Due to the length constraints imposed by Blogger, the original T-72 article was split into two parts. This part covers the second half of the article. You can view the first half here.

TABLE OF CONTENTS, PART 2

- Protection

- Common Characteristics

- Weakened Zones

- Weight Growth

- Protection Criteria

- Object 172 Series (172M, 172M1, 172M-1)

- 80-105-20 Armour

- 60-105-50 Armour

- Appliqué Armour

- Monolithic Steel Turret

- "Kvartz" Turret

- Object 184 Series

- 60-15-15-15-50 Armour

- 60-10-10-20-20-50 Armour

- "Reflecting Plate" Turret

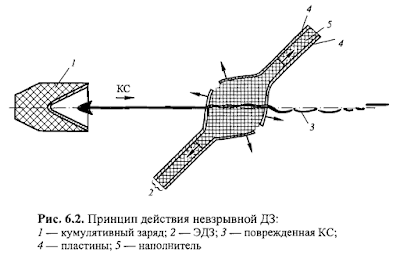

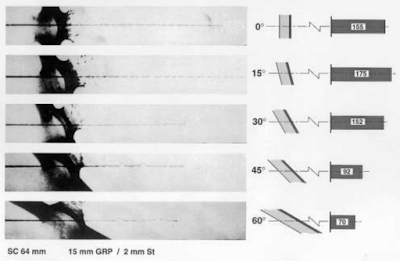

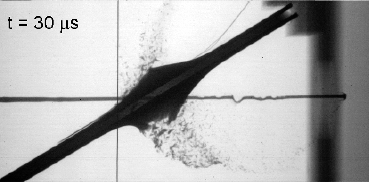

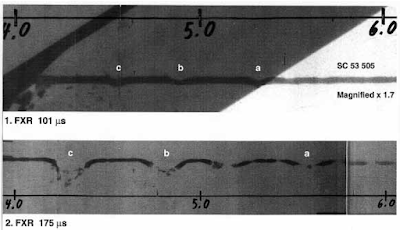

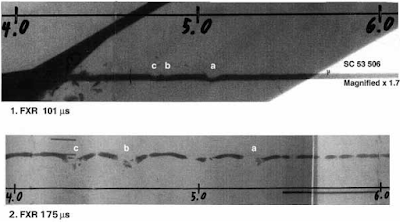

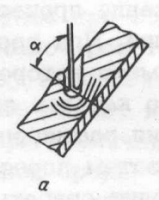

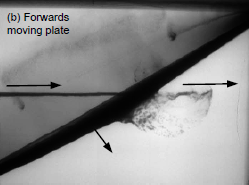

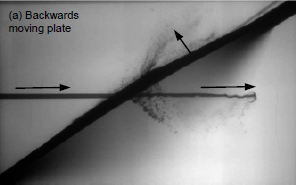

- Background on NERA

- Gill Armour

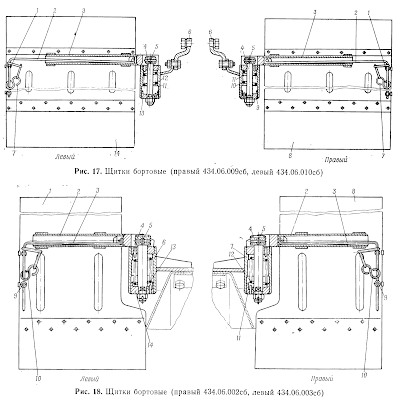

- Steel-reinforced Rubber Side Skirts

- Kontakt-1

- Kontakt-5

- "Relikt" Side Skirts

- 4S22 Blocks

- Smoke Screen

- NBC Protection

- Firefighting

- Mobility

- Engines

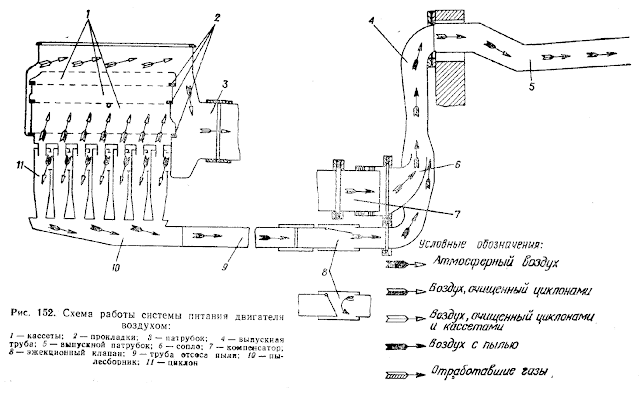

- Cooling System

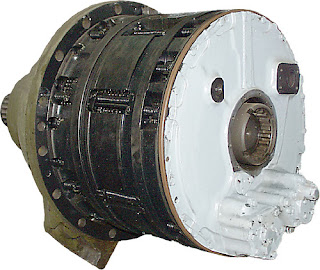

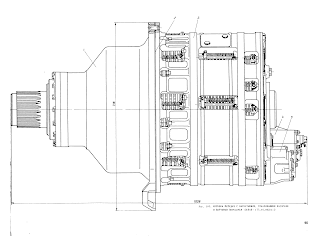

- Transmission

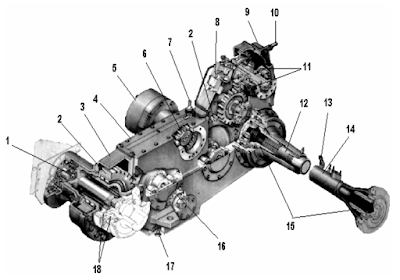

- Suspension

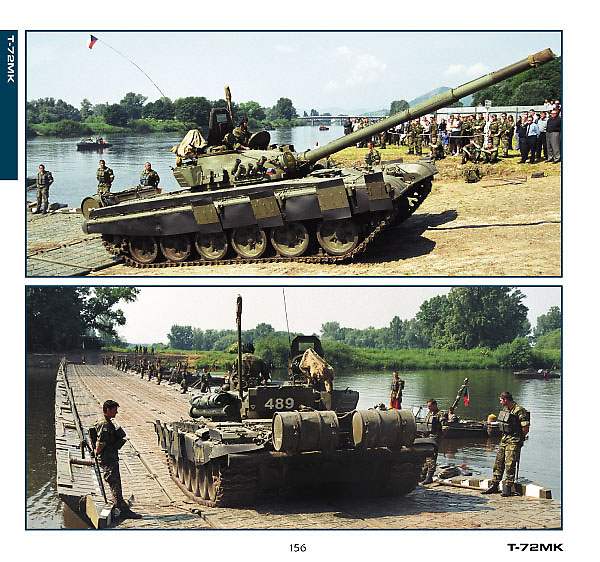

- Water Obstacles

- Fuel Tanks

PROTECTION

A good indication of a tank's true survivability is its resistance to catastrophic destruction, which can refer to the tendency for a fire to start and the likelihood of that fire spreading and consuming the entire vehicle or the possibility of the ammunition exploding or the death of too many crew members for the tank to continue fighting. The reasoning is that the resistance of a tank to a catastrophic kill (K-kill) is quite distinct from the resistance of a tank to a mobility kill (M-kill) or firepower kill (F-kill). All tracked tanks are equally vulnerable (more or less) to the loss of its tracks from enemy anti-tank fire, and all tanks are generally equally vulnerable (more or less) to the loss of their weapons or their sighting systems from enemy fire. The main difference lies in the ability of a tank to withstand direct hits on its armour and its ability to minimize the damage inflicted on the inhabitants of the tank as well as the internal equipment in case the armour fails. In this sense, the T-72 stands on equal footing with many of its contemporaries and surpasses some of its rivals due to a combination of sturdy armour, a rational internal layout, shock damping mounts for internal equipment and the inclusion of an anti-radiation liner that also behaves as a spall liner. However, many modern tanks now include separated ammunition storage, which is something the T-72 lacks and has proven to be an issue in certain circumstances.

Regardless, the protection level of the T-72 was remarkably high for its time as a result of its combination of thick armour and low silhouette and the low placement of ammunition in the hull reduced the chances of the ammunition suffering a direct hit. The main drawback of the location of the ammunition is that any fuel or hydraulic fluid leakage will inevitably pool on the floor of the hull and if an internal fire is started, it will reach the ammunition eventually. The best practice is for the commander to give the order to bail out and then press the master switch for the fire extinguisher system, thus greatly reducing the chances of an ammunition explosion from occurring before all crew members escape.

The location of the batteries in the front of the tank as opposed to the engine compartment reduces the chances of the tank losing its electrical power if the engine compartment was hit. This gives the T-72 a better chance of surviving an internal fire as the fire extinguishing system will still have electrical power, and the smoke grenade launching system can still be used to obscure the tank from further attack. If the batteries at the front of the tank were hit by a frontal armour perforation, the tank may not necessarily lose electrical power as the generator in the engine compartment is still intact. The only problem is that the engine cannot be started electrically after it is turned off without a battery replacement, but it is still possible to start the engine with compressed air. The compressed air cylinders are refilled by an engine-driven compressor, so the tank can remain fully autonomous indefinitely without batteries if necessary, as long as it has fuel. This high level of redundancy contributes to a high level of survivability as the tank can still continue to fight after sustaining serious damage.

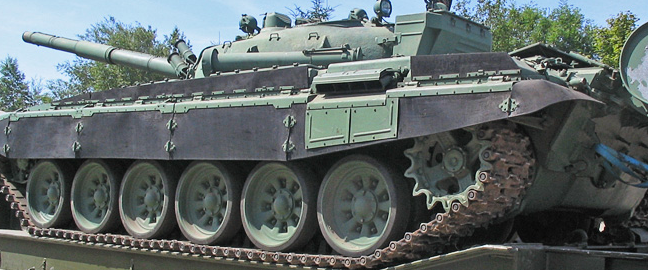

Besides a disinclination to internal fires, the survivability of the tank was enhanced by its low profile. Even though it was certainly not the shortest of all Cold War era main battle tanks, it was still an impressively diminutive target. The original T-72 had a height of 2.19 meters (measured up to the turret roof) and the T-72A was the same. The T-72B had a marginally taller turret along with slightly more ground clearance, combining to slightly increase the height of the tank to 2.23 meters. Overall, the tank is shorter than the T-62 and T-54/55 that preceded it, and compared to tanks like the M60A1, the T-72 can only be described as a dwarf.

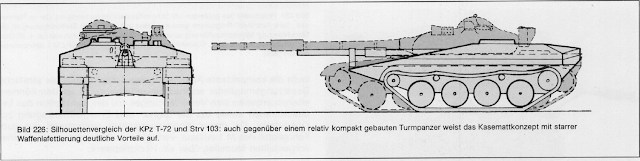

Although the tanks produced in the Soviet Union are most famous for emphasizing low size and weight, the reality is that all nations were actively pursuing such reductions and the Leopard 2 and M1 Abrams were examples of West Germany and the U.S making great strides towards this objective. Even so, the T-72 was still slightly shorter than the M1 Abrams and Leopard 2 which had a height of 2.39 meters and 2.48 meters respectively (measured up to the turret roof). In terms of height and overall profile size, it is beaten only by the Strv 103 which also had the upper hand in terms of overall length. By comparison, the Strv 103 had a height of only 1.9 meters when the suspension is in the travelling condition, and having a "bullpup" configuration gave the Strv 103 a uniquely short overall vehicle length without compromising gun barrel length such that its ability to maneuver through dense forests could be better than other tanks. The difference in size can be seen in the drawing below, and the drawing below it comparing the Strv 103 with the M60A1 gives a reference point. Both drawings are taken from "Kampfpanzer: Die Entwicklungen der Nachkriegszeit" by Rolf Hilmes.

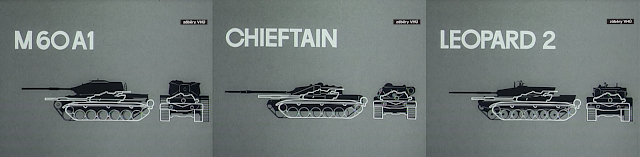

The three film stills below show drawings that superimpose the T-72 on comparable NATO tanks to illustrate the difference in the size. The scale appears to be slightly exaggerated in favour of the T-72 in these drawings; the height of the M60A1 seems to be warped as the turret is depicted is too tall and the commander's cupola is too short. Despite this, these drawings are accurate enough to gain a general impression of the difference in size. These film stills were taken from archival footage from a Czechoslovakian Army training film. Original video from the VHU channel.

However, even though the Strv 103 is shorter than the T-72, the casemate hull is still significantly wider, especially at the top part due to the large sponsons over the tracks. Overall, the area of the frontal silhouette of the Strv 103 including the tracks is 4.25 sq.m whereas the area of the frontal silhouette of the T-72 is only 4.0 sq.m, which also happens to be half of the frontal silhouette of the M60A3 (8.0 sq.m). As such, despite being slightly taller than the Strv 103, the T-72 manages to still present a comparatively smaller frontal projection if both tanks are travelling over open ground. Needless to say, this is not a trivial achievement.

In a hull-down position where the height of the turret matters more than the tank's full silhouette, the small turret of the T-72 also has an advantage. With a maximum height of just 750mm when measured from the hull roof to the highest point of the turret roof, the T-72 turret is slightly taller than a T-62 turret (720mm) but shorter than a T-54 turret (810mm). The difference between foreign tank turrets is even more noticeable: the Centurion Mk.10 turret had a height of 956mm, the Chieftain turret had a height of 975mm, and the M60A1 turret had a height of 970mm. A large amount of effort was spent to reduce turret heights in the West, resulting in the turret of the M1 Abrams (and all variants thereof) having a height of 900mm. On page 2409 of the "Department of Defense Authorization for Appropriations for Fiscal Year 1983", it is asserted that the projected area of the M1 Abrams turret is equal to the M60A1, but has a lower profile. From the side, the projected area of the M1 turret is stated to be approximately 6% smaller than the M60A1 turret. The M1 turret could have been shorter, but there was a need to have a sufficiently large internal height to accommodate a human loader and some of this height had already been sacrificed because of the short hull with a reclined driver's seat. Together, the combination of a lower turret and hull gave the M1 a smaller overall projected area compared to the M60A1. The Leopard 2 had a conventional driver's seat and a taller hull, so the turrets of all models of the Leopard 2 (excluding the latest models with additional roof armour) could afford to have a reduced height of 830mm, less than the Abrams. The reduction in turret height was a objective worth achieving even if the projected area is not reduced.

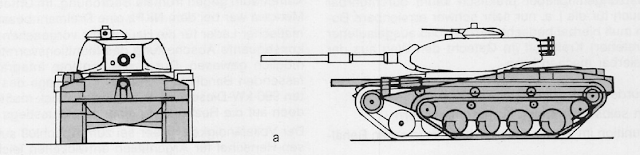

Additionally, the difference in the area of the silhouette of the T-72 does not merely manifest from a frontal view, but also when the turret is turned to one side. When the turret is turned to the side such as shown in the drawing below, the area of the silhouette of the turned turret (dark grey) is the same as the area of the silhouette of the turret when it is facing straight forward (light grey). On the other hand, the area of the silhouette of the turret of an M1 Abrams when it is turned (dark grey) is significantly larger than when the turret is facing straight forward (light grey). The same principle is true for turreted tanks with long bustles like the M60A1 and the Leopard 2. Drawing taken from "Kampfpanzer: Die Entwicklungen der Nachkriegszeit" by Rolf Hilmes.

The increase in the area of the silhouette of the turret has the effect of increasing the chance of receiving a hit on the turret. Additionally, this advantage is non-trivial in a defensive scenario where both tanks are hull-down, dug-in and concealed. The longer turret of an M1 Abrams or Leopard 2 will appear larger to an observer when it is turned away from his direct line of sight, thus making it easier to see. This also has the side effect of causing the movement of the turret to become more obvious, as the change in silhouette size during the rotation of the turret will be more likely to invite the attention of watchful eyes. The lack of any change in the silhouette of a T-72 turret as it rotates renders it harder to notice. Of course, these advantages may be nullified under certain circumstances, such as those facing Iraqi tankers during the first Gulf War. Many T-72M and T-72M1 tanks were dug-in and hull-down, but were easy to see due to the featureless terrain of the desert, especially from the sky. Furthermore, the dug-in tanks baked for hours directly under the hot sun, making them glow brightly in the thermal imaging sights of Coalition tanks and infantry fighting vehicles. These problems are not present in a hypothetical European battlefield due to the abundance of foliage and shade.

The use of a long turret bustle is not inherently bad, of course. Like any other technical solution, it has its own set of merits and demerits. The merits include better turret balance (because the long bustle behaves as a counterweight to the heavy gun and armour at the front of the turret), and quicker loading speed for both manually loaded tanks and tanks with autoloaders if ammunition is stowed in the bustle. This is confirmed by ergonomics studies on manual loading and by autoloader optimization studies done in the USSR. Of course, the downside to having ammunition stowed in the bustle is that the turret is statistically more likely to be hit so that ammunition stowed inside is also more likely to be hit if the turret armour is defeated, and this is quite an important consideration to make. When the turret of a tank with a long bustle is turned to the side, it becomes possible to hit the bustle from the front. For tanks without compartmentalized ammunition and blowout panels like the M60A1, the thin side armour makes it comparatively easy to perforate the bustle armour compared to the frontal armour, thus making it possible for even obsolete anti-tank weapons to defeat the tank from the frontal arc. This is mostly avoided in the M1 Abrams, but not entirely.

Offensively, the smaller overall size of the tank made it more difficult to hit when it was on the move in open terrain. Defensively, the low turret made it hard to detect and even harder to hit, and the armour protection of the turret could also be enhanced if the tank is on a reverse slope. The roof of the turret is angled at around 78-80 degrees, so when the tank is on a gentle reverse slope and the gun is laid at the maximum depression angle of -6 degrees, the angle of the turret roof becomes 84-86 degrees (critical ricochet angle for virtually all long rod APFSDS) and the projected area commander's cupola is partly hidden behind the turret cheek armour, thus minimizing the weakened zones of the turret and making the tough frontal protection of the turret even tougher.

The superior target-finding capabilities of the hypothetical enemy granted by the widespread adoption of thermal imaging technology would also be negated if the tank were hull down, as the hot engine and running gear would be concealed below ground level while the turret may not be hot enough to offer sufficient thermal contrast, especially if it were covered in camouflaging elements like special netting and foliage cloaks or even field expedient solutions like branches. The main factor that gives the surfaces of tank armour a different thermal signature from the surrounding environment is the heating of the steel by solar radiation at a different rate than soil and vegetation, so by covering these surfaces with netting and branches, it is possible to strongly reduce or even eliminate the thermal signature of the tank. On a typical T-72 from the 1980's, a few parts of the tank such as the steel-reinforced rubber side skirts, the plastic gun mask cover, and the anti-radiation cladding on the turret are thermal insulators by design, particularly the anti-radiation cladding as it is designed to resist the heat flash from a nuclear blast. These external components reduce the thermal signature of the tank and may expedite the camouflaging process.

To summarize, the T-72 was not just a capable offensive tool but also quite formidable when used defensively. The only drawback was the slow reverse speed which prevents the tank from quickly withdrawing from a compromised position and performing an effective tactical retreat. However, the slow reverse speed would not have been an issue when firing from a hull defilade behind a reverse slope or a berm as it is quick enough for the tank to rapidly return to a turret defilade. This is mainly due to the low height of the turret, which means that a lower reverse speed is sufficient to completely hide the turret within the same time period as a tank with a taller turret and a quicker reverse speed.

Of course, it is not possible to remain completely unseen indefinitely. The formidable armour of the tank is the most obvious major factor in reducing the casualty rate of its crew and ensuring the success of a combat mission, but the criteria for knocking out a tank does not only depend on defeating its armour. In fact, it is not only possible to disable a tank without perforating its armour plating, but also quite common. One of the easiest ways to do so would be to simply de-track the tank, but the tank can still fight albeit from a compromised position. Another effective method of eliminating the combat capability of a tank would be to destroy its observation devices. In that case, the most important objective would be the destruction of the gunner's sights which would prevent the tank from using its weapons.

The location of the gunner's sight aperture depends on the individual tank, but generally speaking, tanks with a telescopic gun sight have the sight aperture in the gun mantlet or near it, making them vulnerable to damage. For a tank like the T-54, the sight aperture is located in a slit cut into the turret armour next to the gun barrel, directly at the center of mass of the tank where most shots are expected to land. Furthermore, a hit from a solid armour-piercing shot on the well-sloped upper glacis may produce enough secondary fragmentation to damage the sights indirectly, and the detonation of an explosive shell on the upper glacis is quite likely to do so owing to the large amount of fragmentation expected. Tanks with a periscopic gun sight usually have the gun sight aperture located on the turret roof or some other part of the turret above the frontal armour facings. The T-72 belongs in this category as the aperture of its primary sight and night vision sight are both located on the turret roof, making it less likely to be damaged by explosive shells impacting the front of the turret or the upper glacis.

The T-72 has proven its worth in various conflicts when placed under competent command, but the lack of media coverage on the successes does not help its case. Even though many tanks have been destroyed, often irrecoverably, many more have survived such that the tank's ability to endure severe punishment simply cannot be considered low. To list one incident in Grozny, in the year 2000, a T-72B with the tail number 611 took 3 hits from Fagot anti-tank missiles and 6 hits from RPGs during 3 days of intense fighting and remained in battle with only minor damage. Most of the hits landed on the sides of the tank, with one rocket impacting the lower rear of the hull. Other cases involving older models such as the T-72A more often ended on a sadder note, but in general, it took several hits from anti-tank grenades and missiles to reduce the combat capacity of a T-72 and at least half a dozen hits on the weakened zones (sides, rear) are usually required for the ammunition to detonate or a fire to start in the tank.

More examples come from a World of Weapons magazine article (March 2005 issue) on tank action in Grozny containing details on multiple T-72As lost in combat. The 131 Separate Motor Rifle Brigade (OMSBR) tasked with capturing the Grozny rail station sustained many casualties during combat, losing a total of 157 men, 22 tanks, 45 infantry fighting vehicles, 37 cars and all 6 of the Tunguska anti-aircraft systems operated by the air defence division attached to the brigade. While providing supporting fire, the tanks belonging to the brigade received multiple anti-tank grenades from every direction in return for each shot fired. One T-72A with the tail number 533 sustained four or five RPG grenade impacts on the engine compartment, and the tank caught fire. It eventually exploded, long after the crew escaped. Another T-72A, with the tail number 537, withstood six or seven hits from RPG grenades before suffering an ammunition explosion, killing its entire crew instantly. A third T-72A, with the tail number 531, sustained four hits from RPGs before its turret drive failed, and the tank was finally knocked out of action after an APFSDS round fired from 100 meters impacted the turret on the commander's side. A fire was started, but fortunately, the gunner (left hand side of the turret) was only heavily concussed because the bulky breech assembly of the cannon saved him from the spall and fragments entering the turret on the commander's side (right hand side of the turret). Both the gunner and driver were able to escape the tank before it eventually succumbed to the fire and exploded 20 minutes later. None of these tanks had reactive armour installed.

In another example, a T-72B1 from the 276 Motor Rifle Brigade with the tail number 221 was penetrated twice in combat during the battle for the Grozny hospital in January 16, 1995. After repairs, it was damaged again on January 21, 1995 during combat near the building of the Council of Ministers where it was hit with five RPG grenades. Four of the hits were located on the sides of the hull, one of them on right side, on the fourth roadwheel, and the other three on the left side. The fifth hit was located on the turret, above the gun barrel. The autoloader was damaged by the turret strike, but the tank survived and was sent for an overhaul.

More interesting examples can be found in the article "Танки Т-72 В Войнах И Локальных Конфликта" (T-72 Tank in Wars and Local Conflicts) by V. Moiseev and V. Murakhovsky and published in the "Arsenal of the Fatherland" magazine, issue 4, 2013. One of them is taken from an after-action report on the death of a tank commander in a T-72 after an attack by RPG-type weapons. The tank was a T-72B1 built in December 1985 in Uralvagonzavod. After being pulled into a repair facility, the tank was inspected and eight damage points were observed. Five of the hits were recorded on the hull, and of these, three were from RPG grenades impacting the sides of the tank in the areas protected by reactive armour, one was from an RPG grenade impacting the rubber side skirt of the tank in an area unprotected by reactive armour, and one was from a fragmentation grenade (possibly a VOG-17M) impacting the rear of the engine compartment. The remaining three hits were recorded on the turret, one on the front, one on the side, and one on the rear.

It was noted that the tank was in a marching status prior to the attack, having the cannon locked in the travel position and the 12.7mm machine gun locked facing backwards. Also, the commander's hatch was ajar or opened completely, so that the death of the commander was most likely caused by the combined explosion of an anti-tank grenade and the reactive armour occurring outside the tank, given that the armour was not perforated. Overall, the tank remained combat capable despite receiving damage in the autoloader and in the stabilizer system, as the driver and the gunner were still alive at the end of the ordeal and the gun could still be fired using the manual controls.

In general, photos of destroyed T-72 tanks cannot be said to be proof of the low survivability of the tank, but are instead often indicators of the sheer ferocity of the fight that led to its destruction.

COMMON CHARACTERISTICS: HULL

The protection qualities of the frontal armour depend greatly on the specific model, but there are many characteristics that were shared across all models. This includes the side armour, hull belly armour, hull roof armour, and others. Protection was focused on the frontal arc of the hull.

The frontal arc of the tank is not the same for the hull and the turret. Various definitions of a tank frontal arc are handily compiled in the drawing below, taken from the article "Elements of Tank Design" by Gerald A. Halbert published in the November-December 1983 issue of the ARMOR magazine. For the hull, the Soviet definition of the frontal arc places the center point of the arc at the centerline off the hull (first from left). For the turret, the center point of the frontal arc is placed at the center of the turret (first from right). When the effective armour protection is given for the turret, it is almost always referring to the frontal arc protection using a reference side angle of 30 degrees under this frontal arc definition.

The Soviet definitions are used throughout this article and other Tankograd articles.

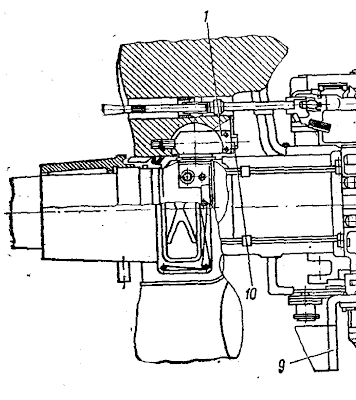

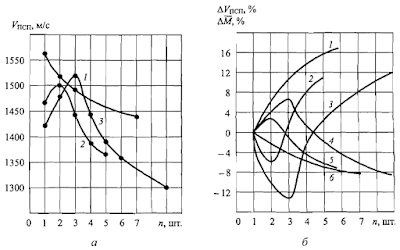

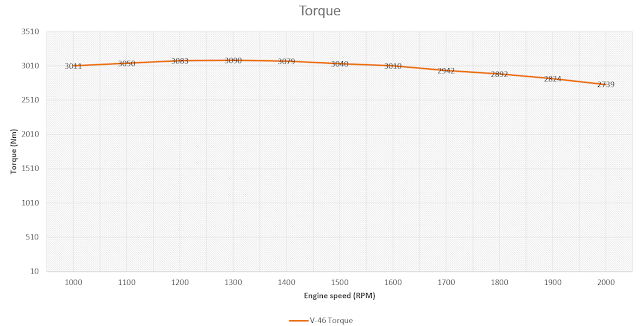

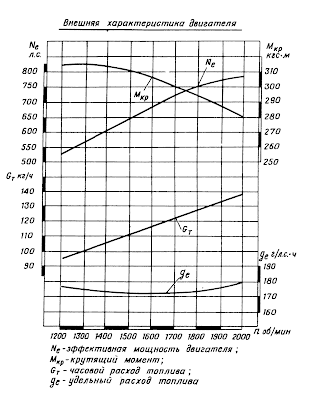

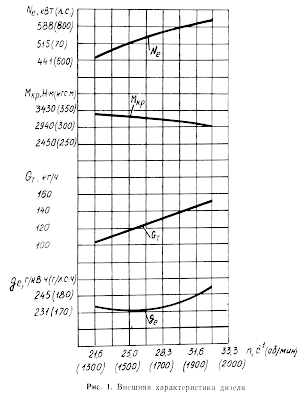

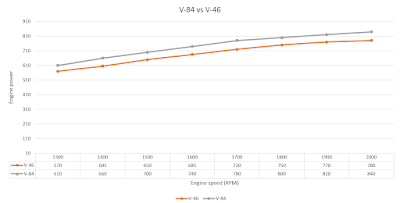

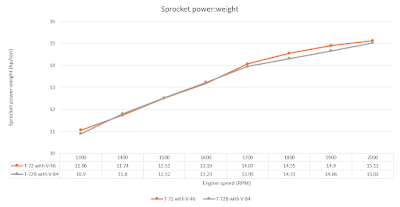

Generally speaking, the level of protection was quite formidable although some concessions were made during its development which put it slightly below the level of the T-64A. It is widely known that increasing the volume of a tank leads to an increase in armour mass without an increase in armour thickness because of the need to add armour to protect a larger surface area. This was a source of inefficiencies in the design of the T-72. When the UKBTM design bureau of the Uralvagonzavod factory designed the Object 172 prototype using the T-64A as the foundation of their new tank, one of the modifications made was to replace the compact 5TDF opposed piston engine with the V-46 V-shaped 12-cylinder engine developed by the Chelyabinsk tractor plant (ChTZ). The V-46 engine itself was larger than the 5TDF, but the difference in dimensions was not as significant as the decision to use the conventional centrifugal fan-driven cooling system from the T-54 instead of the ejection-type cooling system of the T-64. The volume of the engine compartment had to be increased by 0.5 cubic meters to accommodate this new equipment, and in turn, the increased volume generated a larger surface area. Added together with the increased mass of the running gear, the weight of the T-72 increased considerably and none of the extra mass went towards thickening the armour. To the contrary, the side hull plating had to be thinned down to 80mm from 85mm in order to put the weight gain in check. This was partly nullified by the larger diameter roadwheels of the T-72 which could cover parts of the hull, but the wheels are made of aluminium and not particularly thick, so this was not a true remedy but merely an unintended bonus.

The hull side, hull roof, hull belly and rear armour of all T-72 models are identical, regardless of the variant. As stated earlier, the armour of the side of the hull is 80mm thick. Tthe armour on the sides of the engine compartment is 70mm thick. The side armour of the hull is more than enough to withstand 20mm armour-piercing ammunition fired from various aircraft as well as 20mm and 25mm APDS rounds from autocannons.

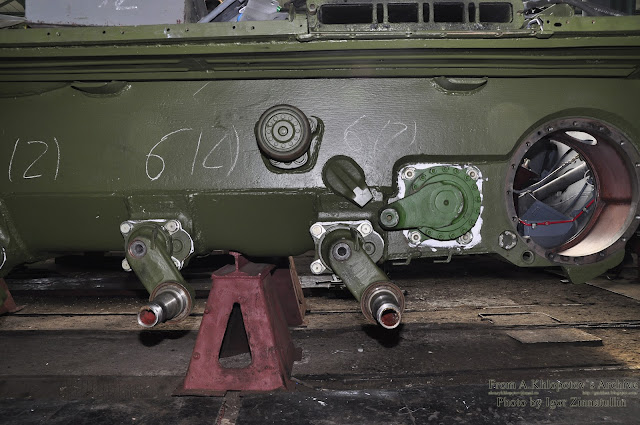

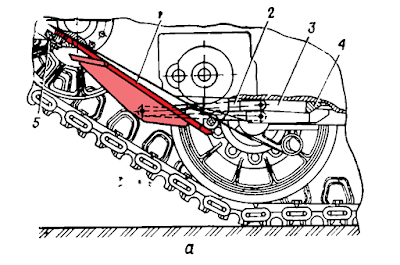

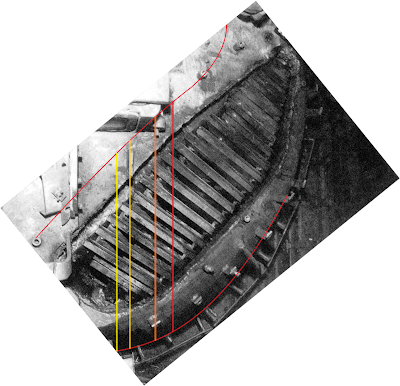

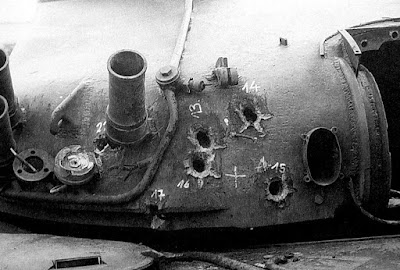

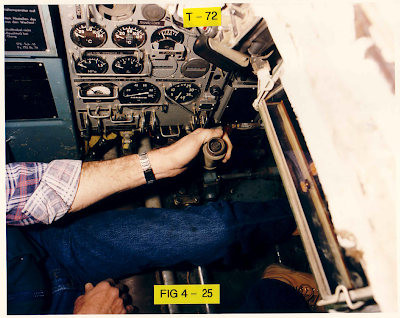

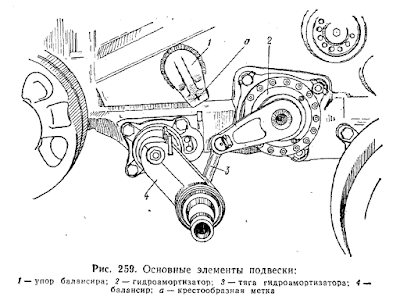

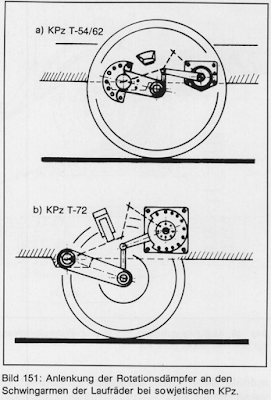

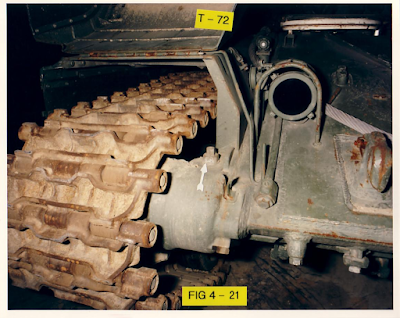

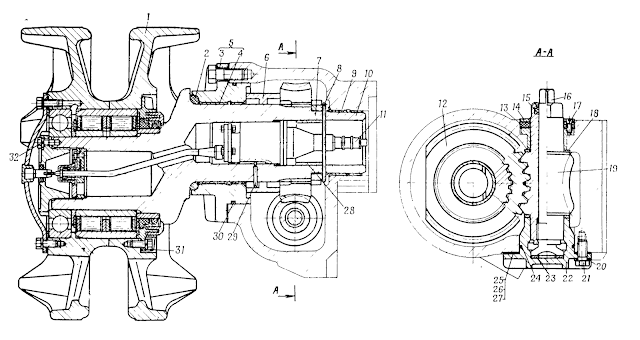

There are several zones in the side of the hull that may not be entirely on the same level as the rest of the armour such as the one shown in the photo below. As you can see, the thickness of the steel armour at the drive sprocket and the rear shock absorber is reduced. It is thinner than the side armour of the engine compartment, and even though the shock absorber unit and the drive sprocket are backed by some amount of armour, the level of protection at these zones is not equal to the side of the engine compartment.

Note that in the first photo, the cut in the armour plate above the shock absorber is angled whereas the same cut is perfectly horizontal in the second photo. This is because of the slight offset of the roadwheels caused by the use of a torsion bar suspension. On the T-72, the roadwheels on the left side of the hull (port) are displaced slightly forward from the roadwheels on the right side (starboard). As such, the roadwheels on the right side of the hull (starboard) are slightly closer to the drive sprocket, so the shock absorber for the sixth roadwheel had to be moved closer to the drive sprocket and angled slightly to facilitate the same range of vertical travel.

The thickness of the armour at the holes for the installation points for the shock absorbers and the final drives is 40mm. The shock absorber itself has a casing made from armour-grade cast steel and has a considerable bulk which adds some protection on its own, and the final drive is protected by the drive sprocket and the drive sprocket hub.

Besides these weakened zones, the mounting points for the roadwheels and track support rollers can be considered reinforced zones. The armour thickness at these zones is much greater than the parts of the hull where they are located. The mounting points for the roadwheels are especially thick as they are separate milled blocks of steel welded onto the belly plate. The thickness of steel at the mounting points for the roadwheels probably exceeds 100mm and the thickness of the steel at the mounting points (also thick blocks of milled steel welded) for the track support rollers easily exceeds 100mm.

The side armour is thickest at the top half and thins down to just 20mm at the lower quarter of the side hull profile. The upper and lower sides are not the same plate. The upper side armour is a single rolled steel plate whereas the lower side armour is actually a part of the belly armour plate. The belly plate is a large stamped piece of steel, bent into a tub shape and welded to the upper side armour. It joins with the upper side plate at an angle of 32 degrees from the vertical axis. The lower side hull armour has a height of 250mm or 270mm if the thickness of the plate itself is included. The upper side hull occupies around three quarters of the area of the side hull profile and the weaker lower side hull occupies one quarter. This thin strip of the side armour is usually not visible as it is completely concealed behind the roadwheels which add a modicum of spaced armour. The roadwheels cover a height of around 350mm of the lower part of the hull, and thus cover the entirety of the lower hull sides and also cover a part of the upper hull sides as well. The short height of the lower side hull armour makes it statistically unlikely to be hit and the additional protection provided by the roadwheels offsets the reduced thickness of the armour, so overall, it is not a flaw in the protection scheme of the tank. It is worth noting that the side armour of many other tanks are configured in a similar way, including the Leopard 2 as shown on the right next to the T-72 on the left.

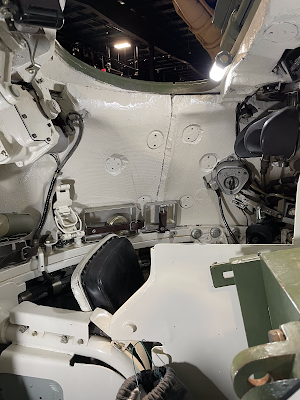

The interior surface of the upper side hull armour is coated in a 45-50mm layer of "Podboi" anti-radiation lining, which can help absorb spall and other secondary penetrator fragments or even stop residual penetration from less energetic projectiles. This is discussed later in the "NBC Protection" section of this article.

It is without a doubt that the sides of the tank were only sufficient for a very limited period of the service life of the T-72. Being only 80mm thick, the side armour plate could offer only a fraction of the protective value of the front armour, and this was not a trifling issue. The number of hits sustained by a tank's sides were statistically significant, as shown by the analyses conducted by Dr. Manfred Held in "Warhead Hit Distribution on Main Battle Tanks in The Gulf". The charts below are from the study.

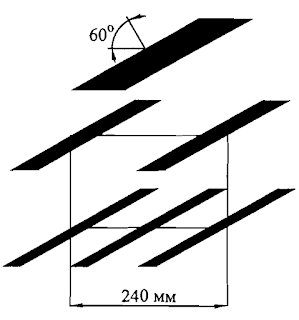

The sides would have been mostly resistant against 105mm APDS like the L28 round (M392 in the U.S and DM13 in West Germany) at a range of 2,000 meters within a somewhat reasonable 40-degree arc, but this arc is still relatively narrow and it limits the tank's freedom to maneuver in open spaces. At a range of 200 meters, the side armour is only capable of resisting DM13 at a side angle of 17.5 degrees, so the protected frontal arc would only be 35 degrees. The appearance of 105mm APFSDS rendered the side armour completely inadequate as protection against contemporary anti-tank firepower.

The hull roof is 30mm thick, while the thickness of the hull roof around the turret ring is 20mm. It can be seen in the photo below. The rear armour plate over the engine compartment is 40mm thick, sloped at 30 degrees, and the hull belly is 20mm thick. The thickness of the "Podboi" anti-radiation lining on the hull roof is 50mm. As it is not inhabited by the crew, the engine compartment lacks an anti-radiation lining.

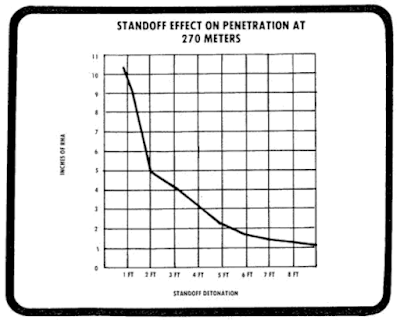

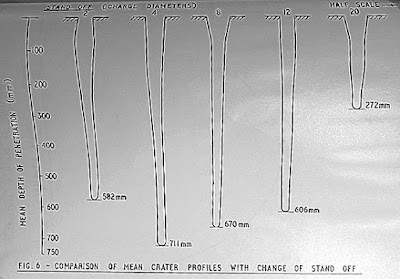

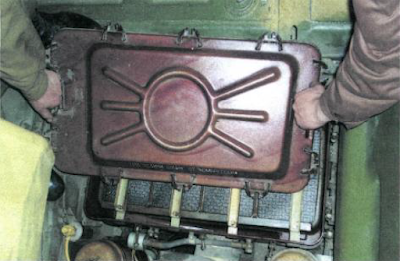

The engine access panel is 20mm thick and is supplemented by a stamped steel radiator cover. The cover is used to seal the radiator during snorkelling operations and it is stowed on top of the engine access panel when not in use. Its contribution to the overhead protection of the engine is limited, but it may prove beneficial against certain threats. For example, the damage from grenades, shells, bombs and other high-explosive ordnance may be reduced by the standoff distance created by the cover. Fragments from airbursting artillery shells may also be negatively affected by the spaced armour effect created by the cover.

The thickness of the hull belly plate is comparable to tanks like the M60 series and is slightly thicker than the 16mm belly plate of the Centurion and Chieftain, but is soundly beaten by the arched 36mm-thick belly of the M48 which was known to have excellent mine protection. The hull belly of the T-72 is only sufficient against explosive charges with a mass of less than 10 kg detonated over the tracks and not directly under the hull. These parts of the hull are most likely constructed from the same steels used in the same locations in the T-54 and T-62: 49 S grade steel for rear armour plate and the hull roof, 43 PSM grade steel for the floor. These grades of steel were first used in the T-54 obr. 1953.

The hull bottom is constructed from a single plate of rolled steel, which is then stamped into a complex shape with protruding ribs for the installation of torsion bars and a depressed section in the floor to accommodate the driver. Reinforcing nubs were pressed into the plate between every torsion bar rib to improve the stiffness of the floor. The side edges of the plate were bent upward at a 30 degree angle to join with the side hull plate, thus forming a tub shape. This was possible due to the ductility of 43 PSM steel, which is a soft annealed steel and cannot be considered equivalent to RHA. 43 PSM has a yield strength of 400 MPa, a tensile strength of 600 MPa, and a hardness of 180-250 BHN. The elongation limit of 25% for 43 PSM is very high compared to RHA. These qualities make the steel plate easy to process by stamping and potentially more useful for mine protection because softer steels like 43 PSM have a reduced resistance to deformation but higher resistance to rupturing compared to high strength and high hardness steels. The rigidity of the belly plate is augmented by the lateral ribs for the torsion bars and the longitudinal embossed nubs on the belly plate.

Initially, cast turrets for the T-72 were made from MBL-1 cast armour steel with a hardness of 270-290 BHN. This grade of steel was first used in the turret of the T-62. The high hardness armour used in the turret of the T-72B is BTK-1Sh, a high hardness, high strength electroslag remelted (ESR) steel with a hardness of around 450 BHN. The appliqué armour plate installed on the 1983 modification of the T-72A and earlier T-72 variants is not known but it has been credited with a hardness of more than 500 BHN by credible sources. In Poland, an armour grade equivalent to MARS 500 was used. In the USSR, BT-70Sh steel may have been used.

The upper glacis is a multi-layered armour array angled at 68 degrees. Although the composition of the composite armour was changed many times over the course of the long career of the T-72, the angle of the upper glacis always remained the same. The high obliquity was an advantage against APDS ammunition, HEAT ammunition (due to fuzing issues) and early composite APFSDS rounds including Soviet models, but additional challenges arose when long rod APFSDS ammunition became commonplace in the 1980's due to the increased performance of long rod penetrators on highly oblique armour. But even so, this did not necessarily mean that the high slope of the upper glacis became a detriment - these matters are not so simple when composite armour is involved. The nuances of this design decision are discussed further later on in this article.

LOWER GLACIS

The armour protection of the lower glacis changed very little during the service life of the T-72. The properties of the plate are identical to the other welded plates used for the hull, like the side armour plate and the front plate of the upper glacis. The lower glacis is reported by some sources to be 80mm plate sloped at 61.5 degrees, identical to the T-64A, but it is stated to be 85mm sloped at 60 degrees according to "Kampfpanzer: Technologie Heute und Morgen" by noted German armour expert Rolf Hilmes. The difference in effective thickness between these two figures is minimal and may be explained by possible variations in discrete T-72 models, but the angle of the lower glacis is marked as 61.5 degrees in the Object 172M factory drawings, lending much more credence to the notion that it is also 80mm in thickness (identical in thickness to the T-64A).

Being a traditionally weak area on most tanks, the relatively poor armour of the lower glacis is largely counteracted by its small size and low exposure to enemy fire. It occupies less than 20% of the total area of the front hull. The low number of hits recorded on the lower parts of tank hulls have been independently verified by multiple sources, as discussed previously in this article in the section on the autoloader of the T-72. Again, it should be noted that statistics on the hit distribution on combat-damaged tanks during WWII showed that 90% of hits were recorded one meter above the ground, as reported by Sergey Gryankin on pages 12-13 in his article "T-54", published in the "Техника-молодёжи" magazine (Technology of the Youth). Moreover, Richard Ogorkiewicz writes on page 394 in "Technology of Tanks" that on average, the first 0.7 meters of a tank's height is covered by the terrain irregularities. If grass or other forms of vegetation are also present, this would mean that the lower glacis of a T-72 would almost always be obscured from direct vision and would usually be physically protected by the terrain due to its low height. Such statistics directly influenced Soviet tank designers in determining the optimal height of the lower glacis.

The vulnerability of the lower glacis can be reduced even further if the tank is in a hull defilade position behind a natural obstacle. Even if the obstacle does not provide enough resistance to stop an incoming projectile, the fact that it hides the lower part of the tank will shift the point of aim upwards, away from the lower glacis.

LOWER GLACIS WITH DOZER BLADE

If natural cover is not available and a static defensive position must be created, it is possible to for any T-72 model to self-entrench using the integral dozer blade installed on the lower glacis. Only the Object 172 prototype tanks created from 1968-1970 lacked a dozer blade. 17 tanks of this type were produced, and they were not delivered to the troops. A dozer blade was present on the Object 172M prototypes created during the summer of 1972 for performance trials (shown in the two photos below), and the final Object 172M model that was accepted into service in the Soviet Army as the T-72 Ural on the 7th of August 1973 had a dozer blade.

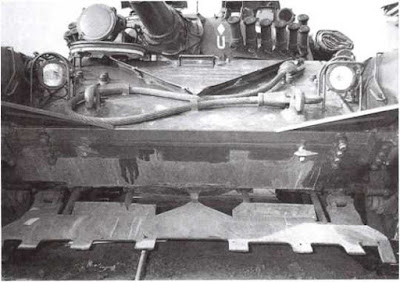

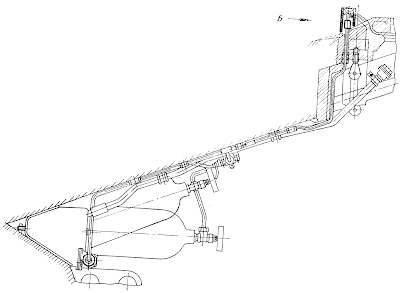

The dozer blade can be used for self-entrenchment or to augment existing cover with additional concealment. It also allows the tank to be used as a tractor and a digger for general construction work when specialized vehicles are not available. The blade secured by two rotating latches which are turned with a wrench to release the dozer blade. The dozer blade has a width of 2.14 meters.

The dozer blade is suspended from the belly of the tank by four structural support rods which can be seen in the two photos above. Two of these can be seen in the photo below. When the dozer blade is unlocked and released, these support rods retract backwards into special troughs to orient the dozer blade at the proper angle for digging.

With the dozer blade, the T-72 can be used to build a tank trench for itself in 15-20 minutes on soil. On snow, it can take as little as 5 minutes, but conversely, it takes much longer to self-entrench on frozen dirt. Due to the limited width and capacity of the dozer blade, the tank must make a few passes when digging out a suitably sized hole for itself. The tank commander and gunner exit the tank and continuously guide the driver during this process. Further improvements to the tank's firing position can be done by hand with the pioneering tools carried on the tank (spades, picks).

If necessary, the dozer blade can also be used to overcome anti-tank trenches by filling them in or creating a ramp. This may be the only option for regular tank units if the engineering company of a tank regiment is not available to support them for whatever reason, or if too much time would be wasted in waiting for support. This greatly reduces the effectiveness of such trenches in delaying an attacking force composed of T-72 tanks as compared to any other tank, excluding the T-80 series and later models of the T-64 series.

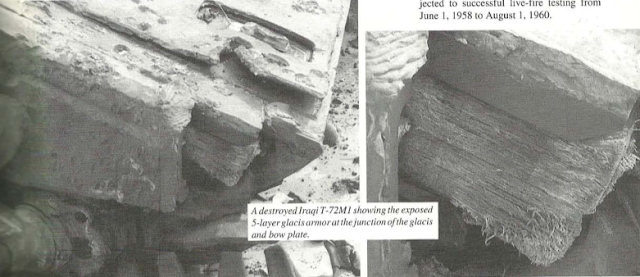

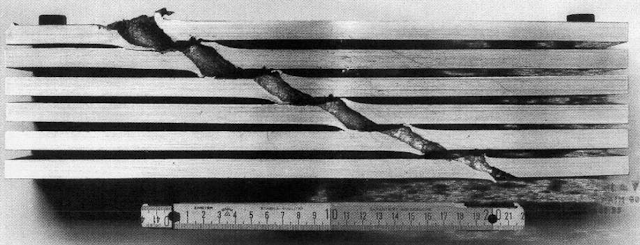

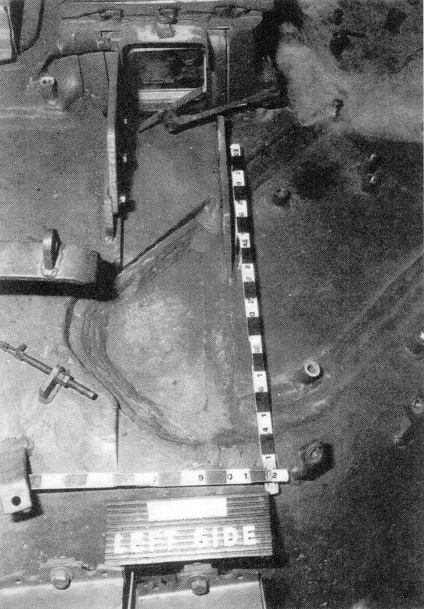

In the total absence of natural cover, the presence of the upper glacis armour array will partly reduce the height of the lower glacis weakened zone. The photos below (left photo courtesy of Stephen Sutton) shows the thickness of the front plate of the upper glacis array by the seam joining it to the lower glacis plate so that you can visualize the approximate reduction in the size of the weakened zone. The tank on the left is a T-72M1 (formerly Iraqi) and the tank on the right is a T-72M, so both have an improved hull armour array with a 60mm front plate. The dozer blade has some overlap with the array which further minimizes gaps in the armour.

Actual measurements done on a T-72M shows that the distance between the surface of the upper glacis and the edge of the dozer blade is 290mm. Knowing that the upper glacis has a thickness of 215mm on the T-72M, the gap between the area of the lower glacis protected by the dozer blade and the area overlapping with the upper glacis is only 75mm. When viewed from the front, the height of this gap is around 37.5mm, or just one and a half inches. Needless to say, hitting this part of the lower glacis is extremely challenging. On its own, the lower glacis plate is highly vulnerable to 105mm APDS, but this vulnerability is greatly reduced by the aforementioned factors.

The dozer blade is a very thick and heavy steel plate. According to T-72 manuals, it weighs 200 kg. It is probably made from a high hardness abrasion-resistant or armour grade steel. It is very likely that high hardness armour steel grade is used for the dozer blade of a military vehicle like the T-72 because a high hardness blade can be used to shift abrasive rock and frozen soil as well as provide additional ballistic protection. Case in point - high hardness impact resistant steels like Hardox 500 are standard for bulldozer blades and loader buckets used in mines and construction sites where large quantities of rock must be shifted, and high hardness steel dozer blades are also standard for military combat engineering vehicles. The measurement on the left below (done by Jarosław Wolski) shows that the thickness of the dozer blade on an old Polish T-72M1 is 20mm. The measurement on the right, taken from the T-72.org Facebook group, shows that the dozer blade of a T-72M is also around 15-20mm thick, although it is not possible to be sure. The measured dimensions are congruent with the given weight of 200 kg. At an unknown point in the production of the T-72, possibly beginning with the T-72B, the thickness of the dozer blade was increased to 25mm. This increased its weight to 250 kg. The T-90 and T-90A are verified to feature this thickened dozer blade.

Due to the obscurity of this topic, it is rather difficult to ascertain if the T-72M and T-72M1 differed from their domestic counterparts in the thickness of the dozer blade. However, it seems safe to assume that if the T-72M1 had a dozer blade with a thickness of 20mm, then the T-72A would also have one of the same thickness. It is worth noting that the dozer blade is not simply laid on top of the lower glacis plate, but it is actually slightly spaced. This is shown in the drawing below, taken from a T-80B manual. The T-80B has the same dozer blade installed.

This is beneficial against AP and APDS ammunition. An armour configuration consisting of a high hardness steel plate on top of an RHA plate at high obliquity is more effective than a solid RHA plate of the same weight, which is not only demonstrable with test firings against laboratory model targets but also in live fire tests. E.g. the solid 118mm RHA upper glacis of the Centurion Mk. 7 and Mk. 8 was found to be noticeably less effective on a thickness basis compared to the uparmoured upper glacis of Centurion Mk. 3 and Mk. 5 tanks, consisting of a 44mm RHA plate welded on top of the 76mm base RHA plate. The presence of an air gap between the two layers can provide an additional benefit against AP and APDS, supplementing the positive effect of layered armour.

The overlapping section between the upper and lower glacis plates combines with the dozer blade to make the lower glacis a problematic target to defeat. To put the level of protection into perspective, Rolf Hilmes credits the lower glacis of an ex-East German T-72M with 250mm RHA of protection against KE attack, which is incongruous with the combined LOS thickness of the lower glacis and dozer blade on their own (only around 208mm). This appears to be the only published figure on the armour value of the lower glacis. It is worth noting that if Hilmes' figure is correct, then the weakest part of the T-72 hull is nominally more resilient than the frontal armour of a T-54 and is on the same level as the turret armour of the Chieftain tank, especially after the slope of the armour is considered. The additional 5mm of thickness for late T-72 models increased the effective thickness slightly, but did not change the fundamental level of protection.

In all likelihood, L52A1 or M728 APDS with a penetration of 130mm at 60 degrees at 1 km and 120mm at 60 degrees at 2 km may fail to defeat the lower glacis from a range of approximately 1.5 km and more. The older L28A1 or M392A2 rounds had significantly worse performance on oblique armour and would certainly fail to defeat the lower glacis from 1 km or less. Of course, the L15A4 APDS round fired from the 120mm L11 with a penetration of 130mm RHA at 2 km should succeed against the lower glacis of the T-72 quite easily from any distance. Needless to say, these ranges would be unacceptable for the main armoured surfaces of the tank, but for a minimally exposed target such as the lower glacis, it is a very respectable level of protection, especially when compared to tanks like the Chieftain or M60A1.

It is worth noting that according to Russian historian Mikhail Pavlov mentions that the lower glacis plate of an Object 432 (T-64) can be nominally defeated by 105mm "subcaliber shells with a muzzle velocity of 1,475 m/s" at a distance of 2,500 meters, which is the same distance limit given for the lower glacis of the T-55 and T-62 (100mm RHA at 55 degrees). The lower glacis of the T-64 is the same as the T-72, but the tank lacks a dozer blade. HEAT rounds of a modest caliber would not face any difficulties in defeating the lower glacis armour, but against HESH, the physical separation of the dozer blade from the lower glacis fulfills the essential role of preventing the transmission of stress waves to the lower glacis plate from the blast, which prevents spalling. The considerable thickness of the blade itself allows it to resist deformation and thus fulfill its function even when impacted by HESH shells of a large caliber, as tests on Conqueror tanks have shown that thinner 14mm spaced plates ("burster plates") were effective at defeating 183mm HESH shells and Malkara missiles (HESH warhead).

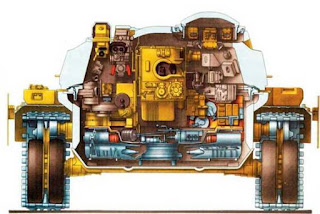

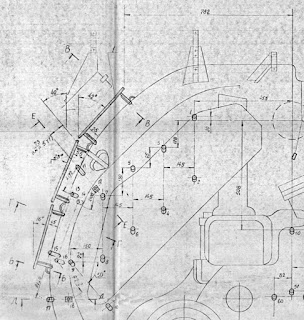

However, all of this is only true if the incoming projectile impacts the middle section of the lower glacis, as the lower part of the lower glacis has a reduced thickness. For the original T-72 Ural model, the reduction in thickness was a necessity because the torsion bars for the first pair of roadwheels are in the way, as you can see in the drawing on the left below (T-72 Ural). However, the geometry of the lower glacis was changed at an unknown time and became even thinner at the area in front of the torsion bars, as shown in the drawing on the right (T-90). Also note that the dozer blade on the T-90 is not spaced from the lower glacis plate, or has so little spacing that it is practically irrelevant.

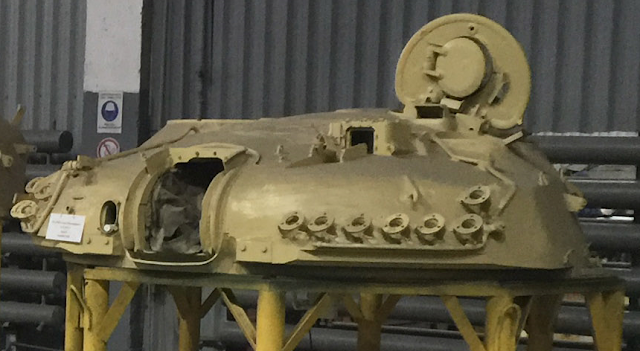

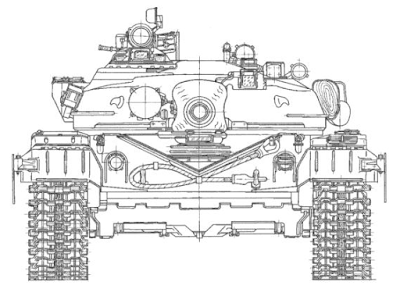

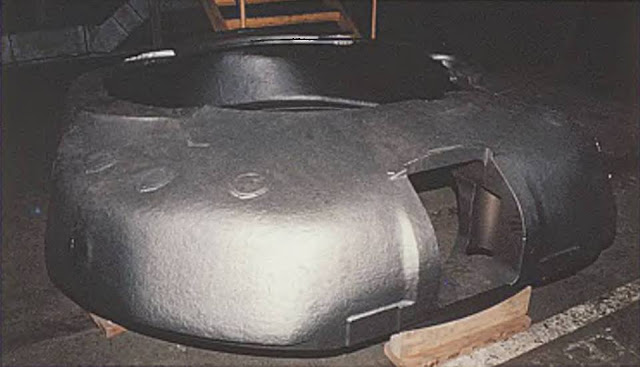

COMMON CHARACTERISTICS: TURRET

The turret is a two-piece casting. The walls, base, the bulge for the commander's cupola and some parts of the turret roof are formed from a single casting, onto which the cast roof is welded. The side armour is curved at a considerable rearward angle to form a point at the very back of the turret, forming a teardrop shape. This was especially exaggerated in the T-72B variant due to the larger and thicker turret cheeks, which earned it the humorous "Super Dolly Parton" moniker. The rear of the turret of all T-72 variants have a distinct step joining the turret roof to the bulge at the rear of the turret. This was inherited from the turret design of the T-64A, like so many other details of the T-72 series.

As there is no discrete transition from the frontal cheek armour to the side armour owing to the complex shape of the cast turret, the turret sides are simply defined as the region of the turret directly next to the crew seats, labelled 'Д' in this drawing of a T-64B turret. As mentioned before, the side of the turret has a physical thickness of around 80mm near the base and the curvature of the turret sides provide a minor increase in line-of-sight thickness to around 88mm when viewed perpendicularly. The turret sides becomes negligibly thinner towards the roof, but the curvature of the turret enables the same line-of-sight thickness to be maintained along the entire height of the sides. The amount of vertical sloping is relatively minor as the turret is built with a heavy emphasis on horizontal shaping; the side of the turret is horizontally sloped rearward at an angle of 42 degrees, as measured tangentially to the side of the turret. The LOS thickness of the side armour is therefore 118mm when viewed perpendicularly. The rear of the turret is around 65mm thick, but varies considerably in actual protective value due to the complex shape of the casting. This part of the turret is notably tougher than the T-64 and T-80 pattern of turrets as they are completely flat and therefore have a lower effective thickness.

With a thick layer of anti-radiation lining backing it and with the storage bins (plus cargo) adding a modicum of resistance, the sides are more than enough to withstand any 20mm and 23mm shell at point-blank and any 25mm autocannon shell at the higher end of typical combat ranges (in the vicinity of 1,500 m) when hit at a perpendicular angle. This is including the 25mm M919 APFSDS shell. However, the armour is not thick enough to reliably resist 30mm, 35mm and 40mm shells. In order to do so, the shot must impact the side armour from the frontal arc of the turret and not perpendicularly to the side. The rear of the turret, however, is only sufficient against 20mm autocannons unless it is attacked at a considerable angle of incidence, although the rear armour is actually somewhat pointed due to the teardrop shape of the turret. This would certainly improve the level of protection. From a perpendicular angle of attack, the turret cheeks can still offer a respectable defence due to the large thicknesses of steel, but the sides of the turret over the crew stations provide only a modicum of protection from light shoulder-fired HEAT grenades weapons like the M72 LAW. The presence of stowage bins made it difficult to achieve reliable penetration with such small caliber grenades, particularly when they were fully packed with spare parts and equipment, but it was not a comprehensive remedy.

On the T-72B3 UBKh, the sides of the turret have been completely covered with an advanced ERA kit capable of defeating tandem warheads at the expense of valuable stowage space and the rear has been reinforced with slat armour.

The shape of the turret of the T-72A and T-72B is such that the sides will be completely unreachable by enemy fire from within the frontal 70-degree arc. This means that if the side of the turret was shot at an angle of attack of 35 degrees, the thin sides of the turret will be hidden behind the turret cheeks. If the angle of attack is increased to 45 degrees, the sides will be visible, but the angle of incidence will increase to 87 degrees - steep enough to guarantee a ricochet. When the angle of attack is increased to 55 degrees, the angle of incidence is still 77 degrees. This is steep enough that many shaped charge warheads will fail to fuse and APDS projectiles are very likely to ricochet. Even if an attacking projectile manages to dig into the armour, the LOS thickness of the thin side armour from the horizontal angle of the turret alone at such a steep angle of incidence is very formidable at 391mm. This is already enough to resist the majority of shoulder-fired HEAT weapons used by opposing armies. This is also a noticeably higher level of protection than the side turret armour of the Abrams series from the M1 to the M1A2, as that only offers an effective thickness of 380mm RHA against an 81mm shaped charge warhead from a 45-degree side angle. The difference in the level of KE protection is even greater - the homogeneous cast armour at this zone of the T-72 turret would offer between half as much to twice as much protection at 55 degrees based on the calculated thickness efficiency coefficients of the Abrams turret side armour, and the protection provided at 45 degrees is infinitely higher because the angle of incidence is simply too high (87 degrees) whereas the side of the Abrams turret would offer only around 200mm RHA in effective thickness.

In other words, the turret of the T-72 is a very, very tough nut to crack from a wide range of angles. The unique teardrop shape of the turret makes it possible to present a high thickness of armour across the frontal arc and, more importantly, accomplish this without adding excessive weight to the tank. Indeed, based on the hit distribution data from multiple conflicts during the 20th Century, the teardrop shape is mathematically ideal for conventional large scale mechanized warfare on a fundamental level. This shape could not have been implemented effectively without restricting the turret crew to two men, and in turn, a combat-effective two-man turret design could not have been implemented without an autoloader.

However, this shape does not come without drawbacks. It is extremely efficient in the distribution of armour mass because it can provide a very high level of protection in its frontal arc with comparatively little armour compared to heavier turrets, but because the vast majority of the mass is disproportionately allocated to the front, the turret also became unbalanced. It is quite the opposite for NATO tanks like the M60A1, Chieftain, Leopard 2, M1 Abrams, AMX-30, and even the Leopard 1 to some extent. For these tanks, the inclusion of a large bustle containing ammunition or other equipment was a convenient counterweight to the frontal armour, thus shifting the center of gravity closer to the geometric center of the turret ring. This not only reduces the load on the horizontal turret stabilization system when the tank is situated on non-level ground and especially so when the tank is in motion over rough terrain, but a balanced turret also generates a more stable load on the stabilizer, making it easier to implement faster and more precise turret rotation drives, and it also reduces the stress on the turret ring from firing the main gun at various gun elevation angles and at various tank orientation angles. For instance, the turret of a basic T-72A weighs 12 tons (including the weapons and a full set of standard equipment) and its center of gravity is 500mm above the level of the turret ring race ring and horizontally offset 430mm from the geometric center of the turret ring. The turret of the T-72B has even heavier frontal armour and is even more unbalanced, and the addition of explosive reactive armour on the frontal arc further exacerbates the issue.

Tanks like the T-64B and T-80B used externally-stowed auxiliary equipment as counterweights with limited success. Presently, the relatively new T-72B3 UBKh modernization shifted more weight to the rear of the turret when reactive armour blocks were added to the sides of the turret over the inhabited zones and a slat armour screen was installed over the rear of the turret, but again, the effect is still limited simply due to the massive allocation of armour mass to the turret cheeks. More recently, the approach taken by Uralvagonzavod engineers with the new Proryv-3 turret of the T-90M can be seen in the retention of the teardrop shape and the addition of a segregated ammunition compartment to the bustle to act as a counterweight and to reduce the quantity of ammunition stowed openly in the fighting compartment. This solution is not perfect, but it is a suitable adaptation of the basic teardrop geometry for modern needs.

Nevertheless, the unbalanced turret of the T-72 is still lighter than the turret of tanks like the M1 Abrams or Leopard 2. The turret of a Leopard 2A4 reportedly weighs 16 tons (fully equipped), and would weigh even more if the designers had decided to provide any serious amount of protection for the sides of the turret bustle. As it stands, that is the weight of a Leopard 2A4 turret with only 80mm of flat RHA steel protecting the sides of the turret bustle (4 times less protection than the sides of the T-72 turret). In this respect, the T-72 turret design certainly has a major advantage and the decision to use a teardrop shape for the turret could be considered eminently justifiable.

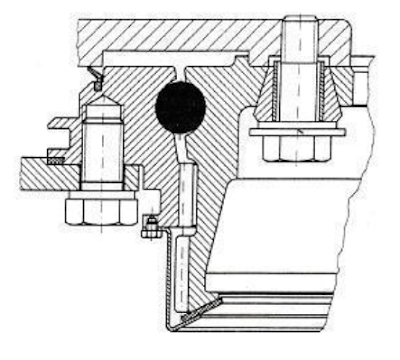

The turret ring of the T-72 is a simplified form of the T-64 turret ring design with the MZ autoloader carousel mounting ring removed. The design was created based on the T-54 and T-62 turret designs which placed the ball bearing race ring of the turret ring above the level of the hull roof in a cutout in the turret armour. This made the structure vulnerable to jamming from direct hits to the lower edge of the turret where the turret ring was located as the thickness of the armour is lower. For the T-72, the hull roof around the turret ring is thinner (20mm) than the hull roof above the driver's station (30mm) to accommodate the turret ring, but even so, the ball bearing race ring is still located in a cutout in the turret armour, above the level of the hull roof. As such, only a limited thickness of turret armour is present in front of the race ring, which poses a problem if an armour piercing round impacts the joint between the turret and the hull as it is much more likely to defeat the armour and jam the turret ring or enter the tank and cause internal damage. The turret ring design is shown in the two drawings below. The drawing on the left shows the rear of the T-72 turret and the drawing on the right shows the front.

The difference between the T-64 and the T-72 turret ring designs is apparent when they are compared. The T-72 turret ring is shown on the left with the interior of turret ring facing to the right of the drawing, and the T-64 turret ring is shown on the right with the interior of the turret ring facing to the left of the drawing.

Two rubber gaskets below the ball bearing race ring seal the turret ring from water ingress. A raised collar prevents artillery splinters and bullets from slipping into the gap between the turret and the hull roof. The depression of the hull roof around the turret ring can be seen in the photo below along with the protective collar.

The merits of various turret ring protection methods are examined in the study "Некоторые Вопросы Проектирования Защиты Стыка Корпуса И Башни" by O.I Alekseev et al. It was noted that turret ring designs that required a cutout in the lower part of the turret like the T-54 turret was a liability. Conversely, the solution implemented in the M48 Patton, M60 and M103 where the turret ring was installed in a raised flange cast together with the hull was also assessed to be a non-ideal solution as it still fails to prevent the turret from being jammed by a hit to the joint between the turret and the hull. The low thickness of the flange also results in a low level of armour protection. The best solution was found on the IS-3, T-10, Chieftain, Leopard 1 and M46 Patton. These tanks had the ball bearing race ring recessed below the hull roof, and in the case of the T-10, M46 and Chieftain, the gap between the turret and the hull roof was covered by raised parts of the hull. For example, the Leopard 1 shown below clearly has the turret ring race ring placed below the hull roof (photo taken by T. Larkum). The T-72 turret ring design belongs somewhere in between the first and third categories as the ball bearing race ring is still installed in a cutout in the lower part of the turret, but the height of the race ring is reduced compared to the T-54 and T-62.

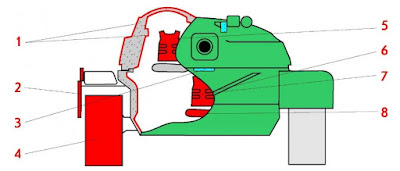

At the front of the turret, the cast steel gun mask can be considered a common feature of all T-72 variants, although this is not true in the strictest sense as the gun mask is different depending on the model of cannon mounted in the tank. The gun mask is a single solid steel casting that is bolted on the gun mounting cradle. The gun mask has a width of 390mm. It does not contact the gun barrel and does not interfere with the harmonics of the barrel, nor does it have any effect on the dynamics of the recoil stroke of the cannon. The gun mask is connected to the co-axial infrared spotlight on the right of the gun by a set of pushrods that allows the spotlight to be aimed vertically in sync with the tank's night vision sight albeit with a great deal of horizontal parallax if the spotlight is used at a different distance than the distance that it was previously calibrated for.

The gun mask has a ring of screws around the base of the barrel which are designed for securing a plastic gun mask cover. The cover is meant to prevent rain from ingressing the tank through the gap between the gun mounting cradle and the turret, but it also functions as a seal to prevent the ingress of NBC contaminants. The photo below by Thomas Voigt shows the gun mask of a T-72M with a plastic cover.

The ring of screws is also used in tank models with Kontakt-1 reactive armour as the mounting point for a metal frame holding a set of three reactive armour blocks on top of the gun mask, as shown in the photo below of a T-72AV. This contraption is also found on the T-72B.

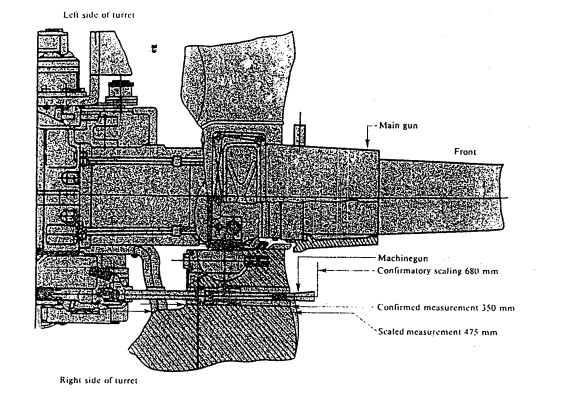

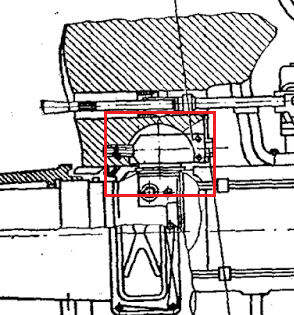

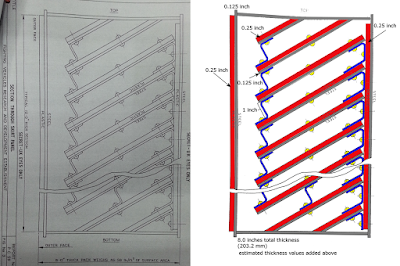

The gun mask is not meant to stop serious anti-tank weapons, but is instead simply a protective cover for the base of the gun barrel to protect the barrel and breech block from bullets and fragments and blast damage from shells impacting the turret. The gun mask is also designed with protruding edges that overlap the gap between the gun barrel and the turret in order to limit the possibility of bullets and fragments potentially jamming the gun in elevation. Due to the nature of the type of threat, the thickness of the casting is not particularly high, as shown in the photo on the left, below. Measurements on the protruding edges of the gun mantlet are shown in the two photos on the right, below. The measurements were done by Jarosław Wolski.

The thickness of the thinnest part of the base of the gun mask of the T-72M1 is around an inch. Based on the photo on the left, above, the thickness of the armour wrapped around the gun barrel is around an inch as well. According to "Возможная Компоновочная Схема Танка" ("Possible Tank Layout Scheme") by S.A. Gusev, the gun mask of the T-72B is only rated to stop 12.7mm B-32 armour piercing rounds from a distance of 100 meters. However, the rounded design of the casting and the thickness of the plate makes it quite obvious that this is the minimum guaranteed level of protection, as there are many sections where the combined thickness and slope of the mask should make it more than sufficient against 12.7mm B-32 at even point blank range.

The form of the gun mask changed slightly during the evolution of the T-72. The photo on the left shows the gun mask of an early T-72 Ural. The photo in the center by Stephen Sutton shows a T-72M1, analogous to the T-72A. The photo on the right shows a T-72B. Note the presence of a large nut in the corner of the gun mask of the T-72 Ural and T-72A. The nut is mirrored on the other side. On the T-72B, there are four nuts arranged at each corner of the gun mask. These nuts are attached to bolts that join the gun mask to the gun mounting cradle.

The change in the number of nuts is related to the upgrade to the 2A46M cannon with a quick-detach barrel, although the precise reason is not known.

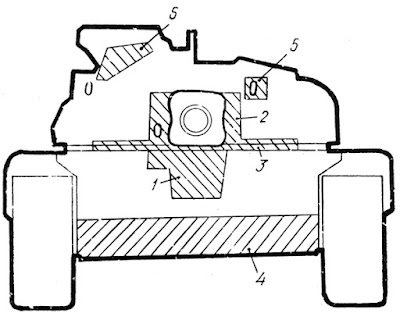

WEAKENED ZONES

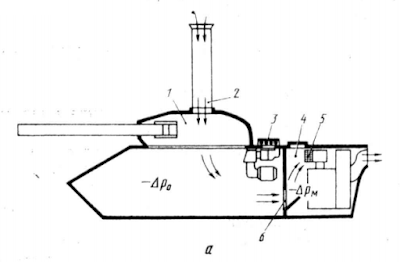

Although the armour scheme of the tank is good, the fact that some parts of the tank have less armour protection than others cannot be ignored when evaluating the overall level of protection. The critical zones of reduced armour protection (weakened zones) are:

Lower glacis (4): The lower glacis has already been discussed, of course, so there is no need to examine it again.

Gunner's primary sight aperture (5): The gunner's primary sight aperture weakened zone is an artifact of the sloped roof of the turret. Due to its periscopic construction, the sight must extend through the roof, which creates a gap in the roof armour. When viewed from the front of the tank, this gap is a narrow area where there is practically no armour, but in fact, the weakened zone includes the turret roof directly around the gap. This is because the gap is a structural weakness that may cause the roof armour to fail when impacted by a kinetic energy penetrator.

Gun mantlet area (2): The gun mantlet area weakened zone exists due to the need for space to accommodate the co-axial machine gun and the mechanical linkages that connect the gunner's primary sight to the cannon.

Turret ring area (3): The turret ring area is simply an inherent weakness created by the joint between the turret and hull. It is practically unavoidable for turreted tank designs.

Commander's cupola (5): The commander's cupola weakened zone is, of course, the cupola itself, which extends above the turret roof and cannot be armoured as thickly as the rest of the turret for obvious reasons.

Driver's periscope area (1): The weakened zone at the driver's periscope is created by the void in the upper glacis necessitated by the installation of the driver's TNPO-168V periscope as well as the need to accommodate the driver's head. This weakened zone is particularly interesting.

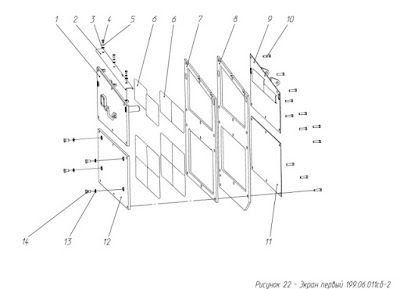

The weakened zone at the driver's periscope area can be seen in the cross-sectional drawing of the T-72 Ural shown below. The slope of the upper glacis is interrupted by the periscope, and the composite armour of the upper glacis is supplemented by a thick triangular reinforcing steel wedge to compensate for the reduction in line-of-sight (LOS) thickness caused by the interruption in the slope of the glacis.

The dimensions of this weakened zone is not available in literature, but it can be deduced from other sources of information. It can be seen from the drawing above that the height of the void is roughly equivalent to the height of the TNPO-168V periscope (274mm), and from the photo on the left below, it can be seen that the width of the void is roughly equivalent to the width of the driver's hatch (530mm). From these dimensions, the area of the void is around 0.145 sq.m. This, however, only considers the upper glacis when struck from the direct front. The reduction in LOS thickness is also apparent if the cutout is attacked from a side angle. Like the front wall of the cutout, the side walls are reinforced, but only along the front half, which has the largest projected area from the side. The side reinforcements are indicated by the large arrows in the photo on the right below. The rear half of the sides of the cutout are not reinforced, having a wall thickness of only 20mm.

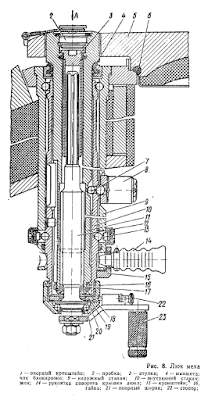

The thickness of the rear half of the sides of the cutout can be seen in the drawing below, which shows the driver's hatch mechanism. Although from this perspective it appears as if the upper glacis ends with a flat surface behind the mechanism, the drawing actually does not show the area behind the cylindrical hatch mechanism but rather the side of the driver's cutout in the upper glacis. The glacis armour is to the left of the driver's hatch mechanism, and the right wall of the driver's cutout is to its right, complete with a 10mm anti-radiation lining. Judging by the proportions depicted in the drawing, the side wall of the driver's cutout is a 20mm plate.

Besides that, as illustrated in zone (1), the weakened zone includes an additional area next to the driver's cutout. This is due to a cylindrical hole where an air sampler device for the NBC protection system is fitted, behind the opening and closing mechanism of the driver's hatch. The driver's hatch mechanism itself, situated inside the upper glacis next to the hatch, does not create a weakened zone by itself even though it intersects with the upper glacis armour. The difference in armour protection between the area containing the mechanism and the unaltered upper glacis armour array is more difficult to quantify due to the relatively small size of the mechanism and the fact that the mechanism is constructed from steel, with several telescoping concentric cylinders within that form a nearly solid barrier, so it still contributes to stopping a penetrating projectile. Moreover, it is also worth noting that the cylindrical hole for the air sampler device will also contribute to the weakening of the armour from a side angle, further compounding the lack of reinforcement at this area.

Whether the effective thickness declines drastically when the upper glacis is struck from a side angle will depend on the context. Due to the increased impact angle, the protection offered by the upper glacis improves, as does the side aspect of the cutout. While the side aspect of the cutout is undoubtedly thinner than the rest of the upper glacis from this perspective, the increased protection offered by the increased angle may at least provide the side aspect of the cutout with the same or similar protection as the upper glacis from the front. The weakest part of the side aspect is the rear part, which is the top edge of the glacis. This part is significantly weaker, owing to the lack of reinforcement. The only mitigating factor is that it is a smal area.

Besides that, as illustrated in zone (1), the weakened zone includes an additional area next to the driver's cutout. This is due to a cylindrical hole where an air sampler device for the NBC protection system is fitted, behind the opening and closing mechanism of the driver's hatch. The driver's hatch mechanism itself, situated inside the upper glacis next to the hatch, does not create a weakened zone by itself even though it intersects with the upper glacis armour. The difference in armour protection between the area containing the mechanism and the unaltered upper glacis armour array is more difficult to quantify due to the relatively small size of the mechanism and the fact that the mechanism is constructed from steel, with several telescoping concentric cylinders within that form a nearly solid barrier, so it still contributes to stopping a penetrating projectile. Moreover, it is also worth noting that the cylindrical hole for the air sampler device will also contribute to the weakening of the armour from a side angle, further compounding the lack of reinforcement at this area.

The dimensions of the weakened zone is not necessarily the same as the dimensions of the driver's periscope area void - the triangular reinforcing wedge in the upper glacis armour in front of the driver's periscope may not only compensate for the reduced LOS thickness, but instead increase the effective armour thickness to a certain extent against APDS and APFSDS ammunition. As such, certain portions of the so-called "weakened zone" are not actually weak when compared to the unaltered upper glacis armour, especially for the earlier armour designs incorporating glass textolite as the interlayer material. This is because the shape of the wedge is such that the thickness of steel increases as the LOS thickness of the upper glacis decreases, thus compensating for the reduction in the thickness of glass textolite. At the apex of the triangular wedge (one third of the height of the weakened zone), the LOS thickness of steel is 390mm. This is nominally enough to resist 120mm APDS rounds and indeed, considering that the unaltered upper glacis armour of the T-72 Ural is only equivalent to 305mm RHA against long rod APFSDS, the driver's periscope "weakened zone" for the T-72 Ural can actually be slightly stronger than the full upper glacis armour array at certain zones against KE threats, although it is undoubtedly still weaker in terms of HEAT resistance.

Even so, 390mm of solid steel is still more than enough to resist the grenade of an M72 LAW or other grenades with similarly small and light warhead, to list just a few. The resistance of this part of the armour is also higher than the unaltered upper glacis armour in a more nuanced sense due to its flat back surface which would not suffer the same structural shortcomings of a thin 20mm back plate, and as a homogeneous armour block, it avoids the issue of asymmetric forces causing the premature failure of a sloped armour plate. Overall, the dimensions of the weakened zone for a T-72 Ural (relative to the unaltered upper glacis) can be considered to span an area of 530x135mm (0.072 sq.m) - around half of the dimensions of the driver's periscope void itself. To fully understand the magnitude of this figure, it is necessary to take a better look at the total area of the frontal hull:

The projected area of the front hull is 2.08 meters according to "Возможная Компоновочная Схема Танка" ("Possible Tank Layout Schemes") by S.A. Gusev. Therefore, the void at the driver's periscope area occupies around 7.0% of the total area of the front hull and the actual weakened zone in the case of the T-72 Ural is only 3.4% of the total area. Considering that the area of the upper glacis is approximately 1.48 sq.m and the area of the lower glacis is approximately 0.6 sq.m, the driver's periscope weakened zone seems extremely small, especially when compared to the much larger lower glacis weakened zone on the front of the hull (29% of the total hull area), but again, it must be noted that the location of the driver's periscope at the center of mass of the tank makes it much more vulnerable than its relative size implies.

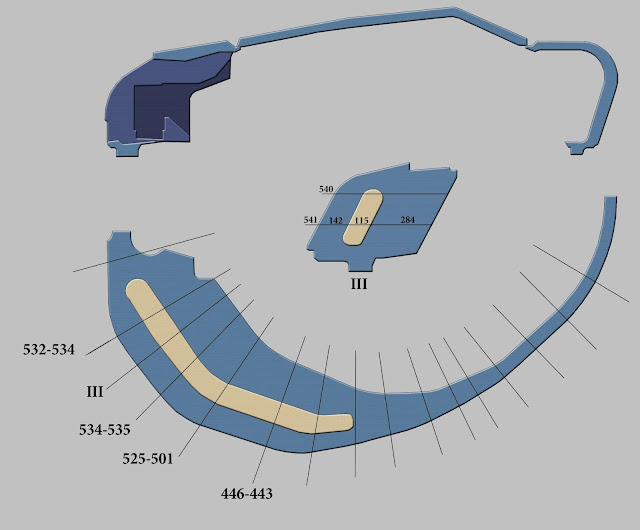

The size of the void does not change (0.145 sq.m), but the relative weakness of the driver's periscope area depends greatly on the specific round fired at the tank as well as the specific model of the tank. As the T-72 evolved, the different upper glacis armour designs prompted changes in the internal configuration of the armour in front of the driver's periscope area. For example, while the actual area of the weakened zone on the T-72 Ural is only 0.072 sq.m against 105mm APDS and other threats, the area of the weakened zone on the T-72B against 125mm BM-26 APFSDS is 0.12 sq.m. This area is 5.7% of the total area of the front hull. During live fire testing of the frontal hull armour of a T-72B, it was found that the driver's periscope area weakened zone could be defeated by BM-22 or BM-26 at a distance of 1.7 km at the midpoint of the zone.

Determining the size of the weakened zone on the lower glacis is somewhat more straightforward although it is still fairly complex in its own right due to the overlapping of the upper glacis composite armour with the lower glacis plate. According to "Возможная Компоновочная Схема Танка", the area of the lower glacis weakened zone that is vulnerable against 100mm BM-8 APDS is 0.33 sq.m, which is 16% of the total area of the front hull. The other 0.23 sq.m is presumably the area where the upper and lower glacis overlap.

As for the turret, the weakened zones are more numerous than the hull on account of the complex cast construction, although it is clear that the design of the turret can still be considered good. As discussed previously in Part 1 of this article in the section regarding the AZ autoloader, the turret of the T-72 is generally tougher than the front hull armour. This was necessary for the simple fact that most hits land on the turret and not the hull during tank combat, so it is more profitable to distribute a larger share of armour mass to the turret. The size of the turret was also kept to an absolute minimum in order to reduce the probability of receiving a hit, and the teardrop shape of the turret was designed such that the area of the turret projection would remain low from a variety of angles. This was accomplished by the use of an autoloader and ammunition stored in the hull (which is expected to sustain much fewer hits). The area of the turret from the front at a 0 degree angle is 1.7 sq.m, which is smaller than the frontal hull (2.08 sq.m).

The height of the T-72 turret from the turret ring level up to the top edge of the turret cheek is shown in the photo below to be 380mm. The photo is from the T-72.org Facebook group. The height of the turret in this context does not include the height of the turret ring area, so this is not the actual height as measured from the level of the hull roof.

The gap between the hull roof and the turret cheek on all T-72 tank turrets is considered the turret ring weakened zone. This gap has a height of 60mm, as shown by the photo below, taken from the T-72.org Facebook group. As the internal turret ring diameter of the tank is 2,162mm, the area of this weakened zone is 0.13 sq.m. The turret ring weakened zone occupies 7.64% of the total area of the turret.

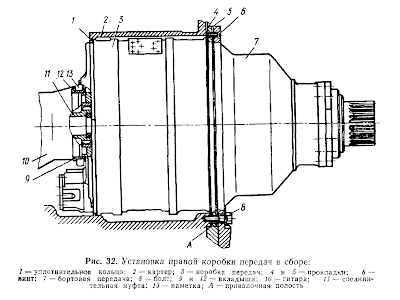

The gun mantlet weakened zone is thinner than the turret cheeks, and beginning with the introduction of the "Kvartz" composite turret, the relative weakness of the gun mantlet area became exaggerated as it was still only homogeneous steel, thus making it comparatively more vulnerable to shaped charge attacks. The turret ring area is also just a homogeneous casting, and of a rather low thickness as well. However, it should be understood that the gun mantlet weakened zone still has a formidable thickness of steel. Referring once again to "Возможная Компоновочная Схема Танка", it is reported that live fire testing revealed that the gun mantlet area of the T-72B could be defeated by BM-22 or BM-26 at a distance of 1.65 km. It is known that the armour penetration of these two rounds at a 0 degree impact angle at 2 km is between 420mm RHA to 490mm RHA, depending on the source. Therefore, the thickness of the gun mantlet weakened zone of the T-72B must significantly higher, taking into consideration the reported distance limit of armour defeat (1.65 km instead of 2.0 km). With that in mind, the vulnerability of the gun mantlet area of the T-72B against BM-22 and BM-26 does not necessarily translate to a vulnerability to contemporary 105mm APFSDS or even 120mm APFSDS like DM13 and DM23. Indeed, this so-called "weakened zone" would still be highly resilient to 105mm DM23 and DM33, as well as 105mm M833 and 120mm DM13 and DM23.