The T-10 heavy tank was formally revealed to the public in its first and only Red Square appearance on the 7th of November, 1957 in the parade for the 40th anniversary of the Great October Socialist Revolution with the T-10 obr. 1956 model representing the series. The parade was held just one month after the successful launch of Sputnik 1, the first artificial satellite to enter low Earth orbit in human history. Among those that made their first appearance on Red Square were the new R-5M mobile strategic nuclear missile on its transporter, the T-54 medium tank, the ZSU-57-2 self-propelled anti-aircraft gun system, and many others, marking this parade as one of the most grandiose political-military displays of the decade as well as one of the most significant from a military intelligence standpoint.

The T-10 was the culmination of over a decade of continuous heavy tank development in the Soviet Union and is the most advanced design of its class to see service in its homeland. It was also arguably the sleekest of all Soviet heavy tank designs, having extremely well-sloped armour on both its hull and turret arranged in a rather pleasing way. As a series, the T-10 boasted a level of technological sophistication that was unmatched in the Soviet Army until the T-64 entered service, and even then, there was significant overlap in the capabilities of the two classes. Soviet armoured doctrine saw the heavy tank as a breakthrough weapon capable of operating independently or alongside other armoured vehicles in mixed tank units that can, by design, eliminate any opposition that a medium tank cannot.

In fact, this was the same general doctrine that dictated the deployment of the M103 heavy tank in the service of the U.S Marines, which made little distinction between heavy and medium tanks in the operational sense. Ken Estes, who is probably the world's foremost expert on the M103 tank series, notes in page 38 of "M103 Heavy Tank: 1950-1974" that "there was no specific doctrine calling for the support of medium tanks in the field by heavy tank units, and in general it was assumed that the specific situation at hand would determine if the heavy tank company would support an infantry regiment in combat, form as part of the division’s antitank plan, or, in the rare case that the tank battalion was used en masse, to operate as part of an armored task force".

The T-10 was organized into heavy tank regiments which would be integrated into a tank division alongside two medium tank regiments. It could also be organized to form heavy tank divisions, but as the purpose of heavy tank divisions on the strategic scale became uncertain in the USSR during the late 1950's, they were eventually declared obsolete, making heavy tank regiments the largest dedicated unit size for heavy tanks.

The development of the T-10 was managed by Zhozef Yakovlevich Kotin, the chief designer of the Chelyabinsk Kirov Plant (ChKZ) design bureau who was previously responsible for the IS-2 and the IS-3, and the design work was handled by chief designer M.F Balzhi who had previously been involved in the design of both the IS-3 and IS-4. The new heavy tank was developed to be the direct successor of the IS-3 (Object 703) and IS-4 (Object 701). Needless to say, an evolutionary progression in tank technology is quite natural, but in this instance, it was prompted by the inadequacies of the first postwar heavy tanks. Problems with the IS-3 emerged shortly after it entered service and it was tentatively supplanted by the IS-4, but the IS-4 itself turned out to be rather flawed and it was discontinued just three years after production began. Conceptually, both of these tanks were designed during WWII and were created under late-war requirements with a late-war engineering school of thought which made them less than adequate for the needs of a postwar USSR.

In the December 2012 edition of the "Отечественные Бронированные Машины 1945-1965" series of articles authored by M.V Pavlov and published in the "Техника И Вооружение" magazine, Pavlov states in page 54 that the IS-4 failed its 1,000 km mobility trial due to the failure of the final drives, destruction of roadwheel and idler wheel bearings, failure of the oil pressure gauges in the engine, premature wear and destruction of the brake pads, failure of the transmission, failure of the hydraulic transmission control mechanism, and more.

Pavlov also mentioned other severe shortcomings of the tank, such as the unacceptably noisy fans of the cooling system. The whistling noise from the pair of radial cooling fans on the engine deck caused such a high amount of acoustic interference that it actually shortened the range of the onboard radio transceivers, and the fans could reportedly be heard from a staggering distance of 7-8 kilometers while the tank was moving. The concentration of carbon monoxide in the tank from the engine and from propellant fumes was also unacceptably high, making it difficult for the crew to operate the tank effectively. To top it all off, the escalation in weight led to one IS-4 costing almost three times as much as an IS-3 without bringing an equal increase in combat effectiveness. Much of this cost was related to the short supply of thick rolled steel armour plates and the difficulties in assembling a tank with such thick armour.

This is all the more unfortunate when earlier on, the initial IS-4 design (Object 701) still had a more modest combat weight of 55 tons in its prototypical form and it exceeded the IS-3 in several technical characteristics including tactical mobility such as having a 25% higher average speed when moving cross-country despite being a heavier tank. Mobility trials confirmed that the IS-3 was quicker and the difference in the mobility between the Object 701 and IS-3 continued to increase as the Object 701 gained more armour in later prototypes. At this stage, the IS-7 was still optimistically projected to weigh just 54-56 tons. In actuality, the pursuit of all-round armour protection would cause the IS-4 to bloat to a combat weight of 60 tons and the IS-7 would weigh a staggering 68 tons. The issues that arose from the weight gain made the IS-4 unsustainable; the mass production of the IS-4 was terminated on the 9th of April 1947. The IS-4M modernization was created with the aim of fixing these issues or at least ameliorating them, but not all IS-4 tanks were modified to this standard by the time the programme was terminated on the 22nd of March 1949.

On the 9th of April 1952, all IS-4 and IS-4M tanks were withdrawn from their frontline stations and relegated to the Reserves of the Supreme High Command (RVGK) - the strategic reserves - and served in this capacity in the Far Eastern Military District. When the Korean War took off, military units stationed in this district including IS-4 tanks were sent to Primorsky Krai (Manchuria) to secure the border between the USSR and North Korea, and when the Sino-Soviet split occurred, IS-4 units stationed in the Far Eastern Military District were mobilized once again and sent to the Transbaikal region bordering China, and the ones stationed in Manchuria were turned towards also China.

In practice, the troubles with the IS-4 meant that the IS-3 was the de facto heavy tank of the Soviet Army despite its own flaws which were being gradually ironed out in new tanks during production and later corrected on existing tanks via an expensive refurbishment programme to become the IS-3M.

The plethora of issues plaguing the IS-4 prompted great skepticism towards the IS-7 as the latter represented an even greater escalation in weight. This had an indirect effect on the eventual rejection of the IS-7 and catalyzed the decision to restrict the weight of all future heavy tanks. On February 18th 1949, the Council of Ministers of the USSR passed resolution No.701-270ss which formally prohibited all further work on heavy tanks with a mass of more than 50 tons. This would allow the crossing of civilian bridges, pontoon bridges, and other tactical bridges for crossing obstacles as these had a weight limit of 50 to 60 tons. It would also allow the heavy tank to be transported piecemeal by rail as the maximum weight capacity set by Soviet railway authority at the time was 55 tons. Attached to resolution No.701-270ss was the order for the LKZ and ChKZ design bureaus to develop a new heavy tank with a weight of 50 tons or less. The Object 730 prototype of the new tank, designed by the ChKZ design bureau with Zhozef Kotin at the helm, was ready for trials just seven months later under the tentative designation of IS-5, not to be confused with the Object 248 prototype from 1944 that was also known as "IS-5".

The IS-5 had a hull design taken directly from the IS-7 but streamlined and trimmed down for reduced weight at the expense of armour protection. Its turret was a completely original design. The IS-5 had the transmission of the IS-4 and used a similar cooling system driven by a pair of large axial cooling fans on the engine deck in the same style as the IS-4, closely patterned after the cooling fans used on the German Panther tank. The image below shows the IS-5 in its 1949 configuration with all of these features.

However, the reliability issues of the IS-4 transmission reemerged on the IS-5. The test report noted the following:

"1. Испытание машины начато 22.09.49 г. за это время она прошла 1012 км, из них:а) проселочная дорога — 501 км;б) пересеченная местность — 511 км.

2. Двигатель проработал 67 ч 36 мин.

3. В процессе испытаний получены следующие средние скорости чистого движения:

а) проселочная дорога 29–27 км/ч;

б) мокрый луг 17,7-16,5 км/ч;

в) болотистый луг (движение осуществлялось преимущественно погружением клиренса), пройдено 314 км 12–14 км/ч.

На отдельных участках сухого пути получали скорость 31–27 км/ч.

4. Основные дефекты:

а) Разрыв и разрушение по швам и целому телу алюминиевых топливных баков после 441 км. Внутренние баки заменены на стальные.

б) Выход из строя обоих бортовых редукторов по причине закручивания и изгиба ведущих валов.

5. В настоящее время машина находится на втором техническом осмотре"

Translated to English:

1. The test of the machine started on 22.9.49 during which it covered 1,012 km, of which:a) Country roads - 501 kmb) Rough terrain - 511 km

2. The engine worked for 67 h 36 min

3. During the test, the following average net speeds were obtained:

a) Country roads 29-27 km/h

b) Wet meadow 17.7-16.5 km/h

c) Marshy meadow (the movement was carried out mainly with sunken clearance), covered 314 km at 12-14 km/h

On some parts of dry roads, the speed was 31-27 km/h.

4. Major defects:

a) Formation of gaps and the destruction at the seams and the whole body of aluminum fuel tanks after 441 km. Internal tanks replaced by steel tanks.

b) The failure of both final drives due to the tightening and bending of the axles.

5. At this time, the machine is undergoing the second technical inspection (author's note: second level of maintenance as part of a planned maintenance schedule).

The main emphasis of the test was that the transmission was unreliable. The tank failed its 2,000 km factory warranty trial due to the failure of the transmission, signalling the need for a new and more robust design. As a result, a new 8-stage planetary transmission was installed in the tank. During the course of the redesign, many other refinements were made to the tank, including the replacement of the fan-based cooling system with a forced-ejection cooling system inspired by the IS-7 project. By the time the tank entered service as the T-10, it combined several of the successful design features of the IS-4 running gear with several features from the IS-7, so it can be said to have an amalgamation of all the best parts of its predecessors in a refined form. At that point, the "Object 730" designation had been applied to three modifications of the same tank under three different names.

Although the T-10 obr. 1953 (right below) was externally similar to the first IS-5 design from April 1949 (left below), the end product had several distinguishing features. The hull underwent minimal modifications, but the turret was given a more rational distribution of armour thicknesses. The armour protection was somewhat increased, and as testing of the tank continued in the mid-1950's, improvements to the casting technology and the distribution of armour mass were continuously made on the production line.

With the less-than-glamorous history of the IS-3 and IS-4 in mind, the T-10 could be rightfully considered the most successful heavy tank to serve in the Soviet Army during peacetime and was unquestionably a good, solid tank worthy of its place, at least by the standards of typical heavy tanks as the T-10 still had all of the drawbacks commonly associated with its class such as high production and maintenance costs and a somewhat low cost effectiveness relative to its actual combat capability. The strategic decision to impose an artificial weight limit of 50 tons undoubtedly had a large influence on the relatively unproblematic career of the T-10.

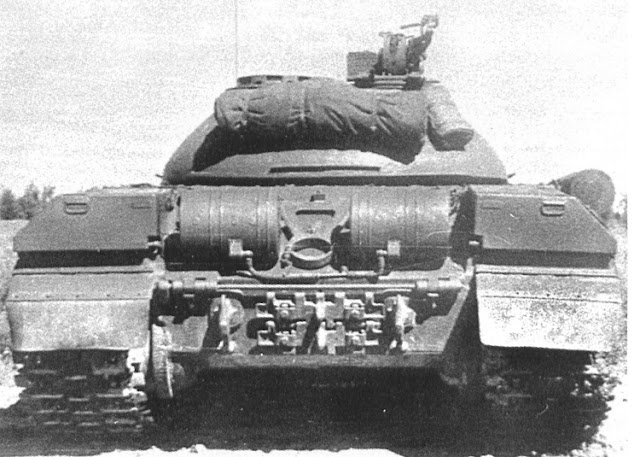

While the IS-4 primarily served in the reserves and only lasted only a few years in active service, the T-10 saw over a decade of active service in the Western Military District as the backbone of Soviet heavy tank divisions before being slowly withdrawn to the strategic reserves during the tail end of the 1960's, and several heavy tank units equipped with T-10M tanks even continued to serve in the GSFG until the late 1970's. Some sources state that the withdrawal of the last T-10M battalion occurred in 1979.

On the 28th of November 1953, the T-10 officially entered service in the Soviet Army and on the 15th of December 1953, the order was given to put the new heavy tank into mass production under the product code of Object 730. Factory No. 200 was responsible for the manufacture of turrets and hulls. Production of the original T-10 was slow, with only 30 units produced in 1954, 90 units produced in 1955 and 70 units produced in 1956 when the production run ended. Together with the ten pre-production tanks manufactured in 1953 prior to the official induction of the tank into the Soviet Army, the total number of T-10 tanks amounted to only 200 units. This paltry figure was less than a tenth of the total number of IS-3 tanks produced during its own short run and was utterly miniscule compared to the production run of workhorse tanks like the T-54, but even so, even at this early stage the T-10 series already outnumbered the Conqueror of which only 185 examples were built in a longer production run from 1955 to 1959.

However, these T-10 tanks had a number of issues related to the poor quality control of Factory No. 200 for the manufacture of the cast turrets. In 1954, a whopping 50.9% of the turrets of the tanks delivered to the Soviet Army exceeded the design mass of 6,500 kg by the tolerance limit of 5% (325 kg). This improved to 11.5% by 1955, but it was revealed during extensive live fire tests in the same year that 32% of the tested turrets (22 in total) did not meet the design specifications for ballistic resistance. As such, it was recognized that further refinement of the turret design was still needed in order to curb the wastage of resources and ensure that the design criteria for protection could be met consistently. The two photos below show one of the T-10 tanks built in 1954.

On the 17th of May 1956, the T-10A entered service and began production at ChKZ under the product code of Object 731. Although this model officially replaced the T-10 on the production line, there was a transitional period of a few months where both models were being produced simultaneously, with many components being shared by both. Less than one year later, the T-10B entered service on the 11th of February 1957 and began production at ChKZ under the product code of Object 733. Only 110 examples of the T-10B model were delivered when on the 26th of September 1957, the T-10M entered service and fully replaced it on the production line the next year. It had the product code of Object 272. Interestingly enough, the T-10M had a combat weight of 51.5 tons so it exceeded the official weight limit by just a hair, but this was likely considered acceptable as it was still well within the 55-ton railway load limit.

The T-10M obr. 1957 was manufactured simultaneously at both ChTZ and LKZ, but in slightly different forms. The ChTZ factory produced the Object 734 and the LKZ factory produced the Object 272. The two factories produced slightly different models because the ChTZ factory had only recently mastered the production of T-10 hulls when the new Object 272 design from LKZ was adopted as the next primary tank model. Because ChTZ was unable to switch production to the new Object 272 hull rapidly, they had to resort to the compromise solution of mating Object 272 turrets to Object 730 hulls, thus creating the Object 734, known as the Chelyabinsk T-10M as opposed to the original Leningrad T-10M. In 1962, ChTZ was finally prepared to switch to producing Object 272 hulls, so both factories were standardized on the Object 272 specifications. The final modification of the T-10M entered service in 1963 as the T-10M obr. 1963 and the tank continued to be manufactured in this form until 1965.

From 1953 to 1965, a total of 1,439 T-10 tanks and variants thereof were produced in the USSR. The T-10M lasted the longest on the production lines by far and can be considered the definitive representation of the T-10 series, being not only the most advanced model but also the most numerous by a large margin. Although no modernization programmes to bring earlier T-10 models to the T-10M standard were carried out in the USSR, some tanks were retrofitted with night vision equipment to close the gap in capabilities. Some tanks only received a partial modernization as not all parts and facilities were available for the units equipped with T-10 tanks.

To put the production figures of the T-10 into perspective, it can be compared to the M103 and the Conqueror. In 1955, the first Conqueror was built in the Royal Ordnance Factory and production continued until 1959, ending with a total of 185 tanks delivered to the British Army. A total of 20 Mark 1 and 165 Mark 2 Conquerors were built.

The M103 was much more numerous, but the time frame of its deployment was relatively late compared to the T-10. The T43E1 prototype of the M103 heavy tank (it was not designated the M103 yet because it had not been type-classified) entered mass production at approximately the same time as the T-10 but was considered unfit for service in its initial form. The Continental Army Command (CONARC), had finished testing these T43E1 tanks and found them unsatisfactory for issue to the troops as of June 20, 1955. A total of 144 modifications were deemed necessary, but due to the lack of urgency after the conclusion of the Korean War, the Army opted for a simpler refurbishment that applied just 98 of the 144 modifications. The M103 was type classified on the 26th of April 1956 and the first batch of 80 M103 tanks that were modified to the Army standard were operational by the middle of 1957 after troops trials in early 1957 had concluded. By this time, a decade had passed since the production of the IS-3 ceased, the T-10B had already begun mass production and the T-10M was only a year away from replacing it on the production line.

Only around 300 examples were produced, which is barely more than a fifth of the final size of the T-10 fleet. That said, the U.S Army had abandoned all of their heavy tank projects and moved on from the heavy tank concept and had shifted the focus on a main battle tank that could combine the capabilities of a medium tank and a heavy tank in a new and rather forward-thinking battle doctrine. Ultimately, this would prove to be the correct mindset even though the main battle tank borne from the new doctrine, the M60A1, did not have most of the characteristics that are now considered essential for a tank to truly belong under this classification. Ironically, the new main battle tank that made heavy tanks redundant in the eyes of the U.S Army bureaucracy became a source of upgrades for the M103A1 which was overhauled with a large number of M60 components to become the M103A2.

When the production of the T-10M ceased in 1965, it ended its eight-year production run and twelve years had passed since the original T-10 was accepted into the Soviet Army. The primary factor in the eventual downfall of the T-10 was not in any particular flaw in its design or in any deficiencies of its technical characteristics. Rather, it was a combination of various new developments in tank technology leading to the obsolescence of heavy tanks as a class. The main domestic threat to the existence of the T-10M was the excellent performance and stellar cost effectiveness of the T-54 medium tank, and the threat was further amplified by the appearance of the T-62 with its powerful 115mm smoothbore gun and APFSDS ammunition which would have been more effective against the armour of tanks like the M60A1 than any full caliber AP shell, thus voiding some of the firepower advantage that the T-10M previously held over medium tanks. The gap in the payload of the HE-Frag shells between the 122mm M62-T2 and the 115mm U-5TS was also much smaller than the gap that existed between it and the 100mm D-10, further eroding more of the credibility of the T-10 series as a viable instrument of war.

The final blow to the T-10 series and to Soviet heavy tank development in general was dealt by the materialization of the main battle tank concept in the Soviet Union in the form of the T-64 which was not only more mobile than the T-10M, but also more heavily armoured and exceeded it in terms of firepower thanks to an automatically loaded 115mm 2A21 smoothbore cannon with a highly sophisticated fire control system that included a fully stabilized optical rangefinder.

In 1961, the order to terminate all work on heavy tanks was given by the Council of Ministers, but before this, the induction of new vehicles based on heavy tanks had already begun to wind down. For instance, the well-known Object 268 casemated self-propelled gun based on the T-10 hull had passed state trials during the late 1950's and was ready to formally replace the ISU-152 of WWII vintage, but the new tactical and technological trends in armoured warfare did not favour this class of vehicle. A reevaluation of the heavy tank concept yielded the same conclusions. Not only could main battle tanks accomplish all the tasks that were normally delegated separately to medium and heavy tanks, but the tactical-technical characteristics of a main battle tank exceeded both classes of tanks in all operating characteristics including mobility, firepower and armour protection while remaining within the weight category of medium tanks.

The T-10M continued to serve as a frontline heavy tank in the GSFG until the end of 1976, after which they began to be withdrawn from Germany. Some were sent to training regiments before eventually being delivered back to the Soviet Union. The photo above shows a T-10M of the GSFG photographed in 1974. The withdrawal of the T-10M in 1976 coincided with the deployment of the T-64A main battle tank to the GSFG in the same year, although some units were reequipped with T-55 medium tanks instead. T-10 tanks of all models entered reserve storage and starting from the mid-1980's, they began to be written off, were stripped and used as hard targets at gunnery ranges, or simply scrapped. On the 23rd of September 1997, a presidential decree was issued to officially remove the T-10 series from service and all tanks remaining in storage were ordered to be scrapped

Overall, the T-10 was a low-profile tank with good armour protection, a relatively low weight, high mobility characteristics, acceptable crew accommodations, an advanced fire control system and an effective complement of weapons at its disposal. By all metrics of tank quality, the T-10M model was a serious contender for the best tank of its class during its heyday.

INDEX

- Ergonomics

- Ventilation

- Commander's Station

- Communications

- Gunner's Station

- Sighting Complexes

- TSh2-27 Articulated Telescopic Sight

- TPS1 Stabilized Periscopic sight

- TUP-21 Auxiliary Telescopic sight

- T2S-29-14 Stabilized Periscopic Sight

- TPN-1-29-14 Night Vision Sight

- Loader's Station

- Ammunition Stowage

- Loading Assistance Device

- - for D-25TA, D-25TS

- - for M62-T2

- Rate of Fire

- TAEN-1 Powered Controls

- Stabilizers

- PUOT "Uragan"

- PUOT-2 "Grom"

- PUOT-2S "Liven"

- D-25TA, D-25TS

- Ammunition, 122x785mm

- M62-T2

- Ammunition, 122x759mm

- Coaxial, Anti-Aircraft Machine Guns

- DShKM

- Anti-Aircraft DShKM

- KPVT

- Anti-Aircraft KPVT

- Protection

- Hull

- Upper Glacis

- Lower Glacis

- Driver's Hatch

- Side Armour

- Belly Armour

- T-10, T-10A, T-10B Turrets

- T-10M Turret

- Firefighting System

- Smokescreening System

- Driver's Station

- Escape Hatch

- Mobility

- V12-5 Engines

- V12-6 Engines

- Cooling System

- Suspension

- Fuel System

- Water Obstacles

ERGONOMICS

It is popularly perceived that Soviet tanks were designed with little attention to comfort or safety and that Western tanks were generally the opposite. Although this is evident to be true in some cases, Soviet tanks generally met and sometimes exceeded the minimum ergonomic requirements stipulated by the U.S Army and were not any less safe to operate than any other tank. It's just that in many cases, American tanks (and tanks of other nations) usually exceeded these minimum requirements by a larger margin. However, the fulfillment of those minimum standards implies that the standards of comfort were sufficient to ensure that the tactical-technical requirements could be met.

It often goes unmentioned that Soviet tank designers had to pay attention to crew ergonomics while under the obligation to deliver a product that met the challenging set of requirements put forward by the GBTU (Main Directorate of Armoured Forces). However, ergonomics had not been firmly established as a formal science at the time so only basic stipulations were given for the required dimensions of the tank crew stations. Much of it was left to the discretion of the design bureau under the advice of the Main Military Medical Directorate of the Soviet Army.

The basic external dimensions of the hull did not change during the production run of the entire T-10 tank series. The height of the hull is 1,015mm from the fighting compartment floor to the fighting compartment roof, including the armoured belly and roof themselves. However, the floor underneath the transmission has a bulge with a depth of 47mm, so the maximum height of the hull is 1,046mm when measured from this point.

The torsion bar housings protrude below the hull belly, but do not protrude below the transmission bulge. Internally, the height of the hull in the fighting compartment measured from the rotating floor is only 835mm while the height of the hull at the driver's compartment is 969mm. The total length of the hull is 6,925mm. The total external width of the hull is 3,162mm when measured across the sponsons, and the width of the lower part of the hull is 1,790mm. These dimensions are nearly identical to the IS-3. The internal width of the hull at the lower half is 1,630mm and the maximum internal width of the hull is 2,810mm as measured across the sponsons.

One of the most common misconceptions is that the liberal application of sloped armour plating for the construction of the hull led to a reduction in interior volume, but there is no evidence for this. On the contrary, a closer inspection of the configuration of the hull as depicted in the cross-sectional drawing below immediately dispels this widespread misunderstanding and shows quite the contrary.

The hull belly is constructed from a steel plate pressed into the shape of a tub with steeply sloped sides which are joined to the side hull armour plates. This ostensibly cramps the interior of the tank and reduces the floor space in the hull to a narrow corridor, but in actuality, this space is only used to house the torsion bar suspension. The rotating floor for the three-man turret is mounted on a platform and lies on top of the torsion bar housings (140mm in height from the hull floor), giving the crew the full space provided by the internal width of the hull at the expense of the vertical space. Considering that conventional single torsion bar suspensions already take up almost the same amount of hull height in most cases. The loss of vertical space in this design is thus not directly related to the hull shape, but the torsion bars.

Nevertheless, the space underneath the rotating floor is not entirely wasted as small arms ammunition for the crew's personal weapons and some equipment is stored underneath it. The small arms ammunition can be retrieved through an access panel on the 6 o'clock sector of the rotating floor when the turret is locked in the forward position.

The internal width of the hull is notable, seeing as the rotating floor upon which the loader stands has a diameter close to the internal width of the lower part of the hull. For a lack of a written source, the diameter of the rotating floor is estimated to be 1,570mm based on factory drawings. This is very similar to the rotating floor in the Conqueror heavy tank which had a diameter of 1,625mm or 64 inches and it is considerably wider than the rotating floor of the T-54/55 which was 1,370mm in diameter. The remains of a partially rotted and highly vandalized rotating floor in a dilapidated T-10M can be seen in the photo below (photo from the Net-Maquettes website). The gunner's seat can be seen at the top left corner of the photo in its fully lowered position.

The turret ring diameter of all T-10 variants is 2,100mm. This figure lies squarely between the 2,160mm turret ring diameter of the M103 and 2,032mm turret ring diameter of the Conqueror. It is important to note that the turret ring of the IS-3 is only 1,840mm in diameter which is not only markedly inferior to the T-10 but also only negligibly larger than the 1,825mm diameter of the turret ring of the T-54. With the D-25T gun being a shared feature between the T-10 and IS-3, it is evident that the T-10 turret was markedly superior in the width and length of its fighting compartment.

The increased length of the fighting compartment helped to ensure that the physical spaces of the commander and gunner do not intersect. Like the vast majority of other tanks, both foreign and domestic, the T-10 places its commander's seat within the turret ring, so the space between the commander and gunner is directly linked to the turret ring diameter. Generally speaking, unless it is balanced out by the addition of more equipment in front of the gunner, a larger turret ring diameter usually meant that there was more space between him and the commander behind him. In the T-10, there is just under a meter of space behind the gunner's seat and more than enough space for the commander to sit with his knees well clear of the gunner's back, unlike in the T-54 where the commander needed to sit with the gunner between his knees. The drawing below shows the fighting compartment of a T-10B with the turret ring marked as a red circle.

Due to the large diameter of the turret ring and the impressive width of the hull across the sponsons, the internal volume from the perspective of the crew in the fighting compartment is relatively large. The photo below, taken from the Net-Maquettes website, shows a view of the hull from behind the fighting compartment. The rotating floor of the turret can be seen in the bottom left corner.

Combined, the hull and turret structures for the T-10 up to the T-10B measure 1,881mm in height. Measured from the ground, the height of the hull is 1,506mm, making it much shorter than an average man. This is a normal height for any tank.

The total height of the tank measured to the top of the commander's cupola is 2,460mm for the T-10, T-10A and T-10B, and 2,585mm for the T-10M. However, the height of the tanks when measured up to the turret roof was just 2,300mm for the first three models and 2,427mm for the T-10M. When the ground clearance of the tank is taken out of the equation, the structural height of the tank is only 1,807mm for the first three models and only 1,930mm for the T-10M. This was directly comparable to the T-54 and it was considerably shorter than Western medium tanks like the M47 and M48 Pattons and the Centurion, not to mention Western heavy tanks.

The increased height of the T-10M was entirely due to the slightly taller turret which accommodated a gun depression angle of -5 degrees for its M62-T2 gun instead of the normal -3 degrees for the D-25T series of guns mounted in previous models, although the design of the turret itself is only partly responsible for providing the additional two degrees of depression. A full examination of this topic is provided in the section of this article on the M62-T2 gun. Both the Object 272 from Leningrad and Object 734 from ChTZ shared the same height despite the retention of the basic T-10 hull on the Object 734 since they both shared the same turret.

Internally, the height of the T-10 fighting compartment in the turret was 1,600mm as measured from the rotating floor to the ceiling of the turret. This is the same as the IS-2, IS-3, T-54, and several other Soviet tanks of the era. The two images below give a good perspective on the height of the tank scaled against Soviet tankers.

Naturally, a side effect of the increased height of the T-10M turret is the increased headroom for the crew, and most importantly, for the loader. The internal height of the T-10M as measured from the rotating floor to the turret ceiling is 1,725mm which is tall enough that standing completely upright may be possible for an average Soviet military age male who would have a height of 1.7 meters. The loader also has a cupola which is raised above the turret roof, so in practice, he could have more headroom if he stands directly underneath his cupola when performing some loading actions.

For a seated gunner or commander, shoulder height and seated height are the most important dimensions. The amount of space needed for these two crew members to carry out their duties effectively is not large, especially for the gunner who practically does not need to move at all if his controls are well laid out. The commander in a T-10 needs space to operate the radio, read maps, and so on, but in combat, his main tasks are to observes the battlefield through the viewing devices in his cupola, receive orders from his superiors or transmit orders to subordinate tank commanders (as a platoon or company leader) and to micromanage the rest of the crew using verbal commands, neither of which require a large working space. For a loader, however, space is much more important as his duties are inherently much more physical. The most important dimensions for a loader are the standing height, elbow width, and elbow height.

The width of the hips of an average man is only 350mm but the shoulder width of an average man is 450mm. Immediately it becomes obvious that it is possible to optimize the layout of a tank by narrowing the hull and increasing the width of the turret. The width of the loader's station should be as large as possible at elbow height as a human loader grasping a large caliber cartridge would hold it at elbow height, but generally speaking, the maximization of the internal width of the tank above the hip level of a standing man is beneficial to all the members of the crew, especially the loader.

Because of such nuances, it is not really possible to accurately express crew conditions by simply looking at the volume of the crew members' stations, although it can certainly be used as a tool for comparing two tanks with similar layouts and internal dimensions to some extent.

The photo below, from "T-10 Heavy Tank and Variants" by James Kinnear and Stephen Sewell, shows the left side of a T-10M turret. Without actual crew members sitting on the seats for the commander and gunner, it is somewhat difficult to form an accurate perspective on the amount of space provided for the two men but at least the layout of the equipment and furniture can be appreciated from this angle.

The inclusion of sponsons allowed a turret ring of a larger diameter to be implemented than would otherwise be possible with a hull that had completely vertical sides, that is, unless special platforms extending from the sides of the hull were used to accommodate the turret ring. This is best exemplified by the T-62 medium tank which features a 2,245mm turret ring despite having a hull with a width of only 2,020mm. This design solution enables a turret ring of a larger diameter than the maximum width of the hull to be installed, but there is no possibility of stowing a significant amount of ammunition or equipment in the extensions. The area above the tracks can still be used as a stowage space, but only expendable items such as tools and spare parts or fuel can be placed in these areas due to the lack of armour protection.

In the drawing above, it can be seen that ammunition is stowed in the hull sponsons and that additional external stowage space is available underneath the sponsons in sheet metal bins. The bins all had the same shape and general dimensions, differing only in length and in the number of hatches. There is a long bin with two hatches, a short bin with one hatch, and one long bin with one hatch.

The hatches are hinged to open upward, allowing items to be placed inside the bins easily. This was a notable improvement over the IS-7 stowage bins which had an unconventional design that was simple to a fault. It is demonstrated in Nicholas Moran's "Inside the Chieftain's Hatch" video on the IS-7, Part 1.

Two more stowage bins were added to the fenders on the T-10M model. The additional stowage space was probably appreciated by the crews but unfortunately, the bins also slightly disrupted the sleek prow of the tank. The photo on the left below is from Dave Haskell and the photo on the right below is from the Net-Maquettes website.

As usual for a Soviet tank of the 1950's, the standard-issue tarpaulin was strapped to the rear of the turret. The tarpaulin was a general-purpose item but it was often used as a tent. One excellent way of using it on cold nights was to turn the turret back and elevate the gun to its highest angle, and then draping the tarpaulin over the gun barrel. The crew would then sleep on the toasty engine deck which would remain warm until daybreak.

In 1959, the T-10M received an add-on metal stowage bin on the turret bustle. The tarpaulin which previously occupied this area was relocated to the right side of the turret. The beveled shape of the stowage bin was dictated by the need to ensure free air flow to the engine air intake and the radiator intakes on the engine compartment deck.

The bin is made from light gauge sheet metal so it does not significantly increase the protection of the rear of the turret nor does it offer much protection for its contents from gunfire, shell splinters or fragments, but its location makes it much less likely to suffer damage compared to all other stowage bins on the T-10. It is waterproof when sealed properly and will survive a snorkeling operation. The stowage bin is accessed from single large curved hatch on the top.

The width of the bustle stowage bin was close to the total width of the turret and it occupied the entire height of the bustle, so it was quite spacious. This bin was mainly used for stowing the personal effects of the crew and it was much more useful in this role than the sponson bins which were more exposed to direct fire and could potentially be blown off if the tank ran over a mine.

The total internal volume of the tank was 12.72 cubic meters, of which 8.21 cubic meters was allocated for the crew compartment and 4.51 cubic meters for the engine compartment. This was not particularly large compared to contemporary Soviet medium tanks such as the T-54 and T-62. For reference, the total internal volume of the T-54 measured in at 11.4 cubic meters, of which 8.05 cubic meters forms the crew compartment and 3.35 cubic meters forms the engine compartment, and the T-62 has a total internal volume of 12.5 cubic meters and the crew compartment occupies a volume of 9.23 cubic meters. From this, it seemingly appears that the T-10 is more spacious than a T-54 but more cramped than a T-62, but as always, further examination is necessary to gain a more detailed understanding of the true situation.

Given that many components from the T-10 and the two medium tanks share similar dimensions or are outright identical as is the case with the radio equipment, the main differences lie in the size of the cannon and the ammunition, and immediately the T-10 loses out in spaciousness. The massive 122mm cannon of the T-10 and T-10M is larger than the 100mm cannon of the T-54 and the 30 rounds of bulky 122mm cartridges take up more space than the 34 rounds of 100mm cartridges carried in the T-54. However, the T-10 does not carry any fuel in the fighting compartment whereas the T-54 holds 530 liters of fuel in four internal fuel tanks, two of which occupy useful space in the fighting compartment. As such, the available space in the T-54 is lower by 0.53 cubic meters which somewhat offsets the difference in the size of the gun and ammunition.

Of the internal volume allocated for the fighting compartment of the T-10, the driver's compartment at the front of the hull occupied 1.35 cubic meters and the fighting compartment occupied 6.86 cubic meters. According to the article "Human Factors and Scientific Progress in Tank Building" by M.N. Tikhonov and I.D. Kudrin, the commander is allocated a volume of 0.871 cubic meters, the gunner is allocated a volume of 0.367 cubic meters, the driver is allocated a volume of 0.650 cubic meters and the loader is allocated a volume of only 0.762 cubic meters. In total, the crew of the turret appears to have 2.0 cubic meters of space and the remaining 4.86 cubic meters of volume is dedicated to the internal equipment of the tank.

Two hatches were installed on the roof of the turret, one for the commander as a part of his cupola assembly and one for the loader. The gunner is forced to exit through the commander's hatch if the crew is ordered to bail out. This is not ideal in terms of individual crew comfort and the speed of a hasty escape, but this arrangement was normal for manually loaded tanks. For comparison, the Conqueror was equipped with three roof hatches on its turret; one for each crew member stationed within. This was possible because of the unconventional seating arrangement with the commander stationed in the turret bustle, separated from the rest of the turret crew. Both hatches were of the lift-and-swing type so that they do not interfere with the commander's view from his cupola if left open for whatever reason. The downside of the unconventional layout that this made for a very long and heavy turret and created an enormous shot trap at the rear of the turret.

The worst design by far was the turret of the M103. Like in the Conqueror, the commander was seated separately in the bustle in an exceptionally large and long turret and he was provided with his own hatch, but the gunner and two loaders were forced to share a single roof hatch that was officially termed the "front loader's escape hatch" since it was directly over the front right loader's station. The hatch layout of all three tanks can be seen in the drawings below and the size of their turrets can also be appreciated.

Two 20-liter jerry cans for drinking water were provided in the T-10M. They were stowed side-by-side on the hull wall to the left of the driver, behind the accumulator pack.

For ventilation, the T-10 featured an intake fan and two exhaust fans that worked to blow air through the crew compartment. The ventilator intake fan is prominently placed on the turret roof, and the two ventilator exhaust fans were installed in the bulkhead between the fighting compartment and the engine compartment. These worked by drawing air from the crew compartment and passing it into the engine compartment. Each fan was driven by an MV-42 electric motor with a power of 175 watts, which is extremely powerful considering that the internal volume of the crew compartment is only 8.21 cubic meters. The two top corners of the drawing below show the two ventilator exhaust fans. The bulkhead is not present in the drawing, revealing the engine and the engine air supply system.

During combat, the ventilation intake fan on the turret roof acts as a blower that brings fresh air into the fighting compartment, and also serves to remove some propellant fumes after each shot is fired by blowing the fumes downward where they are sucked out of the fighting compartment by the exhaust fans. The drawing below shows the position of the ventilation fan in the turret of a T-10B. Its location is the same in the T-10 and T-10A.

The drawing on the left below shows the location of the fan from another perspective and the drawing on the right shows a cross section of the entire ventilator dome, including the S-shaped design of its intake duct. This shape prevents bullets impacting the dome from hitting the fan itself through the duct.

Naturally, it is desirable to keep the hatches opened in hot weather so that the maximum amount of fresh air can enter the crew compartment, but when the hatches are closed, air can only enter the tank through a few possible intakes: the gaps in the gun mask, the gun barrel bore (if the gun is not loaded), the ventilation intake fan on the turret roof, small gaps in the turret ring between the turret and the hull, gaps in the periscope mountings, and gaps from the imperfect seals of the hatches.

The internal width of the hull is notable, seeing as the rotating floor upon which the loader stands has a diameter close to the internal width of the lower part of the hull. For a lack of a written source, the diameter of the rotating floor is estimated to be 1,570mm based on factory drawings. This is very similar to the rotating floor in the Conqueror heavy tank which had a diameter of 1,625mm or 64 inches and it is considerably wider than the rotating floor of the T-54/55 which was 1,370mm in diameter. The remains of a partially rotted and highly vandalized rotating floor in a dilapidated T-10M can be seen in the photo below (photo from the Net-Maquettes website). The gunner's seat can be seen at the top left corner of the photo in its fully lowered position.

The turret ring diameter of all T-10 variants is 2,100mm. This figure lies squarely between the 2,160mm turret ring diameter of the M103 and 2,032mm turret ring diameter of the Conqueror. It is important to note that the turret ring of the IS-3 is only 1,840mm in diameter which is not only markedly inferior to the T-10 but also only negligibly larger than the 1,825mm diameter of the turret ring of the T-54. With the D-25T gun being a shared feature between the T-10 and IS-3, it is evident that the T-10 turret was markedly superior in the width and length of its fighting compartment.

The increased length of the fighting compartment helped to ensure that the physical spaces of the commander and gunner do not intersect. Like the vast majority of other tanks, both foreign and domestic, the T-10 places its commander's seat within the turret ring, so the space between the commander and gunner is directly linked to the turret ring diameter. Generally speaking, unless it is balanced out by the addition of more equipment in front of the gunner, a larger turret ring diameter usually meant that there was more space between him and the commander behind him. In the T-10, there is just under a meter of space behind the gunner's seat and more than enough space for the commander to sit with his knees well clear of the gunner's back, unlike in the T-54 where the commander needed to sit with the gunner between his knees. The drawing below shows the fighting compartment of a T-10B with the turret ring marked as a red circle.

Due to the large diameter of the turret ring and the impressive width of the hull across the sponsons, the internal volume from the perspective of the crew in the fighting compartment is relatively large. The photo below, taken from the Net-Maquettes website, shows a view of the hull from behind the fighting compartment. The rotating floor of the turret can be seen in the bottom left corner.

Combined, the hull and turret structures for the T-10 up to the T-10B measure 1,881mm in height. Measured from the ground, the height of the hull is 1,506mm, making it much shorter than an average man. This is a normal height for any tank.

The total height of the tank measured to the top of the commander's cupola is 2,460mm for the T-10, T-10A and T-10B, and 2,585mm for the T-10M. However, the height of the tanks when measured up to the turret roof was just 2,300mm for the first three models and 2,427mm for the T-10M. When the ground clearance of the tank is taken out of the equation, the structural height of the tank is only 1,807mm for the first three models and only 1,930mm for the T-10M. This was directly comparable to the T-54 and it was considerably shorter than Western medium tanks like the M47 and M48 Pattons and the Centurion, not to mention Western heavy tanks.

The increased height of the T-10M was entirely due to the slightly taller turret which accommodated a gun depression angle of -5 degrees for its M62-T2 gun instead of the normal -3 degrees for the D-25T series of guns mounted in previous models, although the design of the turret itself is only partly responsible for providing the additional two degrees of depression. A full examination of this topic is provided in the section of this article on the M62-T2 gun. Both the Object 272 from Leningrad and Object 734 from ChTZ shared the same height despite the retention of the basic T-10 hull on the Object 734 since they both shared the same turret.

Internally, the height of the T-10 fighting compartment in the turret was 1,600mm as measured from the rotating floor to the ceiling of the turret. This is the same as the IS-2, IS-3, T-54, and several other Soviet tanks of the era. The two images below give a good perspective on the height of the tank scaled against Soviet tankers.

Naturally, a side effect of the increased height of the T-10M turret is the increased headroom for the crew, and most importantly, for the loader. The internal height of the T-10M as measured from the rotating floor to the turret ceiling is 1,725mm which is tall enough that standing completely upright may be possible for an average Soviet military age male who would have a height of 1.7 meters. The loader also has a cupola which is raised above the turret roof, so in practice, he could have more headroom if he stands directly underneath his cupola when performing some loading actions.

For a seated gunner or commander, shoulder height and seated height are the most important dimensions. The amount of space needed for these two crew members to carry out their duties effectively is not large, especially for the gunner who practically does not need to move at all if his controls are well laid out. The commander in a T-10 needs space to operate the radio, read maps, and so on, but in combat, his main tasks are to observes the battlefield through the viewing devices in his cupola, receive orders from his superiors or transmit orders to subordinate tank commanders (as a platoon or company leader) and to micromanage the rest of the crew using verbal commands, neither of which require a large working space. For a loader, however, space is much more important as his duties are inherently much more physical. The most important dimensions for a loader are the standing height, elbow width, and elbow height.

The width of the hips of an average man is only 350mm but the shoulder width of an average man is 450mm. Immediately it becomes obvious that it is possible to optimize the layout of a tank by narrowing the hull and increasing the width of the turret. The width of the loader's station should be as large as possible at elbow height as a human loader grasping a large caliber cartridge would hold it at elbow height, but generally speaking, the maximization of the internal width of the tank above the hip level of a standing man is beneficial to all the members of the crew, especially the loader.

Because of such nuances, it is not really possible to accurately express crew conditions by simply looking at the volume of the crew members' stations, although it can certainly be used as a tool for comparing two tanks with similar layouts and internal dimensions to some extent.

The photo below, from "T-10 Heavy Tank and Variants" by James Kinnear and Stephen Sewell, shows the left side of a T-10M turret. Without actual crew members sitting on the seats for the commander and gunner, it is somewhat difficult to form an accurate perspective on the amount of space provided for the two men but at least the layout of the equipment and furniture can be appreciated from this angle.

The inclusion of sponsons allowed a turret ring of a larger diameter to be implemented than would otherwise be possible with a hull that had completely vertical sides, that is, unless special platforms extending from the sides of the hull were used to accommodate the turret ring. This is best exemplified by the T-62 medium tank which features a 2,245mm turret ring despite having a hull with a width of only 2,020mm. This design solution enables a turret ring of a larger diameter than the maximum width of the hull to be installed, but there is no possibility of stowing a significant amount of ammunition or equipment in the extensions. The area above the tracks can still be used as a stowage space, but only expendable items such as tools and spare parts or fuel can be placed in these areas due to the lack of armour protection.

In the drawing above, it can be seen that ammunition is stowed in the hull sponsons and that additional external stowage space is available underneath the sponsons in sheet metal bins. The bins all had the same shape and general dimensions, differing only in length and in the number of hatches. There is a long bin with two hatches, a short bin with one hatch, and one long bin with one hatch.

The hatches are hinged to open upward, allowing items to be placed inside the bins easily. This was a notable improvement over the IS-7 stowage bins which had an unconventional design that was simple to a fault. It is demonstrated in Nicholas Moran's "Inside the Chieftain's Hatch" video on the IS-7, Part 1.

Two more stowage bins were added to the fenders on the T-10M model. The additional stowage space was probably appreciated by the crews but unfortunately, the bins also slightly disrupted the sleek prow of the tank. The photo on the left below is from Dave Haskell and the photo on the right below is from the Net-Maquettes website.

As usual for a Soviet tank of the 1950's, the standard-issue tarpaulin was strapped to the rear of the turret. The tarpaulin was a general-purpose item but it was often used as a tent. One excellent way of using it on cold nights was to turn the turret back and elevate the gun to its highest angle, and then draping the tarpaulin over the gun barrel. The crew would then sleep on the toasty engine deck which would remain warm until daybreak.

In 1959, the T-10M received an add-on metal stowage bin on the turret bustle. The tarpaulin which previously occupied this area was relocated to the right side of the turret. The beveled shape of the stowage bin was dictated by the need to ensure free air flow to the engine air intake and the radiator intakes on the engine compartment deck.

The bin is made from light gauge sheet metal so it does not significantly increase the protection of the rear of the turret nor does it offer much protection for its contents from gunfire, shell splinters or fragments, but its location makes it much less likely to suffer damage compared to all other stowage bins on the T-10. It is waterproof when sealed properly and will survive a snorkeling operation. The stowage bin is accessed from single large curved hatch on the top.

The width of the bustle stowage bin was close to the total width of the turret and it occupied the entire height of the bustle, so it was quite spacious. This bin was mainly used for stowing the personal effects of the crew and it was much more useful in this role than the sponson bins which were more exposed to direct fire and could potentially be blown off if the tank ran over a mine.

The total internal volume of the tank was 12.72 cubic meters, of which 8.21 cubic meters was allocated for the crew compartment and 4.51 cubic meters for the engine compartment. This was not particularly large compared to contemporary Soviet medium tanks such as the T-54 and T-62. For reference, the total internal volume of the T-54 measured in at 11.4 cubic meters, of which 8.05 cubic meters forms the crew compartment and 3.35 cubic meters forms the engine compartment, and the T-62 has a total internal volume of 12.5 cubic meters and the crew compartment occupies a volume of 9.23 cubic meters. From this, it seemingly appears that the T-10 is more spacious than a T-54 but more cramped than a T-62, but as always, further examination is necessary to gain a more detailed understanding of the true situation.

Given that many components from the T-10 and the two medium tanks share similar dimensions or are outright identical as is the case with the radio equipment, the main differences lie in the size of the cannon and the ammunition, and immediately the T-10 loses out in spaciousness. The massive 122mm cannon of the T-10 and T-10M is larger than the 100mm cannon of the T-54 and the 30 rounds of bulky 122mm cartridges take up more space than the 34 rounds of 100mm cartridges carried in the T-54. However, the T-10 does not carry any fuel in the fighting compartment whereas the T-54 holds 530 liters of fuel in four internal fuel tanks, two of which occupy useful space in the fighting compartment. As such, the available space in the T-54 is lower by 0.53 cubic meters which somewhat offsets the difference in the size of the gun and ammunition.

Of the internal volume allocated for the fighting compartment of the T-10, the driver's compartment at the front of the hull occupied 1.35 cubic meters and the fighting compartment occupied 6.86 cubic meters. According to the article "Human Factors and Scientific Progress in Tank Building" by M.N. Tikhonov and I.D. Kudrin, the commander is allocated a volume of 0.871 cubic meters, the gunner is allocated a volume of 0.367 cubic meters, the driver is allocated a volume of 0.650 cubic meters and the loader is allocated a volume of only 0.762 cubic meters. In total, the crew of the turret appears to have 2.0 cubic meters of space and the remaining 4.86 cubic meters of volume is dedicated to the internal equipment of the tank.

Two hatches were installed on the roof of the turret, one for the commander as a part of his cupola assembly and one for the loader. The gunner is forced to exit through the commander's hatch if the crew is ordered to bail out. This is not ideal in terms of individual crew comfort and the speed of a hasty escape, but this arrangement was normal for manually loaded tanks. For comparison, the Conqueror was equipped with three roof hatches on its turret; one for each crew member stationed within. This was possible because of the unconventional seating arrangement with the commander stationed in the turret bustle, separated from the rest of the turret crew. Both hatches were of the lift-and-swing type so that they do not interfere with the commander's view from his cupola if left open for whatever reason. The downside of the unconventional layout that this made for a very long and heavy turret and created an enormous shot trap at the rear of the turret.

The worst design by far was the turret of the M103. Like in the Conqueror, the commander was seated separately in the bustle in an exceptionally large and long turret and he was provided with his own hatch, but the gunner and two loaders were forced to share a single roof hatch that was officially termed the "front loader's escape hatch" since it was directly over the front right loader's station. The hatch layout of all three tanks can be seen in the drawings below and the size of their turrets can also be appreciated.

Two 20-liter jerry cans for drinking water were provided in the T-10M. They were stowed side-by-side on the hull wall to the left of the driver, behind the accumulator pack.

VENTILATION

For ventilation, the T-10 featured an intake fan and two exhaust fans that worked to blow air through the crew compartment. The ventilator intake fan is prominently placed on the turret roof, and the two ventilator exhaust fans were installed in the bulkhead between the fighting compartment and the engine compartment. These worked by drawing air from the crew compartment and passing it into the engine compartment. Each fan was driven by an MV-42 electric motor with a power of 175 watts, which is extremely powerful considering that the internal volume of the crew compartment is only 8.21 cubic meters. The two top corners of the drawing below show the two ventilator exhaust fans. The bulkhead is not present in the drawing, revealing the engine and the engine air supply system.

During combat, the ventilation intake fan on the turret roof acts as a blower that brings fresh air into the fighting compartment, and also serves to remove some propellant fumes after each shot is fired by blowing the fumes downward where they are sucked out of the fighting compartment by the exhaust fans. The drawing below shows the position of the ventilation fan in the turret of a T-10B. Its location is the same in the T-10 and T-10A.

The drawing on the left below shows the location of the fan from another perspective and the drawing on the right shows a cross section of the entire ventilator dome, including the S-shaped design of its intake duct. This shape prevents bullets impacting the dome from hitting the fan itself through the duct.

Naturally, it is desirable to keep the hatches opened in hot weather so that the maximum amount of fresh air can enter the crew compartment, but when the hatches are closed, air can only enter the tank through a few possible intakes: the gaps in the gun mask, the gun barrel bore (if the gun is not loaded), the ventilation intake fan on the turret roof, small gaps in the turret ring between the turret and the hull, gaps in the periscope mountings, and gaps from the imperfect seals of the hatches.

Due to the large work capacity of the ventilator exhaust fans, it can be surmised that the air flow through the crew compartment is very strong, which is good for the crew in the summer heat. However, this ventilation system is not ideal in the winter because it simply takes cold air and circulates it in the tank when warmth is needed instead. To circumvent this issue, the exhaust fans can simply be deactivated without closing the shutters for the vents. This allows heat from the running engine to radiate into the fighting compartment, thus providing warmth. The downside is that there is no airflow to remove propellant fumes, so it may still be necessary to turn on the ventilator intake fan during combat.

In principle, the ventilation system of the T-10 was typical of other Soviet tanks of the immediate postwar era like the T-54, and interestingly enough, it was also quite similar to the M4 and M4A1 variants of the Sherman tank with an air-cooled radial engine. Its cooling system used a pair of large and powerful fans that drew air from the crew compartment and passed it through the engine, thus producing a strong draught in the crew compartment. This was an excellent feature during summer or in the Pacific theatre, but a major issue with this system was that there was no alternate airway for the cooling system, so there was no way to prevent the cooling fans from drawing air from the crew compartment. At night and during winter, this chilled the crew compartment even further and made the crew rather miserable. This unfortunate drawback was mentioned by Dmitriy Loza in his book "Commanding the Red Army's Sherman Tanks: The World War II Memoirs of Hero of The Soviet Union". According to Loza, the crews of the M4 Shermans under his command had the habit of having the commander sit on the left fender next to the driver, who drove with his head out of his open hatch. Naturally, these two men were the most exposed to windchill from the cold night air which had an ambient temperature of 8-10 degrees Celsius according to Loza. To resist the cold, the commander and driver helped themselves to extra portions of alcohol. The ventilation system of the T-10 did not suffer from this problem, but with that said, rations of vodka would still have been appreciated by the crew in cold weather, of course.

COMMANDER'S STATION

The turrets of all T-10 models have a conventional seating arrangement with the commander seated at the rear left quadrant of the turret behind the gunner and adjacent to the loader. The commander's seat is attached to the turret ring and the height can be adjusted between five different positions. If desired, the seat cushion can be folded away to permit easier access the hull without dismantling the entire seat. The seat cushion is round as opposed to a more comfortable molded shape like on the M103, so there is not much thigh support. This could make it somewhat uncomfortable for the commander to remain seated for very long periods.

In a major departure from the IS-3 and IS-4, the commander was given a relatively large conventional cupola with an inclusive hatch. The hatch was much smaller as a consequence, but the number of viewing devices was vastly improved. The cupola offered all-round protection from 12.7mm AP bullets and artillery shell fragments. It has insufficient protection from autocannons, but was unlikely to be hit directly by such weapons due to its low height.

Unlike an IS-3 or IS-4 commander who was given only a single MK-4 rotating periscope, the commander of a T-10 is furnished with seven fixed TNP periscopes arranged around the circumference of his rotating cupola and one magnified forward-facing binocular periscope which is vertically adjustable, giving him an uninterrupted circular view of the surrounding environment.

The TNP periscopes arranged around the commander's cupola are medium sized. The width of the periscope body is 133.5mm and the width of the actual periscope prism is slightly less than that. As shown in the photo below on the right, the periscopes around the circumference of the cupola are covered by a step guard, allowing the commander and gunner to step on the edge of the cupola or grip it when exiting the hatch without fear of damaging the periscope windows. The size of the gaps between each periscope can also be seen. Each of the eight observation devices are installed in 45-degree increments around the perimeter of the cupola.

The greatly improved visibility afforded to a T-10 commander compared to IS-3 and IS-4 commanders reduced his incentive to fight from an open hatch, but if the commander chose to do so regardless, the hatch design gives him much better protection from bullets and shell splinters at the small cost of having a more distinctive silhouette when opened.

Two cupola types were used in the T-10 series, each type having two iterative models with improvements. The first type, used on the original T-10, was practically built into the turret. The cupola ring mount was first fitted to the hole in the turret roof with bolts, then the cupola itself would be placed on top of it, and then the ball bearings inserted into its race ring to secure the two parts together. It was not possible to simply unbolt the cupola and remove it from the turret without first dismantling it. The cupola race ring was protected by a thick steel collar welded to the turret roof. The electrical connectors in the cupola were connected to the electrical network of the tank with loose wires. An improved cupola design was introduced in the T-10A. The sealing of the cupola was improved, a new traverse lock with two positions (facing forward and backward) was introduced, and most importantly, a new electrical contact ring was implemented to supply power to the commander's target designator system integral to the cupola. The contact ring was a textolite ring with copper-lined grooves, connected to wires embedded inside the textolite, serving as a conductive ring to allow current to flow from the turret to the commander's target designator system via brushes riding on the grooves. The contact ring was placed between the rotating cupola and the fixed ring mount within its own sealed chamber, beneath the race ring. This was done to prevent the ingress of contaminants which could obstruct the grooves of the contact ring or interfere electrically.

The cupola seal consists of a rubber flap which is joined to the cupola, and is pressed against the collar on the turret roof with a steel loop. This creates a fairly tight moisture and dust seal without impeding the rotation of the cupola, as the friction that the commander must overcome is between the steel loop and the steel turret collar, rather than a steel-rubber interface, which would create much more resistance and rapidly wear out the rubber.

The commander's hatch is hinged to the cupola roof where the TPKU-2 periscope is installed. The hatch has the shape of a circular segment and has a width of 492mm and a depth (axial width) of around 400mm (excluding the hinges). This is enough for a man of average shoulder width and chest depth, but the hatch opening may be too narrow if thick winter clothing is worn. On average, winter clothing adds four inches to the width of a man. Fabric is a flexible material, of course, so the commander can still squeeze into the hatch with reasonable speed, but the man's belt, holster, harness, binoculars case and document case are all worn on top of his winter uniform and become much more liable to be caught on the edges of the hatch opening. The hatch has a shallow dome shape to increase the headroom in the cupola for the commander. The cupola and the hatch can be seen in the drawings below.

The second T-10 cupola type, shown in the drawing below, was used on the T-10B, followed by the T-10M. It differed from the first type in having an entirely new mount, with a spaced collar to protect the cupola race ring. Bolts placed behind the ring guard secure the cupola to the turret. This new design allowed the cupola to be installed or uninstalled without needing to dismantle it, the only requirement is that the rain guard is taken off beforehand.

The T-10M cupola featured an enlarged hood over the TPKU-2 periscope to further decrease the splashing of rain on the periscope window and to further protect from rain water dripping onto the periscope mount. The new cupola has three traverse lock positions, and a new sealing system with a particularly noteworthy seal tightening feature. Unlike the original cupola which had a rubber flap permanently fitted to the cupola to seal the race ring, the new cupola has a rubber flap fitted to the fixed cupola ring mount which is tightened against the cupola with a cable.

The design of the cupola remained largely unchanged from the T-10B to the T-10M, with the exception of the increased protection of the race ring. This was achieved by increasing the height of the spaced armoured collar surrounding the cupola from 22mm to 33mm. The thickness of the collar remained at 20mm. This upgrade further reduced the possibility of jamming the cupola with concentrated heavy machine gun fire, shell fragments, and other ballistic threats. The design of the periscope step guard was also modified from a fully enclosed cover to a partial cover, but remained interchangeable with the earlier version.

Unfortunately, there are a few factors that can degrade the commander's visibility. The fact that the commander's cupola is offset to the left side of the turret unavoidably exaggerates the size of the dead zone to the right while reducing the dead zone to the left, and depending on the T-10 model, there may be a number of items on the turret roof which obstruct the commander's view from his cupola. On the T-10 and T-10A, the ventilation dome on the turret roof partly obstructs the commander's view from his TNP periscopes in the 1 o'clock direction, and on all T-10 models, the loader's cupola can obstruct the commander's view to his right, mainly from the dome shape of the loader's hatch. This is illustrated in the cross-sectional drawing below. However, the field of view from the TPKU-2 periscope is almost entirely uninterrupted because it is mounted higher to clear both of the aforementioned obstructions. It is worth mentioning that the anti-aircraft machine gun on the loader's cupola is not an obstruction as it is mounted on a raised pintle, so there is a large gap between the machine gun itself and the top of the loader's cupola, enough to not significantly interfere with the commander's field of view in elevation.

It is obvious that the T-10 commander enjoys an unparalleled amount of overall visibility compared to his peers in an IS-3 or IS-4, but the cupola design of the T-10 also offers appreciably better vision than the cupola of the IS-2 obr. 1944 which had six vision slits supplemented by an MK-4S rotating periscope (Gundlach periscope) installed in the cupola roof, especially since the T-10 also benefits from having a magnified periscope with a target designation function. The MK-4S had no magnification and as such, it only permitted the commander to spot a tank-type target from a maximum distance of 1,000 meters to 1,500 meters.

The difference between the IS-2 obr. 1944 and the IS-3 and IS-4 in this particular aspect mirrors the difference between the split-hatch cupola of early M4 Shermans to the "vision cupola" of late model Shermans. During modernization programmes in the 1950's, IS-2, IS-3 and IS-4 tanks were upgraded into IS-2M, IS-3M and IS-4M tanks and had their MK-4S periscope replaced with the TPK-1 periscope with a combined unmagnified viewing window and a magnified 2.5x binocular device, but even with this upgrade, the T-10 still held an advantage because the TPK-1 was a generation behind the TPKU-2 and the upgraded tanks were not retrofitted with a target designation system.

However, the good all-round visibility from the T-10 cupola does not necessarily make it superior to the cupola of contemporary Soviet medium tanks in practical terms. Beginning with the T-54 obr. 1949, most Soviet medium and main battle tanks used a cupola with a forward-facing binocular periscope supplemented by four general vision periscopes covering the forward half of the cupola's perimeter. On the T-54 and T-62, two TNPO-170 periscopes were installed in the fixed cupola roof and two 54-36-318-R periscopes were embedded into the commander's hatch itself. Both of these periscopes have a width of 230mm and differ only in that the periscopes embedded in the hatch (54-36-318-R) do not have an internal electric heater for defogging whereas the TNPO-170 does. By comparing the width of the periscope casings alone, the TNP is 51% narrower than the TNPO-170 and 54-36-318-R periscopes. The cast aluminium periscope casings for all three models have a fixed thickness, so the difference in the width of the glass prisms inside the periscopes is not directly proportional to the difference in the width of the periscope casings. In actuality, the glass prisms in the TNPO-170 and the 54-36-318-R are more than 51% wider than the TNP. This is only slightly offset by the lower periscopicity of the TNP periscope.

In a direct side-by-side comparison, it is evident that the T-54 and T-62 cupolas provide better visibility in the forward half simply by virtue of having the same number of periscopes in the same layout, but with wider periscopes that grant a wider field of view. However, the rearward visibility from the T-54 and T-62 cupolas is non-existent unless the cupola is rotated so that one or more of the periscopes is facing rearward, so the T-10 cupola has a weighty advantage here. On the other hand, the relevance of this advantage in a combat situation is debatable.

The characteristics of a tank commander's observation practices when buttoned-up in a fixed cupola with eight periscopes and one fixed forward-facing sight in the turret were examined in the 1974 study "Некоторые Статистические Характеристики Процесса Наблюдения Командира Танка" (Some Statistical Characteristics of a Tank Commander's Observation Processes) by G.G Golub et al. The findings of the study were that 30% of all battlefield observations were carried out using the forward-facing unmagnified periscope and at most, 5% of observations were done using the magnified 8x optic with a stabilized field of view because there was little need given that the topographic range of visibility of targets during the study was 1.0-1.5 km. However, it was also found that in certain tactical situations such as when carrying out a breakthrough mission, the frequency of the use of a magnified optic to search for targets increases up to 50%. Overall, more than 70% of observations were made using only three periscopes at the front of the cupola covering a 100-degree frontal sector and over 95% of observations were made in a 200-degree frontal sector. Most interestingly, the experiments revealed that the highest recorded frequency of usage of the rear-view periscope was only 0.8%. It was also noted that the periscopes installed at more than 110 degrees off the centerline axis of the cupola (8 o'clock) were difficult to use due to neck strain when the tank was in motion. One of the conclusions of the study was that observation devices installed in the commander’s cupola at angles greater than ± 100 degrees (outside the 200-degree frontal arc) were difficult to use.