After the conclusion of the Second World War, at a time when the exploration of new technologies such as jet propulsion and nuclear bombs was being actively pursued by all of the world's major military powers, heavy investments were made in researching the means of guided payload delivery in the U.S and the USSR. The primary applications of this technology were in anti-aircraft missiles to destroy bombers and in long-range ballistic missiles, both of which were given the utmost attention as they were viewed as being the deciding factors in a potential future conflict.

However, in the USSR during the early to mid-1950's, the concept of guided anti-tank weapons was not fully appreciated by the military and the state, so all domestic projects were created exclusively under the private initiatives of design bureaus. There were several of these anti-tank missile projects, developed under the name "UPS", which stood for "guided anti-tank projectile". A large variety of guidance technologies were tested with working prototypes, from wire guidance to television guidance, but none progressed beyond the experimental stage, and there was no directive from the state to pursue further developments.

After intelligence reports on the use of SS.10 ATGMs by French forces against Egypt during the Suez Crisis arrived, great interest was aroused in the ministry of defence, resulting in a total reevaluation of priorities regarding ATGM technology. In 1956, the Council of Ministers issued a resolution titled "development of work on the creation of guided anti-tank weapons", officially commencing the familiarization process for this new technology among the specialists of the country; intelligence reports and technical data from foreign sources were transferred to research institutes, and intense research programmes kicked off. In fact, according to Alexander Shirokorad, manuals on the Cobra, SS.10 and SS.11 were acquired, and some live samples of foreign ATGMs were even obtained for study. In the book "Отечественные бронированные машины. 1946-1965 гг.", it is specified that research was undertaken on samples of captured German experimental X-7 "Rotkäppchen" ATGMs and the French SS.11.

On May 8, 1957, another decree from the Council of Ministers titled "On the creation of new tanks, self-propelled tank destroyers and guided rocket weapons for them" was issued. This officially launched the rapid development of tank, man-portable and heavy missile systems, with the tank missile systems being seen as promising alternatives for high-powered guns. From this, a series of domestic First Generation missile systems was born.

Despite the late start, Soviet ATGM development progressed extremely rapidly, qualitatively matching the best NATO missile systems by 1960 with the "Falanga" and then the "Malyutka" in 1963. Even the "Shmel", having an exceptionally conservative design, had some merit in its ease of manufacture and simplicity, as this gave it a high reliability rate that not all ATGMs shared. This led to a rather interesting situation where by the turn of the decade, the USSR joined the Swedes, Germans, and Swiss as major contenders in the international ATGM market, second only to France, while the U.S - the single most influential Western military force in the event of a major European war - was not even in the running. During the 1960's, the USSR occupied a relatively large market share largely thanks to its captive market among the Warsaw Pact nations as well as Soviet market domination in Africa (where the Soviet share of weapons imports sometimes reached 100%), supplemented by a few Arab clients and a few Asian clients, including Vietnam. Following the unprecedented mass deployment of ATGMs during the 1973 Yom-Kippur war, international interest in Soviet ATGMs exploded, influenced by somewhat alarmist reporting from Western military journals and magazines, and further buoyed by erroneous Soviet claims of up to 800 Israeli tanks being destroyed by the "Malyutka". It was also because of this conflict that every ATGM became known as a "Sagger" among NATO nations and in Israel.

In the aftermath of the 1973 war, the USSR surpassed France in terms of export volume as well as the size of the customer base, gaining a plethora of clients in the Middle East, Asia and also gaining Yugoslavia. According to a 1980 SIPRI yearbook, there were a cumulative total of 11 clients who ordered the MILAN in the period between 1970-1980, the earliest order being in 1976 (to the U.K), followed by Belgium, Spain, and so on. During this same period, 17 clients ordered "Malyutka" and "Fagot" ATGMs from the USSR. In terms of the scale of domestic use, the Soviet Army surpassed the French Army as the most prolific individual operator of ATGM systems during the 1960's by virtue of its sheer size and industrial capacity.

This article will examine the seven major Soviet anti-tank guided missiles that entered service and saw widespread use.

INDEX

- First Generation

- Aerodynamic Considerations

- Manual Guidance Considerations

- 3M6 "Shmel"

- General Design Features

- Aerodynamics

- Guidance System

- Steering

- Engine

- Warhead

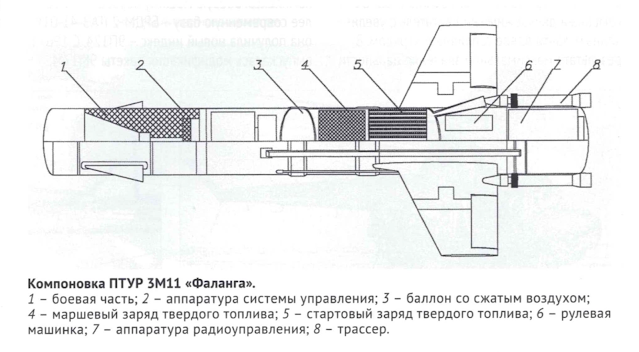

- 3M11 "Falanga"

- General Design Features

- Aerodynamics

- Guidance System

- Steering

- Engine

- Warhead

- 9M14 "Malyutka"

- General Design Features

- Aerodynamics

- Guidance System

- Engine

- Steering

- Warhead

- Second Generation

- Guidance considerations

- 9M111 "Fagot"

- General Design Features

- Aerodynamics

- Guidance System

- Steering

- Ejection Charge

- Engine

- Warhead

- 9M113 "Gaboy"

- General Design Features

- Aerodynamics

- Guidance System

- Steering

- Ejection Charge

- Engine

- Warhead

- 9M114 "Kokon"

- General Design Features

- Aerodynamics

- Guidance System

- Steering

- Ejection Charge

- Engine

- Warhead

- 9M115 "Metis"

- General Design Features

- Aerodynamics

- Guidance System

- Steering System

- Engines

- Warhead

FIRST GENERATION

The decree from the Council of Ministers, "On the creation of new tanks, self-propelled tank destroyers and guided rocket weapons for them" contained a list of eight ATGM projects to be pursued. All eight projects were distinct from one another in fundamental ways, from the guidance method to the aerodynamic scheme. The large number of systems ordered was due to the novelty and complexity of the task; there was no institutional experience in developing guided weapons of such a small size, and hardly any backlog of research to indicate the most promising design solutions to implement. As such, the intent was to assign a wide diversity of projects to multiple design bureaus and choose the best designs to introduce into service and to use as the basis for further work. There was no unified vision for what an ideal ATGM would look like, so the concepts were developed in a piecemeal fashion. There was at least one missile conceptualized for each conceivable application, from man-portable, self-propelled, heavy missile tank, medium missile tank, and an add-on missile for existing tanks.

OKR "Shmel" was the least ambitious research and development project, created with the intent of providing a basic failsafe option in case the other projects failed to produce workable products. The task of developing the "Shmel" system, listed as "Topic 7", was assigned to the Kolomna Special Design Bureau (SKB) in a decree issued by the Council of Ministers on May 27, 1957. SKB later became KBM. The creation of a control system for the ATGM was assigned to the famous TsNII-173 research institute, which had extensive experience in the development of steering drives and remote control systems for various guided vehicles. The development of the "Falanga" system was carried out under "Topic 8" by OKB-16, which later became KB Tochmash. After the initial round of development concluded, OKR "Malyutka" was borne out of the failure of the "Shmel" to fulfill the requirements of its original tactical niche. Of the two, only the "Malyutka" was a true man-portable system, as a number of design simplifications were made to "Shmel" which severely bloated its weight and dimensions, but these simplifications were commensurate with the spirit of the desire to have at least one failsafe ATGM option in service and were thus tolerated.

This article will explore the three first generation ATGMs that went into service in the Soviet Army. These were:

- 3M6 "Shmel"

- 3M11 "Falanga"

- 9M14 "Malyutka"

As with many attempts to classify technology into discrete generations, the dividing line between missiles of the first and second generations is rather blurred, as there are very few primary technologies that conclusively distinguish a first generation ATGM from a second generation model. The only tangible feature that is shared among all first generation ATGMs without exception but not present in second generation models, is that they were launched in a lofted trajectory, and not directly towards the target.

In the long period between the advent of the first ATGM, the French SS.10, in 1956 to the adoption of the first second generation ATGM in 1972, a number of technical innovations made their way into first generation systems that became standard on the following generation. Even the distinction between manual (MCLOS) and semi-automatic (SACLOS) control is not a useful distinguisher, as this technology is related to the launcher rather than the missile itself. First generation ATGMs have been used with SACLOS guidance quite extensively, most notably with the limited deployment of "Malyutka-P" systems by Syrian and Egyptian forces during the 1973 Arab-Israeli war. A lack of containerization, which was a universal feature of second generation missiles, is also not a useful distinguishing feature, as the Bantam and Swingfire ATGMs were both packed in hermetically sealed launch containers.

In practical terms, the most meaningful identification of a first generation ATGM is made by taking a holistic view of their technical details rather than individually, as the generation following them was borne out of the desire to combine all of their best characteristics without the drawbacks thereof. Very few first generation ATGMs had advantages that so thoroughly overwhelmed their downsides to justify continued use. The longest-lasting models in Soviet service were the "Malyutka" and "Falanga", both of which achieved a level of technical excellence that placed them on the border between the two generations, allowing them to endure the transition in their careers not merely out of expediency and cost, but for their own technical merits.

AERODYNAMIC CONSIDERATIONS

At the most basic level, an anti-tank guided missile is an aircraft - a flying machine, in the technical sense of the term. With that, it possesses most of the design challenges associated with flying machines, the most basic of which is the ability to maintain a given altitude, as the effects of gravity must be counteracted by some means. Being rocket-propelled weapons, the first inclination of a designer may be to rely on rocket thrust for this purpose, but this is not practical. As the missile will be flying directly towards a target situated on the ground, the missile will be oriented almost parallel to the ground, which inherently limits the vertical thrust component of its rocket engine to a near-negligible amount. Instead, wings are needed to support the weight of the missile, which is achieved by having the aerofoil of the wings produce a lift force that is equal to the downward force from the mass of the missile under acceleration by gravity; its weight. This ensures that the missile is capable of level flight - that is, it can maintain a given altitude. On top of that, the missile must also be capable of changing its flight vector so that its trajectory can be steered towards a target in both the horizontal and vertical axes. The missile must therefore have steering mechanisms, which can either rely on aerodynamic control surfaces or on the manipulation of rocket thrust. When these two basic features are present, it can be considered a guided weapon, and the military definition of a missile is satisfied. However, in order to have an effective missile, a number of aerodynamic considerations must be taken into account in its design.

STABILITY

The first and most important aerodynamic consideration in the design of an ATGM is its aerodynamic stability. In particular, high static and dynamic stability have special importance to MCLOS systems because it improves the controllability of the missile in the presence of wind and other irregularities. The most important metric for controllability is the ability of the missile to maintain a given flight attitude, dictated by the operator, which requires the missile to resist changes in pitch whenever they are induced by external forces. The main issue is crashing the ATGM into the ground, because tanks are low-profile targets, usually requiring the missile to be travelling no more than 1-2 meters above ground level, and potentially less than a meter above the ground, if the tank is in a hull-down position. A crash may be caused by a tailwind, which reduces the relative airspeed and thus the lift, a strong downdraft, which may physically displace the missile downward, or an updraft, which induces the missile to steer into the direction of the air current, causing it to nosedive into the ground. These forms of external influence can cause a missile flying close to the ground to crash before the operator can even react, and the resistance of an ATGM to this aerodynamic interference is primarily governed by static stability.

With a positive margin of static stability, the missile resists changes in its flight vector. If its attitude is disturbed by a wind, it will return to its original attitude on its own, and thus the flight vector remains the same. With negative static stability, the missile will accelerate in whichever direction it is directed, whether by intentional control or by external factors, and with neutral static stability, the missile will not resist a change in its attitude nor will it accelerate any changes. If the original attitude was changed, it will simply remain in its new attitude and the flight vector changes accordingly. This applies equally to the pitch and yaw axes. Resistance to crosswinds is also important for all types of ATGMs because it can cause a miss, particularly on moving targets, so yaw stability has its own importance even if it is not as critical as pitch stability.

If the missile possesses static stability, the next issue is dynamic stability, which defines the oscillatory behaviour of the missile after the initial disturbance. The behaviour of a missile with negative, neutral and positive dynamic stability is shown in the drawing below in red, blue and green lines respectively, with the black axis indicating the original flight vector of the missile. With negative dynamic stability, the missile accelerates in its oscillation, each swing becoming more and more violent (divergent oscillation). Neutral dynamic stability simply means that the missile oscillates at the same period and amplitude as its initial recovery arc when the missile responded to the disturbance (undamped oscillation). With positive dynamic stability, the oscillations of the missile are damped. Essentially, the margin of static stability dictates the initial amplitude of the oscillation, and if the missile possesses dynamic stability, the margin of dynamic stability dictates how strongly the oscillation is damped.

In all cases, it was ideal for the missile to be heavily damped, especially in the case of early MCLOS missiles. Removing or at least suppressing the oscillation of the missile about its heading simplifies guidance and reduces the dispersion of the missile during its approach to the target. It also reduces the likelihood of errant terrain, or even fuselage collision, for missiles launched from aircraft. In all of the Soviet ATGMs explored in this article, intrinsic dynamic stability came entirely from aerodynamic damping. Additional artificial damping could come from operator inputs, but there was no integral system of artificial damping, as found in self-contained guidance systems.

To ensure controllability and resistance to crashing, all ATGMs have positive static stability and positive dynamic stability, but with varying margins depending on their design parameters. Both forms of aerodynamic stability are essential in providing controllability, even in SACLOS missiles which are automatically steered by the guidance computer. Furthermore, as ATGMs are almost always symmetrical in design, or spin in flight, they possess the same level of stability in both the yaw and pitch axes. With positive static stability, the missile is able to execute a vertical steering command, changing its flight vector up or down, left or right, and once the steering command is removed, the missile will return to its original vector under the balancing moments generated by the lift forces of the missile lifting surfaces, which are designed to be in equilibrium about the center of gravity of the missile when it is traveling at a specific angle of attack, known as the equilibrium angle. The missile will also tend to return to this attitude if disturbed by wind, not only by pitch steering commands.

Static and dynamic stability is achieved by placing the center of gravity of the missile ahead of its center of pressure, where the sum of all aerodynamic lift forces act upon the missile. The further the center of gravity is forward of the center of lift, the larger the margin of stability, because the moment arm is longer and thus, the balancing force generated by the wings will create a larger balancing moment. An excessively large margin of stability is undesirable, because an ATGM has a finite load capacity, and its steering mechanism generates a finite steering force. If the steering moment is only slightly greater than the balancing moment, the control responsiveness of the missile is poor, and is normally felt by the operator as a sluggish response. Moreover, it is disadvantageous to design an ATGM with powerful steering mechanisms to generate a steering moment powerful enough to overcome an enormous balancing moment, as that would only increase the parasitic mass of the missile. It is best to ensure a good balance, and this must be ensured at the very beginning of the design process. In general, the lighter the missile, the easier it is to obtain a favourable compromise.

Furthermore, it is important that the center of gravity changes as little as possible during flight, so as to not compromise either the stability or control responsiveness of the missile. To that end, the center of gravity of ATGMs is universally defined by the position of its rocket engine, so that as its fuel depletes over the course of the flight, the depletion occurs at the center of gravity, so the balance is shifted as little as possible, although the total lack of change is usually not guaranteed since rear end-burning solid fuel engines are predominant among ATGMs.

LEVEL FLIGHT

The second aerodynamic consideration is the ability of the missile to maintain altitude in all operating conditions - that is to say, it must be capable of level flight. Level flight is attained when two critical conditions are met:

- Achieving equilibrium between the missile weight and its aerodynamic lift

- Achieving equilibrium between thrust and air resistance

The two are interlinked, as the lift generated from aerofoil wings is proportional to the airflow over the wing. By generating enough thrust to equal air resistance, thus maintaining a fixed air speed, the lift produced does not change, and a level altitude can be maintained. However, the reference point for level flight is usually not set at normal conditions (+20°C). Because ATGMs are required to operate in extremely cold weather, as low as -40°C or even -50°C, engine thrust which matches air resistance at normal conditions will be insufficient at such low temperatures, as the fuel will have a lower energy content, generating reduced thrust, whereas the air resistance it must overcome will be greater due to the increased density of the air. Such a missile would have to fly at an increased angle of attack, and by doing so, suffer from high induced drag and poor pitch responsiveness. If the operator manages to keep the missile flying, it would not be capable of achieving its specified maximum range, which is normally a cause for rejection by the military testing commission. Because of this, the sustainer engine of most if not all ATGMs with a dual-thrust propulsion system will produce a surplus of thrust at normal conditions (+15-21°C), so that they meet the thrust requirement for level flight in extreme cold. Consequently, they have a tendency to climb when used at temperatures above -50°C or -40°C if a pitch-down command is not periodically given. Only the earliest ATGMs were designed without consideration for temperature differences, namely the 3M6 and the SS.10. It became a standard design feature in French ATGMs beginning with the SS.11, and domestically, it began with the 3M11 "Falanga".

RELATIONSHIP BETWEEN LIFT AND ANGLE OF ATTACK

For a given wing design, the greater the airspeed or the greater the angle of attack, the greater the lift. This means that, for a given wing design, a slow ATGM must assume a high angle of attack to produce enough lift to remain in level flight, and conversely, a faster ATGM can fly at an angle of attack closer to 0 degrees. For a given angle of attack, a faster ATGM can also afford to have smaller wings with a smaller lift coefficient, which also reduces the lift-induced drag and is thus more supportive of higher speeds. For low-velocity missiles, mainly ATGMs of the first generation, the low lift from the low air speed can be compensated by enlarging the wings, or by increasing the angle of attack of the missile to increase the lift coefficient of the wings. Most first generation ATGMs were designed with very large wings for this reason, as illustrated in the image below.

An increased angle of attack is naturally needed when an ATGM is launch, as the missile must not drop to the ground or hit an obstacle during the time it accelerates to the velocity needed for level flight. For this reason, virtually all early ATGMs are launched from an elevated rail, and the majority of SACLOS missiles assume a positive angle of attack during their boost phase immediately after leaving the container. During sustained flight, however, an increased angle of attack harms the penetration potential of the warhead, especially on sloped armour.

For instance, the SS.10 and ENTAC missiles both require a positive angle of attack for level flight. The necessary angle of attack for both missiles is 6-7 degrees, while a higher velocity missile such as the Vickers Vigilant flies at an angle of attack of +5 degrees. As to the effect of the angle of attack, one way or another, it compromised the penetration power of the warhead as the incident angle of the shaped charge jet on an armour plate is increased, particularly on steeply sloped armour. If an SS.10 struck a steel armour plate measuring 200mm thick and sloped at 60 degrees, it would not have to perforate 400mm, which is the geometric LOS thickness, but rather, face an effective thickness of 492mm.

From this, it is clear that special caution must be exercised when reading penetration figures for first generation ATGMs, as they tend to be reported according to the maximum achievable penetration at an optimum standoff, in addition to having been done in static tests, without acknowledging the attitude of the missile in real flight conditions. To escape these pernicious effects, ATGMs benefit from having wings of the largest practical size, and as quick of a flight speed as possible, thus producing a great deal of lift without resorting to a high angle of attack.

For missiles that decelerate during flight for whatever reason, whether it is due to sustainer engine burnout (Falanga series) or simply due to the lack of a dual-thrust engine (TOW), the angle of attack can increase considerably during the course of its flight. The TOW missile series, for instance, relies on a short but powerful boost engine to bring it up to nearly 300 m/s, wherein a distance of around 300 meters is covered, but the missile is left to glide for the remainder of its trajectory. For earlier TOW models with a maximum range of 3,000 meters, the speed of the missile falls to around 140 m/s by the end of its flight, and for later TOW models with a maximum range of 3,750 meters, it is as low as around 105 m/s. The small wings, which are adequate during the first few seconds of flight, gradually lose their effectiveness as the missile speed declines. To compensate for the gradual reduction in air speed, the missile must, axiomatically, increase its angle of attack. Determining a single exact angle of attack is somewhat futile for the TOW, because it increases during the gradual deceleration of the missile during its flight. In the specific case shown in the images below, taken from a Raytheon promotional video showing a wireless (radio-guided) TOW-2A, it is around +5 degrees.

The most serious implication of this behaviour is that the penetration power of the warhead also degrades according to range, proportionate to the change in its angle of attack. A missile impacting the upper edge of a tank turret might have its shaped charge jet fail to enter the tank at all, and missiles impacting sloped armour, particularly sloped reactive armour panels, could have their effectiveness eroded considerably by a combination of increased armour thickness and stronger disruptive effect from the reactive armour. From this, it is plain to see that the perceived property of HEAT warheads in maintaining a consistent penetration power regardless of velocity or range is not the entire truth. For this reason, penetration data based on static testing may substantially overrepresent the real penetration capability.

MANUAL GUIDANCE

In piloted aircraft, flight control for a collision course with a target occurs in a two-point mode where the pilot simply aligns his aircraft at the target. With three-point control, the operator visually tracks both the missile and the target, and steers the missile until his line of sight with the missile is aligned with his line of sight of the target. When firing at a static target, the guidance process is at its simplest. First generation ATGMs are designed to be launched at a lofted trajectory, gaining an altitude of several meters (normally around 6 meters) to ensure that collision with obstacles is impossible, and the task of the operator is to gently lower the missile until it is superimposed onto the target, whereupon it impacts and (hopefully) destroys it. The main source of interference in this process is a crosswind. Because it is propelled throughout its entire flight, the missile will tend to steer into the crosswind, rather than being carried along with it, as a bullet would. To negate a crosswind, the operator observes the direction of the wind before launch, and once the missile is airborne, he periodically inputs a brief steering correction in the opposite direction whenever the missile begins to drift.

However, missile guidance is complicated by the fact that, despite the static and dynamic stability of a missile, it will possess a certain amount of inertia from each steering motion, in both the pitch and yaw axes. For example, whenever a horizontal steering input is made and then the control joystick is returned to the neutral position, the missile will stabilize itself to its original flight vector due to its inherent dynamic stability, but there is still a sideways moment of inertia from the prior steering moment. Owing to this inertia, the missile will drift to the side at a rate that is only slowly damped by air resistance. To correct this, a steering input of the same magnitude and period (duration) as the previous input is made, but in the opposite direction. The counter-momentum nullifies the side inertia of the missile and returns it to a direct trajectory.

In the Vickers Vigilant, and later on, the Swingfire, the nullification of inertia was done automatically by the control panel. The magnitude and period of an input is recorded, and when the control thumbstick is returned to the neutral position, an opposite input of the same magnitude and period is made. This made the guidance process faster and easier, as it is one fewer task for the operator to deal with.

Beyond these basic guidance principles, there are also good practices to increase the probability of a hit.

If a steering correction is to be made to align a missile with the target, then the operator must make a gentle deflection of the control joystick in the appropriate direction for a short period, return the joystick to the neutral position, and then input the same deflection for the same period in the opposite direction, and return the joystick to the neutral position again. For the operator to become accustomed to this method of steering, he must undergo training until he is familiar with the steering dynamics on a reflexual level, and he must have good hand-eye coordination. According to the textbook, only up to 10% of trainees were discovered to be capable of guiding missiles to the required accuracy standards. To properly guide the missile, calmness is of critical importance, as hasty, jerky steering inputs must be avoided if possible. The image below shows an incorrect method of guiding an MCLOS missile (solid black line), and the correct method (dotted line).

In the incorrect method, the sequence of events is as follows:

- Point A: the missile is assumed to have deviated to the left, and the operator wishes to return it to the direct LOS between himself (O) and the target (Ц). The operator gently deflects the joystick to the right, but he sees that the missile is still moving to the left, albeit at a slower rate.

- Point B: in response, he jerks the control joystick to the right, and the missile rapidly turns right.

- Point C: the missile has reached the LOS between the operator and the target, but it has overshot due to the excessive violence of the earlier steering command.

Seeing this, the operator attempts to bring it back to the left by jerking the control joystick to the left, then to the right, and with such violent maneuvers, the missile is never properly aligned to the target, and it invariably misses.

To adjust the flight trajectory of the missile correctly, the operator must gently deflect the joystick to the right while observing the missile. It will slow down in its leftward motion, then begin to move to the right. Once it is aligned with the line of sight between the operator and the target, the operator inputs a gentle steer-left command, and the missile hits its target.

This dynamic between the human operator and the missile and the strong influence of good hand-eye coordination has serious design implications. The first and most obvious design consideration is that the steering system should be capable of bringing the missile to bear on a target that is off-angle to the initial launch direction of the missile, so it should be capable of imparting a strong steering moment, and the missile components should be capable of withstanding the lateral accelerations produced when such maneuvers are made. At the same time, the steering system should be precise enough that the operator can make gentle and minute adjustments to the flight trajectory of the missile. The second design consideration is that it must be feasible for the operator to guide the missile onto target even at a close range without being too taxing on his reaction time and ability to make fine inputs under great time stress. This was solved in virtually all first generation ATGMs by having a thrust surplus from the sustainer stage of their engines, which is also a cold weather performance factor as detailed in the previous section. By having an accelerating flight profile, the amount of time available to the operator to engage a target at close range is increased, yet the missile can reach a target at long range without an excessively long flight time.

Live missile launches at the gunnery range was permitted only after the trainee completed around 1,000 simulated launches. Though this figure is rather dramatic, it is important to keep in mind that the flight time of a missile such as the "Malyutka" to its maximum range is just 25 seconds. Given that each engagement could last a maximum of 25 seconds, the total time spent in a simulator can be up to 7 hours, but the real training duration is undoubtedly less, because simulated engagements at closer ranges (around 2 km) were predominant.

"Shmel" ("Bumblebee")

3M6

The urgency of the Soviet ATGM programme can be best appreciated by looking at the development period of the "Shmel" in comparison with its direct counterpart, the SS.10. The SS.10 began development in 1946, had its first unguided flight tests in 1949, and entered service in 1955 - a total period of 9 years. For comparison, the "Shmel" project began in 1957, it had its first unguided launch tests in April 1958, proceeded to controlled launches in June 1958, and was demonstrated to the military in August 1959. Overall, the development of the 3M6 was 3 times shorter than the SS.10 along every milestone in its timeline.

The 3M6 missile entered service on the 8th of January 1960 as an integral component of the 2K15 and 2K16 missile systems incorporating it, implemented on the 2P26 and 2P27 missile carriers respectively. The 2P26 was made for, and procured by the VDV, while the 2P27 was procured by the Ground Forces. The 3M6 was the first Soviet ATGM to enter service, followed shortly by the 3M11 missile of the 2K8 "Falanga" system which entered service several months later, on the 30th of August 1960. A production line was set up in the Degtyaryov factory, almost simultaneously and in parallel with the production line of the S-75 missile, and the first serially produced batch of missiles was delivered to the Soviet Army in 1961. Mass production of the 3M6, along with the 2P26 and 2P27, lasted from from 1961 to 1966.

In some sources, such as the article "Первые ОКР по противотанковым и танковым управляемым ракетам" by I. Pavlov and A. Sorokina, published in the September 2018 issue of the "Техника и вооружение" magazine, it is stated that the continued production of 3M6 missiles until 1966 was purely for replenishing existing stocks expended in training and to support the demand from export clients. The modernization of the "Shmel" was cancelled due to the appearance of the "Malyutka" system, which surpassed it in all technical characteristics and had great potential for future developments.

Interestingly enough, in a rather unusual turn of events, the "Shmel" ATGM was very quickly approved for export and licenced production among the Warsaw Pact nations and the GDR, despite guided anti-tank missiles being an entirely new military technology. The 3M6 enjoyed much greater longevity among these export clients than in the Soviet Army, serving to form the backbone of the ATGM arsenal of those militaries prior to the mass introduction of "Malyutka" systems in the early 1970's. Poland, for example, received 3M6 launchers in 1962, and technical manuals translated from the Soviet originals were approved in 1962 and were published by 1963. The USSR granted Poland the licence to produce the 3M6 in 1963, and exported 2P26 and 2P27 tank destroyers until 1966. According to the article "Przeciwpancerne pociski kierowane w ludowym Wojsku Polskim" (Anti-tank guided missiles in the Polish People's Army) published in the February 2021 issue of the Polish technology magazine "Nowa Technika Wojskowa", local production of the 3M6 began in 1965, and by early 1967, the Polish People's Army posessed 8 2P26 tank destroyers and 72 2P27 tank destroyers. Mass production of 3M6 missiles continued from 1965 to 1972, and they continued to be used until 1979 at the latest.

Like in the USSR, local improvement projects were not carried out amongst the licenced manufacturers of the "Shmel" in the Warsaw Pact, presumably because the export and grants for licenced production of the "Malyutka" began in a timely manner.

Though "Shmel" missile systems were mass-produced in the USSR and issued to the troops, the predominant impact of the system was to build up valuable expertise in the Kolomna design bureau and to give the Soviet Army a degree of operational familiarity with ATGMs. In the latter context, the "Shmel" served the same purpose as the SS.10 in the U.S.A, where it was procured by the U.S Army as the MGM-21A in 1960 after domestic attempts to create a workable ATGM system stalled.

GENERAL DESIGN FEATURES

A conservative design philosophy was adopted for the 3M6, whereby the decision was made to implement the flying wing aerodynamic scheme, wire guidance, dual-stage engine and spoiler steering system of the SS.10 as it was a proven missile system, so naturally, the technological solutions it used were considered to have the lowest technical risk. The intent was to ensure that if all other ATGM development projects failed, the Soviet Army could be guaranteed to have at least one basic, functional ATGM system. That said, the design concept was the only similarity between the 3M6 and the SS.10 - the former was by no means a physical copy of the latter and the two do not even share a visual resemblance, as the 3M6 was a domestic design in all respects.

If the "Shmel" did not distinguish itself by its technological sophistication or innovation, it was at least reliable, having a failure rate of less than 2.5% according to the article "Первые ОКР по противотанковым и танковым управляемым ракетам".

The diameter of the 3M6 fuselage is 136mm and its total length is 1,150mm. The complete missile weighs 24 kg. Far too heavy to be carried by infantry, the 3M6 was only used from missile carriers, those being the 2P26 tank destroyer based on the GAZ-69, and 2P27 tank destroyer based on the BRDM-1. In terms of its weight and performance, the 3M6 was stuck in an unhappy medium, being far too heavy for an infantry system like the SS.10, yet also lacking the high performance of a heavy ATGM, not even having advantages in stowage capacity compared to missiles like the SS.11 due to its large, obtrusive wings. In terms of capabilities and combat load, the closest analogue to the 2P26 would be the French missile carrier based on the M201 jeep (known as Jeep SS.10), which carried three SS.10 ATGMs instead of the four "Shmels" on the 2P26.

Internally, the layout of the 3M6 has a straightforward layout consisting of a warhead section, a guidance section, and an engine section, fitted sequentially in series. The warhead section consists of the shaped charge warhead and its fuzing system. Vacuum tube electronics were used for the guidance equipment. It is worth noting again that, although the 3M6 was directly inspired by the SS.10, it differs considerably in its layout, as the SS.10 has its guidance equipment arranged in the same fuselage compartment as the rocket engine, which also has a completely different design. Overall, it is impossible to view the 3M6 as a copy of anything, even superficially.

AERODYNAMICS

Aerodynamically, 3M6 had a tailless delta aerodynamic scheme, with four large, fixed, cropped delta wings (also known as clipped delta). The wingspan is 750mm. As the missile is tailless, the wings provide lift, flight stabilization and steering all at once. The wings are symmetrical aerofoils, being flat plates with wedge-shaped leading and trailing edges, a shape known as a modified double wedge aerofoil. The construction of the wings consist of an aluminium alloy skin bonded to a plastic foam filler. The production process of the wings was detailed in the article "Первенец противотанкового ракетостроения родился на ЗиДе" published in the March 20, 2019 issue of the "Дегтяревец" Degtyarov factory newsletter by V.A. Golunov. Phenoplast (phenolic resin) is backfilled into the space between the aluminium wing skins, and then heat-activated adhesive is wadded in. With that done, the wing blank would be installed in a metal mould, and then heated in a heating cabinet, which expands the phenoplast into a phenolic foam and activates the glue, and thus the entire wing cavity is filled. This type of thin wing has very low drag in theory, but it also generates limited lift, and in practice, the low aspect ratio of the wing translates to high induced drag. Thin, stubby wings are normally used on supersonic aircraft and are not the most aerodynamically efficient shape for a subsonic missile.

From a design and production standpoint, however, it is among the simplest and lightest practical aerofoils, and it is a popular choice of aerofoil on the foreign ATGMs such as the SS.10 and the Cobra. Due to the low lift coefficient of this aerofoil, a large surface area is needed, resulting in the distinctive large wings present on these first generation ATGMs. The only simpler construction is to have no aerofoil at all, which is the case with the ENTAC, which used simple steel plates as wings, or the Bantam, which had composite plastic plates for wings. On the other side of the spectrum, there is the Mosquito ATGM which has a high camber, flat bottomed aerofoil, an optimal shape for subsonic wings.

Immediately after launch, the missile is automatically rolled clockwise by 45 degrees to change the wing profile from a cruciform to an "X" under the influence of a hard-coded program in the steering system. This allows all four wings to generate lift, though the lift coefficient of each wing is reduced due to the smaller horizontal span as compared to a level wing. The X-wing shape balances out roll forces from the wings on both sides, and has neutral roll stability. That is, the missile will not self-correct to its original orientation if a roll angle is induced, nor will it amplify any induced roll. On the 3M6, roll stabilization is provided by the gyroscopic steering system which detects changes in roll angle and automatically stabilizes the missile using aileron spoilers throughout its flight trajectory.

Unlike tailless delta wing designs on aircraft, where the tips are twisted to a lower angle of attack than the rest of the wing to provide pitch stability, the wings on 3M6 are flat, so the net lift force has an upwards vector. As the center of gravity of the missile is ahead of the center of lift from the delta wings, this would cause the missile to overturn if not continuously trimmed. Trim is automatically applied by the onboard autopilot via the spoilers based on changes to the missile attitude measured by the gyroscope.

Interestingly enough, the 3M6 was the only Soviet ATGM to have fixed wings, not only in service, but also among all experimental missiles in development in the country. The advantages of folding wings were universally understood, but as the design priority of "Shmel" project was conservatism, it emulated the international practices in this regard. Conversely, virtually all MCLOS missiles in the NATO repertoire had fixed wings with the sole exception of the Swingfire, which was an unusually late addition to the first generation family and is an atypical design overall. The Swedish Bantam ATGM also had folding wings, but Sweden was not a NATO member.

The wings have a moderate sweep angle of 45 degrees, less than the optimal range for supersonic flight but well within the range of approximately 30-50 degrees for subsonic, high lift applications. Currently, delta wings with moderate sweep angles are very popular for light propeller-driven UAVs which fly at low velocity and require high lift, for the same design reasons that justify their use on the "Shmel".

Because the wings are not asymmetric aerofoils, and they are not structurally affixed at a positive angle of attack, they do not generate lift if the missile itself is at a neutral angle of attack. To fly on a level trajectory, the missile must maintain a positive angle of attack of a few degrees, wherein both the fuselage itself and the large wings can provide enough lift at the cruising velocity of 110 m/s. The angle of attack is not regulated automatically by any onboard systems based on the internal gyroscope - it was calculated based on early test flights, and it is achieved by using a hard-coded program in the operator's control panel that automatically pitches the missile up at regular intervals. The pitch-up signal is additive to the pitch commands entered by the operator via the joystick. This program is active 0.8 seconds after launch (timed to activate after booster burnout) and acts throughout the flight of the missile.

It is not known what the angle of attack is taken by the 3M6 during trimmed flight, but its large wings, with a presumably high lift coefficient, would combine with the relatively high speed of the missile to produce a great deal of lift, more than the smaller wingspans of the French ATGM trio are capable of. This, in turn, implies that the necessary angle of attack to maintain trimmed flight would be lower for 3M6. Beyond this, little else can be said of the flight attitude of the missile.

Due to the massive wingspan of the missile, the operator had to be closely adhere to the rules of the three-point guidance technique to avoid accidentally clipping a wingtip on the ground, which would invariably lead to a crash. The placement of tracers on two wingtips helped in this regard by allowing the operator to track the missile by two opposite points marking its maximum dimensions. Moreover, the large surface area of the wings makes the missile very susceptible to being blown off course by wind. According to the technical manual for the 2P27 tank destroyer, firings are not recommended in crosswinds of 8 m/s, or when gusts of crosswinds of up to 12 m/s are present.

In principle, the use of a hard-coded program for this task has a number of inherent shortcomings. The main issue is that the calculated angle of attack needed for level flight would only apply for a set of standard conditions, and deviations from these conditions, such as when firing the missiles from high altitudes or in cold weather, would cause the missile to either drift upwards or slowly descend. Moreover, there is no ability to automatically apply corrections in the event that a headwind causes the missile to generate excess lift and pitch up. Stable flight under such conditions would be entirely dependent on the static and dynamic stability of the aerodynamic design of the missile.

GUIDANCE SYSTEM

The guidance system consists of the T-70M thermal battery, a pair of command wire coils stored in bobbins, the gyroscope, a simpler roll correction circuit, and a signal amplifier.

The T-70M thermal battery is of the molten salt type. It serves as the onboard power source for the control unit (autopilot) and for actuating the spoilers. Since the first use of thermal batteries on the German V-1 bomb, this type of power source established itself as the de facto standard for single-use applications, including guided missiles. The main advantage is that the electrolyte could be stored in a solid state at a wide range of temperatures for long periods of time with no electrical discharge whatsoever, and be activated on command by the transformation of the electrolyte into a partially molten state by intense heating, normally provided by a pyrotechnic charge, which is the case in the 3M6 missile. The primary drawback of thermal batteries is their low power density and heavy weight, increasing the parasitic payload in a missile. The T-70M battery provides a current of 2.2 A at a voltage of 22-26 V for 30 seconds. Upon pressing the launch button on the control console, the pyrotechnic heaters of the T-70M battery would be ignited, and the battery becomes fully operational within 2-3 seconds. The gyroscope and on-board missile control equipment are also activated during the 2-3 second preparation period, and once it elapses, the missile is launched.

Curiously enough, the use of a thermal battery was an innovation that was not found on the SS.10 or SS.11, which used troublesome wet and dry cell batteries respectively. The battery of the SS.10 had to be primed before combat, as the electrolyte would have settled during storage or transport, while the three dry cell batteries of the SS.11 were stowed separately and had strict servicing requirements as well, described in the COMHART book as being "very penalizing". Though the main issue with wet and dry cell batteries was not disclosed, the most likely issues are self-discharge and possible electrolyte leakage during high accelerations. It was only a few years later that the SS.11 was upgraded with a thermal battery, with the SS.11 B1 model in 1965. The SS.10 was not provided a battery upgrade before it was discontinued.

The gyroscope in the 3M6 is a rate gyro, with two degrees of freedom. The gyroscope is spun to its operating speed just before launch by an electric motor powered by the launch platform itself, rather than the thermal battery in the missile. Once it is spun up, the motor is disengaged, the power supply is cut, and the missile launches with the gyroscope rotor continuing to spin under inertia. The gyroscope is paired with a potentiometer to generate reaction signals in the roll axis. Deviations in the roll angle of the missile generate a feedback voltage, which is processed by the autopilot program by amplification and the resultant reaction signal for a roll correction is generated. Roll corrections are made using the ailerons to ensure that the four wings are always oriented in an X-shape. Due to the need for correct roll stabilization, the firing platform for the missile must not exceed a roll angle of 3 degrees, so when preparing a firing position for a 2P26 or 2P27, a flat patch of ground is ideal, but if the ground is not flat, then the crew must use pioneering tools to flatten it as much as possible.

The command wires, held in two bobbins, are 2,300 meters long. Both bobbins and both wires are identical and are interchangeable. The surplus length of 300 meters was to provide the operator with enough freedom to guide the missile on a curved flight path, which is needed to align the trajectory of the missile to the operator's line of sight when firing remotely, or when engaging a moving target. This is because the launchers and optics on the 2P26 and 2P27 tank destroyers have a very limited traverse arc, and so the missile needs a larger margin of maneuverability to hit targets that are not more or less in front of the launcher. Because the steering system is electrically powered, and the nominal operating time of the battery exceeds the 21-second flight time of the 3M6 to 2,000 meters, there is no real obstacle in achieving this.

Voltage pulses of a specific width are used to communicate steering information in the command signal. The command signal generated from the guidance unit is in the form of a rectified sine wave of a fixed amplitude transmitted down each of the two wires; one wire for each steering axis. One wire is used to transmit up and down pitch signals, and the other is used for left and right yaw signals. The amplitude of the control signal is fixed. The rectification of the sine wave into negative and positive pulses is used as the means of differentiating the sign of the command. That is, a positively rectified waveform in the pitch control channel would communicate a pitch-up command, while a negatively rectified waveform would communicate a pitch-down command. Information about the magnitude of the steering intensity (inputted by varying the deflection angle of the operator's joystick) is controlled by varying the pulse duration (width).

The wires are steel, with an insulated cladding, and a diameter of 0.16mm. Based on colour photos, the cladding is very likely to be plastic, as the wires for inert mockups have a blue cladding whereas the wires for live missiles have a yellowish green cladding. At the same time, however, the visible length of wire on missiles installed on launchers appears too thick to match the known wire diameter of 0.16mm, so it appears that the initial portion is either bimetallic or has additional insulative protection to prevent burn damage from the exhaust of the missile booster engine. The remainder of the wire is most likely to be simple enameled wire, based on the fact that a sample of guidance wire was apparently stolen and used as fishing wire by an employee of a factory that once produced the 3M6. Enameled wires are simply wire filaments coated in a layer of varnish for insulation, and would have the same colour as the wire material, in this case a silvery grey. This is similar to the SS.10, which used enameled steel wires measuring 0.15mm in diameter. The end connectors on the two wires are locked onto protruding contacts on the launch rail manually during loading. These contacts can be seen in the two photos below. The two wires are unwound from the bobbins at a speed of more than 1,000 turns per second.

If a command wire is severed during flight for any reason, the missile control system automatically executes a self-destruct program that steers the missile down and to the left to prevent an uncontrolled flight.

Some two-wire systems have a small possibility of shorting out when the electrical impedance of a wire is more than the electrical impedance of the water between the neighbouring wire, causing a short circuit to form. If the insulation is poor or compromised, this particular issue can arise due to the extremely low thickness of the wire cores used in guidance wires, making them filament-like. It is a particularly serious issue for the TOW, because its wires are not insulated enameled copper, but merely enameled steel. The electrical resistance of a wire increases as its thickness decreases due to the lower cross-sectional area through which current can pass, so if the guidance wires are submerged, the resistance of the water may be less than the resistance of the remaining length of wire ahead of the point of submergence. If the resistance of the water is less, a steering signal transmitted down one of the wires will be routed up the neighouring wire and back to the launcher, causing a short circuit in the guidance system. The severity of the issue is determined by the tautness of the wires and the height of the launcher above the water surface, which determines if and where the wire sags low enough to become immersed in the water.

Steering was accomplished using a joystick with a two-axis rheostat mechanism, allowing the steering input to have a variable magnitude in any direction. When the control joystick is deflected to the right and left up to 40 degrees, the steering intensity coefficient of the generated command in the yaw axis (either yaw-left or yaw-right) smoothly changes from 0 to 0.6-0.8 until the joystick reaches 40 degrees, whereupon the intensity jumps to 0.95 or more. When the control jostick is deflected away from the operator by up to 40 degrees, the coefficient of the pitch-up command smoothly changes from 0.36 ± 0.06 (the coefficient of the trimmed flight command) to 0.6-0.8. When the control joystick is deflected towards the operator, the trimmed flight command is gradually nullified, with the steering intensity coefficient reaching 0 once the angle of deviation of the joystick is approximately 25 degrees, and with a further deflection of the joystick up to 40 degrees, the pitch-down command coefficient smoothly varies from 0.1-0.3. The maximum pitch command is presumably equal to an angle of attack that is just below the stall angle of the wing.

The control panel can be dismounted from the vehicle, mounted to a platform with a binocular sight, and then used by the missile operator from outside the vehicle. One of the most important reasons for this capability is to enhance the concealment of the launch vehicle by having it parked on a flat piece of ground in a defilade position while the operator guides the missile from a more advantageous vantage point. Otherwise, it can be problematic to properly position the vehicle for combat, as it must not be parked in such a way that the roll angle exceeds 3 degrees, but choosing such flat ground can increase the difficulty of camouflaging the vehicle. Dismounted operation does, however, unavoidably increase the firing preparation time considerably, from 10 seconds (when firing from a halt) to 2 minutes and 30 seconds.

Observation of the missile and the target could be done with the naked eye or through the special 8x binocular sight. The binoculars are virtually the same as a regular pair of field binoculars, differing only in that it has a mount and a special reticle. The missile was fitted with a pair of T-17 tracers to permit observation. T-17 tracers are small, measuring only 17mm in diameter (hence the designation of T-17), and are located on the tips of the two single-spoiler wings. Each of the tracers generates a light intensity of 18,000 candelas with a total burn time of 30 seconds.

In order to avoid collision with the ground during the first 2-3 seconds after launch from the potential attempts of overzealous operators to immediately align the missile with the target, inputs in the vertical plane are blocked by the control unit. The operator is only allowed to steer the missile in the horizontal plane. The missile is automatically guided by a special autopilot program in the control unit to fly to a predetermined altitude during these 2-3 seconds, whereupon the operator can then steadily lower it down to his line of sight to the target. This program ensures that the missile does not accidentally impact any terrain features during its initial trajectory, where it is most sensitive to tailwinds and crosswinds. The former reduces the relative airspeed and thus the lift of the missile, the latter can blow the missile off course and into obstacles such as boulders and small trees. When engaging targets at a sufficiently long range, it was recommended for operators to keep the missile at an altitude of 4-8 meters to avoid clipping obstructions on the ground, and then lower the missile onto the target within 500-700 meters before impact.

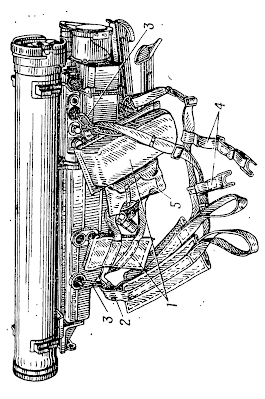

With all of the flight control limitations, it is perhaps not too surprising that control of the missile required a strong training regimen and frequent practice, even for an MCLOS system. In the book "Отечественные противотанковые комплексы" (Domestic Anti-tank Systems), author Rostislav Angelsky states that the difficulty of controlling the missile was a factor in the short lifespan of the "Shmel" system. Testing personnel of the military testing commission and specialists from the TsNII-173 design bureau could operate the missile system almost without misses by the end of military acceptance tests, but after a three-week break, the same people could only score a hit in one of every four launches. Guidance was accomplished with the control set described earlier, consisting of a control panel featuring a joystick and a pair of binoculars affixed to a pedestal. This set of equipment directly mirrored that of the earlier SS.10. The image below, taken from the book "ПТУР сухопутных войск" by G.N. Dimitriev, shows an NVA dismounted 2P27 operator guiding a "Shmel", with the launch vehicle parked some distance behind him.

Based on the results obtained by the state testing commission, the probability of hitting a target was 50-80%. The large variance can be attributed to the fact that the testing commission operators honed their skills by simply receiving practical training via the tests, and their proficiency level greatly improved in the period between the beginning and the end of the tests.

The zone of action of the 3M6 is largely limited by its launch platform, the 2P27. It featured a traversible launcher with a limited horizontal arc of 24 degrees (±12 degrees) and a traversible sight with a horizontal arc of 48 degrees (±24 degrees). Although it is possible to guide the missile in an arc exceeding the traversing limits of the launcher thanks to the wider reach of the sight, it is still necessary for the sight to be aligned with the launcher so that the operator can capture the missile during its initial trajectory, before gradually turning the sight by up to an additional 12 degrees to the left or right. The launch control system has a "ready" signal light to indicate when the sight and launcher are aligned, and the light goes out when the operator turns the sight off alignment by more than 1 degree. When using the full capabilities of the system, the maximum engagement arc is 48 degrees. If the sight is not turned more than ±12 degrees, then the engagement arc is defined by the width of the viewing arc through the sight, giving an arc of 36 degrees. The zone of action when fighting from a 2P27 is marked as Zone 1 in the diagram below.

Aiming the missile in an arc exceeding the viewing arc of the optical sight is only feasible when the system is fired remotely from a dismounted position, with the operator manning an external control post. The operator aims the sight at the target and mentally notes the landmarks that appear within the viewfinder of the sight. When the missile is launched, the operator visually captures the missile with the naked eye and steers it until it is near the predetermined landmarks, allowing it to be tracked through the sight. This method of guidance increases the zone of action to 98 degrees (±49 degrees). Due to the time needed to complete this maneuver, combined with the relatively high initial speed of the missile due to its boost stage, the minimum range of the missile system is increased to at least 1,000 meters. The probability of hit diminishes near the limits of the zone of action, demarcated into Zones 2 and 3 where the hit probabilities are 0.65 and 0.50 respectively. This is because the operator has less time to control the missile in altitude as he is preoccupied with aligning it into the viewfinder of his sight, increasing the chances of the missile overflying the target or having the operator accidentally steer it into the ground.

The curved trajectory of the missile, particularly at the extremes of the engagement arc, made it necessary to pack 2,300 meters of wire. Without it, the maximum range of the missile in Zones 2 and 3 would be less than 2,000 meters. As a side effect, the maximum range within Zone 1 can be greater than 2,000 meters. In the pamphlet "Przeciwpancerny Pocisk Kierowany 3M6" published by the Polish Ministry of National Defence in 1976, the so-called "effective engagment range" of the 3M6 is considered to be 2,200 meters.

The long minimum range of 600 meters, partly caused by the inhibition of operator control during the first 2-3 seconds of missile flight, and partly caused by the delay before the operator can visually acquire the missile in his sight, could only be achieved without degradation in hit probability if the target was within a 6-degree arc in front of the launcher. This can be problematic when engaging a crossing target. If the desired 0.8 hit probability is to be achieved in a larger arc of 48 degrees, the minimum range is 1,000 meters. This long minimum range of 600 meters was shared by the SS.10, which is unsurprising given the close similarity in kinematics between the two missiles.

STEERING

All four wings have a spoiler that can alternately function as a rudder or an elevon, depending on which pair of spoilers are activated. Two wings, forming the upper right and lower left portions of the "X" layout, feature a second spoiler placed at the end of the wing, which functions as ailerons. These only permit roll corrections to be made according to signals generated from the onboard autopilot, and do not respond directly to any steering commands made by the missile operator.

Each spoiler assembly is housed in a bakelite casing screwed onto the wings, which also feature a pair of wing fences to prevent lateral overflow from the spoilers when they are in operation. The spoiler casings are streamlined with a teardrop shape. Superficially, the overall form of the design is the same as the spoilers used in the SS.10 and ENTAC missiles, but the French type had a metal casing, a different aerodynamic form with a pointed casing, narrower spoilers and cruder fences.

Each spoiler used in the 3M6 missile is a plate that is raised through the skin of the wing, interrupting the air flow. The accumulated excess pressure propagates forward, upstream of the flow, and generates a distributed excess pressure on the wing surface in front of the spoiler. This results in an increase in drag, a loss in lift and a change in the pressure differential between the upper and lower surfaces of the wing, which can be used to either roll or steer the missile. The use of wing fences enhances the effectiveness of spoilers by preventing the excess pressure from generating a lateral flow across the wing, dissipating the pressure. The pressure on the lower surface of the wing also decreases when the spoiler is raised, due to the reduction in circulation around the aerofoil. This increases the magnitude of the pressure differential and thus the moment of force pushing down upon the wing.

The diagram below illustrates the excess pressure that propagates forward of a raised spoiler, and the nature of its intensity. In this case, the structure shown is a symmetric wing with a bidirectional spoiler, representing the wing of 3M6, rather than an asymmetrical wing with an upper spoiler as found on aircraft.

The fundamental principle of steering by inducing a pressure differential on the wing is identical to how rudders on wings function, only the mechanical means differ. Spoilers were used primarily for the sake of capitalizing on their sheer simplicity; the actuator of each spoiler is a pair of electromagnets, with the spoiler attached to a hinged armature. It is, essentially, identical to the most rudimentary electric bell. Each electromagnet is used to raise the spoiler on one side of the wing. This device was simpler than servomotors to control rudder deflection, and with a more modest demand on power. The control architecture was also of the utmost simplicity.

On the 3M6, the spoiler plate is swung between the raised and lowered positions at a fixed frequency of 10 Hz using a bang-bang control scheme, where one of the two electromagnets in the spoiler completes the cycle of pulling the spoiler armature towards itself and releasing it at a rate of 10 times a second. The power supplied to the electromagnet is the amplified signal received from the operator's control unit. The signal, having a rectified square waveform and a certain pulse width, is amplified by the missile guidance system, and then transmitted to the electromagnets. The armature is raised to a fixed height, while the length of time it is left in the raised position is regulated by the pulse widths of the modulated control signal. Each time the armature of the spoiler is released by the electromagnet, the spoiler is returned to its recessed position in the center by a spring. A bang-bang system is the simplest control scheme and one of the most popular types, being a universal standard for heaters and refrigerators. The image below shows an example of how a bang-bang control scheme is applied in a heater to maintain a desired temperature by achieving an average between a set of upper and lower thresholds.

Cross section A-A shows a longitudinal cross section of a roll stabilization spoiler, and cross-section B-B shows a longitudinal cross section of a steering spoiler. The curved spoiler plates of both units are of a similar thickness, but the armatures are hinged at different points, and the roll stabilization spoiler has a shorter height limit. Knowing that the intensity of the steering effect is dependent on the height of a raised spoiler, this implies that roll corrections were limited to fine adjustments only.

The higher a spoiler is raised, the larger the effect. This is shown in the graph below, taken from the thesis "Aerodynamic Performance of Low Form Factor Spoilers". This is used as the basis of the steering system in 3M6. By varying the pulse width of the steering signal to adjust the spoiler activation period, the average steering force generated by the spoiler is proportionately varied, allowing the turning force to be finely controlled, giving the steering precision needed to hit tank-sized targets at long range. The control joystick of the 9S41 control station, used in both the 2P26 and 2P27 tank destroyers, could be deflected by up to 40 degrees with a smooth progressive adjustment in steering intensity throughout.

When the operator's control joystick is gently deflected to one side, the pulse width of the signal transmitted over the guidance wire is small. The corresponding pair of spoilers are activated and oscillate at the fixed 10 Hz frequency, and the plates spend less time in the raised position. Due to the shorter period of spoiler extension, the resultant steering force is also small. If the joystick is further deflected, the pulse width increases, the extension time is extended, and the steering force increases accordingly.

The characteristics of spoilers for missile steering are corroborated and further explored in the book "Armements Antichars Missiles Guidés Et Non Guidés" by COMHART (Comité pour l'Histoire de l'Armement Terrestre). It is noted in the book that wind tunnel tests showed that, compared to traditional rudders, the increase in aerodynamic drag is low if the dimensions of the spoiler and its casing are well optimized and if the gains in simplification compared to traditional rudder steering surfaces are taken into account. In addition, it is reported that for the SS.10, the low flight speeds and the simplicity of the general aerodynamics of the missile made the drag penalty even more negligible.

Furthermore, by placing the spoilers at the trailing edge of the wing rather than along the midpoint, behind the leading edge, where the local dynamic pressure and interference effects are largest, the braking effect of this type of spoiler is minimized.

ENGINE

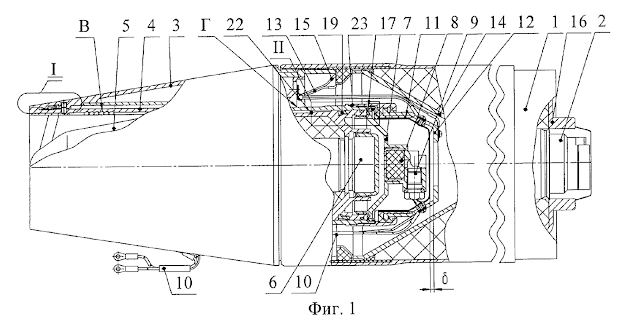

Propulsion was provided by a dual-chamber, dual-thrust engine consisting of separate booster and sustainer chambers. The sustainer is contained in the large forward chamber and the jet of combustion products is routed through a central nozzle, which extends through the length of the booster chamber. The fuel block of the booster engine is wrapped around the sustainer engine nozzle, and the combustion products exit via an annular array of nozzles surrounding the central sustainer nozzle. As the cross-section drawing on the left above shows, the throat of the nozzle for the sustainer engine has a molybdenum insert, where erosion is strongest, but the rest of the nozzle is merely a flared pipe. The annular nozzles for the booster engine do not have molybdenum inserts or any kind of refractory metal insert, which is a cost-saving measure as erosion is a non-issue for the booster, given its short burn time.

The booster generates the necessary thrust to accelerate the missile to 110-115 m/s in 0.6 seconds, followed by the sustainer which generates a thrust equivalent to air resistance, thus sustaining a 110 m/s cruising speed. It can be surmised that the 3M6 does not have an accelerating flight profile at a normal operating temperature, because one of the general instructions for missile operators is to observe if the missile descends or ascends after launch when it appears in the binocular sight, and to input a pitch adjustment accordingly. This strongly indicates that the sustainer engine was calibrated to produce a thrust equal to air resistance for level flight at normal temperature, and will generate a surplus at elevated temperatures and a deficit at lower temperatures.

The total burn time of the sustainer is 20 seconds, though the thrust developed by the engine drops off in the last few seconds. The flight time of the missile to its nominal maximum range of 2,000 meters is 18 seconds, giving the missile an average speed of 110 m/s. The maximum limit of 2,300 meters can be reached without a debilitating degradation in performance, as the onboard battery continues to function normally beyond 2,000 meters, and so flight corrections are still possible. The hard range limit of 2,300 meters is enforced only by the wire length. Interestingly enough, it is noted in the article "ПТУР первого поколения в АОИ" (First Generation ATGMs in the IDF) that the speed of the 3M6 at its maximum range (2,300 m) will be 74 m/s, implying that the high induced drag of the missile rapidly degrades its kinematic performance beyond its nominal maximum range of 2,000 m.

This was principally the same as the propulsion system of the SS.10 missile, as the SS.10 was also designed without consideration for low temperature action. It had a booster engine that provided a thrust of about 2,000 N for 0.65 seconds, and its sustainer engine gave a thrust of 95 N for 18 seconds to sustain a cruising speed of 80 m/s, rather than to provide an accelerating effect. The SS.10 engine has a boost-sustain thrust ratio of 21, which was likely duplicated in the 3M6. Kinematically, the two differences between 3M6 and the SS.10 are in their respective flight velocity profiles and in the greater average speed of the 3M6.

The choice of an intense boost stage lasting for a very short period minimized the launch dispersion of missiles under various environmental conditions, particularly windy conditions. With a predictable trajectory, an operator could visually acquire the missile in his sight more rapidly and begin guiding it. A high launch dispersion is highly undesirable as the missile may not enter the operator's view in his sight after launch, forcing the operator to search for it with his naked eyes.

3N13 WARHEAD

The warhead section consists of the shaped charge warhead, the EMGK fuze, and the metal fairing containing the entire assembly. In total, the warhead section has a weight of 5.4 kg. It is important to note that this is the weight of the entire warhead section, not of the 3N13 shaped charge itself. Together with the conical nose fairing of the warhead, the EMGK fuze gives the "Shmel" a nondescript profile, practically indistinguishable from the nose profiles of a variety of anti-tank grenades, tank-fired HEAT shells, and a few other ATGMs like the West German Cobra. There is no resemblance whatsoever to the more streamlined, ogive fairings of the French first generation ATGMs.

The EMGK fuze is a percussion spitback fuze with a mechanical percussion primer and a tetryl relay. Its firing train has a two-stage electro-pyrotechnic arming mechanism. The first stage consists of a microswitch that is only tripped when the missile is launched from the appropriate launch rail. The second is a mechanical safety shutter between the percussion mechanism and the tetryl relay, which ensures that the firing train is physically blocked before the missile has traveled a certain distance from the launcher and thus the non-functioning of the fuze. This shutter is opened when the sustainer engine is ignited, whereby propellant gasses vented from the sustainer engine are ported to the nose of the missile fuselage via a gas tube, to shift the shutter of the firing train. The image below shows the fuze in its unarmed (left) and armed (states). As the diagram on the left shows, if the striker is pushed before the mechanical shutter is shifted, the striker head is stopped in an empty cavity in the shutter, and is simply returned to its place by a coil spring.

Once the tetryl relay is detonated, the shock causes the spitback charge to detonate, forming an EFP out of the concave lining on the base of the spitback charge. The EFP travels down the apex tube of the funnel-shaped shaped charge liner into a receptacle in the base section of the EMGK fuze, impacting a relay charge, which then subsequently sets off a detonator charge. The detonator charge acts as a booster charge that is necessary to detonate the insensitive main charge. Though this firing train may seem convoluted, the only moving parts in the fuze mechanism are the striker and the safety shutter. All other portions are chemical in nature.

Due to the use of a very conservative striker-based percussion fuze design rather than a piezoelectric type, the 3M6 may have fuzing issues on highly sloped armour surfaces, and it is certainly not graze-sensitive. That said, this was not unusual. Even the SS.10, which had a streamlined crush fuze integrated into the ogival aerodynamic fairing, still relied on having only the tip of the nose crush against an internal electrical contact, limiting the permissible impact angle.

The 3N13 warhead has a copper shaped charge cone, a filling of A-IX-1 and features a wave shaper. A-IX-1 was the first and most widely used hexogen formulation in the USSR, and is known as Gekfol (Гекфол), which is a portmanteau of hexogen (гексоген) and phlegmatizer (флегматизатор).

It is evident from cross sectional drawings and photos that the diameter of the warhead is slightly smaller than the 136mm diameter of the missile fuselage, but the real diameter is not known. The built-in standoff distance is around 2 CD.

In terms of diameter, the 3N13 warhead could be considered to be of a respectable size, close to the fuselage diameter. Based on cutaway drawings taken from the technical manual, the charge diameter is around 110mm, making it equivalent in same size to the 110mm warhead of the SS.10. It is stated in the book "Armements Antichars Missiles Guidés Et Non Guidés" by COMHART the SS.10 warhead used a hexolite explosive charge composed of an RDX/TNT mix with a 63% RDX content. It is equivalent to Comp. B, and substantially weaker than phlegmatized hexogen compositions such as A-IX-1, with a lower detonation velocity by around 10% (7,900-8,000 m/s). It is credited with a penetration of 400mm RHA or 200mm on a plate sloped at 60 degrees. The larger 125mm warhead of the SS.11, filled with the same hexolite charge, was credited with 500mm of penetration in the COMHART book.