vehicle, the commander has to use this hatch. On the MT-LBVM, the replacement of the TKB-01-1 turret with a new NSVT turret provided the commander with an additional semicircular overhead hatch, allowing the commander to stand up directly in his station without using the center hatch, but more importantly, allowing him to reload the machine gun.

Note that the new NSVT turret has no name, with one manual simply stating that the TKB-01-1 turret was replaced with an NSVT-12.7 machine gun. However, the generic TKB designation is sometimes used to refer to the new turret, and as such, the same convention will be used in this article.

Since the crew area at the front of the hull is shared by only two people, and the width of the hull is more than enough for three people in side-by-side seating, there is quite a surplus of room, particularly for the commander, as the driveshaft cover does not symmetrically bifurcate the crew area. On the commander's side, the width from the driveshaft cover to the hull side wall is 910mm. When measured to the sponson, it varies from 1,290mm to the point just ahead of the ventilator to 1,060mm at the windshield, due to the slope of the sponson cheek. This is substantially wider than the driver's station.

However, due to the offset location of the gearbox relative to the centerline of the hull, a wide void was left on the left of the gearbox, which allowed a bulge to be added between the driver's pedals and the left steering brake, thereby providing the necessary space to depress the clutch and brake pedals. On the commander's side, there was only a narrow void, not nearly large enough to expand the commander's legroom, but it was put to use as a stowage space for two 250-round ammunition boxes for the PKT machine gun.

The commander's hatch was installed on the hull roof between the TKB-01-1 turret and the driver's hatch. On earlier models of the MT-LB and its variants, the hatch, which was of a more polygonal design, opened by hinging rearward, and it could be locked in the upright position. When locked open in this way, the commander could sit on the center seat and expose his upper torso above the hatch opening. On later models of the MT-LB, the commander's hatch was revised to use the same hatch as the driver's, merely reversed so that it would hinge forward and lock in the upright position to function as a shield for the commander, which is customary for Soviet vehicles.

Both types of hatches are simple hinged hatches with no spring assist, likely because they are light enough to not warrant it. The hatch design was standard for virtually all postwar Soviet light vehicles, with an upturned lip on the perimeter of the hatch opening and a downturned lip on the perimeter of the hatch to form a physical barrier against bullet splash and leaks, particularly heavy water splashing when crossing water obstacles. Both hatches have a lock to keep them upright when opened, consisting of spring-loaded pawl which rests against the lip of the hatch openin under spring tension when the hatch is closed. When the hatch is opened by 90 degrees, the pawl catches on the raised lip around the perimeter of the hatch opening as shown in the image below, blocking the hatch from hinging back. To release the hatch, the pawl is pulled away from the lip by a ring pull, freeing the hatch to be pulled back and closed. The hatch is prevented from hinging further forward (or backward, in the case of the early model) by a nub welded onto the hinge.

The lock was borrowed from the AT-P, shown in the image below taken from an AT-P manual.

Directly in front of the commander is the R-123 radio, the standard radio for all armoured vehicles of the time. It is fitted on a shelf beneath the windshield, placed at a convenient position. The MT-LB is fitted with the R-124 intercom system, allowing internal communication between the commander, driver and one passenger in the cargo compartment. The R-123 radio and its power supply unit can be seen in the image on the left below, from Reddit user "BT-42". The image on the right below showing the empty shelf for the radio and its power unit was taken from this video.

The front wall of his station underneath the radio is a removable partition between the crew compartment and the transmission compartment, where the commander's control panel is fitted. The control panel has three power switches for his front-facing headlight, the heating for his windshield, and turn on power to his turret. With such a sparse selection of controls, the commander has very little physical authority over the essential functions of the vehicle. Next to the control panel is the commander's A-1 communications switchbox.

The commander is provided with a total of five vision devices in the MT-LB(V) and MT-LBVM. When his hatch is closed, his primary means of observing his surroundings is by the windshield to his direct front, two 54-36-5SB.BM periscopes in the 11 o'clock and 1 o'clock positions, and a B-2 vision block aimed to the right (shown below). The B-2 vision block is fitted with a large thickness of ballistic glass, but even so, it may not provide the same level of protection as the steel armour of the hull. The upside to its large size, however, is that it provides a large field of view. In the combat modifications of the MT-LB proposed by Muromteplovoz, the slits for the vision blocks were patched over and the vision blocks were replaced with periscopes, presumably improving protection in these zones. Bafflingly, in the MT-LBVMK, which is a minor modification of the MT-LBVM with the replacement of the NSVT with the Kord (using an adaptor pin), only the B-2 vision block in the cargo compartment was patched over and replaced with a periscope.

When seated at his station, the commander has good forward visibility as there is a windshield directly in front of him, supplemented by two periscopes, and the B-2 vision block in the side of the hull grants a view to the right. For all-round vision, the commander can use the PP-61B sight installed in his machine gun turret. The sight has a large field of view and permits easy scanning in azimuth using the rotation of the turret, although it does not have a high magnification. In the case of the MT-LBVM, the commander would use his PZU-5 anti-aircraft sight instead.

The two 54-36-5SB.BM periscopes use the same periscope unit as the 54-36-317-R periscopes in the driver's station of a T-54, T-55 and T-62, even featuring the same fixed handle, but they differ in the mounting system and do not provide the possibility of quickly cleaning the windows by quick-releasing the periscope and rubbing it up and down against a cleaning pad inside the housing. Nevertheless, the handles for doing so are still present on the 54-36-5SB.BM periscope. When riding around on rough terrain, the handle on each periscope allows the commander to steady himself with both hands.

The windshield is not armoured, and does not protect from firearms or artillery fragments other than small fragments and debris. When opened, the windshield cover functions as a visor, keeping rain and direct sunlight off the windshield. The windshields are each fitted with an SL-231B wiper to deal with any rain and snow blown onto the windshield, albeit only on a small swept arc. The windshield is a laminated glass assembly with built-in heating.

The commander's seat is mounted to the torsion bar cover of the first roadwheel pair. The seat is rather unusual in that it is a double swivel seat, in addition to standard features like backrest angle adjustment and seat height adjustment. Not only is the seat itself rotatable on its swivel, but the base of the seat itself has a swivel, allowing the seat to be positioned with an offset like in the photo on the left below. The reason for allowing the base to swivel is unclear, but it may have been to allow the seat to be pushed out of the way when moving in and out of the engine compartment corridor. It is very likely that the seat swivel feature was implemented to allow the commander to comfortably operate the machine gun turret, particularly when he must traverse it more than 90 degrees in either direction. The seat cannot be adjusteed in height, but the angle of the backrest can be adjusted in either direction, with the option of folding the backrest forward and flat onto the seat cushion.

With the installation of the TKB turret on the MT-LBVM, the seat was slightly modified by the addition of a cushion on the rear of the backrest. According to the manual, the commander is expected to fold the backrest flat against the seat and sit on the backrest to reach the optical sight in the turret, which is due to the increased height of the sight eyepiece in the new turret. Aside from this change, the seat remained the same.

The metal base of the seat is 280mm from the floor at the highest point, and the seat cushion is 330mm from the floor. When seated normally (and not using the turret for combat in the case of the MT-LBVM), the free space above the commander effectively gives him more headroom than the passengers in the cargo compartment despite his slightly taller seat, to approximately the same extent as the driver, who has a raised cupola, or more.

The metal base of the jockey seat in the middle is 550mm from the floor, and its cushion is only 20mm thick. The driveshaft cover is only around 260mm wide, and the jockey seat atop it is around the same width. Seated here, a commander of average height should expose only his head above the rim of the hatch, which gives him a free view towards the front and sides if the hatch is of the early type that hinges opens to the rear. If the hatch is of the later type that hinges open to the front, the commander has a much more restricted forward view in the tall gap between the hatch and the rim of the hatch opening. With a forward-opening hatch, the best position for the commander would be to sit on the hull roof, resting his feet on the jockey seat, or standing on the driveshaft cover.

It is important to note that, unlike purpose-built combat vehicles with a dedicated gunner, the commander was not furnished with a fire correction optic, which would have been a TKN-3B for the MT-LB. The commander's vision in combat is mainly limited by the fact that he is not provided with such a device, like his counterparts in combat vehicles such as BTRs, BMPs and tanks, where such a periscope was necessary for fire correction purposes. Moreover, not only did the commander lack the surveillance capability offered by the 5x magnification of such a device, he also lacked night vision.

Nevertheless, the all-round vision of the commander can be considered good relative to the commanders of older Soviet combat vehicles like the BTR-60PA and the BTR-50P. Like on an MT-LB, the commander of a BTR-60PA had a windshield in front of him, but it was only supplemented by a single vision slit in the hull side plate and a single rotatable TPKU-2 binocular periscope, while the commander of a BTR-50P had just three fixed generla vision periscopes arrayed in a 120-degree forward arc, and the squad commander was provided with an MK-4 rotating periscope with the option of installing a TKN-1 night vision periscope. Even when compared to contemporary vehicles such as the BTR-60PB, which had been upgraded with a more comprehensive set of vision devices, the MT-LB is quite good. If the three vehicle families are judged according to the quantity of vision devices and the breadth of view offered, the MT-LB compares favourably, especially considering that he has a swivel seat which allows him to comfortably achieve all-round vision using his machine gun sight, whereas these vehicles had fixed forward-facing seats.

However, compared to foreign armoured personnel carriers, the MT-LB was unremarkable or deficient in this regard. For example, the M24A2 cupola of the M113 had five periscopes covering a 180-degree forward arc, and the cupola could rotate so it was very easy for the commander to obtain an all-round view of his surroundings. The cupola of the French AMX-VCI was very similar as it was also rotatable and had five periscopes covering a 180-degree forward arc.

ARMAMENT

MT-LB, MT-LBV

The MT-LB was armed with a single 7.62mm machine gun in a turret for self defence purposes. If it were an armoured personnel carrier expected to take part in battle against enemy troops, a single 7.62mm machine gun would be wholly inadequate. Indeed, although the early BTR-60 models (BTR-60P, BTR-60PA) had just a single forward-facing pintle-mounted SGMB machine gun, there was the option of replacing it with a DShKM and even the possibility of mounting two additional SGMB machine guns on the sides. This was followed by an upgrade to a turreted KPVT and PKT pairing, making it possible to fight lightly armoured vehicles on favourable terms. However, the MT-LB was not built to be an armoured personnel carrier, as that role was already filled by the BTR-50P and BTR-60P. For the needs of towed gun crews, who were armed only with AKM assault rifles, a single 7.62mm machine gun provided a reasonable self-defence capability.

For the MT-LB and MT-LBV, an ammunition load of 1,000 rounds was specified until at least 1976. However, manuals from the 1980's list an increased ammunition load of 1,500 rounds, possibly a revision made as a result of experiences in Afghanistan.

TKB-01-1 TURRET

The MT-LB has a PKT machine gun installed in a small turret operated by the vehicle commander for self-defence purposes. Its main function is to serve as the base of fire for an artillery gun crew if they come under infantry attack, whereby each gun crew member becomes a rifleman while defending the gun emplacement or retreating from it. It also grants the possibility of the MT-LB serving as an overwatch weapon against an enemy infantry screening force moving ahead of their tanks, preventing the infantry from closing in and overruning the gun emplacement. With the exception of the RPG (the anti-tank weapon in this case would be the artillery piece) and the RPD or RPK organic to a Soviet motorized infantry squad, this transforms an artillery gun crew into the equivalent of a BTR-40 or BTR-152 squad in terms of firepower.

Housing the machine gun inside a small turret was the optimal design solution given the constraints of the MT-LB hull design. The machine gun turret fulfilled the same function as the bow machine gun of the AT-P prime mover, but the TKB-01-1 was capable of greater firepower as it could conduct all-round fire and provided the operator with better visibility, more ergonomic controls and a magnified optic. The TKB-01-1 was also directly analogous to a bow machine gun in that the operator controls the machine gun by hand rather than a geared mechanism, which allows the operator to manually stabilize his view and quickly lay the machine gun on a target. This was made easy due to the light weight, and thus low moment of inertia of a 7.62mm machine gun, enhanced by the long control handles, acting as a lever, although this is likely much less intuitive to control than a machine gun on a ball or pintle mount. A turreted system, particularly a non-intrusive type like the TKB-01-1, also increases the internal space available to the operator compared to a bow machine gun, where a rather large swept volume must be allocated inside the vehicle to accommodate the traversing arc of the weapon.

The turret is capable of 360-degree traverse, and the machine gun can be depressed by -5 degrees or elevated by +35 degrees, with the possibility of locking the machine gun at any elevation angle within this range. This is sufficient for engaging virtually all relevant ground targets, including infantry in high elevation positions at close ranges, but it is not suitable for air targets except low flying helicopters. That said, the basic premise of using a 7.62mm machine gun against air targets is somewhat suspect, so it is perhaps fair to say that an elevation limit of +35 degrees is sufficient for dealing with virtually all relevant threats. It is worth noting that the range of elevation is not drastically more than a traditional bow machine gun, but even so, the TKB-01-1 has an advantage in that the sight is fixed, and only the periscopic head elevates. Thanks to this, the operator can maintain a fixed, comfortable position on the eyepiece regardless of the elevation angle of the machine gun, unlike a sighted bow machine gun where the operator would have to contort in awkward ways to aim at the elevation extremes.

The commander elevates the machine gun using a set of two large control handles affixed to the machine gun cradle by a shared stem, and fires it using a thumb trigger button. On the left of the control handle stem is a gun elevation lock handle, marked (21) in the drawing below, also fitted to the cradle on the same crosspin, and loosely resting a clamp against a track fixed to the turret, marked (4) in the drawing on the left below. On the right of the control handle stem is symmetrically mirrored elevation lock handle. When the machine gun is free to elevate, the elevation lock handle will be at the same angle as the stem of the control handles, but when pulled back, the clamp is tightened against the track to lock the machine gun in elevation. The drawing below does not accurately portray how far the elevation lock handles must be pulled to clamp the machine gun firmly in place. The image on the right below, taken from a military film shared by the VHU YouTube channel, shows the control handles.

The image on the right below, from Reddit user "BT-42", shows the two elevation lock handles (behind and above the eyepiece of the sight) pulled sharply back relative to the control handles to keep the machine gun locked in place.

The set of controls described was the type used in the majority of MT-LBs. There was a design preceding this type, where the elevation lock handles were much longer, and there was only a single large control handle for the commander to elevate the machine gun. This early type is shown in the photo on the left below. The later type is shown in contrast on the right below. It is not known when the switch to the more common two-handle type was made.

The turret is very small, having a height of just 264.5mm and a maximum external diameter of 798mm. This was made practical by the small dimensions of the PKT, being a 7.62mm machine gun. The armour protection offered by the turret matches the protection level of the MT-LB itself, but due to its small size, the turret weighs just 109 kg with all internal equipment installed, though not including ammunition. The wall of the turret is a single 14mm plate bent into the shape of a truncated cone.

The main advantage of having a small turret rather than an external remotely controlled machine gun is that it enabled the commander to operate and access the machine gun without leaving the vehicle. This made it possible to clear stoppages and reload it from under armour. A secondary benefit is that the machine gun itself was better protected from damage, particularly from shell or mortar bomb splinters. At the same time, by having a turret built solely to house the machine gun, the weight and silhoutte of the turret was drastically smaller than a traditional turret, which makes it much easier to control manually and it improves the concealability of the vehicle.

In practice, the use of a turret rather than a simple pintle mount for the machine gun such as on early BTR-60 models effectively increased the firepower provided by the same weapon, because it served to isolate the operator from the outside environment, thus rendering enemy suppressive fire ineffective or less effective at the very least, while nullifying the issue of operators being unwilling to expose themselves to sniper fire - an issue which manifested when M113 armoured personnel carriers saw action in Vietnam and was only partly ameliorated by the addition of a gun shield. The same issue led to vehicles such as the Ferret scout car receiving a fully enclosed machine gun turret to replace its pintle-mounted machine gun.

The disadvantage of this method of laying the machine gun is that the shot dispersion obtained from it will be much greater than when it is fitted onto a fixed mount as a tank coaxial machine gun. According to the manual, the dispersion of a PKT or PKTM fired from the TKB-01-1 turret is considered normal if the radius of 80% of the impacts (R80) from a 10-round burst at 100 meters does not exceed 15 cm, equating to an angular dispersion of 1.5 mils. For comparison, the norm for a PKT or PKTM on a fixed mount is for 80% of a 10-round burst to fit within a 14 x 16 cm rectangle at 100 meters. Relatively speaking, the difference in the size of the dispersion area is enormous - fired from the TKB-01-1 turret, the 80% dispersion area is 707 sq.cm, whereas a PKT(M) fired from a fixed mount has an 80% dispersion area of just 224 sq.cm; over three times smaller. The precision of fire from the TKB-01-1 is somewhere between a PK fired from its bipod (R50 of 15.5cm, R100 of 35.5cm) and a PKS, which is a PK fired from a tripod (R50 of 7.3cm, R100 of 16cm). In terms of precision, it could be considered roughly equivalent to a free pintle mount. However, it is likely that when the elevation lock is used, the dispersion can be improved.

In practice, the possible ramifications are that the amount of ammunition needed to destroy point targets may be increased, and the effective beaten zone produced by the PKT(M) in the TKB-01-1 may be more constrained with regard to target area and range; while a tank coaxial PKT(M) may be capable of providing a high fire density on a small infantry unit concentrated on a narrow frontage at long range, the larger beaten zone from the PKT(M) in the TKB-01-1 may result in an insufficient fire density to effectively deal with the same target under the same conditions.

There is a dome light on the turret ceiling, located directly above the ammunition box, allowing the commander to conveniently handle the reloading and operation of the machine gun. Power to the turret is transmitted via a brush and a contact ring integrated into the turret ring. Power must be turned on for the commander to turn on the dome light, use the electric solenoid trigger on his machine gun control handles, and to use the sight window heater in cold weather.

The machine gun and the turret controls can be swung up to the maximum elevation angle of +35 degrees and locked using a travel lock on the turret roof in non-combat conditions to free up space in front of the commander.

The machine gun is sighted using the PP-61B periscopic sight, which is essentially identical to the more ubiquitous PP-61AM used on the BTR-60PB, differing only in that the PP-61B has a different glass insert with a range scale marked for the PKT alone instead of a KPVT and a PKT combination. The sight has a fixed 2.6x magnification and a large field of view of 23 degrees, and is well suited for low light conditions with an exit pupil diameter of 6mm. The aperture window on the turret is electrically heated to prevent fogging. The aperture window is the only protection provided for the sight embrasure in the turret; there is no shield to prevent fragments or a bullet from passing through the embrasure.

Having a magnified optic for the machine gun effectively increases its firepower as it extends the effective range of fire by aiding in the observation of enemy forces, the sensing of shots fired downrange, and by making it easier to adjust fire thanks to the range scales marked in the viewfinder.

Normally, the most significant downside of a fully enclosed turret is the reduction in the occupant's visibility, especially if the turret is not large enough to provide the occupant with multiple vision devices for an all-round view. This is the case in the much larger turret of the Ferret Mk. 2 scout car, which accommodates the upper torso of the commander, but has only a single forward-facing periscope that serves as the machine gun sight (via an unmagnified collimator). The TKB-01-1 avoids this issue by being particularly short so that when operating the machine gun, the commander's head does not intrude into the turret. The PP-61B sight has a periscopicity of 285mm, and as the viewing window is installed halfway up the height of the turret, this means that the commander's eye level is 153mm below the turret ring, or around half a foot.

The same design solution of having an uninhabited turret was used for the machine gun turret developed for the BTR-60PB, later shared with the BRDM-2, but differing in the scale due to the much larger bulk of the 14.5mm KPVT.

Because the commander's eye level is well below the level of the hull ceiling, he can freely use the vision devices embedded in the MT-LB hull when operating the machine gun turret without needing to adjust the height of his seat. To achieve a more complete all-round view, he must rely on the machine gun sight and rotate the turret. With a field of view of 23 degrees, it would serve quite adequately as a general observation device.

Due to the large weight of the 250-round ammunition box, the mounting cradle, the machine gun itself, and the additional weight of any collected spent casings, the weapon system is rather rear-heavy. To properly balance the entire setup, there is a coil spring equilibrator on the turret ceiling, which is hooked onto the gun mask. The machine gun recoils a short distance against a buffer spring on its mount, providing some recoil absorbtion and damping the firing vibration.

The machine gun is fed with 250-round boxes, a standard capacity for all armoured vehicles armed with PKT machine guns. The ammunition boxes are the same as those used in turreted BTRs, having a tall and narrow shape designed to fit more easily into narrow one-man turrets, as opposed to the square-shaped boxes used on pintle-mounted PKBs and tank coaxial PKTs. A total of four boxes are carried, one mounted next to the gun, and three more tucked in the front right corner of the commander's station. Spent cases and belt segments are ejected to the left, diverted by a deflector and collected in a fabric bag hanging beneath the machine gun. It is large enough to hold a thousand cases and their belt segments, which is the full combat load specified for the MT-LB, and it has a zipper along its bottom to empty out its contents. The photo below (courtesy of Viktor Viktor from Urban3r) shows the sheet steel hood affixed to the machine gun mount to serve as a case and belt deflector.

To reload the machine gun, it must be cranked to its maximum elevation angle as the low clearance afforded by the turret ceiling would otherwise prevent the top cover from being opened.

The drawing on the left below shows the box and the spring catch on its side for hooking onto a box holder to secure the box firmly in place, and the image shown on the right below (courtesy of user akstore), shows the carrying handle lifted.

The main drawback of the machine gun turret compared to a pintle mount is the inability to replace the barrel of the PKT without dismounting it beforehand. When the heat limit of the PKT barrel in continuous fire (500 rounds) is reached, the most practical option is to allow it to cool, rather than dismounting the machine gun to swap out the barrel.

The barrel shroud on the turret encloses the barrel up to the gas tube port. There are no issues with propellant gasses being vented into the shroud, because unlike the infantry guns, the PKT and PKTM were built with a proprietary, fully contained gas system, where the gas ported from the barrel is purged from the gas tube simply by returning up the port and back into the barrel when the pressure drops after the bullet has left the muzzle. Unfortunately, however, there is no fume extractor effect like in tank guns because the gas port is perpendicular to the bore axis, and so a substantial volume of fumes can enter the crew compartment via the receiver due to the open-bolt operating system of the machine gun.

The necessity of dealing with the issue of fume extraction was one of the ramifications of an enclosed turret such as the TKB-01-1, as by having this instead of an external mount, gunpowder fumes can accumulate rapidly during sustained fire, not just from the machine gun itself, but also emanating from the spent cartridge casings collected in the spent casing bag. The turret has no built-in ventilator to extract these fumes under normal combat conditions, relying instead on the high air flow rate developed by the supercharged ventilator when it is set to the overpressure mode. An air outlet built into the right rear quadrant of the turret wall (marked in the section A-A in the drawing below), fitted with a valve tuned specifically to open under the specified overpressure generated by the ventilator, ensures a controlled flow of air through the turret, around the machine gun, and through the outlet, thus extracting fumes. Given the close proximity between the turret and the ventilator, ventilation of the commander's station should be fairly strong while the machine gun is in use. Because the supercharger is in operation even in the basic ventilation mode of the ventilator, then as long as all hatches are closed, fume extraction is provided. The photo on the right below, taken from the Net Maquettes website, shows the bump on the right rear quadrant of the TKB-01-1 turret for the air outlet.

Firing the machine gun is done by pressing the thumb trigger button on the right handle. It is a solenoid switch which, when pressed, energizes the solenoid trigger mechanism on the PKT machine gun, causing it to fire.

The turret ring can be locked facing forward with a spring-loaded stopper for travel. To unlock the turret, the commander pulls out the stopper and locks it in the open position with by screwing in a nut. The race ring of the turret ring is mounted to a cast steel platform with bolts, and the armoured turret walls not only cover the turret ring itself but also overlap with the platform. The gap in the race ring is protected with fragment traps, to ensure that any bullet splash or other forms of fragmentation cannot jam the turret ring by traveling through the gap between the turret armour and the turret platform.

MT-LBVM

On the MT-LBVM, a new turret with an externally mounted NSVT machine gun was fitted, along with a complement of 1,050 rounds of ammunition in 7 proprietary 150-round boxes, with one carried on the gun mount and 6 rack spaces allocated in the center of the cargo compartment. By stowing ammunition this way, cargo space was restricted on the MT-LBVM, which made it impossible to tow an anti-tank gun or howitzer together with its ammunition and crew without stowing most of the ammunition externally, on the roof. The 150-round box is shown below.

Beginning from around the late 2000's, a new standard practice for MT-LBVMs and MT-LBVMKs was observed. Instead of the original proprietary 150-round box, they use a box adaptor enabling standard 50-round infantry ammunition boxes to be loaded onto the mount.

The photo below shows the ammunition racks occupied not by the specified 150-round boxes, but by pairs of standard 50-round boxes for the infantry DShK or NSV machine guns. When using these smaller boxes, there is a net loss of 300 rounds to the combat load.

There are ceiling brackets directly above the central ammunition racks for stowing the NSVT machine gun when it needs to be dismounted for extended periods, such as when transporting the MT-LBVM by rail.

TKB TURRET (NSVT)

The NSVT machine gun is a 12.7x108mm machine gun with a rate of fire of 700-800 rounds per minute, and a nominal effective slant range of 1,500 meters against low-flying air targets, and an effective range of 1,500-2,000 meters against ground targets. However, in practice, the effective range of the NSVT on the MT-LBVM will tend to be much shorter due to factors that will be detailed later.

On the TKB turret, the NSVT is fitted on a cantilever mount and controlled from within the turret using hand cranks. To facilitate the cantilever mount of the machine gun, there is a heavy equilibrator spring installed underneath and between the gun and the ammunition box, held inside a perforated frame. The mount permits a maximum elevation of 75 degrees and depression of -3 to -4 degrees.

On its cradle, the machine gun is mounted semi-rigidly, where its front mounting rails are not slotted into locks but simply ride in open-ended grooves, and the rear mounting eye is pinned to a shock absorber. Unlike most domestic 12.7mm machine gun mounts on armoured vehicles, there is no reciprocating recoil absorbing cradle, only the shock absorber, consisting of a stack of textolite buffer rings on a shank. The shock absorber is only mildly compressed during recoil, so there is very little displacement to dissipate recoil energy.

The machine gun is fed from the right, and the belt hanging between the ammunition box and the machine gun is protected from snagging on vegetation by a brush guard. The machine gun and its external fittings are not provided with any other form of protection, which is a relatively common shortcoming of externally mounted machine guns. Spent casings are ejected to the front and the spent belt exits from the left, where it is collected in a canvas bag for later reuse. When reloading, the commander elevates the machine gun to allow him to place a belt into the feed tray without getting out of the hatch and leaning over the top cover.

Aiming of the machine gun is done using the PZU-5 sight. It is a specialized anti-aircraft sight, with a 1x magnification and a very wide field of view of 50 degrees. It provides lead rings for aircraft traveling at up to 300 m/s, but no range scales or any markings appropriate for firing upon ground targets. The head of the sight is articulated by the gun mount with an external rod linkage. Together with its unmagnified view, the PZU-5 was an awkward choice for the MT-LBVM, especially in comparison to the NSV on the 6U6 universal infantry mount which was furnished with an 1OP81 sighting scope with a 3.5x magnification to engage ground targets in addition to the anti-aircraft reflector sight. Similarly, when used with the 6T7 infantry tripod mount, an NSV could be issued with an SPP optical sight with a variable magnification of 3-6x. Compared to these infantry mounts, the lack of a magnified sight in the TKB turret would have severely hamstrung the commander's ability to leverage the long range of 12.7mm rounds in combat conditions.

As the drawing above shows, the eyepiece of the PZU-5 sight is below the turret ring, but it hangs much higher than the PP-61B, such that the commander's head will be inside the turret when he is looking through the sight. This is due to the low periscopicity of the PZU-5, which was not an issue when it was originally used in a tank cupola, such as the remote weapon station cupola of the T-64B where the eyepiece will be at the same level as the periscopes and the eyepieces of the TKN-3.

Moreover, the horizontal positioning of the PZU-5 was also another bad compromise, and in more than one way. Firstly, there was a compromise between left and right eye dominant operators, as the sight is positioned so that the axis of the eyepiece coincides with the bore axis of the machine gun, which can be seen in the right image of the drawing above. It therefore does not favour one eye over another, but this also means that it is not particularly comfortable to use the sight with either eye, as the commander must twist his body to position his head properly regardless. Secondly, by increasing the penetration of the sight stem into the turret for the sake of positioning the eyepiece centrally, half of the turret volume became wasted space, as the sight stem physically prevents the front half of the turret from being used to accommodate the commander's head, or accommodate a larger hatch.

Besides using the PZU-5 sight, an alternate method of aiming the machine gun is to stand in the open hatch and use the iron sights while operating the controls in the turret. The controls are simple handwheels.