The Soviet Union continued to develop and use anti-tank guns long after the concept was deemed obsolete and subsequently abandoned by other major military powers. This seems appropriate as the USSR was among the first to adopt this class of weapon, and their capabilities were greatly appreciated during the Spanish Civil War and in the Great Patriotic War.

The first Soviet towed anti-tank gun, the 37mm M1930, was a refinement of the 3.7cm Pak L/45 gun design carried out by the Rheinmetall company under a contract from the Soviet state as part of a large technological transfer programme that included the purchase of a dozen Pak L/45 guns. The technical documentation and the necessary machine tools to build the gun were transferred to the No. 8 factory, where the M1930 began to be mass-produced in 1931 under the factory index of 1-K. This was the first step taken to build up the technical expertise needed to form a domestic anti-tank artillery industry.

The original 3.7cm Pak L/45 was the latest and most advanced gun of its type, not only in Germany but also abroad. It was designed in total secrecy in Germany and began low-rate production in 1929, preceding both the French 25mm mle 1934 and the British 2-pdr. In its native country, it was not further developed until 1934 when political changes prompted the rearmament of Germany to further accelerate, but in the USSR, Soviet engineers began improving the M1930 gun as soon as mass production had been officially established. A new 45mm gun was designed on its basis by swapping out the barrel and modifying the breech assembly. The carriage was also improved. The upgraded product, bearing the factory index of 19-K, entered service in 1932 as the M1932. This was the first major divergence from the original 3.7cm Pak L/45 design, and with it, the USSR effectively leapfrogged the British and French in anti-tank artillery development - at least on paper.

The mass production of the gun proceeded badly due to a critical shortage of trained workers and the immaturity of the industry, which was further exacerbated by the intensely ideological nature of the state. After the situation was rectified in 1933, an effort was launched to upgrade the gun in 1934 by replacing the wooden carriage wheels with pneumatic ones and improving the traverse mechanism. These improvements culminated in the adoption of the M1937 gun, the definitive model which served in the Red Army at the outbreak of the so-called Great Patriotic War. Compared to the original 3.7cm gun, it was easier to mass-produce, had considerably better mobility, and its firepower was enhanced by its ability to fire much more powerful ammunition, both in terms of armour penetration power and in anti-personnel capabilities owing to its vastly more powerful fragmentation and canister rounds. It was, arguably, the best in its class in the world.

More importantly, however, the efforts leading to the creation of the M1937 catalyzed the rapid maturation of the anti-tank artillery industry. By the start of WWII, the industry was capable of designing original anti-tank artillery pieces from scratch that could rival the quality and capabilities of foreign designs, and organize the mass production of such guns in optimized assembly line factories that enabled huge quantities of high-quality guns to be built. The ZiS-2 is a prime example, being a completely original Soviet counterpart to the 5cm Pak 38 and 6-pdr guns from same time period.

It is perhaps worth noting that the development cycle of Soviet towed and self-propelled anti-tank guns, divisional guns and tank guns were usually created in separate parallel projects utilizing the same ammunition and sharing the same ballistics, and were often based on existing anti-aircraft or naval guns, as these roles required high ballistic performance. The two most notable examples are the 85mm and 100mm tank guns used in the later half of the Great Patriotic War. On April 15, 1943, the State Defense Committee issued a decree on strengthening the anti-tank defense of the ground forces, leading to an intense effort to place guns of increased power into service. The ballistics of the 85mm mod. 1939 (52-K) anti-aircraft gun were used as the basis for the 85mm D-5 gun borne out of this decree, which entered service very soon afterward in 1943 on tanks and self-propelled guns, but the order to develop a towed 85mm divisional field gun featuring the same ballistics was only issued in 1944 to replace the ZiS-3, later resulting in the D-44. The D-44 had nothing to do with the D-5, being a clean-sheet design, and the D-5 itself also shared nothing with the 52-K gun other than the cartridge and ballistics, having a completely new design and being assembled from proprietary parts This was essentially the same developmental trajectory as towed and self-propelled gun systems in the U.S, Britain and to some extent, Germany. This is exemplified by the towed 3-inch M5 and the self-propelled 3-inch M7 (on the M10) which were created from the ballistics of the M3 anti-aircraft gun, or the 8.8cm KwK 36 which was created from the ballistics of the FlaK 18 anti-aircraft gun.

Similarly, the 100mm D10 tank gun entered service in July 1944, followed by the 100mm BS-3 field gun a month later, and then the KS-19 anti-aircraft gun after the war. These three guns shared nothing in common other than the ballistics, which were inherited from the B-24BM (1939) 56-caliber 100mm naval gun.

In the aftermath of the Second World War, the appreciation of the value of anti-tank guns led to the continuation of anti-tank gun projects for both the ground forces and airborne forces. A myriad of systems were created, ranging from the basic towed variety to self-moving (SD-44) and self-propelled (ASU-57, SU-85) anti-tank guns. In this article, the following postwar artillery pieces will be examined in chronological order with a heavy emphasis on the context of their use:

- D-44 divisional gun (GAU index 52-P-367)

- D-48 anti-tank gun (GAU index 52-P-372)

- T-12 anti-tank gun (GRAU index 2A19)

- MT-12 anti-tank gun (GRAU index 2A29)

The 125mm Sprut-B gun entered service in the Soviet Army, but only in name. It was never procured in any meaningful numbers quantity and was never a serious part of the arsenal. As such, it is not covered in this article. Its self-propelled counterpart, the Sprut-SD, was somewhat more successful, but due to its self-propelled nature, it is also beyond the scope of this article.

INDEX

- Introduction

- Design Challenges

- Basic Organization

- Common Features

- Recoil Devices

- Carriages

- Protection

- Gunshield

- Direct Fire Protection

- D-44

- Deployment

- Mobility

- Carriage

- Protection

- Fire control

- Gun

- Ammunition

- D-48

- Deployment

- Mobility

- Carriage

- Protection

- Fire control

- Gun

- Ammunition

- T-12, MT-12

- Deployment

- Mobility

- Carriage

- Protection

- Fire control

- Gun

- Ammunition

INTRODUCTION

The GAU classification system for artillery pieces was fairly clear and straightforward, assigning a unique identity for each new design. Firstly, the designation of all artillery pieces would be given a "52" prefix, as Category 52 of the GAU index was reserved for artillery. This would be followed by a "P", denoting a gun. The following digits serve as both a categorization and identification number for the product, the first digit being an indicator of its class of caliber and the following digits being a major and minor number to indicate the firepower group and caliber group number of the cannon. According to the textbook "Индексация и маркировка боеприпасов артиллерии" (Indexation and marking of artillery ammunition), classes 1-7 for conventional guns represent the following calibers:

Class 1: 20-40mm caliberClass 2: 40-60mm caliberClass 3: 60-100mm caliberClass 4: 100-150mm caliberClass 5: 150-200mm caliberClass 6: 200-300mm caliberClass 7: 300mm caliber and above

Knowing this, the meaning of the 52-P-367 and 52-P-372 indexes can be deciphered easily. It is a gun in caliber class 3, firepower group 6, weapon number 7. For instance, the 52-P-367 (D-44) was preceded by the 52-P-366, which was the 85mm KS-1 anti-aircraft gun from 1944.

Artillery ammunition - denoted by the "53" prefix and an abbreviation of their type - built for the guns listed in this index were assigned the same categorization number. For example, the 53-BR-412 shell was named according to the index of the BS-3 field gun (52-P-412), the 53-BR-413D shell was named according to the index of the D54 tank gun (52-P-413), and the 53-BR-415 shell was named according to the index of the KS-19 anti-aircraft gun (52-P-415). All three were Class 4 guns, having a caliber of 100mm, were rifled, and had high ballistics. As such, they belonged to the same firepower group, and the different caliber group numbers serve to distinguish between different ammunition, ensuring that they are only used in the appropriate guns. Caliber group '0' for a projectile indicates that the projectile can be used with all guns of the same caliber.

In 1956, a new index was introduced to accommodate the ever-increasing quantity of new weapon systems, including rocket-based systems. The directorate itself was renamed from GAU to GRAU, with the 'R' standing for "Rocket". Unlike the old GAU index, the numbering system of the new index served only as an identification number and could not give away any useful details whatsoever on the nature of the weapon, thus better preserving secrecy. The T-12 anti-tank gun was named the 2A19 under this index, with "2A" denoting that it is a gun (or howitzer or fireworks launcher) and the number 19 simply identifying it as the 19th system to be indexed.

The artillery pieces discussed in this article can all be categorized as "quick-firing" guns, although this is an antiquated term that only remained in use almost exclusively in the British military and in its former colonies. This term was not used in the USSR, even in manuals printed for British anti-tank guns supplied through Lend-Lease. In "Handbook of artillery: including mobile, anti-aircraft and trench matériel", it is stated that the main distinguishing feature of a "quick-firing" gun is that its carriage is not shifted by recoil when firing. Instead, the gun recoils on the carriage and is automatically returned to battery by a recoil mechanism. Other features may contribute to the rate of fire of a gun, but do not constitute their identifying characteristics.

All of the guns examined in this article are field guns, with divisional and anti-tank guns belonging to subcategories of field artillery. According to the Soviet definition, the structure of a towed gun can be divided into three main parts: The gun tube, the recoil mechanism, and the carriage.

- The gun tube ("ствол") is the gun barrel together with a muzzle brake and the breech.

- The recoil mechanism includes the hydraulic buffer and hydropneumatic recuperator installed to the gun tube, forming the complete gun.

- The carriage consists of the suspension, the crossbeam serving as a chassis for the suspension, and the two carriage trails.

Anti-tank guns are a type of field gun but can be readily identified by being readily concealable and having high ballistic performance, typically superior to the field guns and howitzers.

When a rapid deployment in open terrain is necessary, the prime mover tows the gun to the chosen position and the crew disembarks to decouple the gun and set it up. The driver conceals the prime mover a short distance away, then joins the gun crew as an ammunition handler.

DESIGN CHALLENGES

Although an increase in firepower is always desirable, the successful use of towed anti-tank guns in battle was conditional on their concealability and their mobility. As the demands on the firepower of a gun increase, the task of balancing the design priorities becomes ever more challenging. Achieving a further increase in firepower with purely conventional means inevitably leads to a further increase in the size of the weapon. Generally speaking, the enormous weight of the anti-tank guns deemed powerful enough to deal with modern threats by the latter half of World War II drove the desire to mount guns onto low-cost vehicles to create self-propelled tank destroyers. However, with the exception of the U.S Army in 1944, tank destroyers never completely replaced towed guns for the major military powers, if not because of the advantages of towed guns, then simply because it was more expedient to build them in large numbers.

The USSR was somewhat unusual as they continued to pursue the development of new anti-tank guns throughout the Cold War. Although such guns proved to be the most effective anti-tank weapon on both the Western and Eastern fronts, the increased emphasis on mechanized warfare and the improved armour protection of late war tanks made it doubtful that anti-tank guns could remain small enough to be easily hidden - which was one of their primary advantages - yet powerful enough to handle the new generation of tanks.

As a rule, postwar Soviet anti-tank guns were exceedingly lightweight, but even so, the necessity of a large caliber to fight modern tanks left no allowances for lightening the weapon to the extent of matching the portability of the infantry crew-served guns like the 45mm M-42.

Initially, light towed anti-tank guns were proven and were still viable as wartime tanks were still far from being phased out. For this reason, the 57mm ZiS-2 continued production after the war until 1949, when production finally ended with 3,500 guns delivered from 1946 to 1949. Its continued production was necessary to fully displace all 45mm M-42 guns, which had fallen into total obsolescence by the end of the war and was being pulled from active units to enter long term storage or to be distributed to friendly states as military aid. A similar state of affairs transpired abroad, with equivalent guns such as the British 6-pdr continuing to serve in its original role until it was finally deemed obsolete and pulled out of service in July 1960.

Meanwhile, the hand grenades and PTRD rifles of the individual anti-tank soldier were replaced with the RKG-3 and RPG-2 respectively. All of these light weapons were only effective out to a range of several hundred meters, though not because of a decline in armour penetration power at long ranges as with a closed-breech gun, but because of a rapidly diminishing probability of hit. In any case, the effective range of the battalion-level weapons did not deteriorate.

Towed crew-served recoilless guns were widely adopted among the major military powers as a promising replacement for conventional towed anti-tank guns such as the ZiS-2, but they were not a panacea. In the Soviet Army, light anti-tank guns were pulled from high priority units throughout the 1950's beginning with the introduction of the SPG-82 in 1950. In 1954, the 82mm B-10 and 107mm B-11 recoilless guns entered service and took over the role of battalion and regimental-level anti-tank artillery respectively, then they were in turn replaced by the SPG-9 in 1962, which became the definitive weapon of its type for the remainder of the Cold War.

Even so, there was no recoilless weapon capable of the same ballistic characteristics of a towed gun, presumably because the backblast would be so immensely powerful that it would be impractical. In the USSR, the trend for recoilless guns was to reduce size and weight by reducing the caliver, increasing mobility, while also improving the firepower by using more sophisticated shaped charge technology and by implementing rocket assisted grenades. The Soviet Army did not pursue the creation of recoilless guns large and powerful enough to replace the likes of the D-48 or T-12, and quite rightly so. Rather, guided missiles were explored.

FOREIGN DEVELOPMENTS

Abroad, experimental anti-tank guns built to meet these conflicting requirements invariably ended in failure. At the end of WWII, both the U.S and Britain had ongoing projects to meet the requirement for high-powered towed guns, the U.S with their 90mm development programme, which evolved to create the 105mm T8 gun, and the British with their 94mm 32-pdr gun.

The only 90mm towed anti-tank gun to enter service and serial production in the U.S was the T8 gun, which entered service as the M26 gun on the M18 carriage. The gun was tall, but even worse was its enormous weight which reached an absurd level for a gun with only slightly greater muzzle energy than Soviet 85mm D-44 divisional gun and the German 8.8cm Flak guns. On page 41 of the book "US Anti-tank Artillery 1941–45" by Steven J. Zaloga, the weight of the 90mm gun when standardized as the M26 gun on the M18 carriage is reported to be 3,515 kg. The image below, taken from the book, shows the 90mm M26 gun. Its enormous weight may be related to its lack of a muzzle brake, a trait it shared with the 76.2mm M5 anti-tank gun which also had a preposterously high combat weight of 2,211 kg, far greater than the ballistically equivalent 75mm Pak 40 at a weight of just 1,425 kg.

Ultimately, this line of development was doomed by the fact that something with markedly greater firepower - and hence, even bulkier and heavier - was needed to deal with the new German Tiger II and Jagdtiger emerging in 1944. This task was to be handled by the even more powerful 105mm T8 gun, which was prototyped in 1944 and continued development until 1946, when, after tests in February of that year, the project was ended. The T8 weighed a whopping 8 tons, or around 7.2 metric tons.

The reticence to put new towed anti-tank guns into service was also strongly influenced by the high losses of towed guns in the ETO compared to self-propelled tank destroyers, which drove the replacement of all towed guns in tank destroyer battalions to self-propelled tank destroyers in 1945. Given that the technological limit of this class of weapon had been reached and no future prospects were identified, it is rather unsurprising that the War Department Equipment Board concluded in their study of towed anti-tank guns in May 1946 that "There should be no further development of towed anti-tank guns", thus effectively ending all development of this class of weapon in the U.S.

In the U.K, the difficulties in making the 17-pdr a viable weapon were already quite acute on their own. Developing a replacement that could handle future threats was a monumental task that proved to be insurmountable. The primary issue was the same that plagued the 17-pdr: mobility.

The first 150 examples of the 17-pdr were hybrids, consisting of the 17-pdr gun mounted onto the Mk. I carriage of the 25-pdr gun-howitzer. This model was known as the 17/25-pdr gun. It was an intermediate solution to deal with the problem of Tiger tanks in North Africa and brought a number of serious drawbacks. Firstly, though it was relatively light (2,097 kg) and could conduct all-round fire, the gun had practically no traverse arc if used without its rotary firing platform which required preparations to be deployed beforehand. It was also very tall, which was wholly undesirable for an anti-tank gun. As such, the definitive 17-pdr model, the Mk. I, was equipped with a conventional split-trail carriage. However, this gun was unreasonably heavy, having an in-action weight of 2,957 kg (6,520 lbs) or just under 3 tons. This made it extremely challenging for the 7-man crew to manhandle the gun even for short distances, except on paved surfaces.

The successor to the 17-pdr Mk. I was to be the 94mm 32-pdr gun. The first attempted solution was to convert the existing 3.7-inch AA gun by mounting it to a more suitable carriage, but the resulting gun and carriage were "monstrously large", as described by Chris Henry in "British Anti-Tank Artillery 1939-45". Two new proprietary carriages were designed for the new gun, complete with proprietary recoil systems and muzzle brakes, but the war ended before the project could be completed. In September 1945, the General Staff declared that there was no longer any requirement for the weapon, effectively ending the further development of not only the 32-pdr itself, but towed anti-tank guns as a whole.

As the project was never completed, there is no fixed data on the weight of the 32-pdr gun. However, Ian Hogg states in the book "Allied Artillery of World War Two" that the barrel alone would have weighed 2.5 tons, and that the towed equipment (the entire system) would have had a sensational weight of close to 10 tons, presumably short tons (9 metric tons), far surpassing the weight of even the largest 6-inch heavy guns. Naturally, this made it effectively impossible to move the 32-pdr without the use of a heavy prime mover such as the AEC Matador or Scammell Pioneer. In the photo below, the size of the 32-pdr next to the BL 5.5-inch medium gun (6.19 tons) lends credibility to Hogg's estimation of its 9-ton weight. If correct, Hogg's estimation of the system weight implies an extraordinarily inefficient design, bordering on sabotage. The design of the gun mount and shield in particular is highly suspect, inexplicably having a shape and size that is reminiscent of a naval gun turret. It is especially perplexing that so much trouble arose despite the 32-pdr being a smaller, less powerful gun compared to the Soviet 100mm BS-3 field gun.

Without a replacement, the 17-pdr continued serving through the Korean War era, predominantly organized under the Royal Artillery anti-tank regiments but also as individual batteries allocated to support an infantry battalion.

Though the intended successors to the 17-pdr and the M5 ended in failure, their obsolesence was still evident and the need for replacements remained. To fill this niche, large caliber crew-served recoilless rifles were developed to provide the necessary mobility for the guns to closely support small infantry units. In the U.S, the 105mm M27 recoilless gun entered service in 1952 to replace the 57mm M1 and 3-inch M5 guns under the Battalion Anti-Tank (BAT) weapon programme, followed by the 106mm M40 gun under the same programme in 1955. In Britain, the crew-served 120mm L1 BAT entered service in 1953 to replace the 17-pdr. Both developments shared the same design goals and were intended to fulfill the same tactical objectives.

Self-propelled tank destroyers were one alternative as they could serve as a convenient platform for large, powerful guns that would otherwise be impractical in towed form, but after the conclusion of the war, conventional tank destroyer concepts were no longer pursued by the U.S., U.K. and France. The need for a large gun to defeat enemy heavy tank was to be met by heavy tanks, or heavy gun tanks as they were known in the U.S. and U.K.. The American M103, British Conqueror were the products of this line of thought, and they would have been joined by the French AMX-50 if it were not for developmental difficulties. All three sported a high-power 120mm gun with a muzzle velocity in excess of 1,000 m/s, deemed necessary to ensure the defeat of the armour of the Soviet IS-3. In the context of such vigorous demands on firepower, the abandonment of not only towed anti-tank guns but also tank destroyers in favour of recoilless rifles seemed to be a purely pragmatic decision.

Large caliber recoilless rifles, firing large caliber HEAT or HESH ammunition, appeared to solve the problem of defeating the armour of heavy tanks, but they were far from a panacea. These weapons were only adequate for short range engagements given their low muzzle velocity, and the probability of kill against heavy tanks was not high even within their most effective firing range.

The table below, taken from "Ordnance Engineering Design Handbook - Artillery Ammunition Series - Section 2, Design for Terminal Effects" shows the probability of a firepower kill on a static IS-3 with a salvo of two shots from a 106mm M40 recoilless gun, using its integral spotting rifle to aim. As the table shows, even at a close range of 500 meters and with two aimed shots, a large caliber recoilless rifle had just a 1 in 3 chance of scoring a firepower kill. The maximum effective range of the weapon - where there would be at least a 50% probability of a firepower kill - would perhaps be only around 200-300 meters, contrary to its official maximum effective range being listed as 1,350 meters; that is merely the maximum direct fire range. If rated for a 55% probability of kill, as per the Soviet definition, the effective range may be no more than 200 meters.

To gain a better sense of perspective, the instruction for Red Army anti-tank artillerymen during the so-called Great Patriotic War was that guns were to open fire on tanks only from a distance of 600-700 meters while howitzers were to open fire from 400 meters. However, given that a heavy tank such as the IS-3 was practically immune to the Pak 43 and even the APDS ammunition of the 17-pdr at such short ranges, the shortcomings of recoilless guns do not seem debilitating.

BASIC ORGANIZATION

The basic structure of Soviet anti-tank artillery fire platoons, batteries, battalions, regiments and brigades was maintained throughout the entire Cold War. The largest unit of anti-tank artillery organic of a motorized infantry division was a battalion.

- A fire platoon consisted of 2 or 3 guns.

- A battery consisted of 2 or 3 fire platoons.

- A battalion consisted of 3 batteries.

- A regiment consisted of 3 battalions.

The smallest tactical unit was the fire platoon. Individual anti-tank guns were not to be used in isolation.

Outside of motor rifle divisions, a regiment of anti-tank guns was integrated at the army level. An anti-tank regiment could operate independently in the form of an army-level reserve defensive force, covering points of the front where there is a danger from tanks, or they can operate within the framework of a motor rifle infantry division, supporting it at such points as may be necessary, and also operating with the supporting tank group.

In a sector where there is a danger of a massed tank attack, the regiment can cover a large zone in both width and depth. The battalions would be arranged so that the batteries would be arranged in two echelons. Each battery forms an anti-tank strongpoint within the effective range of the other batteries, and would be positioned to permit mutual support. This creates overlapping fields of fire, and allows neighbouring anti-tank strongpoints to hit the side armour of the tanks if they launch a focused attack on the neighbouring batteries.

Soviet artillery divisions also featured a large contingent of anti-tank artillery. Each division would have an anti-tank brigade composed of four anti-tank battalions.

COMMON FEATURES

Some features of practically did not change throughout the evolution of anti-tank guns from the D-44 to the MT-12. These are the gun operating action, its balancing mechanism, its recoil management system, the carriage.

GUN

Unlike modern tank guns which have many built-in counterweights such as a powered elevation mechanism, armoured mantlet, and heavy recoil mechanisms to ensure a short recoil stroke within the confines of the turret, the design of a towed anti-tank gun had to prioritize reducing weight to the maximum extent possible. One example of this is the universal preference for implementing equilibrator mechanisms instead of adding steel ballast plates on the breech end to act as counterweights. Even the simplest and heaviest equilibrators could still offer significant weight savings, particularly for large high-powered field guns. Inside armoured vehicles, space is a more important consideration than weight, so ballast is preferred over equilibrators for balancing tank guns.

All Soviet towed guns had a vertically sliding breech. According to Soviet engineering manuals, if the bore axis of a tank cannon from the floor of the fighting compartment is lower than 950-1,000mm, a vertically sliding breech should be used, but if the bore axis is higher than that, a horizontally sliding breech should be used. This is because the convenience of ramming a shell through the breech changes depending on the height of the bore in relation to the height of the average loader (170cm). If the height of the bore axis is 950-1,000mm or less, the chamber will below the elbow of a standing man, so a vertically sliding breech is more convenient and it allows a long ramming staff to be used by someone standing behind the gun. This was particularly relevant for field guns given that such artillery often had to conduct indirect fire, as elevating the barrel would lower the breech even further.

Being direct fire weapons first and foremost, a large gun elevation arc was not the highest priority for anti-tank guns. The gun elevation limit is intrinsically limited by the bore axis height and the recoil stroke length of the gun. The lower the bore axis and the larger the recoil stroke, the less it will be able to elevate before striking the ground. If the design of the system creates a conflict between these two mutually exclusive specifications, then the elevation limit would always be sacrificed.

RECOIL MANAGEMENT

All Soviet anti-tank guns featured a muzzle brake as one of the principal recoil absorption mechanisms. In the textbook "Основи Будови Артилерійських Гармат Та Боєприпасiв" (The Basics of Artillery Guns and Ammunition) by A.Y. Derev'yanchuk, it is stated that during its recoil travel, the rearward momentum of the moving parts of the gun are absorbed by four primary mechanisms. As a rule, the distribution of braking forces across these four mechanisms are:

Friction: 3 - 5%Muzzle brake: 25 - 30%Recoil recuperator: 10 - 15%The recoil buffer: remainder

It is important to note that this is only a rough generalization. In the textbook "Курс Артиллерии - Книга 4" (Artillery Course - Book 4) from 1947, it is stated that muzzle brakes able to absorb up to 30-40% of the recoil energy are the most common.

As noted by Ian Hogg in the book "Allied Artillery of World War Two", anti-tank guns generally use a muzzle brake so as to save weight in the recoil system and carriage and yet still fire as heavy a charge as possible. The ZiS-3 serves as a good example of the utility of muzzle brakes, as it was ballistically identical to its predecessor, the 76.2mm F-22 USV field gun, but was 24% lighter thanks to a more efficient construction and the use of the lightweight carriage of the 57mm ZiS-2 gun. In turn, these changes were made possible partly due to the use of a double baffle muzzle brake which reduced the recoil force by 30%.

The most contentious feature of muzzle brakes is that the blast and gasses directed sideways cause dust and smoke to be raised across a very broad area across the front of the gun, rather than in a relatively restricted forward cone directly in front of the muzzle. Although it might not be immediately apparent, observation of the target becomes much easier as a result, because less dust and smoke is thrown forward of the muzzle and into the gun commander's line of sight to the target. In fact, a muzzle brake was often used to solve serious target obscuration issues, as was the case during the development of the American 90mm M3 tank gun, and it was the driving force behind the addition of a muzzle brake to the American 76mm M1 gun, leading to the M1A1C variant.

On the other hand, the dust and smoke cloud would be more noticeable to the enemy forces being fired upon owing to its great width, potentially provoking quicker return fire, and the visibility of the blasts to enemy air reconnaissance was also a source of consternation. The issue of muzzle blasts and smoke unmasking the position of guns was routinely expressed as a concern in Russian literature covering the development of artillery systems, while obscuration of the target was rarely ever mentioned in any evaluation of guns with muzzle brakes. In fact, the unmasking factor was sometimes cited as a major justification for the rejection of promising tank gun projects.

The drawbacks of muzzle brakes were essentially unavoidable for most of the towed artillery pieces created in the USSR as there were stringent weight requirements, but it was less of an dilemma for tanks, for which guns without muzzle brakes can be viable, though muzzle brakes would still occasionally find some application on light tanks to shorten the recoil stroke for internal space considerations. For towed anti-tank guns specifically, the tradeoff was always considered worthwhile.

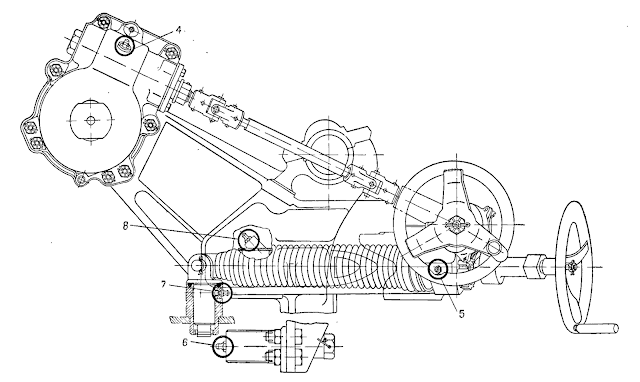

RECOIL MECHANISM

Postwar Soviet anti-tank guns, including the three examples presented in this article, use a modified form of the Schneider independent recoil mechanism. Imperial Russia indirectly took part in the creation of this highly influential system by commissioning Schneider to design a howitzer to a set of specifications. The product of this work was the 152 mm howitzer M1910 howitzer, which served as the basis for many future artillery pieces. Moreover, the chosen caliber of 152mm (6 inches or 60 lines) was standardized in Imperial Russia and its legacy endures til this day.

As with any other hydraulic recoil buffer, braking is achieved by using a piston to drive the flow of oil through restricted openings so that a large hydraulic resistance impedes the flow, thus absorbing the energy from the recoil of the gun.

The entire volume of all three chambers in the buffer were filled with a fixed volume of oil. The flow of oil from the reservoir to the buffer chamber and the piston is regulated by the cross-sectional area of the ring-shaped restrictor bushing between the piston head and the spindle-shaped control rod. The spindle shape of the control rod generates a flow channel with a variable cross-sectional area as the buffer cylinder slides over the piston. The spindle maximizes the bushing area to generate minimum flow resistance during the firing of a shot, then progressively decreases the bushing area to steadily increase the flow resistance during recoil and decelerate the gun, bringing it to a gentle halt.

The drawing on the left below is of a hydraulic buffer, and the drawing on the right is of a recuperator. Both were taken from the textbook "Practical Supplement to the School of the Battery Commander" from the Saumur Artillery School, published in 1918 in English for American artillerymen.

The pistons of both the recuperator and buffer affixed to the immobile gun cradle, while their cylinders, containing large quantities of spindle oil or hydraulic fluid, were affixed to the recoiling gun assemblies. The replenisher tank for the recuperator also recoiled with the gun. This meant that the recoiling mass of the gun could be increased with no actual weight gain for the system as a whole.

Increasing the recoiling mass of a gun gives it more inertia, so that it is more inclined to remain motionless while the projectile travels down the bore. This can have a positive effect on shot dispersion to a limited extent. A heavier recoiling mass also possesses favourable recoil dynamics. Due to the conservation of momentum, the forward momentum of a fired projectile and its propellant gasses will impart a rearward momentum of the same magnitude to both a heavy and light gun, but during free recoil, the velocity of the heavy gun will be less. In turn, this reduces the kinetic energy of the moving gun (recoil energy), so that the buffer mechanism generates a smaller reaction force for a given recoil stroke distance, and due to the lower velocity, the braking time is larger which reduces the recoil impulse. In other words, the recoil of the weapon system as a whole is reduced.

The advantages of the Schneider system, as detailed in the textbook "Theory and Design of Recoil Systems and Gun Carriages" by the United States Army Ordnance Department, are as follows:

- An increased recoiling mass due to the recuperator sleigh containing the cylinders, recoiling with the gun and thereby decreasing the reaction on the carriage.

- The simplicity of the recoil mechanism, especially from a fabrication point of view.

The main disadvantage was that the recoil control was achieved with a spindle-shaped control rod of a fixed shape, and hence, shortening the recoil stroke for high angle firing was not possible. This could be a debilitating issue for howitzers, but not for field guns, and it was completely irrelevant for anti-tank guns.

A more serious downside was that the weight of the recoil mechanism shifted the center of gravity below the axis of the barrel, stressing the teeth of the elevating rack during recoil. This was easily solved by adding a clutch to the elevating mechanism that would be released by pulling the firing lever, so this layout was used on guns such as the A-19 field gun, ML-20 howitzer, the German Pak 36, IG 37, Pak 38 and Pak 40, just to name a few. On some cannons, this was solved by rearranging the buffer to be directly under the barrel and the recuperator cylinder above the barrel so that the center of gravity is aligned more closely with the bore axis. This layout was used on the ZiS-2, ZiS-3, the American 3-inch M5, and many other field guns and howitzers.

The summary of the Schneider system given in the "Theory and Design of Recoil Systems and Gun Carriages" textbook was particularly glowing:

On the whole the Schneider recoil system has proved one of the most satisfactory recoil systems used during the late war, being simple to fabricate and thoroughly rugged, due to its simplicity in design

Due to its compelling advantages, and the ease of bypassing or solving its drawbacks, the Schneider recoil system was copied and used in the vast majority of field guns created after WWI by not only the Americans, who were strongly influenced by French artillery practices, but also the Germans, and the Russians (Soviets) and various minor military powers, with the exception of the British.

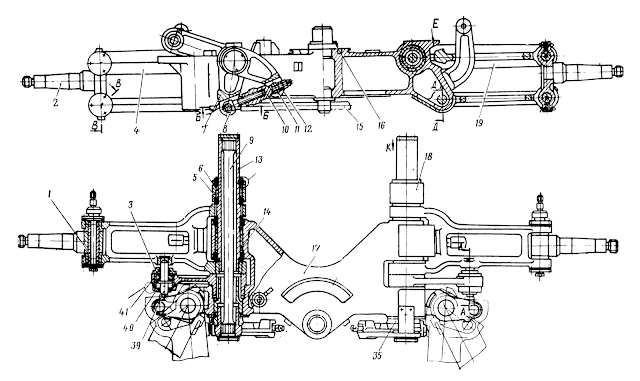

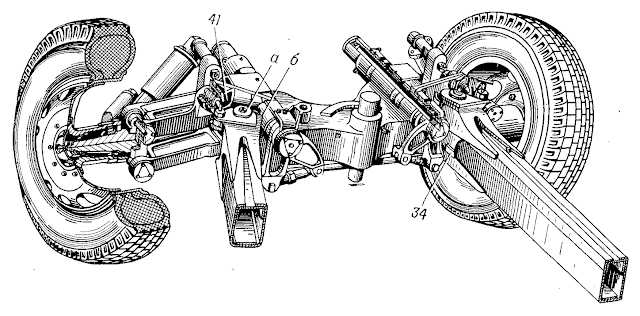

CARRIAGE

A split trail carriage is a type of tripod carriage, as it has three points of contact with the ground. The two wheels constitute one point of contact, and the two trails are another two points of contact. A tripod is ideal for a firing platform because three points always define a plane, so it is inherently stable and a flat surface is not needed.

The length of the trails is determined by the power of the gun, the bore axis height from ground level, and the center of gravity of the weapon system. Because the bore axis is above the center of gravity, the recoil of the gun creates a rotational moment around the fixed anchor (spades), thereby causing the weapon to "jump" on its wheels. This issue is particularly problematic for anti-tank guns as they are powerful guns with strong recoil by nature, and direct fire at gun elevation angles of close to zero is the norm.

Firing at high elevation angles greatly reduces the rotational moment and thus bypasses the stability issue to a large extent, which is why howitzers can have short trails. For most artillery systems, firing at elevation angles close to zero is uncommon during combat, and as such, the carriages of such artillery systems would be optimized to provide maximum stability at elevation angles much greater than zero. In the textbook "Курс Артиллерии - Книга 4" (Artillery Course - Book 4) from 1947, it is stated that for an anti-tank gun, the minimum elevation angle at which it reaches maximum stability is 0-5 degrees, which is much more demanding than howitzers as they can afford to only reach maximum stability at a minimum angle of 12-15 degrees.

To enhance the stability of the system when firing at low or negative gun elevation angles, the distance between the three points of the carriage must be increased. This essentially means having longer trails, and the more powerful the gun, the longer the trails must be. This is undesirable as it adds weight and it increases the length of the weapon, increasing the turning radius of the prime mover and thus complicating maneuvers in built-up environments. A relatively common solution was to have detachable spades, but this only gave a marginal improvement and it also introduced its own share of complications. For these reasons, minimizing the bore axis height is strongly desirable in all field artillery, but particularly for anti-tank guns as it improves their concealability.

Relative to other forms of artillery carriages, the main disadvantage of a split-trail carriage is that it limits the horizontal firing angles to a forward arc, but the desire for all-round fire was nonsensical for anti-tank guns, and other types of carriages brought their own share of drawbacks.

For instance, the cruciform firing platform of the 8.8cm Pak 43 permitted all-round fire, but the suspension had to be dismounted for the gun to be deployed. The inability of deployed guns to instantaneously relocate meant that they were often left behind during a tactical retreat or lost to preventable causes. Similarly, a tripod firing platform as found on the D-30 howitzer could give an all-round firing capability and was stable at all firing angles, particularly when staked deeply to the ground, but it lost all mobility once it was deployed. Not only was it was totally impossible to rapidly uproot the gun once it was deployed, converting it to the transport configuration was also futile as the crew had no way of pushing the gun.

Conversely, a split-trail carriage permits a modicum of mobility at all times. There was also a great advantage in user friendliness when deploying the gun, as staking a tripod gun platform to the ground is slow and laborious on frozen ground. A gun with a split-trail carriage could dig its own spades into hard ground with the force of its recoil.

In general, the firing arc of a gun or a howitzer mounted on a split-trail carriage does not exceed the angle between the trails. The extremes of the arc are invariably reached just before the breech can be traversed directly over the right or left trail. If traversed above one of the trails, a typical gun would be blocked from elevating, or a vertically sliding breech block would not be able to drop down to open. Exceeding the angle between the split trails is to be avoided completely even if the pintle mount technically allows it, as the recoil would generate an abormal stress on the trails.

Unlike foreign carriage designs, the D-44, D-48 and MT-12 carriages had fixed ground spades on each trail, as opposed to the foldable or detacheable spades as found on guns like the Pak 43/41. The rationale is unclear, but it can be inferred that having carriage trails with a single-piece construction with spades permanently welded onto the structure is structurally stronger and more rigid than a comparable design with a hinged spade or removable spade of comparable weight, as there are no joints that require reinforcement.

Though a gun mounted on a split-trail carriage is able to fire without having been dug in beforehand, it is still always desireable to have the spades obstructed on an obstacle to prevent the gun from rolling backwards too far with every shot. The spades prevent the gun from displacing itself this way by digging themselves into the ground with the recoil of each shot. Furthermore, the stability of the gun can be enhanced by entrenching it. This is done by pushing the wheels into pits dug in the ground, then burying the spades and part of the trails into the ground. Chocks can also be placed behind the wheels. This virtually eliminates movement during recoil, and also lowers the profile of the gun. Hand spades are provided as part of the pioneering tool kit of each gun, and the chocks can be any debris found on the site.

As a rule, when preparing a temporary gun emplacement, the spades on each carriage trail should be dug-in before firing to ensure that the recoil of the first shot does not displace the gun rearward. When the crew needs to rapidly move the gun out of its firing position, they can push it forward a short distance to pull the spades out of the ground, join the carriage trails together and deploy the castor wheel, then pull the gun away.

A split-trail carriage does not allow rapid all-round fire, as the gun must first be uprooted and then rotated with great effort to fire outside of its initial arc. If a gun pit was dug with an opening for a predetermined firing arc, it becomes impossible to fire outside of that arc. That said, all-round fire is rarely useful for anti-tank guns, even in the event that they are overrun - in such a case, the outcome of the battle is already clear, and it can be expected that the crew abandons the gun. All-round fire is possible with some examples of field artillery, such as the 88mm 25-pdr divisional gun, 105mm L118 light gun and 122mm D-30 howitzer.

Part of the rationale for the all-round fire capability of the D-30 howitzer (besides lower response times for fire missions) was to ensure it could react instantaneously to the sudden appearance of enemy tanks from an unexpected direction, with the caveat that the gun is already deployed in the combat configuration; the D-30 did not allow emergency firing in the travel configuration. This capability may have occasionally been useful, based on the experiences of the Red Army during the Great Patriotic War in the event of an enemy breakthrough where the divisional artillery unit may not have realized that a breakthrough occurred, or the direction of the main thrust was unclear, or a smaller force broke off from the main thrust to attack the artillery unit. Given that anti-tank guns were a reserve force that would be deployed specifically to halt or delay a successful breakthrough, the ability to conduct all-round fire was totally unnecessary.

And so, with practically no contextually relevant downsides, the split-trail layout naturally became the de facto standard for anti-tank gun carriages among all military powers with an artillery design and manufacturing industry.

To increase the convenience of pushing the gun by hand, a castor wheel would be fitted. The first example of Soviet anti-tank artillery to have a castor wheel was the 100mm BS-3 obr. 1944 field gun, in the form of a separate module that could be fitted to the end of the spades, presumably by one man from the gun crew while the six other crew members hold the trails up.

All subsequent anti-tank guns, including all three guns discussed in this article, had a castor wheel integrated to the left carriage trail for ease of deployment and stowage when shifting the gun in and out of its combat configuration.

The castor wheel is needed on large and powerful guns, because the system is far too heavy for the crew to push or pull it on the ground by the carriage trails like a wheelbarrow. Given that the carriage has to be heavy enough to withstand the strong recoil of the gun, it naturally provides enough weight to counterbalance the gun for such an arrangement to work, ensuring that the castor wheel maintains contact with the ground and the gun does not tip forwards.

Once deployed, the castor wheel converts the carriage to a tricycle. The width of the wheel must be large enough to present a large contact surface, so that the carriage does not sink excessively in soft terrain. Also, the diameter of the wheel should be as large as possible so that less pushing effort is needed from the gun crew to surmount stones, branches or bumps in the terrain, and to reduce the likelihood of the wheel getting stuck in a rut.

Curiously enough, Soviet towed guns had an all-steel castor wheel, without even a rubber rim. Outside of the USSR, the U.S was the only nation to put an anti-tank gun with castor wheel into service; the 90mm M26 gun on M18 carriage. Like the other 90mm guns in development at the time, it featured a a pneumatic castor wheel, which would presumably offer better traction and some degree of damping compared to a steel wheel, but suffer from being susceptible to punctures from all manner of hazards.

The primary drawbacks of towed anti-tank guns include vulnerability to artillery and air bombardment, large manpower requirement to fully crew each gun together with their prime movers and ammunition supply trucks, inability to shift positions while under fire, and high vulnerability to direct hits. To survive contact with an attacking force, anti-tank units had to capitalize on their stealthiness to maintain the element of surprise. The primary survivability factors for a towed anti-tank gun and its crew were the effective use of camouflage, cover, concealment, secrecy and deception.

If the gun emplacement is discovered by enemy reconnaissance or by unmasking itself during combat, the gun crew has very little protection from artillery fire and air attack. Napalm in particular can be especially effective, as it is able to disable guns and neutralize their deeply entrenched gun crews by heat and asphyxiation, not to mention the morale effect.

In this regard, a towed gun has greatly reduced survivability compared to enclosed or even open-topped tank destroyers. However, a properly dug-in gun emplacement also includes trenches for the crew and dugouts for the ammunition stores, which effectively protects the weapon system from attacks of all types. In this context, the disadvantage of a towed gun is that such fortifications require hours if not days to set up, whereas a tank destroyer is innately protected by virtue of its armour plating. It is much more difficult to protect a gun from being disabled by artillery or air attack, as even when dug into a gun pit, the weapon is always still exposed above ground level.

If located by artillery observers, a battery of anti-tank guns could be quickly neutralized by enemy artillery, assuming that accurate fire is possible. The article "The interaction of artillery and heavy infantry weapons" published in the August 1941 issue of the Artilleristische Rundschau magazine gives the following guidelines for sudden fire to annihilate an enemy artillery battery, to be fired within 1 minute whenever possible:

- 72 rounds for each battery of light field howitzers (75mm)

- 60 rounds per 105mm cannon battery

- 48 rounds for each heavy battery of field howitzers (150mm)

Realistically, a more common form artillery fire would be neutralizing fire, which does not necessarily destroy the anti-tank battery, but forces the enemy into cover and temporarily prevents them from manning their weapons. In the same German artillery magazine article, it is stated that to neutralize a battery, the ammunition consumption will depend on the circumstances, but light field howitzers must use at least 120 rounds, and heavy field howitzers at least 80.

Unlike indirect fire artillery batteries that normally have to be set up on flat and open terrain, anti-tank guns were generally less susceptible to being seen by artillery reconnaissance prior to an engagement. This hardly changed throughout the Cold War, as advanced artillery reconnaissance technologies such as counterbattery radars were not applicable to direct fire weapons. Besides aerial reconnaissance, which still depended on manned aircraft, there were few other methods of detecting anti-tank gun positions.

With a dedicated armoured prime mover such as an AT-P or MT-LB, the possibility of fending off an infantry attack was somewhat enhanced owing to the fire support capabilities of the integrated machine gun. This decreases the likelihood of the gun being overrun or at least buys the crew enough time to evacuate from the position.

The main defences of a gun crew would be the terrain, field fortifications, their personal weapons (a Kalashnikov) and any other weapons organic to the battery. The only protection element integral to the gun itself is the gun shield.

GUN SHIELD

Written guidelines for the design of a gun shield are difficult to find. In general, it is a highly contextual matter, seeming to be an aspect of gun design that is left almost entirely to the discretion of the designer and the fancies of the testing commissions. Nevertheless, it is universally accepted that the purpose of a gun shield is to reduce the probability of a gun being taken out of action by enemy fire by protecting the gun crew, at least as far as the French, Americans, Germans, British and Germans were concerned.

A history and justification of early gun shields is provided in article "Shrapnel And Shields", published in the September-October 1906 issue of the Journal of the United States Artillery, Vol. 26 No. 2. The relevant passages from the article are as follows:

Till within quite recent years only two essential requirements were considered in the construction of field guns: power and mobility, While in time of war power was especially demanded, peace has always produced a marked tendency towards mobility. Now, to these two prime factors, power and mobility, a third condition has been added: protection. Up to this time protection has been considered not from thetechnical point of view of construction of material, but as dependent on the tactical employment of artillery (i. e. the disposition of guns behind cover). Therefore it did not receive attention in the designing of field guns.In great battles owing to the increased accuracy of infantry and artillery fire, it is often impossible to obtain sufficient cover by skilful disposition of batteries on the terrain, herce it has become necessary to adapt protection to the piece itself, that is to say, provide the shield. The artillery shield, which couldbe introduced only with the long recoil carriage, was thus a necessary consequence of the new system of artillery. The resulting increase of weight has not the same influence on the rapidity of fire as formerly, as the 5 cm. gun on long recoil carriage can not be fired appreciably faster than one of 7.5cm. of the same system.Attention had already been drawn to the direct protection of guns by means of armor on the carriages. In 1866 extensive tests were made at Mayence with an armored piece constructed by Schumann, the carriage of which was also designed by him. The adoption of axletree seats for field gun carriages might have suggested the idea of making the backs of these seats of sheet steel, thus providing a kind of shield for the cannoneers protecting them from infantry fire and shrapnel bullets. An invention of this nature was noted in the military press in 1892.From that time on, quite naturally, experiments were made in a systematic, continuous manner to determine the thickness, best metal, etc., for the shields, the necessity for which no longer admitted of any doubt. Likewise experiments were begun on the manufacture of projectiles for efficaciously combatting the shields.

The Soviet view point was largely the same, but authoritative military texts never fail to note the additional purpose of protecting the gun itself along with the crew. The textbook "Курс Артиллерии" (Artillery Course) published by the Voenizdat in 1943, devoted a footnote to explaining the purpose of a gun shield, stating that artillery shields are not only intended to protect personnel, but also to protect the gun system itself. It is further elaborated in the textbook "Курс Артиллерии - Книга 4" (Artillery Course - Book 4) that invulnerability of towed artillery from enemy fire is provided by the strength of the structure and shield enclosures that protect the gun crew and fragile parts of the gun from fragments and bullets. Much greater attention is paid to the importance of stealth and deception, noting that an important role is played by the camouflaging of the gun and the creation of shelters for the gun crew in the gun emplacement. In order to disguise the guns, they were made as low as possible and painted in a so-called "protective colour".

The lack of central direction in gun shield design is exemplified in the "Field Artillery Cannon Weapon Systems and Ammunition Handbook" by the U.S Army Field Artillery School, dated October 1981, where it is stated quite plainly that shields installed on (some) towed artillery weapons are constructed to protect the crew from fragmentation or small-arms fire from the front. However, the handbook gives no guidelines whatsoever to dictate their design, despite being the definitive engineering handbook on the topic. Because of this, there is little option other than to make inferences based on some observations. Although gun shields are ostensibly nothing more than simply sheets of steel fastened to the rotating gun mount, their design had their fair share of nuances to consider.

Firstly, it ought to be noted that the gunner's station on an artillery piece is invariably situated on the left, and the loader may either stand behind the gunner or stand to the right of the gun when loading it. Standing directly behind the gun while loading it was strictly prohibited for safety reasons and remains strictly prohibited on all artillery pieces.

The minimum height of the gun shield appears to be determined by the height of the gun breech when the gun is depressed to its maximum limit. If, by chance, the resultant shield meeting this requirement is not tall enough to cover the gunner while he is in a kneeling position, it seems that gun designers often take the liberty to extend it to ensure that the gunner has protection. This can be seen in the photo below of a Polish T-12 gun, which had been dug-in, making its small silhouette size even smaller. The gun shield is just barely tall enough that take cover behind it, the gunner has to be kneeling and hunched down.

The width of the gun shield is primarily dictated by the gun traverse arc and it cannot exceed the width over the tyres of the carriage, which often necessitates a sweep angle to ensure full coverage for the gun. As a side effect, fulfilling these criteria tends to ensure that the shield will also be wide enough to protect the gunner from the direct front. This is sufficient as long as the gun is pointed directly at the enemy, but no more. There are virtually no anti-tank guns that have a gun shield wide enough to protect the gunner from a shot coming from even a modest side angle.

The firing position for a gun is chosen so that its traverse arc can cover the entire width of the expected enemy front or at least the assigned firing sector for the individual gun. Logically, it follows that if the gun were to receive direct fire from the enemy, it would originate from within the same arc. If the gun is fired upon by an enemy located outside of its traverse arc, then the firing position was either overrun or was poorly chosen.

If the gun breech assembly is particularly long but the carriage is narrow, which is often the case for a high velocity large caliber gun, then the gun shield must be swept back to ensure that it provides protection across the entire gun traverse arc without exceeding the maximum permissible width.

If the gun breech assembly is particularly long but the carriage is narrow, which is often the case for a high velocity large caliber gun, then the gun shield must be swept back to ensure that it provides protection across the entire gun traverse arc without exceeding the maximum permissible width.

The 57mm M1 gun serves as a good illustration of this. It was unusual in having a particularly wide carriage which permitted a large traverse arc of 90 degrees, and to provide front protection when the gun was traversed to the extremes of this large arc, the gun was issued with a pair of additional fixed side shields which could be mounted on the carriage. Zaloga states in "U.S Anti-Tank Artillery 1941-1945" that in practice, these shields were rarely used, but nevertheless, the existence of these side shields demonstrates the connection between the gun traverse arc and the necessary shield width.

Shields also served a secondary purpose of improving crew working conditions by behaving as a blast shield. The drawings below, taken and adapted from the book "Engineering Design Handbook - Gun Series - Muzzle Devices" from the U.S Army Materiel Command, shows the reduction in overpressure afforded by a gun shield.

An anti-tank gun is reasonably well protected from the fragmentation of explosive shells when emplaced in a prepared position. Though the crew is exposed, this is largely irrelevant because the gunner is the only member of the gun crew whose duties involve him being obligated to be directly next to the gun when the gun is in action.

By design, all Soviet guns permit all available sighting systems to be installed simultaneously. This is particularly convenient for night fighting because the sight can be set up during the emplacement of the gun, before dusk, and then simply left in its mounting bracket until it is needed. The gunner can switch between any of the three sights at any time, and during night fighting, the gunner always has the option of switching back to the day sight in the event that the night sight malfunctions.

Based on the known penetration characteristics of 7.62x54mm LPS (light ball) bullets, a gun shield constructed from 4.5mm RHA steel should be capable of stopping 7.62mm light ball rounds at a distance of 100 meters. Protection from armour-piercing bullets is not provided. The 7.62x54mm B-32 (AP-I) bullet can perforate a 4.5mm RHA plate at 30 degrees from a distance of 700 to 800 meters, and a .30 caliber M2 AP bullet is capable of perforating 4.5mm of RHA at an impact velocity of 450 m/s, corresponding to a range of 800 meters. Above 700-800 meters, both rounds may be able to achieve partial perforation, so the shield still does not provide adequate protection.

According to the "Handbook on German Military Forces" written and published by the U.S War Department, the steel gun shield of the 3.7cm Pak 36 was sloped at 30 degrees and had a thickness of 3/16-inches, or around 4.76mm. In the U.S, the gun shields on all anti-tank guns had a standardized thickness of 6.35mm, regardless of the shape of the shield and its obliquity. According to Shirokorad, the 45mm M-42 anti-tank gun entered service in the Red Army in 1942 with a 7mm gun shield to provide better protection from armour piercing bullets. The weight of the gun shield increased from 53.7 kg to 79.5 kg.

The 5 cm Pak 38, which replaced the Pak 36, had a new gun shield consisting of two 4mm armour plates separated by a 1-inch air gap, sloped at 30 degrees. This spaced armour scheme was used for all future German anti-tank guns for the remainder of the war. Based on various studies on similar armour with small air gaps, the spaced gun shield of the Pak 38 and other guns provided a modest increase in mass efficiency compared to a single RHA plate, but ostensibly enough to have have been capable of stopping a 7.62mm armour-piercing bullet from 100 meters and above which would have been a notable improvement over a conventional 6.35mm or 7mm gun shield, achieved with only a small increase in weight.

In general, shell splinters are the main threat dictating the protection requirements of gun shields. Direct machine gun fire is not normally used to defeat an anti-tank gun, often because the guns are positioned in such a way that they are too difficult to be engaged with small arms fire. In the U.S Army field manual FM 14-12 "Tank Gunnery" from 1957, simulated anti-tank guns were to be engaged with HE shells from a range of 1,000-1,500 yards during qualifications tests.

The lack of a need for armour defeating capability from the coaxial .30 caliber machine guns on U.S tanks is reflected in the conspicuous lack of armour-piercing rounds in a typical ammunition mix. Throughout the Cold War, a mix of 4 ball rounds and 1 tracer round was the standard. Even if armour-piercing rounds were issued, their effective use is predicated on the tank closing in on the gun, which is not only extremely unwise, but more importantly, is against regulations.

According to the article "Development of Protection Technologies" published in the June 2009 issue of Defence Technology Review, ballistic casualties in general war, including World War II, Korea, Vietnam, Israel, and the Falklands were recorded as 59% from projectile fragments, only 19% from bullets, and 22% from other causes.

The table below, made by the WWII Armor historian group with data taken from TM 9-1907 "Ballistic Data, Performance of Ammunition" and organized into an easily readable format, shows the fragment density produced by a 90mm M71 HE shell, which is representative of the shells used by the 90mm guns of postwar U.S medium tanks. Compared to 75mm and 105mm HE, the fragmentation of M71 is low, but at least it has a slight advantage over 75mm HE in the greater density of fragments capable of perforating 1/4 inches of mild steel. Nevertheless, this is largely irrelevant because the gun shields of anti-tank guns constitute much tougher armour than 1/4 inches of mild steel.

High velocity direct fire guns are less effective against a small target with a low silhouette, such as entrenched anti-tank guns. This is due to the non-optimal fragmentation spray pattern for a HE-Frag shell with a flat trajectory, specifically the low fragment spray density forward and behind the burst. With regard to the American 90mm and British 20-pdr guns specifically, the difficulty in knocking out an anti-tank gun with their HE-Frag shells would have been amplified by a combination of a flat trajectory and poor bursting performance.

With the fuze in the superquick (Frag) or short delay (HE-Frag) modes, a direct hit on the gun shield from a large high velocity HE-Frag shell would also completely destroy the gun and can be expected to also neutralize at least some of the crew through the destruction of the shield itself. A direct hit with a HE-Frag round was responsible for the destruction of the MT-12 shown in the photo below. The gun shield was shattered by the explosion.

Canister ammunition such as the 90mm M336 round also cannot be expected to be effective because of the poor penetration power of the flechettes or pellets, which degrades even further when this ammunition is used outside of their maximum effective range of a few hundred meters (300-400 m) such that even relatively thin pine boards can stop the projectiles. For instance, the M336 round with its 2-gram pellets was only rated to produce one complete penetration per 6 square feet of a 1-inch thick pine board on a target 8 feet high and 90 feet wide at a range of 400 feet. At the same distance, a 7.62mm light ball round can be expected to perforate a stack of pine boards ten times thicker or more. With this limited performance in mind, it should be noted that the flechettes used in APERS munitions, which weigh just 0.5 grams each, have even worse armour penetration power.

With the sole exception of HE shells, all NATO tank gun ammunition was quite poor for the purpose of knocking out anti-tank guns. With the replacement of 90mm and 20-pdr guns by the 105mm L7 and the lack of a HE-Frag shell in its repertoire, the efficiency of NATO tanks against anti-tank guns declined sharply. The generalization that the ammunition available to NATO tanks had a very low efficiency against towed anti-tank guns is quite reasonable. Combat experience during WWII showed that firing explosive shells at the estimated positions of anti-tank guns was effective at suppressing the crew, but generally did not put the guns out of action.

After the so-called Great Patriotic War (GPW), divisional artillery continued to serve a secondary role as anti-tank artillery. Though the D-44 was a great improvement over the existing means of anti-tank defence in the Soviet Army, its capabilities against tanks were fundamentally outmoded. Such weapons would have been in great demand throughout the later half of the war, but by the end, it was recognized that 100mm guns were needed to combat existing heavy tanks and future threats. The development of towed 85mm anti-tank guns began in response to the appearance of the Tiger heavy tank and continued to be pursued after 85mm tank guns had successfully entered service for the IS-85, SU-85 and T-34-85, but none had passed trials by the end of the war. This was a somewhat unique situation compared to the prevailing trends. Anti-tank guns in use by the Germans, Americans and British were invariably first fielded as a towed version, which would inevitably be followed by mobility concerns, prompting the installation of the gun onto a vehicle mount.

A D-44 was provided with a fixed OP1-7 or OP2-7 telescopic sight for direct fire. The OP1 and OP2 series of sights were standardized sighting units with a replaceable glass pane for viewfinder markings. Both series began to be used only on postwar guns. The OP1-7 and OP2-7 models were a standard OP1 and OP2 sight with markings for the 85mm ammunition of the D-44. The OP2 was a later, improved model from the 1950's.

The OP2-7 sight has a slightly different construction. A pair of threads are stretched to form a crosshair in front of the lenses of the eyepiece group. This forms a crosshair in the viewfinder, serving as a reference point of the center of its optical axis.

Once the range is selected, all the gunner must do is elevate the gun until the center chevron is laid onto the target. If deflection has to be applied because of wind or to lead a moving target, the gunner uses the smaller markings on either side of the central chevron as aiming points.

S71-7

Another noteworthy feature is the wavy pattern of the top edge of the shield, commonly observed on Soviet guns. This served to break up the silhouette of the shield into an irregular shape, thus helping it blend in with nature, particularly if the gun was emplaced among rocks and mounds of dirt. This was an additional layer of built-in camouflage, in addition to the so-called "protective colour" of the paint on the gun. The camouflaging effect can be further enhanced by attaching foliage to the gun shield. Even a hasty effort can have a positive effect. The same concept of cutting the edges of gun shields into a rounded or wavy shape was also implemented on some French and British guns, but the vast majority of artillery, including domestic artillery, were built with simple straight-edged shields. Many had completely flat, rectangular shields that seemed to have been designed without any regard for concealability whatsoever.

The thickness of Soviet gun shields is standardized at 4.5mm. The grade of armour steel used for such shields is unknown. This detail was a holdover from the 37mm M1930 anti-tank gun, the first Soviet towed anti-tank gun. In general, this low thickness of armour stops only light ball rifle rounds and shell splinters. With only few exceptions, all Soviet towed anti-tank guns followed the standard set by the M1930 and retained the same 4.5mm thickness. This standard was not followed by other artillery pieces such as the 122mm M-30 howitzer, which reportedly had a 3.5mm shield according to "Энциклопедия Отечественной Артиллерии" (Encyclopedia of Domestic Artillery) by Russian historian A.V. Shirokorad and confirmed by a measurement on a real specimen.

DIRECT FIRE PROTECTION

Based on the known penetration characteristics of 7.62x54mm LPS (light ball) bullets, a gun shield constructed from 4.5mm RHA steel should be capable of stopping 7.62mm light ball rounds at a distance of 100 meters. Protection from armour-piercing bullets is not provided. The 7.62x54mm B-32 (AP-I) bullet can perforate a 4.5mm RHA plate at 30 degrees from a distance of 700 to 800 meters, and a .30 caliber M2 AP bullet is capable of perforating 4.5mm of RHA at an impact velocity of 450 m/s, corresponding to a range of 800 meters. Above 700-800 meters, both rounds may be able to achieve partial perforation, so the shield still does not provide adequate protection.

According to the "Handbook on German Military Forces" written and published by the U.S War Department, the steel gun shield of the 3.7cm Pak 36 was sloped at 30 degrees and had a thickness of 3/16-inches, or around 4.76mm. In the U.S, the gun shields on all anti-tank guns had a standardized thickness of 6.35mm, regardless of the shape of the shield and its obliquity. According to Shirokorad, the 45mm M-42 anti-tank gun entered service in the Red Army in 1942 with a 7mm gun shield to provide better protection from armour piercing bullets. The weight of the gun shield increased from 53.7 kg to 79.5 kg.

The 5 cm Pak 38, which replaced the Pak 36, had a new gun shield consisting of two 4mm armour plates separated by a 1-inch air gap, sloped at 30 degrees. This spaced armour scheme was used for all future German anti-tank guns for the remainder of the war. Based on various studies on similar armour with small air gaps, the spaced gun shield of the Pak 38 and other guns provided a modest increase in mass efficiency compared to a single RHA plate, but ostensibly enough to have have been capable of stopping a 7.62mm armour-piercing bullet from 100 meters and above which would have been a notable improvement over a conventional 6.35mm or 7mm gun shield, achieved with only a small increase in weight.

In general, shell splinters are the main threat dictating the protection requirements of gun shields. Direct machine gun fire is not normally used to defeat an anti-tank gun, often because the guns are positioned in such a way that they are too difficult to be engaged with small arms fire. In the U.S Army field manual FM 14-12 "Tank Gunnery" from 1957, simulated anti-tank guns were to be engaged with HE shells from a range of 1,000-1,500 yards during qualifications tests.

The lack of a need for armour defeating capability from the coaxial .30 caliber machine guns on U.S tanks is reflected in the conspicuous lack of armour-piercing rounds in a typical ammunition mix. Throughout the Cold War, a mix of 4 ball rounds and 1 tracer round was the standard. Even if armour-piercing rounds were issued, their effective use is predicated on the tank closing in on the gun, which is not only extremely unwise, but more importantly, is against regulations.

According to the article "Development of Protection Technologies" published in the June 2009 issue of Defence Technology Review, ballistic casualties in general war, including World War II, Korea, Vietnam, Israel, and the Falklands were recorded as 59% from projectile fragments, only 19% from bullets, and 22% from other causes.

Direct hits on the gun would be effective, but it is difficult to achieve direct hits on anti-tank guns because as a rule, they are very small, well-concealed and there is always extreme stress on the tank gunner from time pressure when attempting to return fire. Real experience showed that explosive rounds were always the first choice for dealing with anti-tank guns.

Information on the effect of the 75mm M48, 3" M42A1 and 76mm M42A1 is given in the report "Army Operational Research Group Memorandum No. 415", shared by the Tanks and AFV News website.

The table below, made by the WWII Armor historian group with data taken from TM 9-1907 "Ballistic Data, Performance of Ammunition" and organized into an easily readable format, shows the fragment density produced by a 90mm M71 HE shell, which is representative of the shells used by the 90mm guns of postwar U.S medium tanks. Compared to 75mm and 105mm HE, the fragmentation of M71 is low, but at least it has a slight advantage over 75mm HE in the greater density of fragments capable of perforating 1/4 inches of mild steel. Nevertheless, this is largely irrelevant because the gun shields of anti-tank guns constitute much tougher armour than 1/4 inches of mild steel.

High velocity direct fire guns are less effective against a small target with a low silhouette, such as entrenched anti-tank guns. This is due to the non-optimal fragmentation spray pattern for a HE-Frag shell with a flat trajectory, specifically the low fragment spray density forward and behind the burst. With regard to the American 90mm and British 20-pdr guns specifically, the difficulty in knocking out an anti-tank gun with their HE-Frag shells would have been amplified by a combination of a flat trajectory and poor bursting performance.

Interestingly enough, the survivability of Soviet anti-tank guns was indirectly enhanced by the proliferation of HESH shells among NATO armies as an alternative to HE shells.

According to the figures given in the memorandum "HEAT vs HESH Paper", studies done for the Trilateral Tank Main Armament Evaluation, held from December 1973 to August 1975, showed that the 105mm M393A2 HEP shell had a lethal area of 114 square meters against prone infantry, which is slightly inferior to a Soviet 85mm Frag shell (nominal kill zone of 130 sq.m). Also, HEAT shells were also much less effective owing to their small explosive charge and the non-optimal shape of the warhead. In terms of lethal area, HESH or HEP are considered approximately 40% superior to HEAT of the same caliber, implying that the lethal area of 105mm M456 would be approximately 70 square meters. Incidentally, it is reasonable to surmise that the fragmentation effect of a 90mm HEP shell would be approximately equivalent to this, which is to say that it is just as bad.

For comparison, the 100mm OF-412 HE-Frag shell has a nominal kill zone of 200 square meters and the 125mm 3OF19 and 122mm OF-471 HE-Frag shells have a nominal kill zone of 300 and 310 square meters respectively. In Soviet and Russian terminology, the nominal kill zone ("приведенной зоны поражения") of a shell is defined as the the area within which there is a 100% probability of a target being struck by one lethal fragment upon the detonation of the projectile. In this case, the target is considered to be infantrymen in the prone position. In principle, it is equivalent to the so-called "lethal area". In practice, the actual kill zone is much smaller because a "lethal" fragment is merely a fragment that contains enough kinetic energy to produce lethal injuries, but the actual likelihood of causing death is highly dependent on where the target is struck.