At present, the T-54 remains history's most enduring tank, and this is largely due to the sheer quantity of tanks used outside of the USSR. Besides the vast numbers of T-54 tanks fielded by the Soviet Army, thousands of tanks were exported and thousands more were produced by China. Dozens of variants of the basic model have been produced, most of them used by the Soviet Army. Production of the T-55 series for the Soviet Army continued until 1967 when it was fully replaced by T-64 and T-64A tanks, but it continued to be built for export clients until 1979, outlasting the T-62 which did not have the same level of export success.

As usual, we will only be covering the models used in the USSR but not abroad. We will be examining the most relevant variants of the T-54 except the models designed to fulfill supporting roles like firefighting and bridge laying.

There were a few prototype models, but the only one that made it to low rate production and small scale issuance was the T-54 obr. 1947, also known as the T-54-1. T-54-1 was first deployed to units in the Belorussian military district for crew familiarization and exercises, and it was there that a myriad of design flaws were discovered. As they were unfit for frontline use, most, if not all T-54-1s were relegated to reserves or storage soon after its more evolved brothers appeared. In the mid 60's, many T-54-1s and T-54-2s were taken apart and their turrets used as static pillboxes along the Chinese border and as coastal defence guns in the Far East.

Here are T-54-1 turrets installed on reinforced concrete pillboxes for coastal defence.

And here are T-54-2 turrets, one used for coastal defence and one on the border. Note the extremely small size and low height of the turret compared to the man.

The T-54 is a descendant of the legendary but obsolescent T-34, but after numerous revisions, the technical similarities between the two medium tank eroded away and the relationship between the two tanks had become purely historical by the early 1950's. Practically speaking, there was very little in common between the T-34 and the T-54 save that they both share roadwheels of the same diameter and the same track pin retention system (T-34-85 tanks stored in reserves were later modernized with T-54 roadwheels in the 1950's and 1960's). The noteworthy use of a transverse mounting scheme for the engine resulted in an enormous reduction in the volume of the engine compartment, leading to a cascading effect where the reduced volume also resulted in a reduced surface area that required armour protection, and the weight of the tank was consequently reduced. This freed up a considerably surplus of weight that could be distributed to other parts of the tank as additional armour thickness.

ERGONOMICS

Being smaller yet roomier and more thickly armoured than a T-34, the T-54 is excellent evidence that smaller tanks are not necessarily more cramped than a larger one. The main parameter is volumetric efficiency, in which the T-54 is rated highly. The total internal volume of the T-54 measured in at 11.4 cubic meters, of which 8.05 cubic meters forms the fighting compartment at the front and middle of the tank and the remainder forms the engine compartment. The share of the fighting compartment volume from the total volume is 71.25%, which is much higher than the 60.4% of the M47, 59.2% of the M48 and 60.7% of the M60A1. Of course, the volume of the T-54 fighting compartment is undoubtedly smaller than the aforementioned tanks in real terms: the M47 which is considered somewhat cramped compared to other Cold War era American tanks has a larger fighting compartment with a volume of 9.06 cubic meters. The roomy M48 has a fighting compartment volume of 10.48 cubic meters and the M60A1 is simply luxurious by comparison, having a fighting compartment volume of 11.17 cubic meters. Of course, one cannot ignore the fact that the M47 had five crew members and carried 71 rounds of 90mm ammunition as opposed to the four crew members of the T-54 and 34 rounds of 100mm ammunition, but the M48 and M60A1 have a clear and overwhelming advantage in terms of the volume allocated to each crew member. With this in mind, it can be said that the T-54 has a remarkably efficient allocation of volume and armour but with relatively little actual room due to the small overall size of the tank. Ideally, the efficient layout of the T-54 could have been scaled up, but the small silhouette of the tank was a serious advantage in terms of survivability at the time as it made the tank harder to hit, especially when it is moving.

Besides the volume allocated to the crew, it is also important to evaluate the furniture inside the tank as its design influences the comfort of the crew. In all T-54 and T-55 models, the turret occupants were seated on seats suspended from the turret ring. The gunner was separated from the D-10T gun by the built-in recoil guard of the gun itself, and a removable fence was attached to the recoil guard to keep the commander away from the recoil of the gun. The gunner's seat did not have a backrest.

Beginning with the T-55, a new recoil guard was added to the turret that separated the commander from the recoil path of the gun, and the gunner's seat received a backrest. The backrest was mounted to the seat cushion with a pole and it could be removed as the gunner moves from the commander's hatch to his station. However, it is often absent because it can impede a quick exit in an emergency.

The T-54 has a turret ring diameter of 1,825mm. In all incarnations of the turret design, the structure of the front half of the turret lies close to the turret ring but the structure rear half of the turret lies on top of a shelf. On the commander's side of the turret, this shelf space is taken up by the radio and control boxes, thus making up for the lack of a bustle. By right, the amount of room available in a T-54 turret should be at least comparable to a tank like, say, the Centurion MK. 2 and all subsequent models which shared the same cast turret, which had a 1.88 m turret ring, but as we know from actual comparison, that is not the case. This is at least partially due to the rather large breech of the D-10T gun and the lack of a turret bustle which was used to mount the radio (on the loader's side of the turret) in the Centurion, and more significantly, the commander in a Centurion is seated on top of the turret ring on the first step of the two-stepped turret bustle. This can be seen in the photo below.

With the commander seated this way, more space was created between the commander and gunner. This also allowed the gunner to have his own backrest - a luxury that the T-54 does not have. However, by placing the commander's seat in the turret bustle, the turret also had to be much taller to accommodate him; according to official drawings it is 959mm tall. This increased the overall height of the tank to 2,635mm when measured up to the turret roof, and the total height was 2,972mm. This also added weight; a combat-loaded Centurion Mk.3 weighed a whopping 50.8 tons - equal to a Soviet T-10 heavy tank and weighing 14 tons more than a T-54, yet having less armour than its Soviet medium tank counterpart, a less powerful gun, worse automotive performance, and a much worse travelling range. It was also not as roomy as an M48 Patton which still managed to weigh 5 tons less. Needless to say, there was no chance that such characteristics would have been acceptable for a Soviet medium tank.

The T-54 turret is slightly wider than the turret of an M46 which had a turret ring of only 1.75 m in diameter, and comparable with the M47, which had a turret ring that measures 1.85 m in diameter. A comparison between these tanks is fitting because they all have a similar needle-nose ballistic shaping with sloped turret sides, unlike the Centurion, which does not have significantly sloped plating on any facet of its turret. All of these tanks had rather narrow turret rings compared to the M48, as that had a 2,160mm diameter turret ring. In a comparison between the T-54 and its closest counterpart, the M48, the T-54 loses out in the amount of internal space available to the crew by a wide margin.

The low profile of the tank is advantageous when concealing the tank in prepared positions and it is also helpful if the tank is driving across open terrain as it reduces the likelihood of being hit, especially since tanks of that period had poor rangefinding capabilities, but the low profile is not so conducive for the loader. With a maximum internal height of only 1,600mm from the crew compartment floor to the turret ceiling, it was not possible for any of the crew members to stand upright in the turret unless they were particularly short. Nevertheless, the available internal height of the tank was considered enough for a loader by Soviet standards and the D-10T gun was designed with a horizontally-sliding breech as opposed to a vertically-sliding breech with this in mind. From this perspective, the T-54 is directly comparable to the M26 Pershing, M46 and M47 Pattons, but not the Centurion or the M48 Patton.

According to factory drawings, the Centurion has a total internal height of 2,057mm, but the tank stows a large quantity of ammunition on the floor of the hull underneath a rotating floor which the loader stands on. As such, the actual internal height from the rotating floor to the turret ceiling is 1,816mm - more than enough for an average man to stand up straight inside the tank. This is partly thanks to the fact that the Centurion uses an externally-mounted Horstmann suspension system which conserves the internal space of the tank, although there is no volumetric miracle as the Centurion is a very tall tank in the first place.

In the case of the M26, M46 and M47, the immense external height of the tanks did not translate into an equally immense internal height in the crew compartment because the turret basket was suspended far above the floor of the hull. For the M26, the floor was suspended more than halfway above the hull itself because a large quantity of ammunition was stored on the floor of the hull. It was the same for the M46 and the M47, both of which stored ammunition on the floor of the hull. Because of this, a large quantity of ammunition could be carried relatively safely in these tanks but the internal height was actually less than the T-54. Furthermore, ammunition was also stowed in vertical racks next to the loader in all of the aforementioned Western tanks, which is convenient for the loader but also takes up a large amount of space as shown in this photo of an M47. As such, the horizontal space for the loaders of these tanks is far less than the turret ring diameter suggests, and the cramped conditions for T-54 loaders are perhaps not so cramped in this context.

VENTILATION

Like all tanks of its era, the T-54 had a ventilation system that supplied airflow globally throughout the tank rather than locally towards each individual crew member. Beginning with the first T-54 model up to the T-54B, crew ventilation was provided by a large exhaust fan installed in the partition between the fighting compartment and the engine compartment. A ventilator intake fan was installed in the turret roof just in front of the loader's hatch to ensure a large supply of air above the gun breech. Both the ventilator intake and exhaust fans were powered by electric motors.

The dome surrounding the ventilator intake fan is a thick armoured steel casting that is welded to the turret. The heavy steel walls of the dome and the S-shaped ducting enables the dome to protect the motor from machine gun fire and artillery fragments. The drawing on the left below shows a winter cover for the ventilator dome and the drawing on the right below shows a cross section of the dome.

During combat, the ventilation intake fan on the turret roof acts as a blower that circulates fresh air through the loader's station and also serves to clear the air of some propellant fumes after each shot is fired, blowing the fumes downward where they are sucked out of the fighting compartment by the exhaust fan. This is shown in the drawing below. When the hatches on the tank are opened, the exhaust fan ensures that the crew experiences a continuous rush of air, but when the hatches are closed, air can only enter the tank through a few intakes: the gaps in the gun mask, the gun bore (if it is not loaded), the ventilation intake fan on the turret roof, small gaps in the turret ring between the turret and the hull, gaps in the periscope mountings, and gaps from the imperfect seals of the hatches.

The ventilation exhaust fan blew air from the crew compartment into the engine compartment. When fording deep bodies of water, this fan also serves as the only source of air for the engine and cooling system as the external air intake had to be shut off to prevent the engine from being flooded. The hole in the engine compartment bulkhead for the exhaust fan is shown in the drawing on the right below, and the drawings on the right below show the exhaust fan with the covers closed and the covers opened.

The loader receives the most airflow thanks to his close proximity to the ventilator intake fan, which is appropriate given his physically demanding duties. In combat, the driver can ensure that he is well ventilated by opening the ventilation porthole in his hatch, and in non-combat situations, it is better for him to drive with an open hatch. The commander's hatch also has a small ventilation porthole that can be opened to allow air to enter and blow down on the commander's shoulders under the suction force of the exhaust fan. Overall, this ventilation system was adequate for most situations, but it was not sufficiently effective at evacuating propellant fumes and it created some potential vulnerabilities. The reliance on small ventilation ports to supply air to the crew members may not have been a problem when the tank was hit by machine gun fire and armour piercing shells, but it presented an entryway for blast overpressure to reach the crew members directly. For instance, a medium caliber explosive shell detonating on the frontal turret armour would not be able to deal significant damage to the tank, but if the driver's ventilation port was open, the blast wave would reach him and some fragments may even find their way through the port. As such, only the commander could safely have the ventilation port in his hatch open during combat. This ventilation system was also incompatible with a collective NBC protection system.

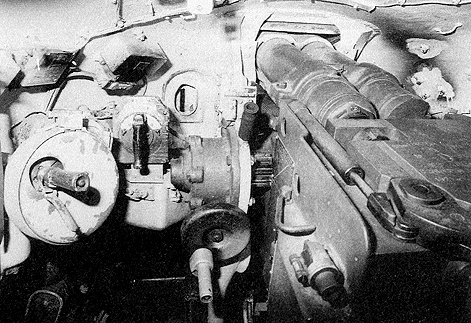

In cold weather conditions, using the ventilation system in its normal operating mode is undesirable because it simply takes cold air and circulates it in the tank when warmth is needed instead. It can simply be deactivated and the vents for the exhaust fan can be left open to allow heat from the running engine to radiate into the fighting compartment, but the downside is that there is no airflow to remove propellant fumes. Also, the driver would not be able to experience much heat as he is seated quite far away from the exhaust fan. There is no dedicated heater for the crew, but heat for the fighting compartment may be supplied by the nozzle-type engine and oil preheater placed in the rear left corner fighting compartment, clearly visible in the photo below (credit to Jim Chandler and the Warwickshire Armour Modellers for the photo). The exhaust of this heater is located on the belly of the hull. This heater can only be used if the tank is not in combat or conducting maneuvers.

The heater had to be moved slightly when a rotating floor was introduced in the T-54B in order to enable a floor of maximum diameter to be installed, although the floor was still somewhat narrow as it had a diameter of only 1,370mm. This was slightly narrower than the rotating floor of the Centurion Mk.7 which had a diameter of 1,549mm. The difference cannot be considered large because even though the total difference in diameter is 179mm, the actual difference on each half of the turret is only 90mm and Centurion tank loaders were separated from the hull by a turret basket wheras T-54 and T-55 loaders were not. It is the same for other NATO tanks as well.

The majority of surfaces of the fighting compartment floor was covered with textured rubber matting to prevent slipping. Unlike contemporary Western tanks, the T-54 lacked a turret basket and only had the rotating floor, although the turret basket floor of tanks like the M47 was also quite narrow because the turret basket tapers inward from the turret ring.

The lack of a turret basket allowed the gunner to stretch his legs into the driver's compartment when the turret was facing forward, but more importantly, it eliminated the need to store the tank's ammunition supply within the boundaries of a turret basket. In the Centurion, Leopard 1 and M48 (to list only a few), a large quantity of ammunition is stored next to the loader in vertical racks or bins which greatly reduces the available space in the loader's side of the turret. In the case of the M48A5, the loader has only half the space that the turret ring diameter alone suggests, as you can see in the photo on the left below. It is more or less the same for the Leopard 1, as shown in the photo on the right below. A T-54 loader is provided with a similar amount of headroom as its Western counterparts and he has more room in other respects.

On a side note regarding the rotating floor of the T-54, it seems rather improbable that the loader or anybody else will get his foot ripped off by the heater when the turret turns. It overhangs the rotating floor by only an inch or two and it is in the left rear corner of the fighting compartment, so the loader will only be in its vicinity in a narrow range of turret azimuths. Also, the loader will often be working with ammunition from the hull, so he should be very much aware of anything that might be dangerous.

Besides the general crampedness of the tank, a minor weakness of the T-54 is the scarcity of storage space. Besides the containers on the track fenders for storing tools and spare parts, there is no dedicated container for the personal effects of the crew. The abundance of external handrails and hooks for camouflage netting made it convenient for the crew to secure their canvas bags around the circumference of the turret (this is standard procedure taught to recruits), but it is not as convenient nor as secure as having proper stowage bins. One of the most common modifications of exported T-54s is the addition of external baskets and bins for stowage.

The handrails (two large ones on either side of the turret, and two small ones at the base of the rear of the turret. See photo above) make for great footholds to help the crew mount the turret.

COMMANDER'S STATION

The commander is seated on a padded triangular seat with a padded backrest, and there is also a cushion attached to the turret ring for him to rest his left knee upon. A fold-out footrest is provided. On earlier T-54 models, the lack of a rotating turret floor made this feature mandatory like on older tanks such as the T-34-85. The commander has access to the turret traverse lock, which is placed next to the radio transceiver on the turret shelf. Aside from that, he does not have any direct control over the turret or the weapons other than the target designation system as the T-54 does not provide duplicated controls for the commander. However, the extremely close proximity of the commander to the gunner's controls may allow him to override the gunner in a somewhat more direct way by simply leaning over and using the gunner's turret traverse controls.

In terms of space, the commander is severely restricted in his ability to move forwards and backwards as well as side to side. The small length of his station is because he is seated very close to the gunner in front of him, and the main culprit of the limited width of the commander's station is the location of the radio set. Being placed on the turret shelf just next to the commander, he can access it more easily than if it were installed behind his backrest, but this comes at the cost of restricting his working space above waist level. The narrow width of the commander's station can be seen in the two screenshots below, taken from the video "Танк Т 55 – снаружи, внутри, на ходу" from Ivan Zenkevich's channel.

The shoulder guard on the commander's right side isolates him from the recoil path of the D-10T cannon. It is possible to remove the arm guard. This gives the commander some much needed breathing space, but this can only be done in non-combat situations, for obvious reasons. This is also done to enable the commander to move to the loader's station, or vice versa, but to do that, the recoil guard behind the cannon breech assembly must be folded down as well. This is all shown in the two screenshots below, again taken from the video "Танк Т 55 – снаружи, внутри, на ходу" from Ivan Zenkevich's channel.

The commander and the loader can move over to each others' positions with relative ease once the deflector shield is folded down, although the keyword here is "relative". Furthermore, the commander's seat can be folded up for better access to equipment located below the turret ring and for maintenance and stowage purposes.

In terms of comfort, the commander gets a somewhat better deal than the gunner, who does not have a real backrest. Still, even though the commander has a footrest he has practically no legroom, forcing him to wrap his legs around the gunner. The advantage is that it is easy to nudge the gunner and give him quick orders. The disadvantage is that it quickly becomes very uncomfortable especially in hot weather, but perhaps it would be the opposite in cold weather. Nevertheless, the high level of physical intimacy between the two crew members is not particularly desirable.

COMMUNICATIONS

Originally, the T-54 was provided with a 10RT-26E radio transceiver mounted to the turret wall next to him. The radio is designed to operate in the 3.75-6.00 MHz frequency range. All Soviet armoured vehicles from the later half of WWII and the immediate postwar period featured a 10RT series radio, but by the early 50's, the series was rendered obsolete by a new government decree allocating the 20.0-22.4 MHz frequency range for the exclusive use of tank radios.

The production of the venerable 10RT series ceased entirely in 1956, having been replaced by the R-113 radio set in 1955. Beginning in 1955, all new production T-54s were equipped with the R-113 radio transceiver set. A video of an R-113 radio in operation can be found here (link). The R-113 belonged to the first generation of Soviet tank radios designed in the post-war era. It is a standard VHF radio operating in the 20-22.375 MHz frequency range with a maximum range of 20 km with the whip antenna extended, reduced to 8-12 km in the presence of noise and 10 km in the presence of jamming. For regular tanks in tank platoons, the radio is usually kept in the simplex receiving mode to receive orders from the platoon leader, while the platoon leader operates his radio in the half duplex mode, although he is forbidden from transmitting except in emergencies. In general, all tanks mainly operate in the receiving mode to receive orders from the company commander. The R-113 radio and the BP-2A power supply unit are shown in the photo below.

The T-54K command tank variant was created in 1959 and came with an additional R-112 radio mounted on the back of the turret. The R-112 operates in the 2.8 - 4.99 MHz frequency range, and has a range of 6 km with a whip antenna and 25 km with a mast antenna. The tank must be stationary to deploy the mast antenna. The R-112 radio allows the T-54K to communicate with the tank commanders of other tank companies as well as battalion commanders. The large size and mass (90 kg) of the radio made it impossible to install it inside the tank without removing something else. In this case, the ammunition rack holding five rounds at the back of the turret behind the deflector shield was removed and the radio is mounted there instead, as shown in the drawing on the right. The single round stored at the back of the hull was also deleted which led to a reduction in the total ammunition capacity from 34 rounds to 28 rounds in the T-54K.

Communication between crew members was facilitated by the their headsets and laryngophones which were connected to the TPU-47 intercom system. The components of the intercom system can be seen on the wall of the turret at the left side of the photo below. The tank in the photo below does not have a radio. The turret traverse lock can also be seen attached to the turret ring, and the metal loops for personal stowage can be seen on the wall of the hull at the bottom of the photo. Each crew member in the T-54 was allotted some space of personal equipment and each crew member was provided with a two-liter aluminium bottle which would be stowed in a special holder near their respective stations. Two clips for stowing two rounds of ammunition can also be seen at the bottom right corner of the photo.

CUPOLAS

Following the precedent set by the T-34-85 and T-44, it was quite natural that the T-54 series would also have this essential design feature. Every variant of the T-54 had a rotating commander's cupola mounted on a separate cast substructure that is bolted onto the turret and multiple cupola designs were implemented throughout the evolution of the tank, ending with the introduction of the T-54A in 1954.T-54 obr. 1947

On the T-54 obr. 1947, the commander's cupola protruded very slightly from the turret roof and the roof of the cupola is almost completely flat as shown in the two photos above, taken from the Net-Maquettes scale modelers' website. There was a single MK-4S periscope (also known as a Gundlach periscope) installed centrally on the cupola roof, supplemented by two viewing prisms that were slightly offset to the left and right. The hatch opens forward and can be locked in an upright position to provide frontal protection for the commander. As one would expect, there was a rubber lining on the underside of the hatch to protect the commander's head. This layout was borrowed from the commander's cupola of the T-44, which in turn was taken directly from the T-34-85, but unlike this older design, the cupola of the T-54 obr. 1947 had a much lower profile and omitted direct vision devices entirely in order to enhance the protection of the commander and reduce the overall height of the tank. However, even though it was certainly an improvement in terms of protection, the T-54 obr. 1947 cupola was not a comprehensive upgrade as it suffered from reduced visibility. Keeping its drawbacks in mind, the cupola of the T-34-85 could at least ensure all-round visibility with five viewing slits arranged around the fixed cupola at equidistant intervals to supplement the single MK-4 periscope in the rotating cupola roof. The photo on the left below shows the cupola of a T-34-85 as seen from below, and the photo on the right shows the cupola of a T-54 obr. 1947 from a similar perspective (photo from the urban3r website).

Each viewing prism in the T-54 obr. 1947 cupola offered a horizontal field of view of 80 degrees and the full viewing arc from the cupola to the front of the turret was only around 100 degrees. In truth, the full viewing arc could have been wider but the commander's view to the right was partly blocked by the ventilation dome on the turret roof. With just three viewing devices available, the commander was forced to rotate his cupola in order to look towards the side and rear of the turret, but the ability to rotate the cupola does not completely solve the issue of reduced all-round visibility as it would take more time for the commander to scan his surroundings and the commander would not be able to notice his surroundings through his peripheral vision. When not in use, armoured covers could be closed to protect the windows of the fixed viewing prisms from gunfire.

The central MK-4S periscope was similar to the other two viewing prisms in that it gave an unmagnified view, but it was adjustable in the vertical axis. Unlike the MK-4 periscope in the T-34-85 or T-44 cupola, it was not possible to look backwards from the periscope by using its reverse view feature due to the non-rotating mount and the armoured hood around the periscope head. This distinguishes the MK-4S variant from the original MK-4. The rear view feature of the MK-4 could be used by pulling down a sliding glass prism over the eyepiece window and then turning the periscope to face the rear.

The MK-4S was obsolete as a primary observation device as it did not provide magnified vision. This limited the commander's viewing range and restricted his ability to conduct fire correction for the gunner. Beginning in 1948, the MK-4S periscope was replaced by the TPK-1 fire correction periscope.

MK-4S

The MK-4S differed from the basic MK-4 by not having a rotating mount with an armoured collar and tin hood.

The MK-4 was a copy of the British AFV Periscope No.1 Mk.1, also known as the Vickers Mk. 4 periscope, which was actually the Polish Gundlach periscope produced under licence. The Soviet designation of MK-4 was taken directly from the Vickers designation, but of course, the Soviet government did not deem it necessary to pay licencing fees for using the design. However, Soviet engineers introduced a handful of improvements over the original design such as simplifying the overly complex handle and modifying the mounting flange to include a rubber seal. As such, the MK-4 was simpler to produce, more durable, and did not leak when it rained. Interestingly enough, the MK-4 was compatible with the No.1 periscope mounting point on British tanks like the Churchill and Cromwell.

The periscope can be elevated by 18 degrees and depressed by -12 degrees for a total elevation range of 30 degrees, but to have an all-round view, the T-54 obr. 1947 commander must rotate his entire cupola as the periscope is fixed in traverse. As the MK-4S is a unity periscope with no magnifying power, the early T-54 obr. 1947 suffers from a bad case of short sightedness.

According to Soviet studies (supported by foreign studies), an optical device with no magnification would allow the gunner to see a tank from a maximum distance of 1.0-1.5 kilometers. This is corroborated by actual combat experience during WWII which showed that users could identify tanks up to a distance of 1,000-1,200 meters. This is the same as viewing with the naked eye. Although this seems adequate, it is too limited to permit the commander to perform fire corrections for the gunner and it does not allow the commander to differentiate between different tank models as he simply cannot discern such details. This was sufficient at the time due to the rather short median tank engagement distances during the war, but it was no longer enough in the postwar era. The inadequacy of the MK-4S meant that it was only ever a stopgap solution before the TPK-1 was ready for production.

The TPK-1 periscope began development in the first half of 1944, but it was only ready for mass production after the conclusion of the war and it first entered service in 1948. The TPK-1 was completely interchangeable with the MK-4S as they both shared the same mount, so it was easy to introduce the TPK-1 to tanks that were originally equipped with the older type.

The TPK-1 was a notable improvement over the old MK-4S for observation at longer distances as it provided a 2.5x magnification power. The requirement set by the GBTU (Directorate of Armoured Forces) was for an effective viewing range of 1,500 meters and easier fire correction than from the venerable MK-4S, and the TPK-1 periscope met those requirements. An internal mirror could be unfolded above the binocular optics to display an unmagnified image through the viewing window above the binocular eyepieces, thus duplicating the function of the MK-4S. This gave the commander the luxury of both a wide-vision 1x periscope and a 2.5x magnified optic in the same device. The photo below shows a T-54 commander looking through this viewing window.

Although the modest 2.5x magnification of the device is totally inadequate for long range observation in a modern context, studies and records showed that tank combat distances during WWII generally did not exceed a kilometer. In fact, combat data from the Aberdeen Proving Ground showed that 80% of all encounters between tanks and other tanks or anti-tank weapons occurred at a distance of less than 1,000 yards. There were practically no encounters beyond 2,000 yards. From this perspective, the device is quite adequate, although not entirely ideal since a higher magnification would certainly have been appreciated for easier target identification at the upper boundaries of expected combat distances. For long range observation, the commander would have to rely more on his personal 8x30 field binoculars, which were usually of superb quality, as most examples of this line of binoculars made in the USSR were built using tooling plundered from the German Zeiss-Jena factory at the climax of WWII.

What a pair of 8x30 field binoculars doesn't have, though, is a stadiametric rangefinder. The stadia markings in the TPK-1 viewfinder allowed the commander to rapidly estimate the distance to a typical tank-type target with a height of 2.7 meters, and the additional markings allowed him to estimate lead for the target to a limited extent. These modest features were not insignificant, considering the fact that the MK-4S periscope lacked any mil markings whatsoever and did not permit even basic range estimations.

That, however, is not the biggest breakthrough from this new device. The most significant feature of the TPK-1 is its ability to designate targets for the gunner. This is done by simply aiming the device at the target and pressing the left thumb button. An electric signal is sent to the turret traverse motor, and by referring to a deflection sensor attached to the cupola ring, the turret is automatically rotated to meet the target. The deflection sensor detects if the cupola is turned away from the 12 o'clock position relative to the turret but does not record the actual azimuth of the cupola. If the sensor detects that the cupola is rotated counter-clockwise relative to the turret, the turret will be rotated counter-clockwise and vice versa. Once the commander has designated a target, the turret will turn until the cupola is once again at the 12 o'clock position relative to the turret - indicating that the turret is facing the same direction as the commander - and the turret traverse motor is halted.

Turret traverse is only conducted at maximum speed in order to minimize the reaction time of the system. As the gun elevation mechanism lacked power controls, it was still up to the gunner to adjust in elevation. The commander does not need to hold the button to slew the turret all the way to the target. A single click will do. Holding the button will prompt the turret to slew to meet the target and remain slaved to the periscope, thus allowing the commander to commandeer the turret as its movement would then depend on the commander rotating his cupola. Small corrections made by rotating the cupola slightly will not cause the turret to jerk onto the new aiming point even though turret traverse is done at maximum speed by default. This is because the traverse motor will need time to accelerate the turret to its maximum speed (due to inertia), so the turret will turn quite slowly if the arc of rotation is very small. The effect is that the commander can guide the gunner onto target quite gently if he turns the cupola slowly enough.

This arrangement can be described as a hunter-killer system, making the T-54 the first tank ever to implement such a system, followed by the British Conqueror heavy tank in 1955. The commander of a T-54 is not provided with duplicated firing controls so he cannot override the gunner completely, but this has little bearing on the definition of a hunter killer system. During the early 1950's, the TPK-1 periscope and the associated fire control modifications was retrofitted to IS-2 and IS-3 tanks to modernize them to the IS-2M and IS-3M standard, thus bringing the hunter-killer feature to the Soviet Army's workhorse heavy tanks as well.

To solve the visibility issues of the earlier cupola design, the T-54 obr. 1949 cupola had five viewing prisms of a new design arranged around the circumference of the cupola roof, thus guaranteeing that the commander could easily survey his surroundings without needing to rotate the cupola. Including the central TPK-1 periscope, there were six viewing devices in total, putting it directly on par with the T-34-85 or T-44 cupola design. Moreover, the viewing prisms also had a larger horizontal field of view of 86 degrees instead of 80 degrees.

However, the diameter of the cupola was not decreased and there was no additional space left for the viewing prisms around the rear half of the cupola, so the commander's hatch was shrunk to accommodate them. The exact dimensions of the hatch are currently not available, but needless to say, the resulting design was far from optimal. The other details of the cupola design such as the periscope mount and the hatch locking mechanism remained largely identical.

The photos below, taken by Vladimir Yakubov, shows a T-54 obr. 1949 housed in the Kubinka Armor Museum. The positions of the viewing prisms on the sides and rear of the cupola can be seen.

Strangely enough, the cupola is shown to be slightly tilted in some drawings, but not in others. If it was really tilted, the small angle probably did not massively affect the balance of the cupola to make it harder to rotate, but it most likely had a minor negative effect on the commander's view of the battlefield through the periscopes.

The cupola design was changed yet again in the T-54 obr. 1951 model to correct the drawbacks of the earlier design. The viewing prisms used in all of the previous T-54 models were replaced with periscopes, and the cupola layout returned to the same style as the T-54 obr. 1947. The height of the cupola was increased, and the commander's hatch gained a dome shape. This greatly increased the amount of headroom in his station and also made it possible to embed the side and rear view periscopes in the hatch itself. By relocating all of the five general vision periscopes to the rotating cupola with three embedded into the hatch itself, it was possible to increase the size of the hatch back to the same dimensions as the T-54 obr. 1947 without increasing the size of the cupola or compromising on the commander's circular visibility. Furthermore, it was level unlike the cupola of the T-54 obr. 1949.

The increased height of the cupola had the beneficial side effect of giving the periscopes more clearance from the turret roof, giving the commander a better view over the loader's cupola and the ventilation dome in front of it. This improved the commander's all-round visibility towards the right side of the turret, but came at the expense of making the cupola a slightly more prominent target.

TPK-1

The TPK-1 periscope began development in the first half of 1944, but it was only ready for mass production after the conclusion of the war and it first entered service in 1948. The TPK-1 was completely interchangeable with the MK-4S as they both shared the same mount, so it was easy to introduce the TPK-1 to tanks that were originally equipped with the older type.

The TPK-1 was a notable improvement over the old MK-4S for observation at longer distances as it provided a 2.5x magnification power. The requirement set by the GBTU (Directorate of Armoured Forces) was for an effective viewing range of 1,500 meters and easier fire correction than from the venerable MK-4S, and the TPK-1 periscope met those requirements. An internal mirror could be unfolded above the binocular optics to display an unmagnified image through the viewing window above the binocular eyepieces, thus duplicating the function of the MK-4S. This gave the commander the luxury of both a wide-vision 1x periscope and a 2.5x magnified optic in the same device. The photo below shows a T-54 commander looking through this viewing window.

Although the modest 2.5x magnification of the device is totally inadequate for long range observation in a modern context, studies and records showed that tank combat distances during WWII generally did not exceed a kilometer. In fact, combat data from the Aberdeen Proving Ground showed that 80% of all encounters between tanks and other tanks or anti-tank weapons occurred at a distance of less than 1,000 yards. There were practically no encounters beyond 2,000 yards. From this perspective, the device is quite adequate, although not entirely ideal since a higher magnification would certainly have been appreciated for easier target identification at the upper boundaries of expected combat distances. For long range observation, the commander would have to rely more on his personal 8x30 field binoculars, which were usually of superb quality, as most examples of this line of binoculars made in the USSR were built using tooling plundered from the German Zeiss-Jena factory at the climax of WWII.

What a pair of 8x30 field binoculars doesn't have, though, is a stadiametric rangefinder. The stadia markings in the TPK-1 viewfinder allowed the commander to rapidly estimate the distance to a typical tank-type target with a height of 2.7 meters, and the additional markings allowed him to estimate lead for the target to a limited extent. These modest features were not insignificant, considering the fact that the MK-4S periscope lacked any mil markings whatsoever and did not permit even basic range estimations.

That, however, is not the biggest breakthrough from this new device. The most significant feature of the TPK-1 is its ability to designate targets for the gunner. This is done by simply aiming the device at the target and pressing the left thumb button. An electric signal is sent to the turret traverse motor, and by referring to a deflection sensor attached to the cupola ring, the turret is automatically rotated to meet the target. The deflection sensor detects if the cupola is turned away from the 12 o'clock position relative to the turret but does not record the actual azimuth of the cupola. If the sensor detects that the cupola is rotated counter-clockwise relative to the turret, the turret will be rotated counter-clockwise and vice versa. Once the commander has designated a target, the turret will turn until the cupola is once again at the 12 o'clock position relative to the turret - indicating that the turret is facing the same direction as the commander - and the turret traverse motor is halted.

Turret traverse is only conducted at maximum speed in order to minimize the reaction time of the system. As the gun elevation mechanism lacked power controls, it was still up to the gunner to adjust in elevation. The commander does not need to hold the button to slew the turret all the way to the target. A single click will do. Holding the button will prompt the turret to slew to meet the target and remain slaved to the periscope, thus allowing the commander to commandeer the turret as its movement would then depend on the commander rotating his cupola. Small corrections made by rotating the cupola slightly will not cause the turret to jerk onto the new aiming point even though turret traverse is done at maximum speed by default. This is because the traverse motor will need time to accelerate the turret to its maximum speed (due to inertia), so the turret will turn quite slowly if the arc of rotation is very small. The effect is that the commander can guide the gunner onto target quite gently if he turns the cupola slowly enough.

This arrangement can be described as a hunter-killer system, making the T-54 the first tank ever to implement such a system, followed by the British Conqueror heavy tank in 1955. The commander of a T-54 is not provided with duplicated firing controls so he cannot override the gunner completely, but this has little bearing on the definition of a hunter killer system. During the early 1950's, the TPK-1 periscope and the associated fire control modifications was retrofitted to IS-2 and IS-3 tanks to modernize them to the IS-2M and IS-3M standard, thus bringing the hunter-killer feature to the Soviet Army's workhorse heavy tanks as well.

T-54 obr. 1949

To solve the visibility issues of the earlier cupola design, the T-54 obr. 1949 cupola had five viewing prisms of a new design arranged around the circumference of the cupola roof, thus guaranteeing that the commander could easily survey his surroundings without needing to rotate the cupola. Including the central TPK-1 periscope, there were six viewing devices in total, putting it directly on par with the T-34-85 or T-44 cupola design. Moreover, the viewing prisms also had a larger horizontal field of view of 86 degrees instead of 80 degrees.

However, the diameter of the cupola was not decreased and there was no additional space left for the viewing prisms around the rear half of the cupola, so the commander's hatch was shrunk to accommodate them. The exact dimensions of the hatch are currently not available, but needless to say, the resulting design was far from optimal. The other details of the cupola design such as the periscope mount and the hatch locking mechanism remained largely identical.

The photos below, taken by Vladimir Yakubov, shows a T-54 obr. 1949 housed in the Kubinka Armor Museum. The positions of the viewing prisms on the sides and rear of the cupola can be seen.

Strangely enough, the cupola is shown to be slightly tilted in some drawings, but not in others. If it was really tilted, the small angle probably did not massively affect the balance of the cupola to make it harder to rotate, but it most likely had a minor negative effect on the commander's view of the battlefield through the periscopes.

T-54 obr. 1951

The cupola design was changed yet again in the T-54 obr. 1951 model to correct the drawbacks of the earlier design. The viewing prisms used in all of the previous T-54 models were replaced with periscopes, and the cupola layout returned to the same style as the T-54 obr. 1947. The height of the cupola was increased, and the commander's hatch gained a dome shape. This greatly increased the amount of headroom in his station and also made it possible to embed the side and rear view periscopes in the hatch itself. By relocating all of the five general vision periscopes to the rotating cupola with three embedded into the hatch itself, it was possible to increase the size of the hatch back to the same dimensions as the T-54 obr. 1947 without increasing the size of the cupola or compromising on the commander's circular visibility. Furthermore, it was level unlike the cupola of the T-54 obr. 1949.

The increased height of the cupola had the beneficial side effect of giving the periscopes more clearance from the turret roof, giving the commander a better view over the loader's cupola and the ventilation dome in front of it. This improved the commander's all-round visibility towards the right side of the turret, but came at the expense of making the cupola a slightly more prominent target.

One drawback of this periscope layout was that the rear view periscope prevented the hatch from being opened unless it was removed. This made it impossible to open the hatch from outside the tank if the periscope was installed. If the commander was already at his station, the need to remove the periscope was an obstacle that complicated a speedy exit through the hatch. There was no real solution for bypassing this issue other than to keep the rear view periscope permanently stowed away.

T-54A (and later)

When the T-54A was created, it was given a new cupola design that remained the final variation to be found on any serial T-54 model and was later used on the T-54B and T-55 series, before also being adopted for the T-62 series and then becoming the template for the commander's cupola of the T-64, T-72 and T-80 main battle tanks.

The cupola was largely identical to the T-54 obr. 1951 design with modifications made to accommodate the new "Uzor" night vision system consisting of an OU-3 infrared spotlight and the TKN-1 night vision periscope. The modifications included the addition of a mounting point for the OU-3 spotlight above the central periscope hood, a hole in the cupola roof for the actuating rod that joins the TKN-1 periscope to the OU-3 spotlight, and the removal of the rear view periscope in the hatch due to the inconvenience it caused.

As the photo below shows, the rear periscope in the hatch that could be found on the T-54 obr. 1951 was replaced with a simple steel handlebar.

The T-54A retained the TPK-1 periscope for fire correction and general observation, but later tanks like the T-54B had the improved TPKUB periscope and later, the TPKU-2B.

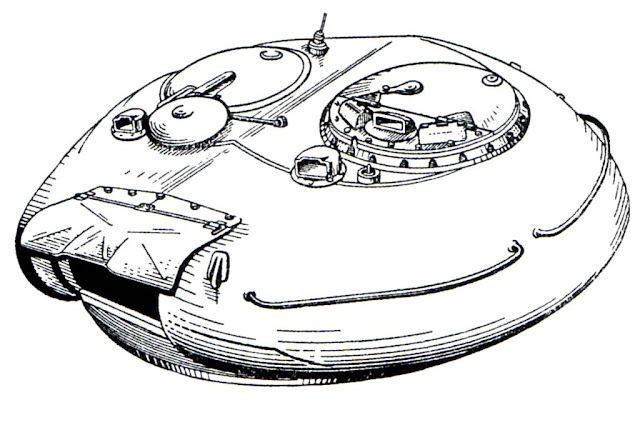

The bolt-on substructure on which the cupola is mounted has a minimum internal race ring diameter of 570mm and the substructure itself has an external diameter of 624mm. The rotating cupola itself fits inside this substructure. As shown in the drawing, the substructure is horizontally slanted by 17 degrees to offset the slope of the T-54 turret roof. This creates a level plane for the cupola to be mounted on, which is important because a tilted cupola makes it extremely difficult for the commander to use the viewing devices and the cupola itself would require more force to rotate.

The cupola and the cupola hatch are shown in the two drawings below. The hatch itself has a total length and total width of 497mm and 670mm respectively, but the actual opening in the cupola through which the commander can ingress and egress is much smaller as the length of the hatch includes the hinge where it attaches to the cupola and the edge where it overlaps with the lip of the cupola race ring. The actual size of the opening is only approximately 400mm long and the width is 570mm as indicated by the minimum internal diameter of the cupola substructure.

The height of the exposed cupola excluding the race ring which fits into the cupola substructure is 131mm and the entire cupola is thickly armoured and sloped.

TPKUB, TPKU-2B

The commander of an early issue T-54B was equipped with the TPKUB binocular periscope. This was a binocular magnified periscope like the TPK-1, but it lacked the wide vision feature of its predecessor. The TPKUB had a single left handle for the commander to grasp, but the much more common TPKU-2B model that came later had two handles. The left handle on both models contains the target designation button for the tank's hunter-killer system. The new periscope was a step forward over the TPK-1 in the observation range thanks to the increased magnification. Many older T-54 models were retrofitted with the TPKU-2B to bring it up to the same level of technology as the T-54B.

The sight has two adjustable magnification settings of either 1x or 5x. Under 1x magnification, the field of view from the sight is 17.5 degrees. This is reduced to 7.5 degrees under 5x magnification. The general layout of the viewfinder and the reticle is the same as in previous periscopes. The viewing distance is improved by the higher magnification factor, but the rangefinding capabilities of the periscope are probably not improved at all. A British-Israeli report made available on the tankandafvnews website reveals some interesting information on the precision of rangefinding through the TPKU-2B: from the table in page 121 (page 64 of the photo album), the mean error in ranging tank-shaped screens, broadside tanks, oblique tanks (meaning: angled hull) and head-on tanks is 14.57%. The results of an analysis of the data were somewhat counter-intuitive.

Page 122 of the report (page 65 of the photo album) mentions that the precision of rangefinding against hull-down tanks was surprisingly unaffected by the fact that half of the target was out of sight. The report does not say why, but we can conjecture that it is because stadia rangefinding is partly technique and partly guesswork. The full report on tankandafvnews is worth reading in its entirety as it is very enlightening.

The tests show that the commander is able to range the target in an average time of 3.3 seconds, and this section of the report concludes that the short time required to obtain a range estimate is unobtrusive to the loading and laying of the gun. This means that by the time the gunner has visually acquired the target, he will already know the range, and can open fire without delay.

Like the TPK-1, the TPKU-2B has a target designation function. The target designation system is a rather simple one; A direction sensor is installed in the 5 o'clock position of the cupola. The direction sensor consists of a roller placed in permanent contact with the cupola race ring, a cam attached to the roller and two switches. The roller is recessed into a notch in the cupola race ring when the cupola is turned to the 0 o'clock position relative to the turret. When the cupola is turned to the right, the motion of the cupola race ring dislodges the roller from the notch and causes the roller to be deflected to the left by friction. The cam attached to the roller also rotates left, causing it to touch the switch on the right (see diagram on the top right, below). The right switch triggers the turret rotation motor to turn the turret to the right until the roller returns to the notch, which would mean that the gun is now facing the same direction as the commander's cupola. The same mechanism is repeated in reverse when the cupola turns to the left. Since the direction sensor is composed of two switches which can only be either on or off, the command to initiate turret rotation is binary. This means that the turret is either turning, or it is not. For that reason, the turret always rotates at maximum speed when the target designation system is activated.

The binary system also does not allow the commander to precisely lay the gun on target, because precision gun laying is done at the minimum turret rotation speed, which would be 0.07 degrees per second in the case of the T-55. Potentiometers would be needed in order to have a variable speed of turret rotation. However, as mentioned before, small corrections made by rotating the cupola slightly will not cause the turret to jerk onto the new aiming point, even though turret traverse is done at maximum speed by default. This is because the somewhat underpowered traverse motor will need time to accelerate the turret to its maximum speed. There is no vertical deflection sensor attached to the TPKU-2B periscope, so it is not possible for the commander to raise the cannon onto the target from his station.

TKN-1, TKN-1S

The TKN-1 periscope was a monocular night vision surveillance device, and it was the first serially produced device of its kind to be used in the Soviet Army. As the TPK-1 and TPKU-2B periscopes lacked any provisions for effective nighttime use, it was necessary to swap it out for the TKN-1 before commencing night operations. The TKN-1 was introduced in 1954, and was used on the T-54A, T-54B, and later on in the T-55 as the TKN-1S.

TKN-1 has a fixed 2.75x magnification. This is insufficient for long range observation, but due to the short range provided by the TKN-1. The angular field of vision is 10 degrees. TKN-1 fits in the same slot as the TPKU-2B. Older model T-54s can also use TKN-1, but only if they have been modernized to include the BT-2-26 power supply system.

The TKN-1 required a source of near infrared light for illumination. This is provided by an OU-3 infrared spotlight that is directed in elevation by a mechanical rod linked to the TKN-1. When the periscope is adjusted to look up and down, the spotlight is rotated around its hinge to follow the commander's line of sight.

The infrared light from the spotlight illuminates the target, and the reflected light entering the objective lens of the periscope is then amplified by an image intensifier tube operating on 17 kV. The power cable connecting the periscope to the tank's electrical system can be seen on the left side of the periscope, as seen in the photos below (Photo credit to ancientpieces from ebay). The power cable supplies power to the transformer housed in the box on top of the eyepiece, and another cable runs from the transformer to the image intensifier installed inside the optic.

Using the TKN-1 with the illumination from the OU-3 will enable the commander to identify tank-type targets at a distance of only 250-300 meters. Due to the short viewing distance, the TKN-1 is generally only suitable for spotting enemy tanks that are also using active infrared illumination, for following the fall of tracers, for observing the impact of shots and for spotting the muzzle flash of enemy tanks. The view through the eyepiece of the TKN-1S is shown in the two photos below (image credit to kmshik from the GAZ 69 forums).

Like the TPKU-2B, the TKN-1 can be used to designate targets by pressing the left thumb button. On the right handgrip is a thumb button to activate the OU-3 infrared searchlight on the cupola. It is not only possible for the sight to be turned to the active infrared imaging mode without turning on the searchlight, it is highly recommended. If enemy tanks have infrared searchlights as well, then the commander will be able to spot them easily without needing to turn on his own, thus remaining hidden. Use of infrared illumination is usually only tactically viable with good coordination and fire control, or when enemy tanks have absolutely no night vision equipment at all.

GUNNER'S STATION

The T-54 gunner sat directly in front of the commander. The gunner's seat was mounted to a frame bolted to the turret wall to the left of the gun cradle and he was provided with a foot rest. His seat could be folded up and to the right and locked flush against the recoil guard of the D-10T gun to permit freer access to the hull, particularly if the gunner wants to crawl out through the escape hatch behind the driver's seat.

The gunner could determine the orientation of the turret in azimuth by referring to an azimuth ring marked on the turret ring. This was quite typical for many tanks of that era, although some already had more sophisticated clock-type azimuth indicator mechanisms that offered higher measuring precision.

In all T-54 models up to the T-54A, the gunner was provided with a single MK-4 periscope for general surveillance. It was installed in the turret roof and was positioned to the left of the telescopic primary sight as shown in the photo above. As mentioned before, the MK-4 has a rear view feature, can be rotated independently, and can be elevated by 18 degrees and depressed by -12 degrees. For T-54 gunners, the main benefit of having the MK-4 was the fact that it had a fixed handle and could be elevated and depressed independently of the turret, so when the tank moved over rough ground, the gunner could grasp the handle of the MK-4 firmly and press his forehead against the brow pad to keep a relatively stable view of the terrain. Keeping in mind that early T-54 models lacked a gun stabilizer, this provided the gunner with the ability to continue contributing to the surveillance capabilities of the tank to some degree while most other tanks did not.

However, the independent rotation and the rear view capability of the MK-4 were not useful for the gunner because of the location of the periscope. The commander's cupola obstructed the gunner's view to the rear, the telescopic primary sight made it difficult for the gunner to look to the left, and the turret wall itself made it difficult to look to the right. As such, the gunner's field of view was not as good as the design of the MK-4 itself implied.

Nevertheless, the MK-4 gave the gunner unusually good situational awareness compared to many other tanks, but in practice, it was somewhat flawed. After numerous field exercises were conducted by units equipped with the T-54 in the late 40's and early 1950's, it was found out that the MK-4 could not be used for too long when the tank was driving over rough ground as the pitching of the tank could give the gunner motion sickness. It was far more profitable to focus on the operating the main sight instead and leave the MK-4 be until it was needed, like when the tank enters a turret defilade position. The gunner would then use the periscope to observe targets without needing the turret to be exposed and without needing to turn the turret, since the MK-4 could rotate independently.

On the T-54B model, the MK .4 was replaced by the TPN-1 night vision sight, so its role was taken over by a single fixed forward-facing periscope installed above the TSh2-22 primary sight. This configuration was kept in the T-55 and T-55A. As a result of the loss in the ability to independently rotate the periscope, the gunner's vision deteriorated slightly. However, the T-54A and T-54B already featured gun stabilizers so the gunner had a stable view of the battlefield through his primary sight when the tank was in motion, so the gunner's ability to scan for targets did not decline but instead increased considerably, and the essential ability to scan for targets when in a turret defilade position was maintained. Overall, the gunner was well-equipped for his duties and the T-54 must be considered excellent in this regard.

Laying the gun in elevation was done using a spirit level affixed next to the gun, and laying the gun in the horizontal plane was facilitated by a turret azimuth indicator, as seen below. The indicator works like a clock with two hands. The indicator can be seen next to the manual turret traverse handwheel in T-54 models beginning from the T-54A (1954).

The azimuth indicator measures the orientation of the turret according to the Soviet mil definition where a full circle is divided into 6,000 mils and the azimuth reading is divided into tens and hundreds with the 3,000 mil position (30-00) being the 12 o'clock position. For example, if the turret is oriented 180 mils to the left, it is in the 28-20 position, and if the turret is oriented 340 mils to the right, then it is in the 33-40 position. The 00-00 and 60-00 positions are equivalent.

The ventilation porthole in the commander's cupola allows a panoramic periscope for indirect fire to be installed.

TSh-20

The TSh-20 was an articulated telescopic sight. Most telescopic sights from the WWII era including the TMFD-7 and TOD sights of the T-34 were fixed to the cannon so that if the cannon elevated, the telescope went up and down along with it. This meant that the eyepiece would never be in the same spot as the gunner fiddled around trying to get a firing solution for his target. In the TSh-20, the telescopic aperture is joined to the telescope body with a hinge, optically connected by cleverly placed mirrors. With an articulated telescopic sight, the eyepiece and the main telescope body could stay fixed while only the aperture moved. This eliminated the problem of gunner fatigue and improved firing accuracy, as the gunner will always maintain optimum eye relief. This arrangement was first used in the Soviet weapons industry in the TSh-16, which was installed in the T-34-85.

The T-34's PT-4-7 sight (below, left) featured a similar system of range adjustment. The horizontal line can be moved while the vertical line remains static, unless lead is applied. The intersection point between the two lines forms the crosshair. As the horizontal line is moved down the range scales to the appropriate distance to the target for a given ammunition type, the crosshair is moved down by the same amount.

The newer TSh-16 (above, right) offered an improved viewfinder arrangement. The viewfinders on the TSh series of telescopic sights generally have a better layout as all of the "clutter" is concentrated in the top half of the sight picture where there is nothing but sky. This means that the gunner's view of everything from the ground up to the horizon is perfect, but his view of the sky is not, which is obviously not important. Insufficient magnification power of the TSh-16 aside (only 2.5x), the design of the viewfinder was considered sound, so it was carried over to the TSh-20.

One excellent feature of the TSh-20 sight is the large rubber brow pad. It is large enough to fit around the gunner's forehead and temples - even if he is wearing his helmet - and stiff enough to hold his head in place, so that even if the gunner's body is rocking about, his head will be held firm and his eyes can be glued onto the eyepiece. This is a traditional feature of almost all gun sights on Soviet and Russian tanks, including later sights present on the T-54, which we will discuss later, all the way up to the Sosna-U on the latest T-90MS.

TSh-20 offers a fixed 4x magnification with a 16° field of view. This is horrible by modern standards, but arguably within acceptable limits for a 1945 product. For example, the M71C for the Pershing had a fixed 5x magnification with a 13° field of view. The extra wide vision arc offered by the TSh-20 enabled the gunner to survey for targets at short to medium distances more easily, but severely handicapped the long range viability of the tank. Whether high magnification was necessary during that particular stage of global tank evolution is not too clear. U.S research showed that the average tank duel in the Korean war occurred at an average distance of only 450 yards (411 m) due to the abundance of natural obstacles and obscurants. In addition to that, Soviet experience and research during WWII showed that almost all tank duels fought by Red Army tanks occurred under 1 kilometer in distance. With heavy, hours-long artillery barrages usually preceding breakthrough assaults, smoke and dust in the air often reduced tank engagement distances to just a few hundred meters, with many tanks only meeting each other at "knife fight" distances (also making head-on collisions, accidental and non-accidental, surprisingly common).

If the T-54 obr. 1947 came early enough to fight in WWII, or if its sequel was conducted in much the same way, then perhaps TSh-20 is good enough. However, it was impossible not to recognize that tank warfare was evolving and that the requirements for sight magnification had become more demanding.

TSh2-22, TSh2B-22

TSh2-22 was introduced with the T-54 obr. 1949. Continual field trials of the T-54 obr. 1947 throughout 1948 had shown that one of the chief complaints was the limited magnification of the TSh-20. Consequently, TSh2-22 features variable magnification settings of 3.5x and 7x. By implementing variable magnification in the gun sight, the gunner could enjoy both wide vision and high power magnification, though obviously not at the same time. For an even wider field of view, the MK-4 rotating periscope would more than suffice. The TSh2B-22 sight was a modification of the basic model with new design features that gave it compatibility with the STP-1 gun stabilizer of the T-54A respectively.

TSh2-22 is directly comparable to the Centurion's No.1 sight which had a variable magnification of 1x or 6x and the M47 Patton's M20 sight, which also had a variable magnification of 1x or 6x. The M20 sight was shared by the M48 as well.

There are multiple variations of the TSh2-22 viewfinder. An early versions (a) has four scales; three for main gun rounds and one for the coaxial machine gun. Listed from left to right, they are: HE-Frag with a full charge (53-UOF-412), APBC (53-UBR-412B), HE with a reduced charge (53-UOF-412U) and finally, the coaxial machine gun. A late version (b) has just two scales for main gun ammunition: HE with a full charge and APBC, plus one for the coaxial machine gun.

Moreover, the later version included additional horizontal lead markings and a stadia rangefinder scale to allow the gunner to quickly measure the range in case the commander is preoccupied or if the tank is running in a degraded state with a 3-man crew. It allows the gunner to switch from battlesight gunnery to precision gunnery, which is necessary to ensure a reasonable probability of hit on targets that are beyond the point blank range of the tank's 100mm armour-piercing ammunition. The stadia rangefinder markings start at 1,220 meters, which is the point blank range for the BR-412B and BR-412D rounds against a target with a height of 2.7 meters.

Another difference is the removal of the range markings on the vertical line below the center chevron. These range markings are meant to be convenient aiming points for common combat distances using APBC shells to aid the gunner if he decides to use the bracketing gunnery technique to engage a target. It is reasonable to assume that with the addition of a stadia rangefinder scale, it became superfluous as it would be slower, less accurate, and more wasteful of ammunition compared to stadia rangefinding. At least, this was the case in other contemporary sights. Multiple viewfinder configurations with various combinations of markings existed and small changes were implemented over time, making it rather difficult to classify the TSh2-22 this way. The markings were etched on a special viewfinder glass disc that could be removed relatively easily and replaced with updated markings when new ammunition became available.

The sight is ordinarily zeroed to a distance of 1,200 meters or more. The drawing below depicts a method of zeroing the sight in field conditions by using a landmark.

By displaying all of the range scales in the viewfinder and not on an external dial, the gunner can conduct the entire target acquisition procedure without removing himself from the sight and losing visual contact with the target. This problem was solved in the Centurion in a rather creative way; a mirror was placed in front of the gunner's left eye at such an angle that the gunner could see the range drum with his left eye as he adjusted it, and then - by just moving his eyes - return to the sight and resume targeting.

To use the rangefinder, the gunner only needs to bracket the target tank between the stadia lines and read the figure corresponding to the height of the target, and then turn the range adjustment dial until the horizontal line is on the correct range scale mark for the desired ammunition type. It is also possible for the gunner to use the multitude of chevrons and lines that form the reticle of the sight viewfinder and combine them with his own memorized information of tank widths and lengths to obtain a range estimate.

The sight aperture port cut into the turret was protected by a pane of glass. This was merely a thin barrier to prevent external debris and water from entering the turret through the aperture. It had no ballistic protection whatsoever.

While Soviet-built tanks had a stadium-shaped glass cover that was affixed to a raised lip that is shaped accordingly, Polish-built T-54 tanks used an oval-shaped glass cover. This can be used to identify the origin of the tank regardless of its markings.

TSh2B-32 was first implemented in the T-54B. The sight was practically identical to the previous articulated telescopic sights with the main difference being that it was designed to connect to the new STP-2 gun stabilizer. This sight continued to be used in the T-55 series as the fire control system did not change. The configuration of the viewfinder markings follows the latest variant of the TSh2B-22. As shown in the photo below, there were range scales for HE-Frag with a full charge, APCBC, HEAT and the coaxial machine gun. Additionally, the markings for HE ammunition with a reduced charge were permanently removed as this type of ammunition had become obsolete.

In January 1965, the TSh2B-32P was installed in the T-54B and T-55. The only difference between it and the TSh2B-32 is the new range scale for 3UBM6 APDS ammunition. The "P" in "TSh2B-32P" stands for "subcaliber". Tanks that had the TSh2B-32 equipped were modified by swapping out the viewfinder glass disc with a new disc with the additional markings to transform them into the TSh2B-32P.

Besides the range scale for subcaliber rounds, there are no other notable differences. It is worth noting that the scale for subcaliber rounds can be used for both APDS (3BM8) rounds and APFSDS (3BM19, 3BM20, 3BM25) rounds due to the very similar ballistic trajectories of both types of ammunition and the low precision of this type of range scale. For instance, the 3BM20 APFSDS shell had a point blank range of 1,690 meters against a target with a height of two meters and a point blank range of 2,040 meters against a target with a height of three meters while the 3BM8 APDS shell had a point blank range of 1,680 meters against a target with a height of two meters and a point blank range of 2,020 meters against a target with a height of three meters. In realistic conditions, this small difference is practically imperceptible.

In the year 1957, the T-54 entered its tenth year of formal service in the Soviet Army and also the tenth year of its continuous evolution, becoming the T-54B. The T-54B became capable of night fighting with the installation of the TPN-1-22-11 active infrared imaging sight and the accompanying L-2 "Luna" infrared spotlight. Although the performance of the night vision system is far from impressive by modern standards, it was a modern product for its time and the inclusion of a night vision sighting system in the T-54B together with a night vision TKN-1 optic for the commander gave it a distinct edge over the contemporary M48A2 which lacked any form of night vision sighting equipment whatsoever. Only the M60A1 from 1962 was equipped with a night vision sight (M32) and a night vision optic for the commander (M36). The armoured hood for the TPN-1 night sight on the T-54B can be seen in the photo below in front of the commander's cupola.

TPN-1-22-11 can operate in either the active infrared imaging mode or the passive light intensification mode. In the active infrared imaging mode, the infrared light supplied by the L-2 "Luna" spotlight mounted coaxially to the main gun is visible through the sight, allowing the gunner to identify a tank-type target at a maximum distance of 750-800 meters. This was quite good for night vision equipment from the 50's. The L-2 "Luna" spotlight uses an incandescent bulb and consumes only 200 W, which is quite weak for a spotlight. In the passive mode, the sight employs a 1st Generation light intensifier tube to amplify ambient light, providing a nominal maximum identification distance of 400 meters for a tank-type target under lighting conditions of no less than 0.005 lux. The sight has an adjustable sensitivity to allow the gunner to obtain the best image under different lighting conditions.

TPN-1-22-11 has fixed 5.5x magnification, and a narrow field of view of 6 degrees. The magnification is quite reasonable for a night vision device, as the IR sight for the Chieftain only had a 3x magnification. The viewfinder is extremely simple, as you can see below. The tip of the chevron is sighted for BR-412D AP rounds for a distance of 200 m, going down to 400 m at the upper tip of the vertical reticle line below the chevron. A more comprehensive adjustment system was not included as the short range of the TPN-1-22-11 night vision system limited engagement distances to 800 meters or less anyway.

The TPN-1-22-11 has an internal lightbulb to facilitate aiming at night. It is either on or off without the option of dimming, but it can be turned on in either the day mode or the night mode as the gunner wishes. It is preferable to remain in the day mode with an illuminated reticle when operating during sunset or twilight hours.

TPN-1-22-11 is similar to the telescopic primary sight in that it is not independently stabilized. It is only connected to the main gun by a mechanical linkage as shown in the drawing below. Disregarding its night vision capabilities, the sight is mechanically and optically quite simple.

During the late 50's, nearly all T-54 obr. 1949 tanks (built and issued from 1949 to 1951) and T-54 obr. 1951 tanks (built and issued from 1952 to 1954) underwent a modernization program to improve its combat capabilities to the level of the T-54B, which was the latest iteration at the time. The technical details for the modernization of older tanks - excluding the troublesome obr. 1947 model - to the standard of the T-54B model was prepared simultaneously with the development of the T-54B itself, thus ensuring that a large part of the Soviet Army's T-54 fleet would be kept up to date at the highest available level of technology. One of the upgrades was the addition of night fighting capabilities via the installation of the TPN-1-22-11 night vision sight and the associated equipment, including the L-2 "Luna" spotlight and a new power supply system to handle the new equipment. The T-54-2 in the two photos below is an example of a tank modernized to T-54B standards. Note the counterweight at the muzzle of the cannon. This will be examined further in the article.

The addition of a night fighting capability to the vast majority of the T-54 tanks in the Soviet Army represented a significant tactical advantage, considering that the M60A1 was only being produced in relatively small numbers during the early 60's and the M48A2 modernization in 1956 did not grant the U.S Army's large fleet of M48 Patton tanks a night fighting capability. Even when the M48 gained a xenon spotlight and the M32 periscope in 1963 as part of the M48A3 upgrade, the T-54 retained an advantage because its night sight had a passive image intensifier mode that made it possible for the gunner to engage targets without turning on its infrared spotlight, whereas the enemy M48A3 and M60A1 tanks were forced to rely entirely on active IR or white light illumination.

The night vision equipment was tested in a British/Israeli assessment of the T-55, among other things. The full report is available in the Tanks and AFV News site. The relevant page of the report can be viewed here (link). According to the test, TPN-1-22-11 allowed the gunner to see: